Preparation method, products and construction method for renovation putties for surfaces of old ceramic tiles

A ceramic tile and putty technology, which is applied to the field of refurbishing putty on old tile surfaces, can solve the problem of difficulty in finding refurbished putty, and achieve the effects of reducing maintenance costs, high production efficiency, and facilitating popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

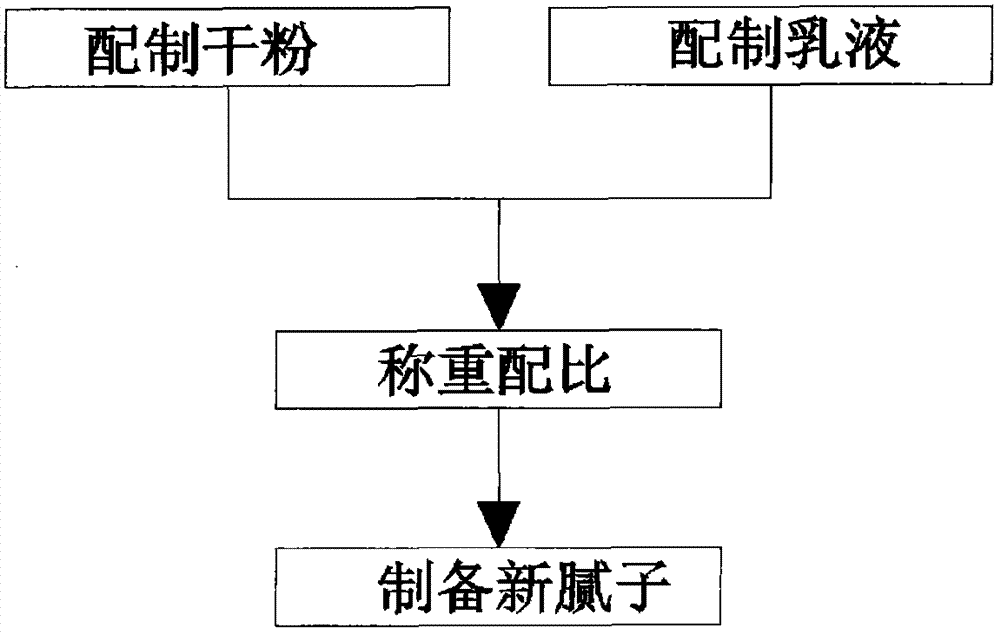

[0062] Example 1: see figure 1 , a kind of old ceramic tile surface renovation putty preparation method provided by the present embodiment, it comprises the following steps:

[0063] (1) Prepare dry powder: each component of dry powder and its weight ratio are as follows:

[0064] Portland cement 350Kg,

[0065] 80~120 mesh quartz sand 535Kg,

[0066] 200 mesh double fly powder 100Kg,

[0069] Wood fiber 2.5Kg,

[0071] Mix Portland cement, quartz sand, double fly powder, cellulose ether, starch ether, wood fiber and calcium formate and stir evenly to obtain dry powder;

[0072] (2) Prepare emulsion: each component of emulsion and its weight ratio are as follows:

[0073] styrene-butadiene emulsion 200Kg,

[0074] Styrene-acrylic emulsion 200Kg,

[0075] Clear water 595Kg,

[0076] Defoamer 3Kg,

[0077] Preservative 2Kg;

[0078] Mix and stir the styrene-butadiene emulsion, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com