Modified oil-well cement, preparing method thereof and production line thereof

An oil well cement and modification technology, applied in the field of special cement, can solve the problems of single mineral admixture, unsatisfactory product performance, and insufficient material cost, and achieve the effect of reducing construction risk, quantity and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

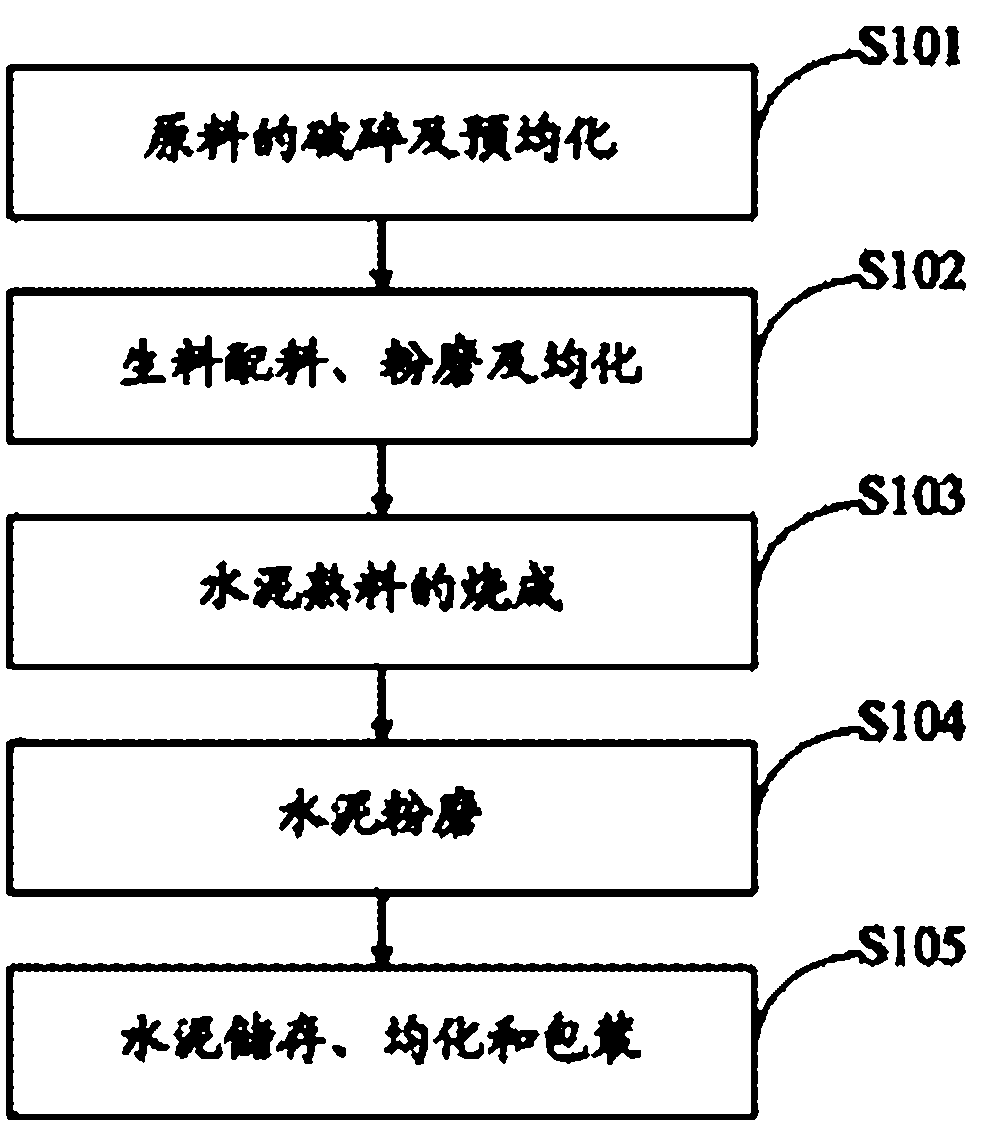

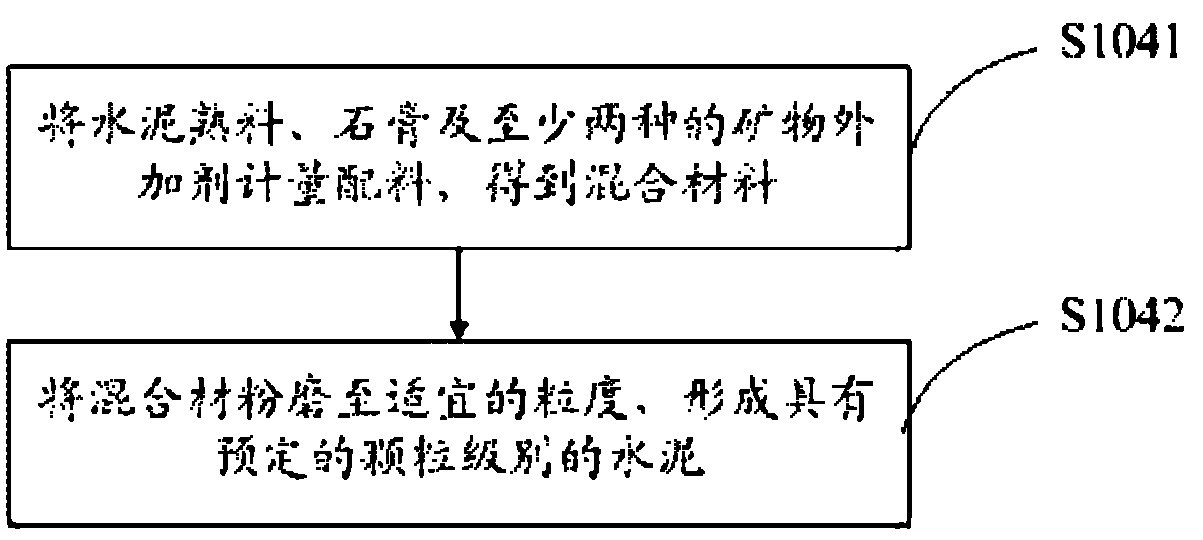

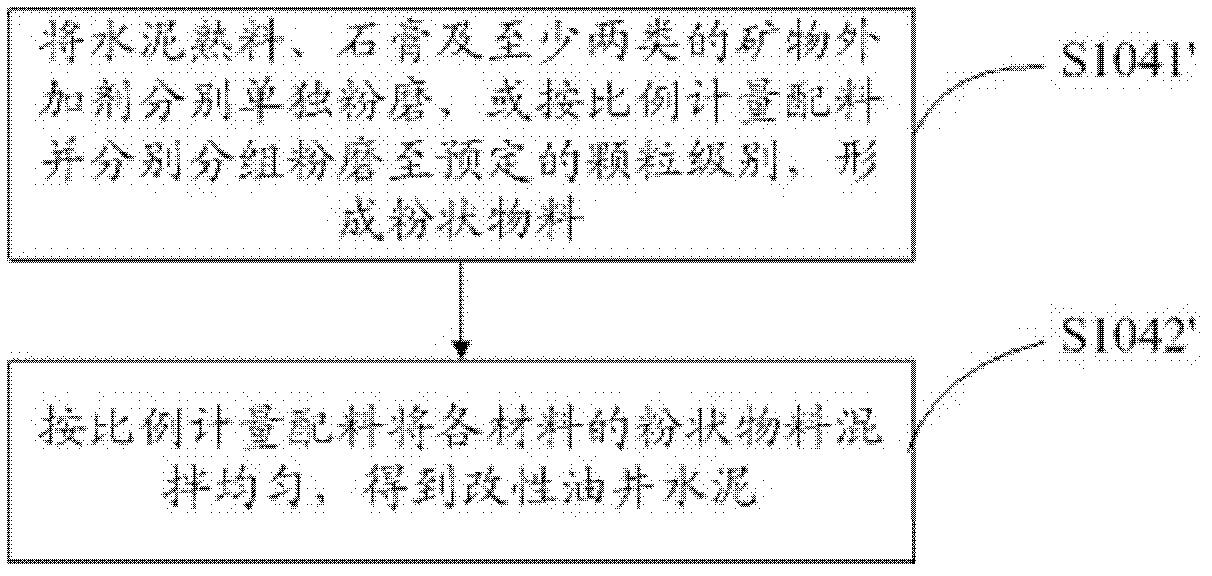

Method used

Image

Examples

Embodiment 1

[0092] Embodiment 1——The first mineral additive is granulated blast furnace slag, and the second mineral additive is one of limestone, basalt, microsilica fume, quartz sand, magnesium slag, phosphorus slag, vanadium titanium slag or steel slag, wherein The mass percentage content of each component is specifically:

[0093] Cement clinker is 20% to 80%;

[0094] Gypsum is 2% to 10%;

[0095] Granulated blast furnace slag is 0.1% to 40%, preferably 2% to 18%, more preferably 5% to 15%, most preferably 8% to 12%;

[0096] Limestone, basalt, silica fume, quartz sand, magnesium slag, phosphorus slag, vanadium-titanium slag or steel slag is 0.1% to 40%, preferably 2% to 18%, more preferably 5% to 15%, most preferably 8% % ~ 12%.

[0097] For example, the preferred components and proportions of a modified G-grade oil well cement are:

[0098] Cement clinker is 75±5%;

[0099] Gypsum is 5±1%;

[0100] The first mineral additive is granulated blast furnace slag with a content of ...

Embodiment 2

[0103] Embodiment 2——The first mineral additive is magnesium slag, and the second mineral additive is one of limestone, basalt, microsilica fume, fly ash, quartz sand, phosphorus slag, vanadium titanium slag or steel slag, wherein each The mass percentage content of component is specifically:

[0104] Cement clinker is 20% to 80%;

[0105] Gypsum is 2% to 10%;

[0106] Magnesium slag is 0.1%-40%, preferably 2%-18%, more preferably 5%-15%, most preferably 8%-12%;

[0107] Limestone, basalt, silica fume, fly ash, quartz sand, phosphorus slag, vanadium-titanium slag or steel slag is 0.1% to 40%, preferably 2% to 18%, more preferably 5% to 15%, most preferably 8% to 12%.

Embodiment 3

[0108] Embodiment 3——the first mineral additive is phosphorus slag, and the second mineral additive is one of limestone, basalt, microsilica fume, fly ash, quartz sand, vanadium-titanium slag or steel slag, wherein each component The mass percentage content is specifically:

[0109] Cement clinker is 20% to 80%;

[0110] Gypsum is 2% to 10%;

[0111] Phosphorus slag is 0.1%-40%, preferably 2%-18%, more preferably 5%-15%, most preferably 8%-12%;

[0112] Limestone, basalt, silica fume, fly ash, quartz sand, vanadium-titanium slag or steel slag is 0.1% to 40%, preferably 2% to 18%, more preferably 5% to 15%, most preferably 8% to 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com