LiAlO2 coated LiNi1-xCoxO2 lithium-ion battery positive electrode material and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as product particle size distribution and surface coating unevenness, difficulty in controlling stoichiometric ratio, and poor electrochemical performance. Achieve the effects of enhancing high-current charge-discharge performance and thermal stability, excellent electrochemical performance, and improving specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

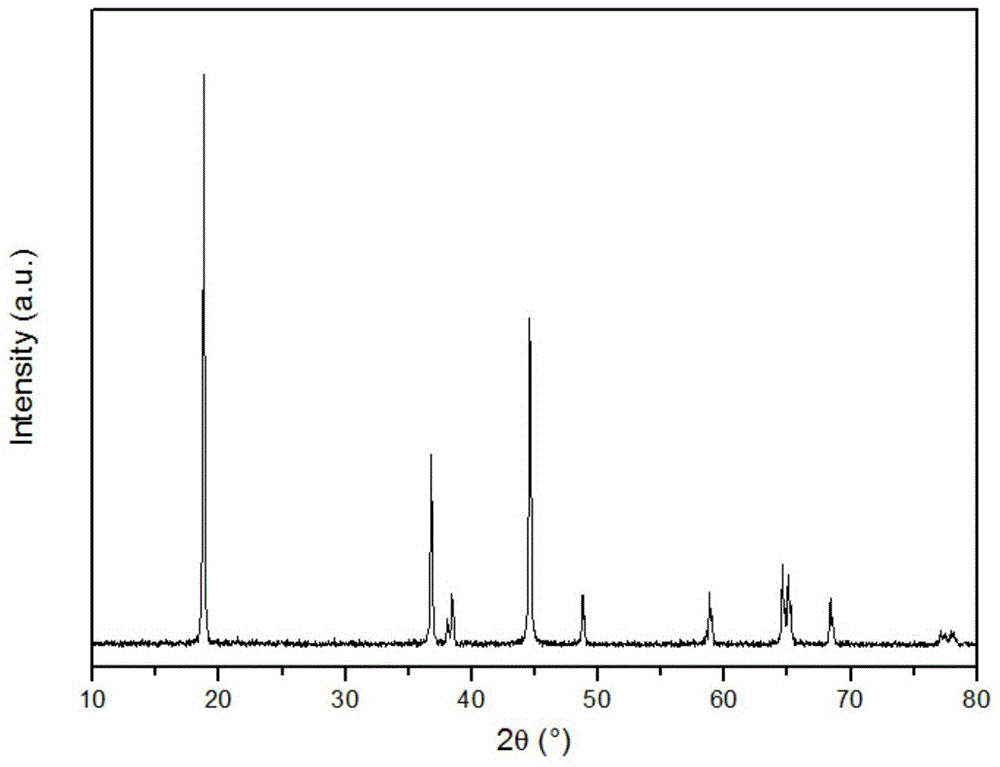

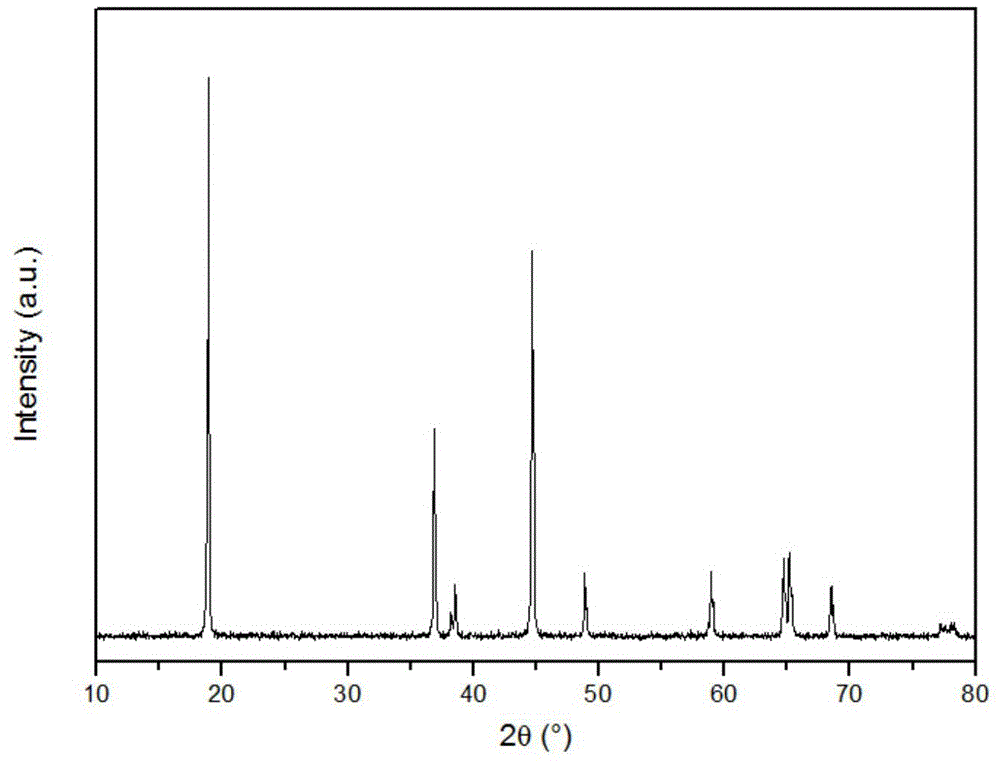

[0041] 1.08-1.15mol lithium hydroxide and 1.0mol Ni prepared by co-precipitation 0.8 co 0.2 (OH) 2 Mix the precursors evenly, put them into a ball mill, add an appropriate amount of absolute ethanol, grind to the required particle size, evaporate, dry, remove and recover the ethanol, and the obtained mixture containing Li, Ni, and Co is heated in oxygen-enriched air and at an appropriate temperature. (350~500℃) pre-fired for 2-10h, take out and grind, then sinter in oxygen-enriched air or pure oxygen atmosphere and at an appropriate temperature (650~900℃) for 10-16h, take out and grind and sieve , take the product between 1 and 25 μm to get LiNi 0.8 co 0.2 o 2 parent cathode material. XRD and electrochemical performance tests were carried out on the material.

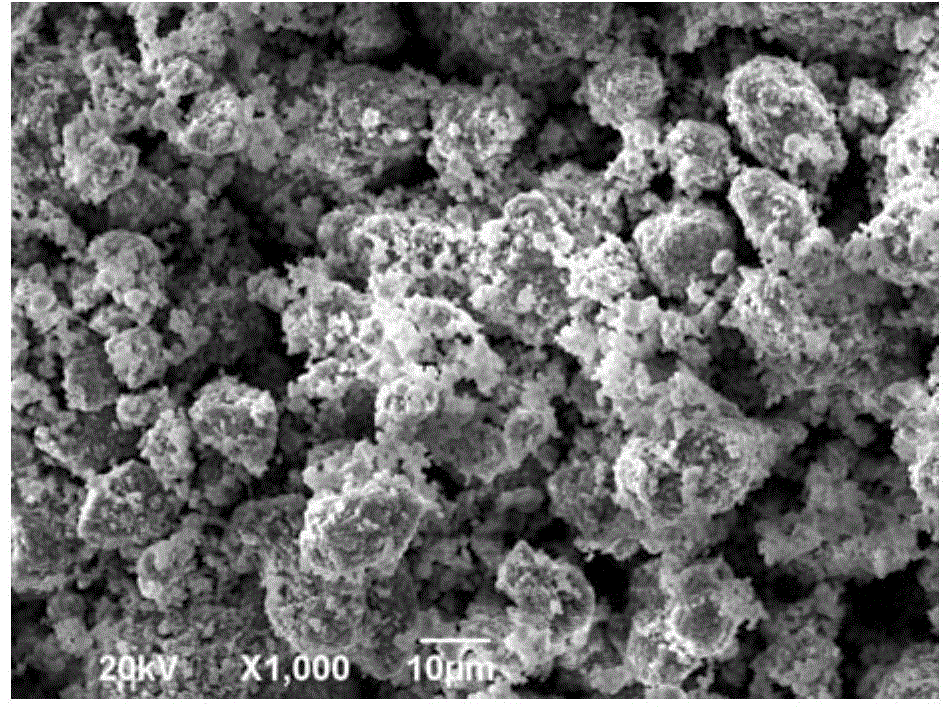

[0042] 1.0molLiNi 0.8 co 0.2 o 2 About 98.0g of the matrix positive electrode material is dispersed in an appropriate amount of deionized water, stirred to obtain a uniform suspension A; a proportional amount o...

Embodiment 2

[0045] Add 1.08-1.15mol of lithium hydroxide, 0.80mol of nickel acetate, 0.20mol of cobalt acetate and 1.2mol of citric acid into the container and mix evenly. Add an appropriate amount of deionized water into the container and stir vigorously until a transparent dark sol is obtained. With stirring, the sol was evaporated on a water bath at 50-80°C until a dark colored gel was obtained. Then the gel was dried overnight at 120° C. in a blast oven to obtain a dark xerogel containing Li, Ni, and Co. The obtained dark xerogel containing Li, Ni and Co is pre-calcined for 2-10 hours in oxygen-enriched air at a suitable temperature (350-550° C.), taken out and ground to obtain a precursor. The precursor is then sintered in an oxygen-enriched air or pure oxygen atmosphere and at an appropriate temperature (650-900°C) for 10-16 hours, taken out, ground and sieved, and the product between 1 and 25 μm is obtained to obtain LiNi 0.8 co 0.2 o 2 parent cathode material. XRD and electroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com