High-capacity cathode material for lithium ion batteries and preparation method thereof

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, batteries, secondary batteries, etc., can solve problems such as poor chemical cycle performance, poor safety performance, and poor thermal stability, and improve the structure and preparation difficulties. Manufacturing Low cost and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

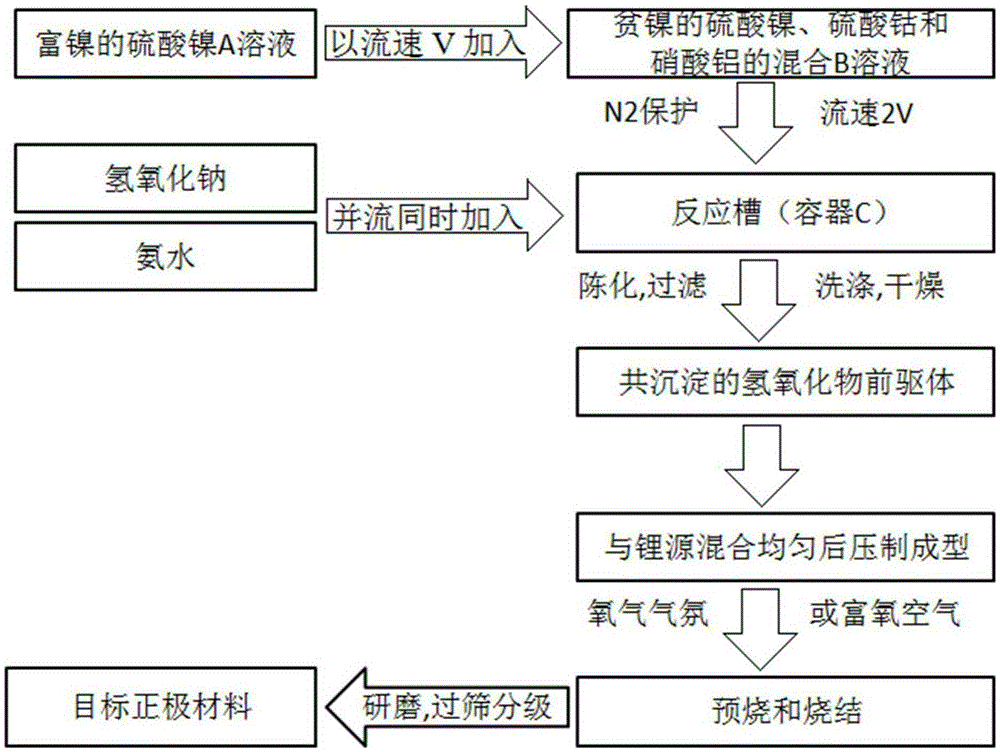

[0041] Such as figure 1 As shown, the preparation method of the lithium ion battery positive electrode material of the embodiment of the present invention comprises the following steps:

[0042] S101: NiSO 4 ·6H 2 O,CoSO 4 ·7H 2 O and Al(NO 3 ) 3 9H 2 O is dissolved in an appropriate amount of deionized water to obtain a molar ratio of Ni 2+ :Co 2+ :Al 3+ =(1-x-y-m):x:y=(1-m):0:0 1.5mol / L nickel-rich solution A (0.1≤m≤0.4);

[0043] S102: NiSO 4 ·6H 2 O,CoSO 4 ·7H 2 O and Al(NO 3 ) 3 9H 2 O is Ni in molar ratio 2+ :Co 2+ :Al 3+ =m:x:y=(20m):3:1 is dissolved in an appropriate amount of deionized water to obtain an equal volume of nickel-poor solution B (0.1≤m≤0.4);

[0044] S103: Add solution A to solution B at a speed (V) of 10mL / min-10L / min, stir vigorously to make it evenly mixed;

[0045] S104: At the same time, put the mixed solution under N 2 Under protection, add it into the reaction tank (container C) at twice the speed of solution A (2V), so that ...

Embodiment 1

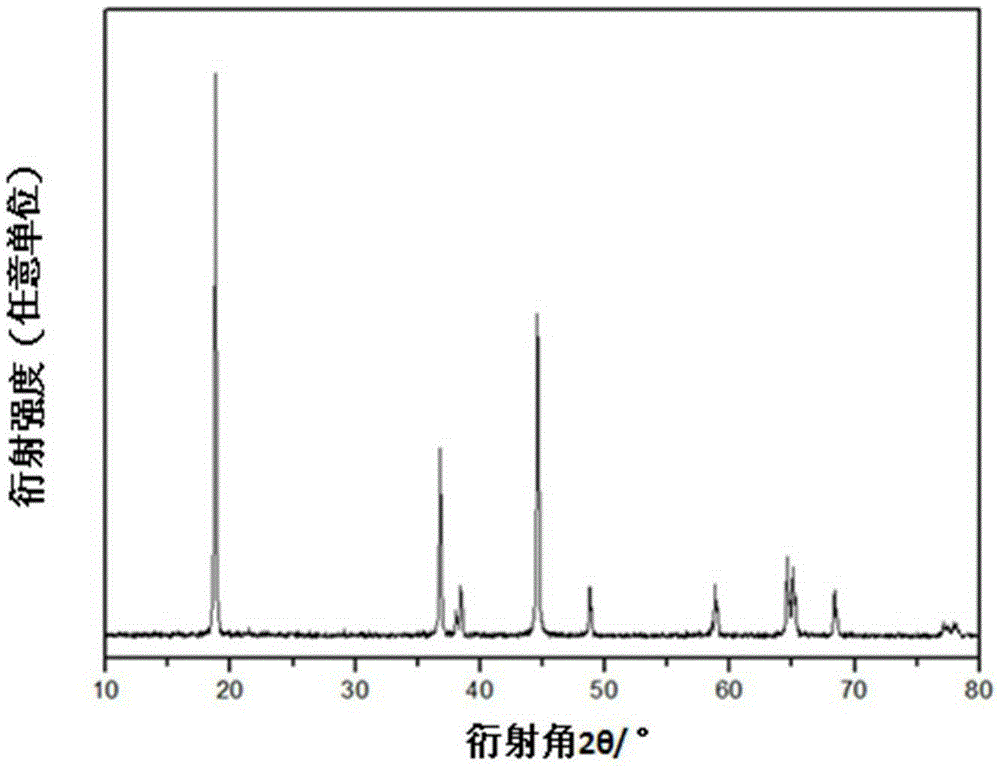

[0058] The technical scheme of the present invention is: lithium-ion battery cathode material LiNi 0.8 co 0.15 Al 0.05 o 2 and LiNi 0.75 co 0.2 Al 0.05 o 2 .

[0059] Lithium-ion battery cathode material LiNi 0.8 co 0.15 Al 0.05 o 2 The preparation method is characterized in that, comprises the following steps:

[0060] Step 1. NiSO 4 ·6H 2 O,CoSO 4 ·7H 2 O and Al(NO 3 ) 3 9H 2 O, Ni in molar ratio 2+ :Co 2+ :Al 3+ =(1-x-y-m):x:y=(1-m):0:0 dissolved in an appropriate amount of deionized water to obtain 1.5mol / L solution A; (0.1≤m≤0.4)

[0061] Step 2. NiSO 4 ·6H 2 O,CoSO 4 ·7H 2 O and Al(NO 3 ) 3 9H 2 O, Ni in molar ratio 2+ :Co 2+ :Al 3+ =m:x:y=(20m):3:1=2:3:1 (m=0.1) was dissolved in an appropriate amount of deionized water to prepare solution B with the same volume as solution A;

[0062] Step 3. Add solution A to solution B at a rate of 20mL / min, and stir vigorously to make it evenly mixed;

[0063] Step 4. Add the mixed solution into the r...

Embodiment 2

[0069] Dissolve 0.30 mol of nickel sulfate in 200 mL of deionized water to completely dissolve it to obtain (nickel-rich) solution A; dissolve 0.10 mol of nickel sulfate, 0.075 mol of cobalt sulfate and 0.025 mol of aluminum nitrate in 200 mL of deionized water to prepare a mixed salt ( Nickel-poor) solution B;

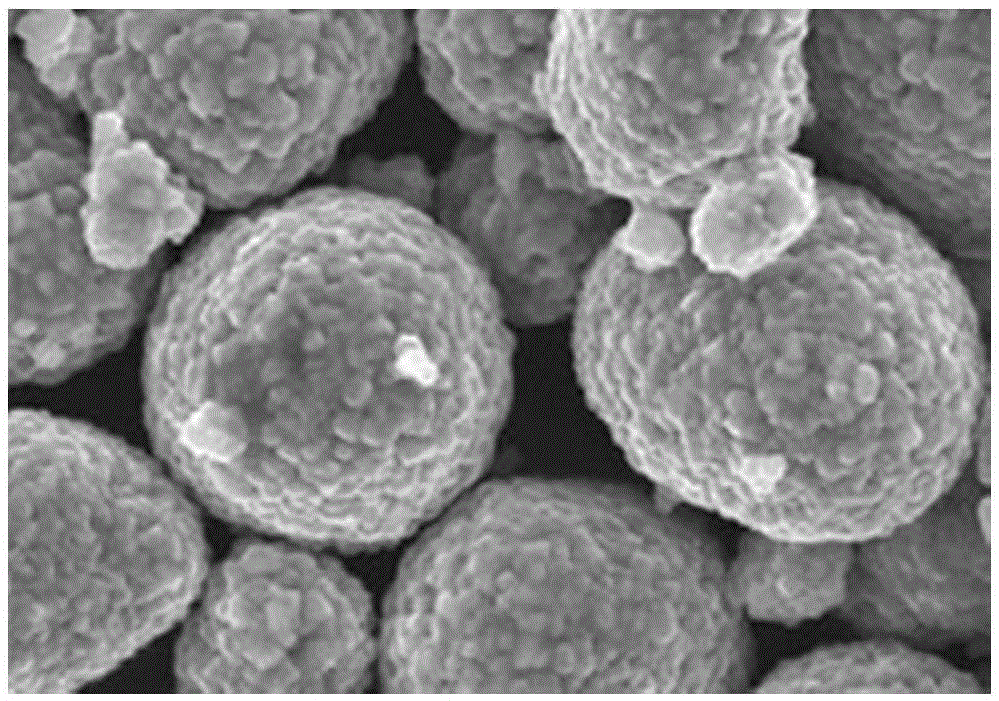

[0070] Add solution A to the mixed salt solution B at a speed of 10mL / min, and keep stirring, and at the same time, add the mixed solution of liquid A and liquid B to the stirring reaction tank under nitrogen protection at a speed of 20mL / min (container C ), while co-currently adding 4mol / L sodium hydroxide precipitating agent and 1mol / L ammonia complexing agent, and adjusting the pH value to 11, the reaction temperature is controlled at 50°C, and the stirring speed is 600rpm; Aged at room temperature for 12 hours, then filtered, washed with hot deionized water for several times, and finally dried in a blast drying oven at 105°C for 24 hours. Mix the dried precursor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com