A modified composite organic binder

An organic binder and binder technology, applied in the field of external wall thermal insulation bonding materials, can solve the problems of high production cost of polystyrene board bonding mortar, cutting corners, polystyrene board falling off, etc., so as to improve the initial adhesion. The effect of junction capacity, cost reduction, performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

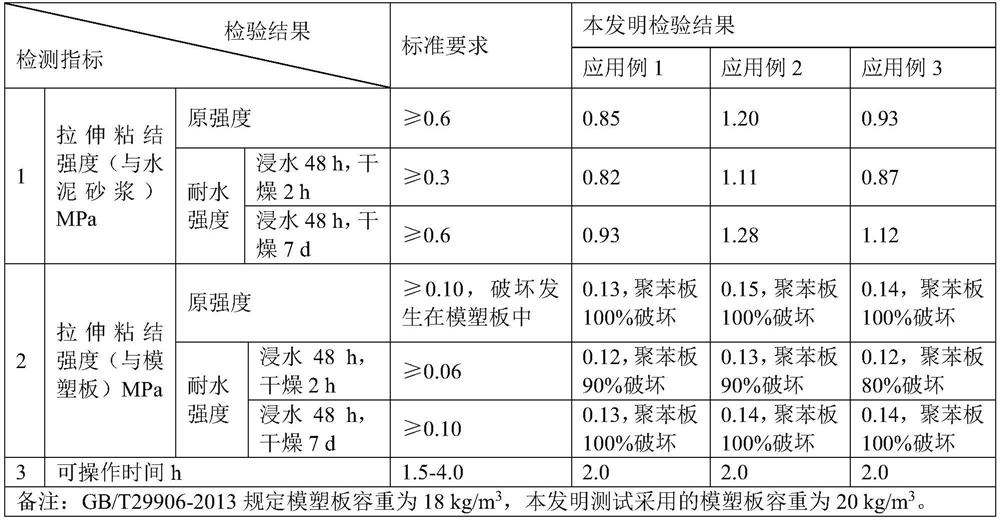

Examples

Embodiment 1

[0029] A modified composite organic binder, comprising the following components by weight:

[0030] 7 parts of inorganic carrier, 53 parts of cellulose ether, 15 parts of binder, 20 parts of modifier, 5 parts of early strength agent;

[0031] The components are mixed to obtain the modified composite organic binder.

[0032] The inorganic carrier used is obtained by mixing 400 mesh heavy calcium and 400 mesh white carbon black according to the weight ratio of 1:0.1;

[0033] The modifier used is obtained by mixing triethylene glycol diisocaprylate and dioctyl isophthalate in a weight ratio of 1:0.5.

Embodiment 2

[0035] A modified composite organic binder, comprising the following components by weight:

[0036] 6 parts of inorganic carrier, 51 parts of cellulose ether, 17 parts of binder, 18 parts of modifier, 8 parts of early strength agent;

[0037] The components are mixed to obtain the modified composite organic binder.

[0038] The inorganic carrier used is obtained by mixing 400 mesh heavy calcium and 400 mesh white carbon black according to the weight ratio of 1:0.2;

[0039] The modifier used is obtained by mixing triethylene glycol diisocaprylate and dioctyl isophthalate in a weight ratio of 1:1.

Embodiment 3

[0041] A modified composite organic binder, comprising the following components by weight:

[0042] 8 parts of inorganic carrier, 50 parts of cellulose ether, 16 parts of binder, 21 parts of modifier, 5 parts of early strength agent;

[0043] The components are mixed to obtain the modified composite organic binder.

[0044] The inorganic carrier used is obtained by mixing 400 mesh heavy calcium and 400 mesh white carbon black according to the weight ratio of 1:0.5;

[0045] The modifier used is obtained by mixing triethylene glycol diisocaprylate and dioctyl isophthalate in a weight ratio of 1:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com