Process for producing blended cements with reduced carbon dioxide emissions

A technology of mixing cement and cement, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of non-competition, increase of setting time, increase and decrease of concrete strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

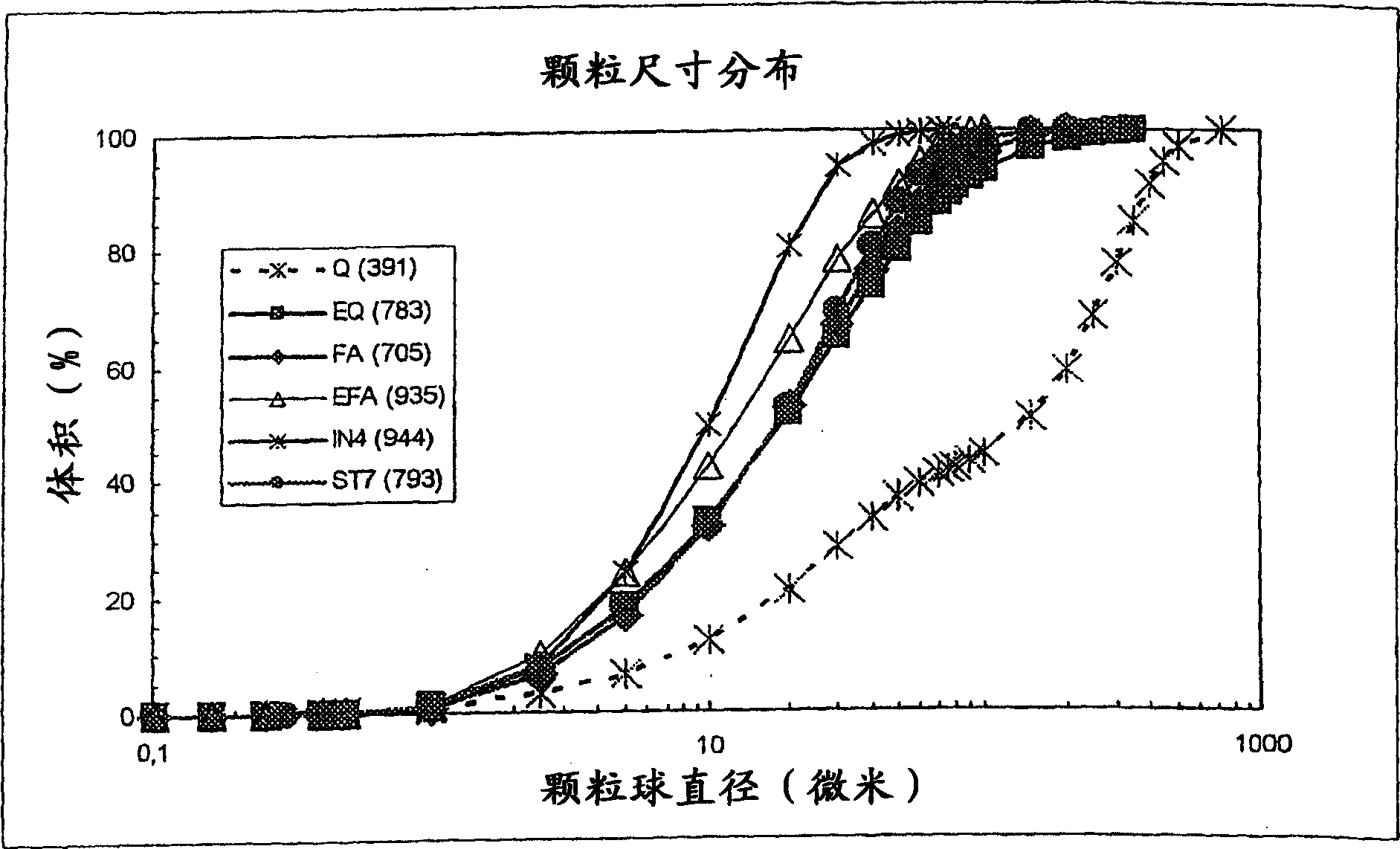

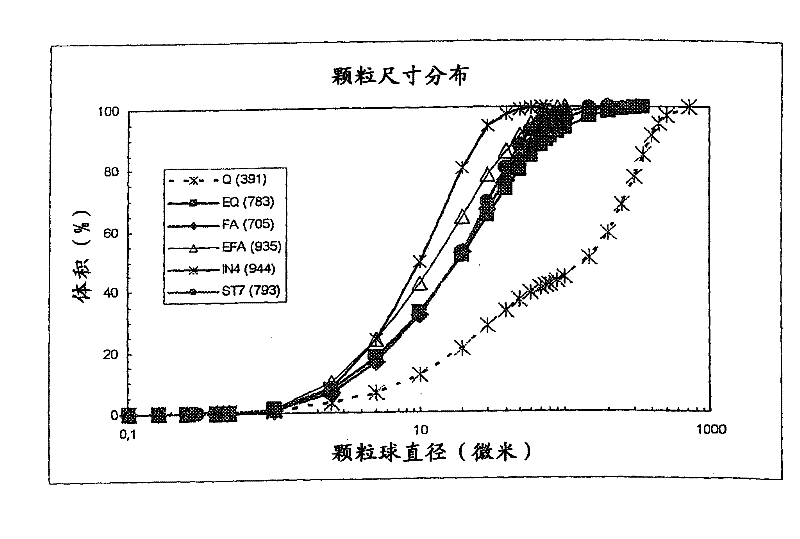

[0038] The following materials were used in the experiments: CEM I 42.5 according to EN-197 or Type I standard Portland cement according to ASTMC 150, (FA) grade fly ash, blast furnace slag (BFS), and quartz filler (Q) . The chemical composition of the materials is given in Table 6.

[0039] compound

PC

FA

BFS

Q

CaO

62.4%

15.0%

35.5%

0.1%

SiO 2

17.8%

49.4%

34.0%

98.2%

Al 2 o 3

4.0%

19.6%

11.5%

0.2%

Fe 2 o 3

3.9%

5.2%

0.4%

0.3%

SO 3

3.2%

0.8%

3.4%

0.1%

Na 2 o

<0.1%

0.3%

0.54%

0.3%

K 2 o

0.3%

1.2%

0.56%

0.2%

[0040] The bonding aid material has been ground separately in a vibrating mill VBM1518 to obtain approx. 1500cm 2 / g(Blaine) specific surface area.

[0041] Said filler has then been mixed in dry state with a highly reactive dry cement mixture produced accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com