One-component dealcoholized room temperature vulcanized silicone rubber and its preparation method and application

A room temperature vulcanization and dealcoholization technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. High viscosity peak, good compatibility, extended shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

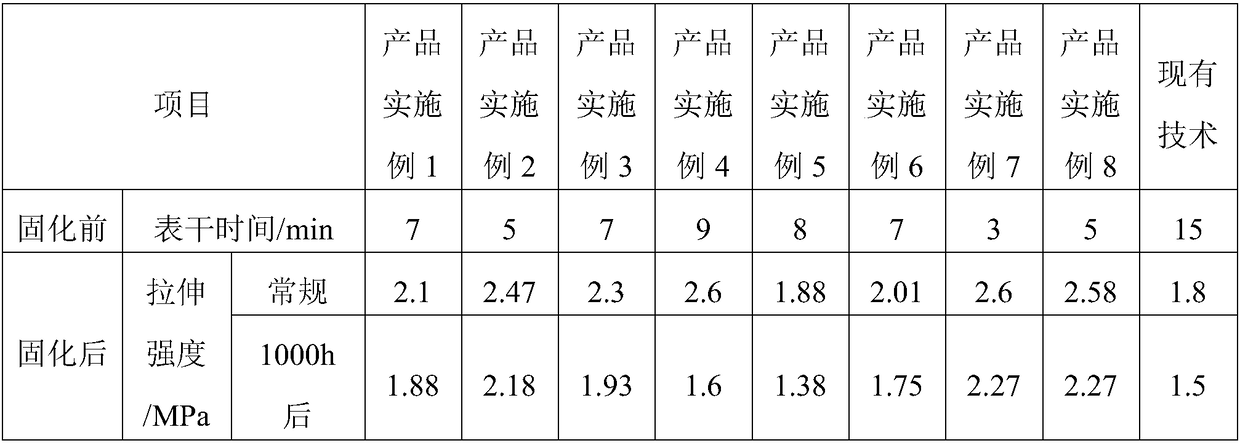

Examples

Embodiment 1

[0021] In Example 1, a single-component dealcoholized room temperature vulcanized silicone rubber is prepared from the following raw materials: 200 parts of 107 silicone rubber with a dynamic viscosity of 5000 cps as a base polymer, 40 parts of a crosslinking agent, and functions The filler is 300 parts and the plasticizer is 20 parts; the functional filler is modified nano-calcium carbonate supported titanate catalyst composite particles, the crosslinking agent is tetramethoxysilane, and the plasticizer is polydimethyl silicone oil.

Embodiment 2

[0023] This example 2 is a one-component dealcoholized room temperature vulcanized silicone rubber, which is prepared from the following parts by weight: 180 parts of 107 silicone rubber with a dynamic viscosity of 20000cps as a base polymer, 20 parts of a crosslinking agent, and functions The filler is 150 parts and the plasticizer is 10 parts; the functional filler is modified nano-calcium carbonate supported titanate catalyst composite particles, the crosslinking agent is tetraethoxysilane, and the plasticizer is MDT silicone oil.

Embodiment 3

[0025] In Example 3, a single-component dealcoholized room temperature vulcanized silicone rubber is prepared from the following raw materials: 150 parts of 107 silicone rubber with a dynamic viscosity of 50,000 cps as a base polymer, 5 parts of a crosslinking agent, and functions The filler is 80 parts; the functional filler is composite particles of modified nano-calcium carbonate supported titanate catalyst, and the crosslinking agent is tetrapropoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com