Preparation method of environment-friendly phase-changed insulated anti-cracking fast-setting spraying mortar

A green and environmentally friendly technology of spraying mortar, which is applied in the field of building materials to achieve the effect of large porosity, less paraffin leakage and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

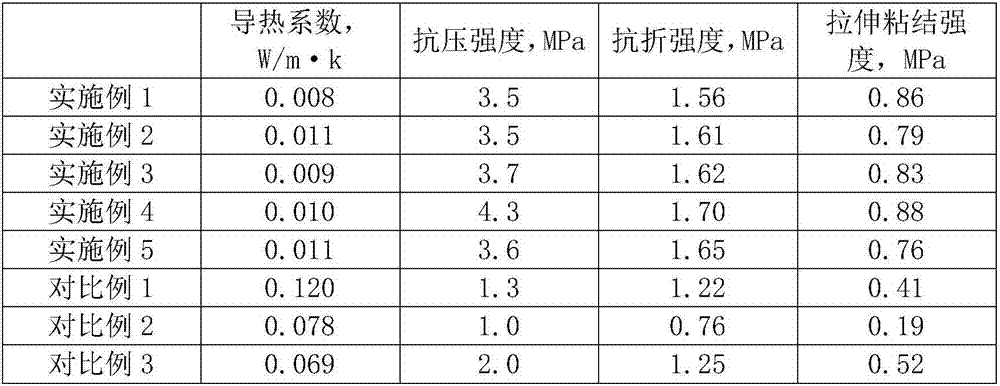

Examples

Embodiment 1

[0033] A preparation method of green environmental protection phase change thermal insulation anti-cracking fast setting spray mortar, comprising the following steps:

[0034] (1) mixing ordinary portland cement and sulphoaluminate cement into mixed cement;

[0035] (2) Expanded perlite is added in the rotary bucket, and the diluted polystyrene emulsion is atomized and sent into the rotary bucket with a sprayer, and rotated and stirred for 10 minutes to obtain the expanded perlite modified by polystyrene emulsion; , the mass ratio of expanded perlite to polystyrene emulsion is 2:1;

[0036] (3) Adopt the decompression adsorption method to make paraffin adsorbed in the pores of expanded perlite; then add the mixed cement prepared above into the expanded perlite adsorbed with paraffin, and stir for 1 hour at 500r / min to obtain the mixed cement-coated bone Material; Wherein, the mass ratio of paraffin and expanded perlite is 1:3; The mixed cement used is a part of the mixed ceme...

Embodiment 2

[0041] A preparation method of green environmental protection phase change thermal insulation anti-cracking fast setting spray mortar, comprising the following steps:

[0042] (1) mixing ordinary portland cement and sulphoaluminate cement into mixed cement;

[0043](2) Expanded perlite is added in the rotary bucket, and the diluted polystyrene emulsion is atomized and sent into the rotary bucket with a sprayer, and rotated and stirred for 15 minutes to obtain the expanded perlite modified by polystyrene emulsion; , the mass ratio of expanded perlite to polystyrene emulsion is 2.5:1;

[0044] (3) Adopt decompression adsorption method to make paraffin adsorb in the pores of expanded perlite; then add the mixed cement prepared above into the expanded perlite adsorbed with paraffin, and stir at 600r / min for 1.5h to obtain mixed cement coated Aggregate; wherein, the mass ratio of paraffin and expanded perlite is 1:4; the mixed cement used is a part of the mixed cement described in...

Embodiment 3

[0049] A preparation method of green environmental protection phase change thermal insulation anti-cracking fast setting spray mortar, comprising the following steps:

[0050] (1) mixing ordinary portland cement and sulphoaluminate cement into mixed cement;

[0051] (2) Expanded perlite is added in the rotary bucket, and the diluted polystyrene emulsion is atomized and sent into the rotary bucket with a sprayer, and rotated and stirred for 20 minutes to obtain expanded perlite modified by polystyrene emulsion; , the mass ratio of expanded perlite to polystyrene emulsion is 3:1;

[0052] (3) Adopt the decompression adsorption method to make paraffin adsorbed in the pores of expanded perlite; then add the mixed cement prepared above into the expanded perlite adsorbed with paraffin, and stir for 2 hours at 700r / min to obtain the mixed cement-coated bone Material; Wherein, the mass ratio of paraffin and expanded perlite is 1:5; The mixed cement used is a part of the mixed cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com