Lithium titanate-carbon nanotube composite material, preparation method thereof and lithium ion battery

A technology of carbon nanotubes and composite materials, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of difficulty in ensuring material consistency, unstable electrochemical performance, and complicated preparation processes, and achieve improved conductivity and small size. Good effect of distribution and composite uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

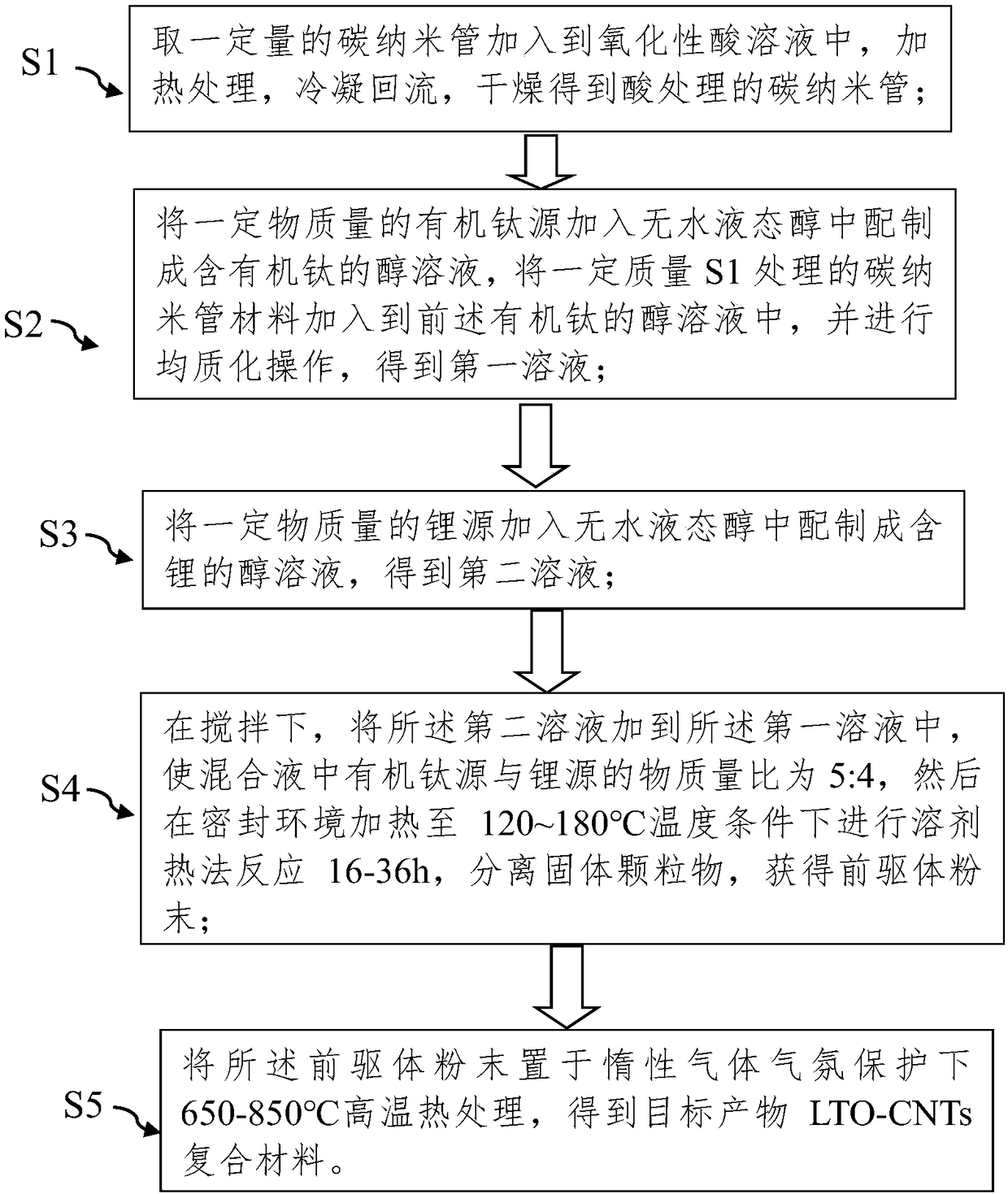

[0046] A preferred embodiment of the synthetic method of the present invention, such as figure 1 shown, including steps:

[0047] S1: Take a certain amount of carbon nanotubes and add them to the oxidizing acid solution, heat treatment, then condense and reflux, and dry to obtain acid-treated carbon nanotubes;

[0048] S2: adding a certain amount of organic titanium source into anhydrous liquid alcohol to prepare an organic titanium alcohol solution, adding a certain amount of carbon nanotube material to the aforementioned organic titanium alcohol solution, and performing a homogenization operation, The first solution is obtained; the organic titanium source is an organic acid of titanium or an organic alcohol of titanium, preferably isopropyl titanate, tetrabutyl titanate, tetraisopropyl titanate, ethyl titanate or n-butyl titanate ; The organic titanium source can be formulated into a 0.15-0.2 mol / L anhydrous alcohol solution; preferably a 0.15-0.18 mol / L anhydrous alcohol ...

experiment example 1

[0059] Experimental example 1: Synthesis of lithium titanate / carbon nanotube composite material (titanium source: isopropyl titanate):

[0060] (1) Get 0.200g of carbon nanotubes and add to the mixed solution of 50ml concentrated nitric acid and concentrated sulfuric acid (V H2SO4 :V (HNO3) =1:1), heat treatment, then condensed to reflux, and freeze-dried to obtain acid-treated carbon nanotubes.

[0061] (2) Add 0.05mol isopropyl titanate dropwise to 300mL of absolute ethanol with magnetic stirring to obtain mixed solution A 1 , and then the above acid-treated carbon nanotubes (diameter 30nm) were added to the above A 1 solution, and then placed in a high-power ultrasonic instrument for ultrasonic homogenization for 3 hours to obtain the first solution;

[0062] (3) 0.0405mol of CH 3 COOLi·2H 2 O was dissolved in 100 mL of absolute ethanol to obtain B 1 solution (for the second solution), under strong magnetic stirring, the B 1 The solution was slowly added dropwise to ...

experiment example 2

[0065] Experimental example 2: Synthesis of lithium titanate / carbon nanotube composite material (titanium source: n-butyl titanate):

[0066] (1) Add 0.200 g of carbon nanotubes to 50 ml of concentrated sulfuric acid solution, heat treatment, then condense and reflux, and freeze-dry to obtain acid-treated carbon nanotubes;

[0067] (2) 0.0398mol of CH 3 COOLi·2H 2 O was dissolved in 100mL absolute ethanol to obtain mixed solution A 1 , and then the above acid-treated carbon nanotubes (diameter 20nm) were added to the above-mentioned A 1 solution, and then placed in a high-power ultrasonic instrument for ultrasonic homogenization for 3 hours to obtain the first solution;

[0068] (3) Add 0.05mol n-butyl titanate dropwise to 300mL ethanol with magnetic stirring to obtain B 1 solution (for the second solution), under strong magnetic stirring, the B 1 The solution was slowly added dropwise to the first solution, and stirring was continued for 2 h at room temperature;

[0069] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com