Adhesive capable of improving compression resistance of plywood and preparation method of adhesive

A technology of compressive properties and adhesives, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of insufficient bonding strength and compressive properties of plywood, and improve flexibility and bond strength , Increase the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

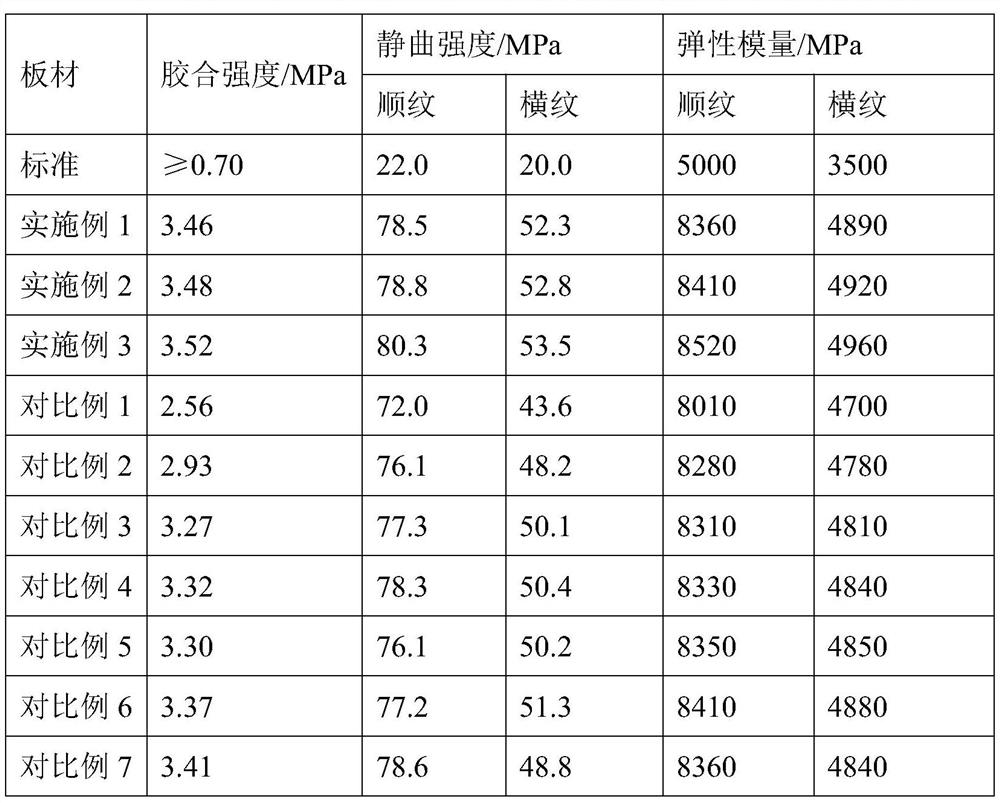

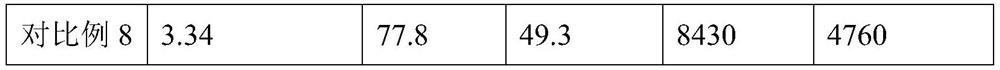

Examples

Embodiment 1

[0028] An adhesive that can improve the compression resistance of plywood is prepared from the following raw materials in parts by weight: 20 parts of formaldehyde, 250 parts of melamine, 150 parts of ammonia water, 300 parts of urea, 3 parts of polyvinyl alcohol, and modified graphene 4 parts, 6 parts of silicate-containing inorganic fillers obtained by mixing talc powder and zeolite powder at a mass ratio of 2:1.

[0029] The preparation method of the modified graphene is as follows: dissolving aminosilane in water, adding graphene, adding graphene, condensing and refluxing, washing with deionized water, and drying at 50°C to obtain modified graphene.

[0030] A preparation method of an adhesive capable of improving the compressive properties of plywood, comprising the following steps:

[0031] S1: Prepare formaldehyde into an aqueous formaldehyde solution with a mass fraction of 30%, add modified graphene, and disperse ultrasonically for 30 minutes at a power of 200w;

[0...

Embodiment 2

[0036] An adhesive that can improve the compression resistance of plywood, prepared from the following raw materials in parts by weight: 10 parts of formaldehyde, 200 parts of melamine, 250 parts of ammonia water, 350 parts of urea, 2 parts of polyvinyl alcohol, modified graphene 2 parts, 4 parts of silicate-containing inorganic fillers obtained by mixing talc powder and zeolite powder at a mass ratio of 2:1.

[0037] The preparation method of the modified graphene is as follows: dissolving aminosilane in water, adding graphene, condensing and refluxing, washing with deionized water, and drying at 60°C to obtain the modified graphene.

[0038] A preparation method of an adhesive capable of improving the compressive properties of plywood, comprising the following steps:

[0039] S1: Prepare formaldehyde into a formaldehyde aqueous solution with a mass fraction of 35%, add modified graphene, and disperse ultrasonically for 40 minutes at a power of 300w;

[0040] S2: adjust the ...

Embodiment 3

[0044] An adhesive that can improve the compression resistance of plywood is prepared from the following raw materials in parts by weight: 30 parts of formaldehyde, 250 parts of melamine, 200 parts of ammonia water, 450 parts of urea, 2 parts of polyvinyl alcohol, and modified graphene 3 parts, 5 parts of silicate-containing inorganic fillers obtained by mixing talc powder and zeolite powder at a mass ratio of 2:1.

[0045] The preparation method of the modified graphene is as follows: dissolving aminosilane in water, adding graphene, condensing and refluxing, washing with deionized water, and drying at 55°C to obtain the modified graphene.

[0046] A preparation method of an adhesive capable of improving the compressive properties of plywood, comprising the following steps:

[0047] S1: Prepare formaldehyde into a formaldehyde aqueous solution with a mass fraction of 40%, add modified graphene, and disperse ultrasonically for 35 minutes at a power of 500w;

[0048] S2: adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com