Anti-scaling drainage and sewage pipe, pipe fitting and preparation method thereof

A sewage pipe and anti-fouling technology, applied in the field of plastic pipes, can solve the problems of pipes with many bacteria, poor drainage wear resistance, easy disease transmission, etc., to reduce the generation of microorganisms, facilitate bonding and connection, and improve anti-fouling properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

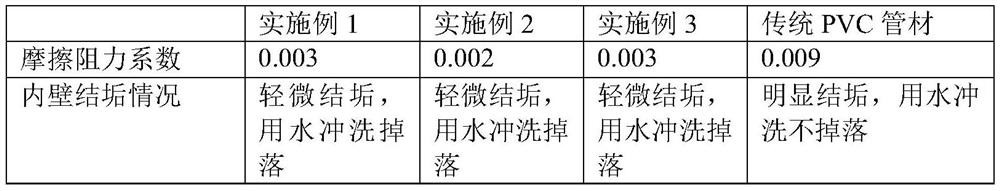

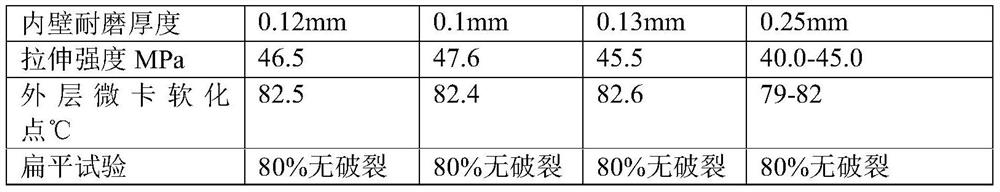

Embodiment 1

[0032] According to the following formula, add the outer layer raw materials and the inner layer raw materials into the mixer respectively, stir at 110°C for 10 minutes, and then cool the raw materials to 30°C;

[0033] Outer layer raw materials: 100 parts of PVC resin; 4.0 parts of calcium zinc stabilizer; 5.0 parts of nano silicon dioxide; 2.0 parts of chlorinated polyethylene; 0.6 parts of polyethylene wax; 2.0 parts of titanium dioxide;

[0034] Inner layer raw materials: 10 parts of PVC resin; 3.0 parts of stabilizer; 90 parts of polymethyl methacrylate (PMMA); 15 parts of polytetrafluoroethylene powder; 15 parts of nano calcium carbonate; 0.6 parts of fatty acid; 5 parts of zinc oxide; 5 parts of copper oxide; 3.0 parts of ammonium dihydrogen phosphate; 15 parts of ABS;

[0035] Add the above-mentioned mixed outer layer raw materials into the hopper of the outer layer extruder and extrude them into shape, wherein the screw temperature of the outer layer pipe extruder is ...

Embodiment 2

[0039] According to the following formula, add the outer layer raw materials and the inner layer raw materials into the mixer respectively, stir at 100°C for 8 minutes, and then cool the raw materials to 28°C;

[0040] Outer layer raw materials: 100 parts of PVC resin; 4.0 parts of calcium zinc stabilizer; 5.0 parts of nano-calcium carbonate; 2.0 parts of impact modifier ACR; 0.6 parts of oxidized polyethylene wax; 2.0 parts of titanium dioxide;

[0041] Inner layer raw materials: 3.0 parts of calcium zinc stabilizer; 50 parts of polymethyl methacrylate (PMMA); 50 parts of acrylonitrile-styrene-acrylonitrile (ASA) copolymer; 15 parts of silicone powder; 15 parts of nano calcium carbonate 0.5-15 parts of chlorinated polyethylene; 0.6 parts of stearic acid; 10 parts of silver ions; 13 parts of ABS

[0042] Add the above-mentioned mixed outer layer raw materials into the hopper of the outer layer extruder and extrude them into shape, wherein the screw temperature of the outer lay...

Embodiment 3

[0046] According to the following formula, add the outer layer raw materials and the inner layer raw materials into the mixer respectively, stir at 100°C for 8 minutes, and then cool the raw materials to 28°C;

[0047] Outer layer raw materials: 100 parts of PVC resin; 4.0 parts of calcium zinc stabilizer; 5.0 parts of nano-mica; 2.0 parts of impact modifier ACR; 0.6 parts of polyethylene wax; 0.3 parts of stearic acid; 2 parts of titanium dioxide;

[0048]Inner layer raw materials: 1.0 parts of PVC resin; 3.0 parts of stabilizer; 90 parts of polymethyl methacrylate (PMMA); 15 parts of polytetrafluoroethylene powder; 15 parts of nano-calcium carbonate; 1.5 parts of MBS; 0.6 parts of stearic acid ; 15 parts of lithium carbonate; 10 parts of ABS;

[0049] Add the above-mentioned mixed outer layer raw materials into the hopper of the outer layer extruder and extrude them into shape, wherein the screw temperature of the outer layer pipe extruder is set to 195°C in zone 1, 185°C in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com