Light-weight thermal insulation anti-crack plastering gypsum

A plastering gypsum, lightweight technology, applied in the field of building materials, can solve problems such as affecting agricultural production and people's drinking water, bank instability, etc., and achieve the effects of high strength, improved compressive and flexural strength, and improved flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

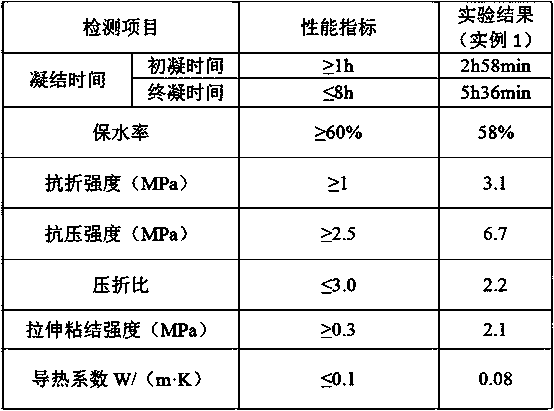

Embodiment 1

[0029] A light heat preservation and anti-cracking plastering gypsum, which is composed of the following raw materials in parts by weight: vitrified microbeads: 15wt%; gypsum: 45wt%; cement: 20wt%; fly ash: 5wt%; silica fume: 3wt% %; hydroxypropyl methylcellulose: 0.5wt%; polypropylene fiber: 0.3wt%; redispersible latex powder: 3wt%; water repellent: 0.5wt%; water accounts for 90% of the total mass of the above components .

Embodiment 2

[0031] A light-weight thermal insulation and anti-cracking plastering gypsum, which is composed of the following raw materials in parts by weight: vitrified microbeads: 17wt%; gypsum: 46wt%; cement: 22wt%; fly ash: 6wt%; silica fume: 3.5 wt%; hydroxypropyl methylcellulose: 0.5wt%; polypropylene fiber: 0.35wt%; redispersible latex powder: 3.5wt%; water repellent: 0.6wt%; 90%.

Embodiment 3

[0033] A light heat preservation and anti-cracking plastering gypsum, which is composed of the following raw materials in parts by weight: vitrified microbeads: 18wt%; gypsum: 48wt%; cement: 23wt%; fly ash: 8wt%; silica fume: 4wt% %; hydroxypropyl methylcellulose: 0.5wt%; polypropylene fiber: 0.4wt%; redispersible latex powder: 4wt%; water repellent: 0.7wt%; water accounted for 90% of the total mass of the above components .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com