Interface mortar for steel structural exterior wall with anticorrosive coating layer

A technology of interface mortar and anti-corrosion coating, which is applied in the direction of building structure, construction, covering/lining, etc., and can solve problems such as hollowing of the enclosure system, unsatisfactory bonding performance, and poor bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

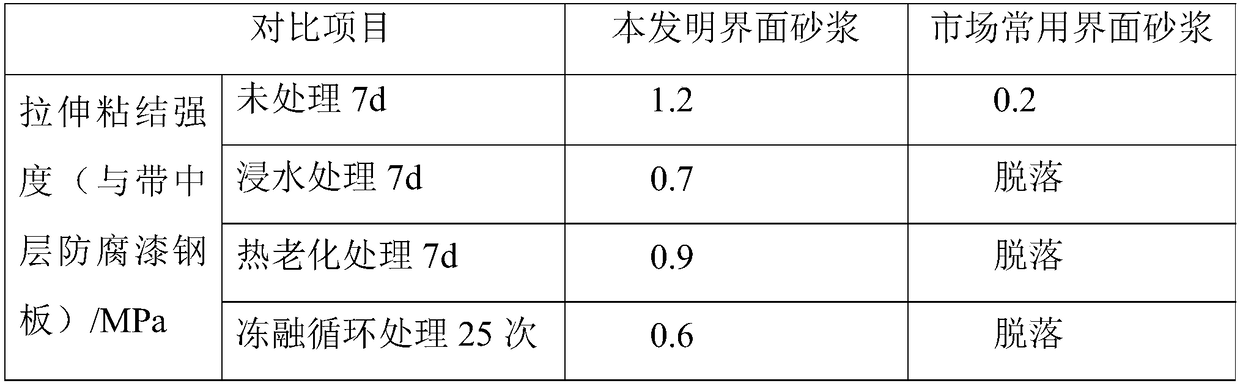

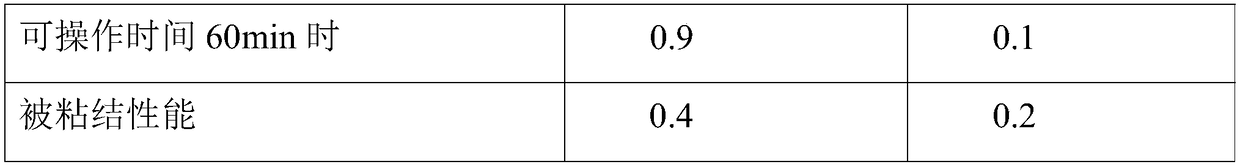

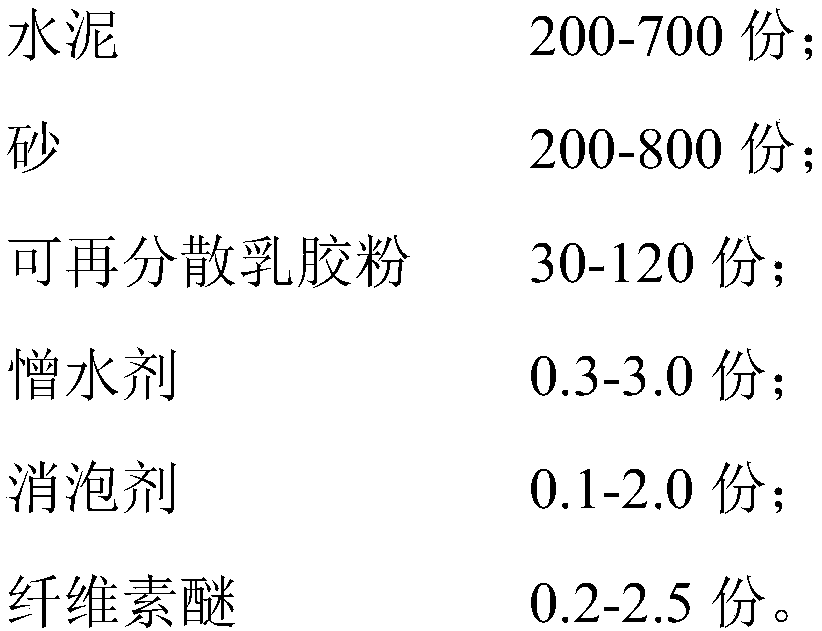

Embodiment 1

[0037]An interface mortar for steel structure exterior walls with an anti-corrosion coating, in parts by weight, consists of 400 grade 42.5 ordinary Portland cement, 600 medium sand, 90 acrylate copolymer latex powder, 0.8 water repellent, defoaming agent Agent 0.4, ethyl methyl cellulose ether 1.0 prepared. Add water with a mass fraction of 140 and stir evenly. After 7 days of standard curing, the tensile bond strength between the mortar provided in this example and the anti-corrosion coated steel plate with a middle layer without any treatment is 1.2 MPa; after 7 days of standard curing, this The tensile bonding strength of the mortar provided in the embodiment and the anti-corrosion coated steel plate with the middle layer after soaking in water for 7 days is 0.7 MPa; Tensile bonding strength is 0.9MPa; after standard maintenance 7d, the tensile bonding strength of the mortar provided by this embodiment and the anti-corrosion coated steel plate with middle layer after freez...

Embodiment 2

[0039] An interface mortar for steel structure exterior walls with an anti-corrosion coating, in parts by weight, consists of 450 grade 42.5 ordinary portland cement, 550 medium sand, 100 ethylene vinyl acetate latex powder, 2.5 water repellent, and defoamer 1.0, prepared from 0.5 parts of hydroxypropyl methylcellulose ether. Add water with a mass fraction of 150 and stir evenly. After standard curing for 7 days, the tensile bond strength between the mortar provided in this example and the steel plate with a middle layer of anti-corrosion coating without any treatment is 1.1 MPa; after standard curing for 7 days, this The tensile bond strength of the mortar provided in the embodiment and the anti-corrosion coated steel plate with the middle layer after soaking in water for 7 days is 0.6 MPa; Tensile bonding strength is 0.8MPa; after standard curing 7d, the tensile bonding strength of the mortar provided by this embodiment and the anti-corrosion coated steel plate with middle l...

Embodiment 3

[0041] A kind of interface mortar for steel structure external wall with anti-corrosion coating, in parts by weight,

[0042] It is prepared by 42.5 grade ordinary Portland cement 550, medium sand 450, ethylene vinyl acetate latex powder 40, styrene-butadiene latex powder 60, water repellent 1.5, defoamer 0.8, hydroxyethyl methyl cellulose ether 0.5 parts . Add water with a mass fraction of 155 and stir evenly. After 7 days of standard curing, the tensile bond strength between the mortar provided in this example and the steel plate with a middle layer of anti-corrosion coating without any treatment is 1.0 MPa; after 7 days of standard curing, this The tensile bonding strength of the mortar provided in the embodiment and the anti-corrosion coated steel plate with the middle layer after soaking in water for 7 days is 0.5 MPa; Tensile bonding strength is 0.8MPa; after standard curing 7d, the tensile bonding strength after 25 freeze-thaw cycles between the mortar provided by this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com