Patents

Literature

40results about How to "Resistant to deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

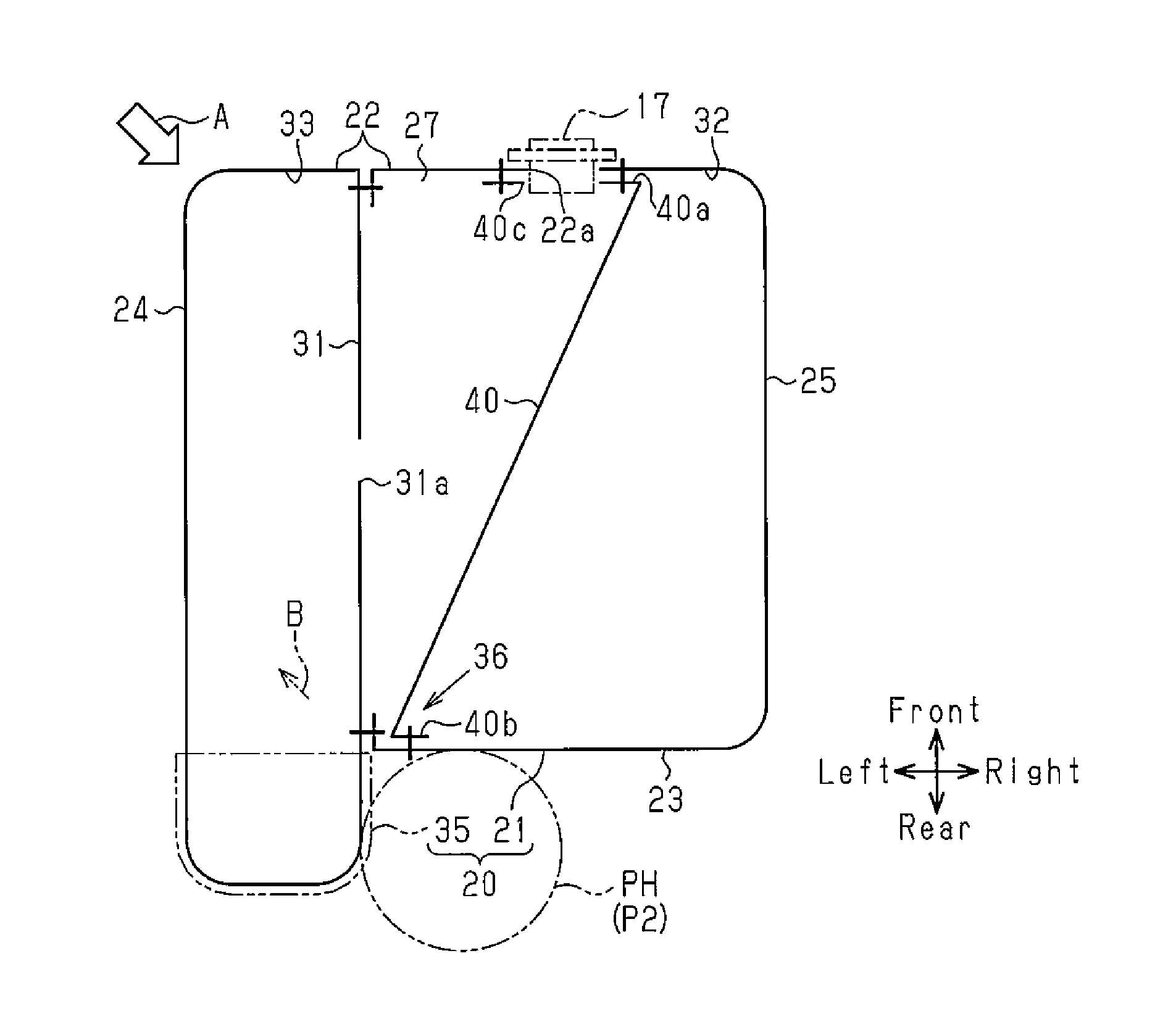

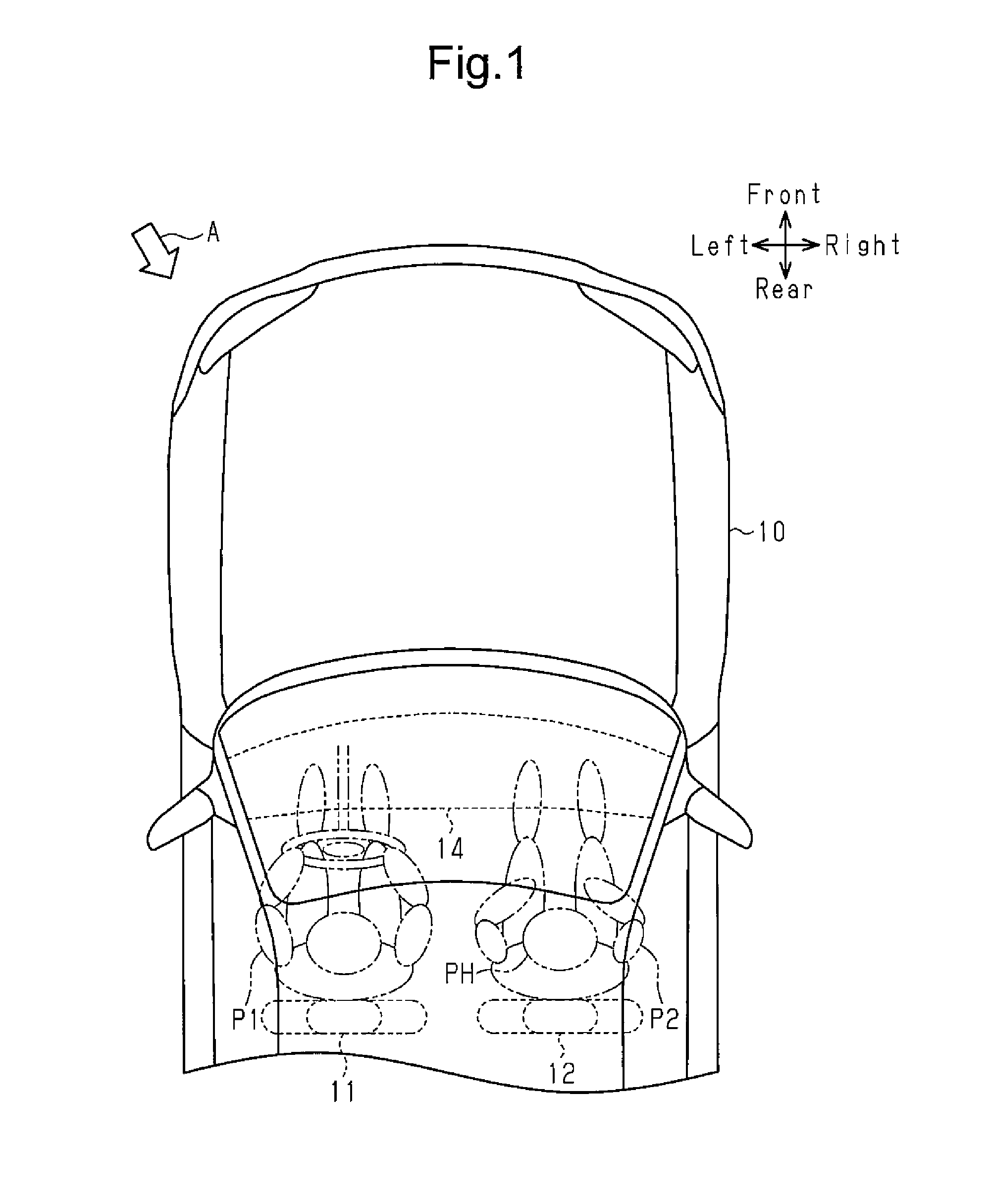

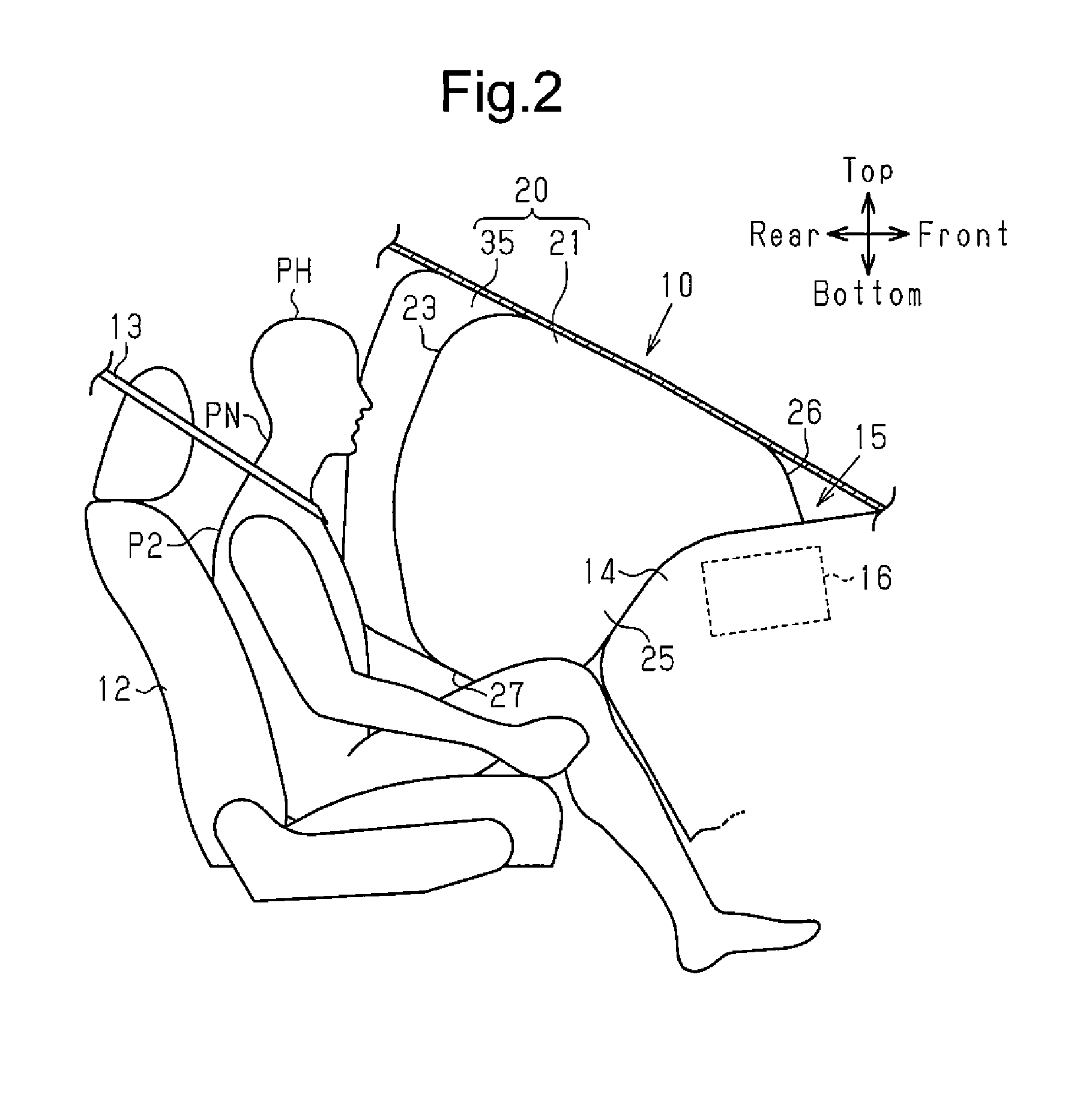

Vehicle airbag

InactiveUS9187055B1Resistant to deformationRestrict rotationPedestrian/occupant safety arrangementEngineeringAirbag

A vehicle airbag includes an airbag main body and an auxiliary airbag portion. A tether is located in the airbag main body. The rear end of the tether is connected to the boundary area between the airbag main body and the auxiliary airbag portion or to a part in the vicinity of the boundary area. The front end of the tether is connected either to a side wall portion closer to the auxiliary airbag portion or to the front wall portion of the airbag main body. The part of the front end of the tether that is connected to the front wall portion is farther from a side wall portion farther from the auxiliary airbag portion than the area in the front wall portion of the airbag main body onto which the part connected to the rear end of the tether is projected forward.

Owner:TOYODA GOSEI CO LTD

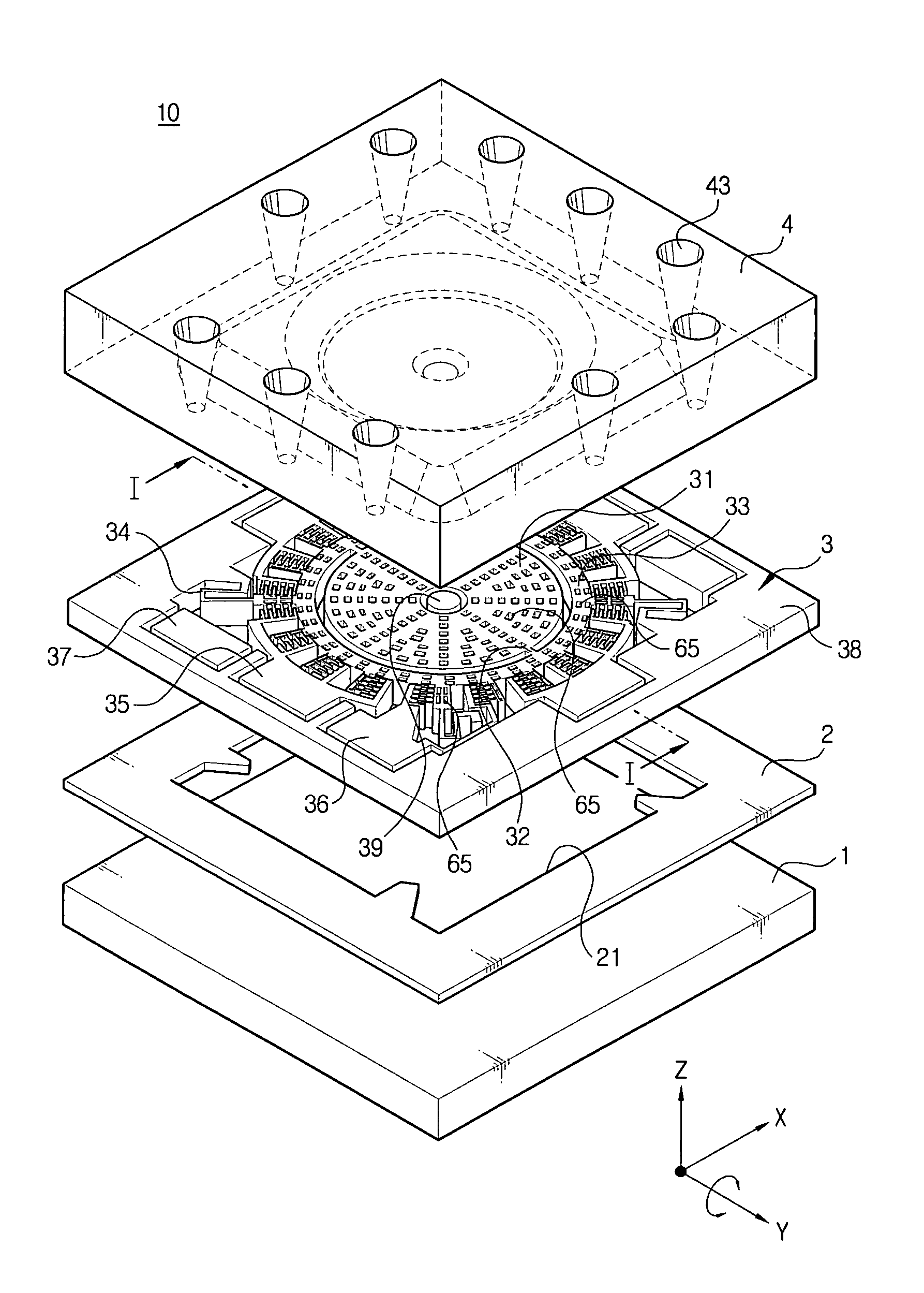

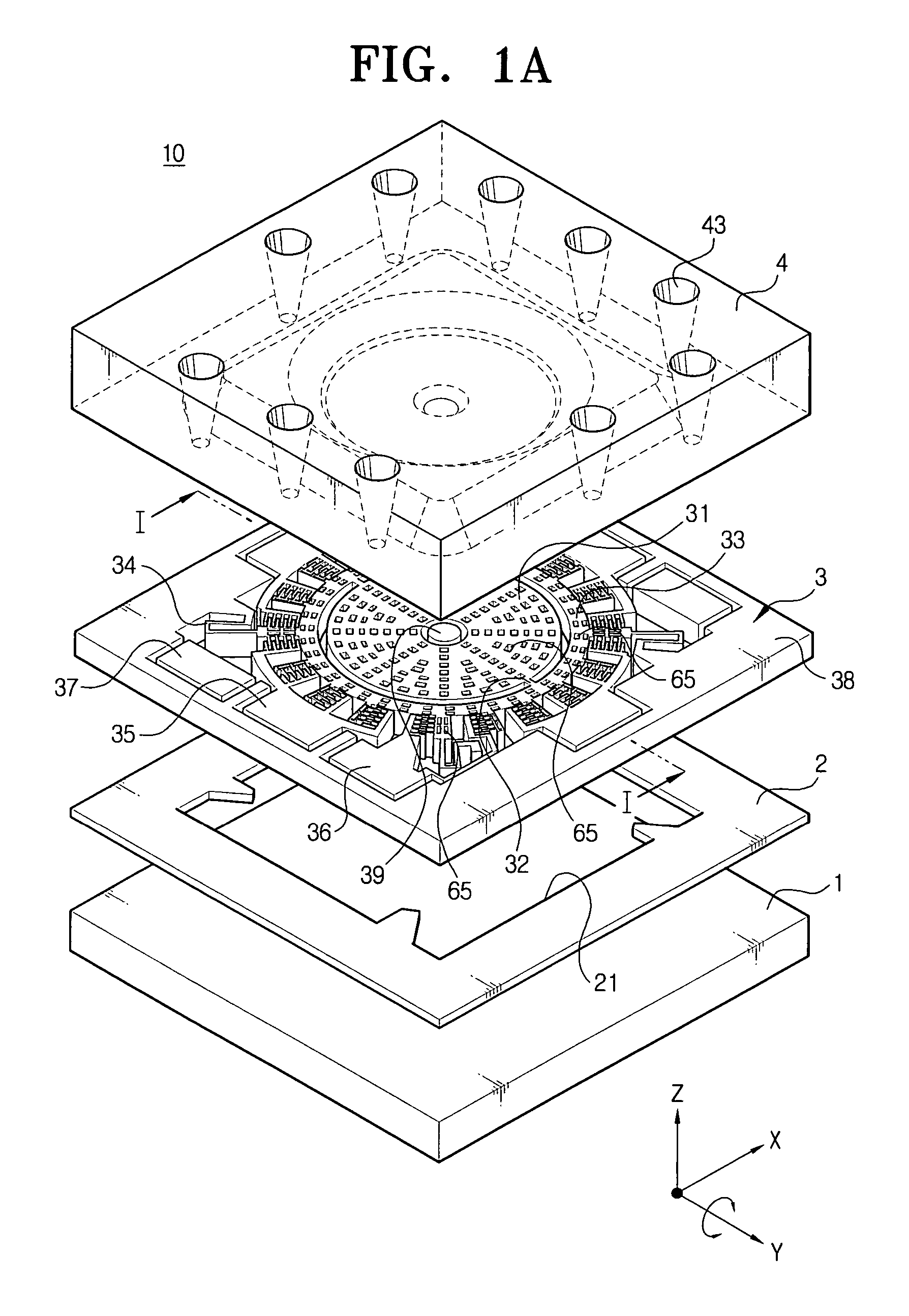

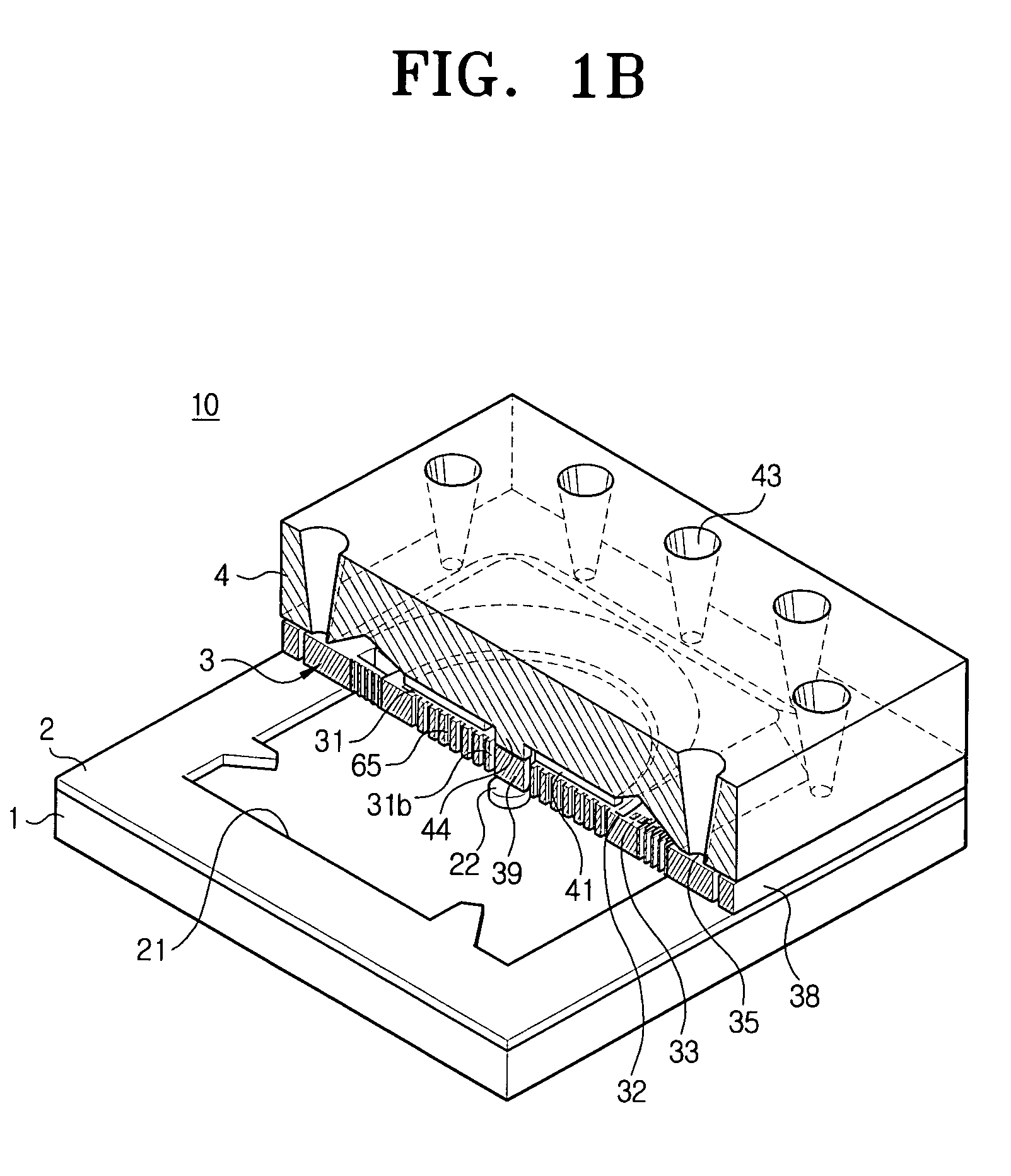

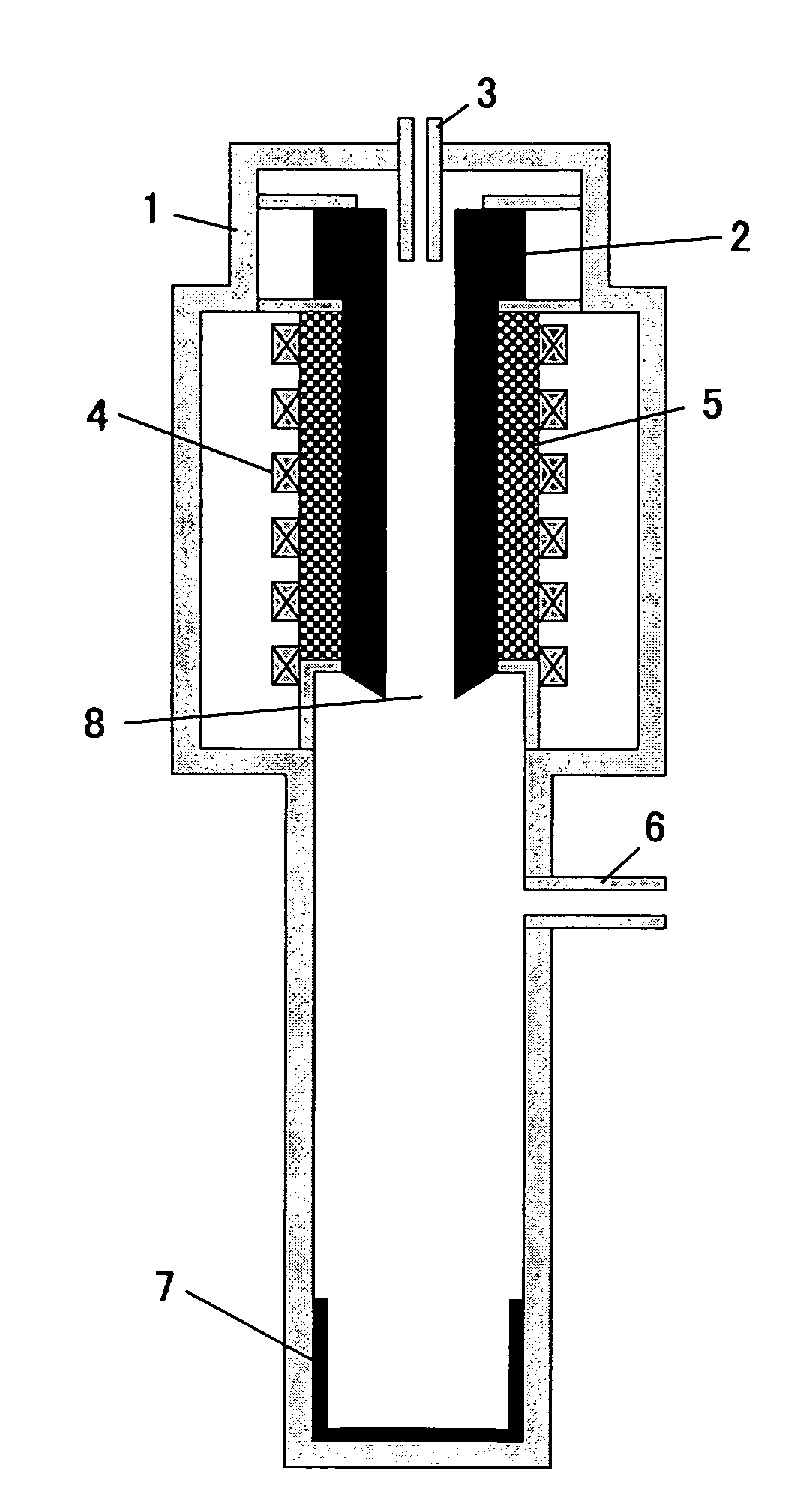

Rotary gyroscope

ActiveUS7043987B2Enhance performanceResistant to deformationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsDriven elementIntermediate structure

A rotary gyroscope includes a base plate, an intermediate structure, including a driven element floating over the base plate and supported by a driving supporter radially extending therefrom, the driven element performing an oscillating motion with respect to a first axis, which is normal to a center plane thereof, a driving electrode driving the driven element, and a sensing element disposed in the driven element and connected to the driven element by a sensing connector to oscillate together with the driven element and concurrently to perform a sensing motion with respect to a third axis, which is normal to the first axis and any second axis, which is parallel to a center plane, due to a Coriolis force when an angular velocity is inputted from the second axis, and a cover covering the intermediate structure and having a sensing electrode to detect the sensing motion of the sensing element.

Owner:SAMSUNG ELECTRONICS CO LTD

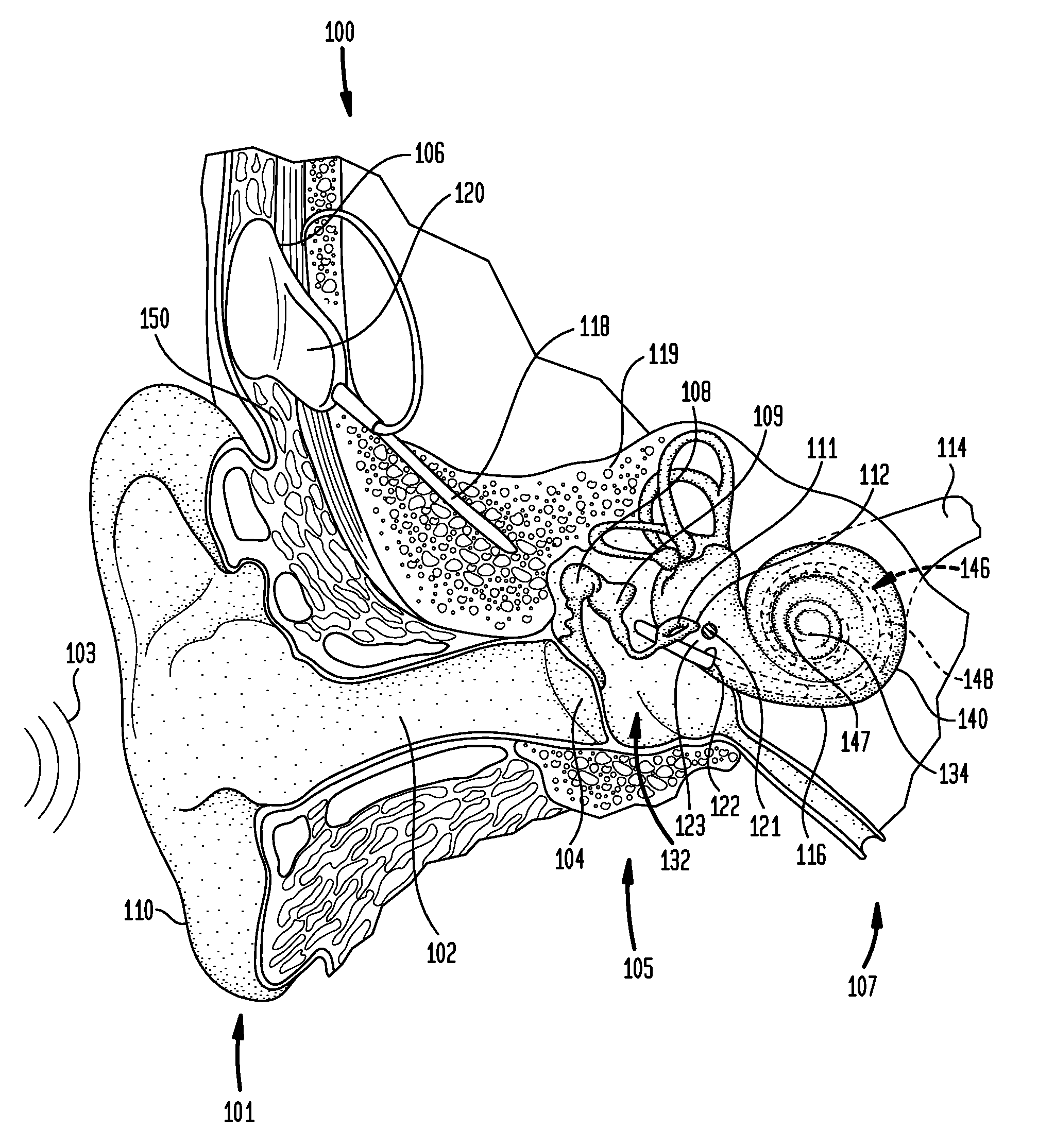

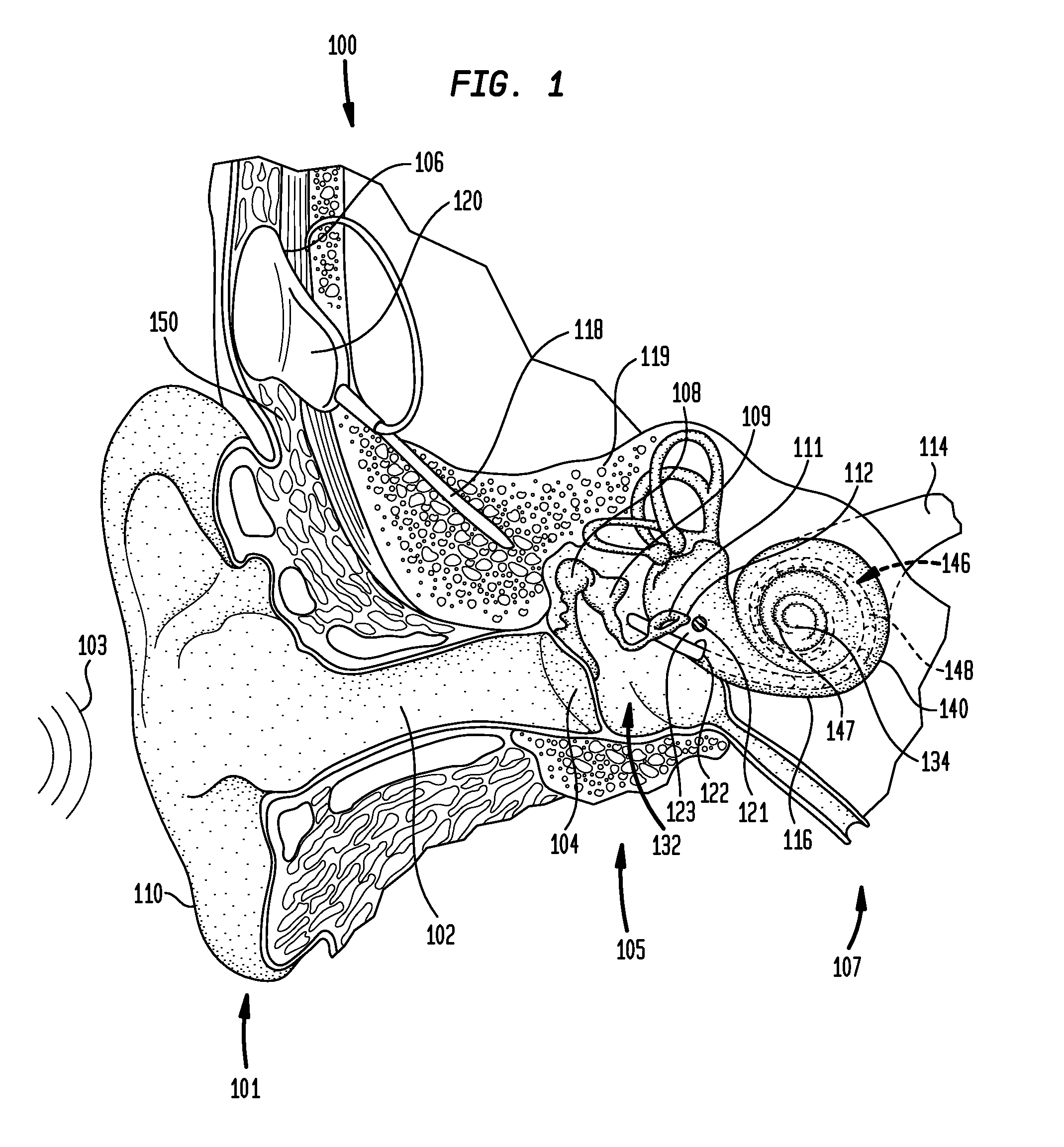

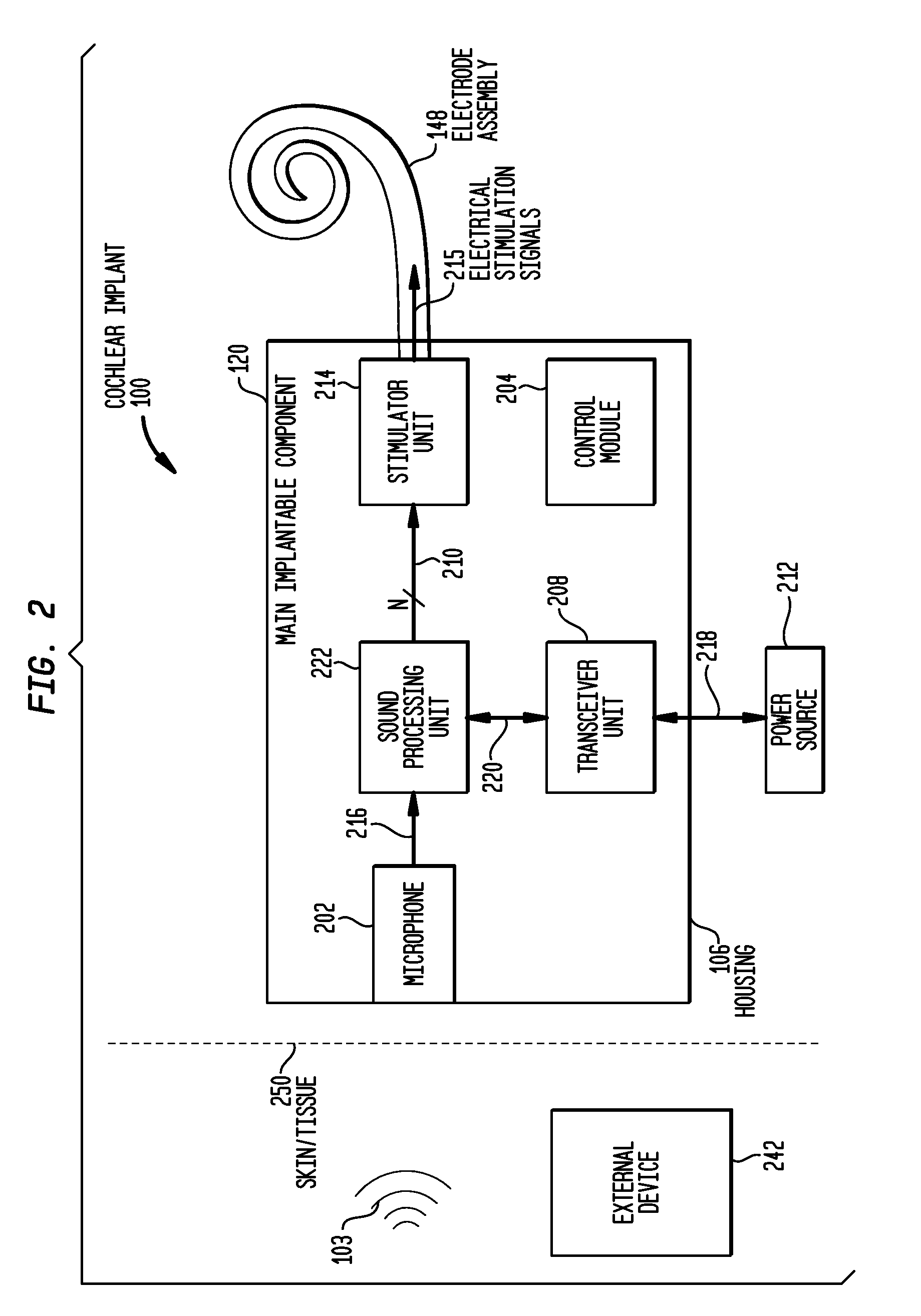

Implantable microphone for an implantable hearing prosthesis

ActiveUS20100092021A1Resistant to deformationResistance to deformationPiezoelectric/electrostrictive microphonesElectrotherapyElastic modulusProsthesis

An implantable microphone for a hearing prosthesis. The microphone comprises: a housing having a diaphragm chamber formed therein, and an aperture extending from the exterior surface of the housing to the chamber; a diaphragm disposed on the exterior of the housing so as to seal the aperture, and configured to vibrate in response to sound signals; a sensor positioned adjacent an end of the chamber opposing the diaphragm, and configured to detect vibration of the diaphragm, and to generate electrical signals based thereon; and a stiffening material substantially filling the regions of the housing external to the sensor and the diaphragm such that that air gaps within the filled regions of the housing are substantially eliminated, wherein the stiffening material has an elastic modulus that enables the housing to substantially resist deformation there of in response to body-noise.

Owner:COCHLEAR LIMITED

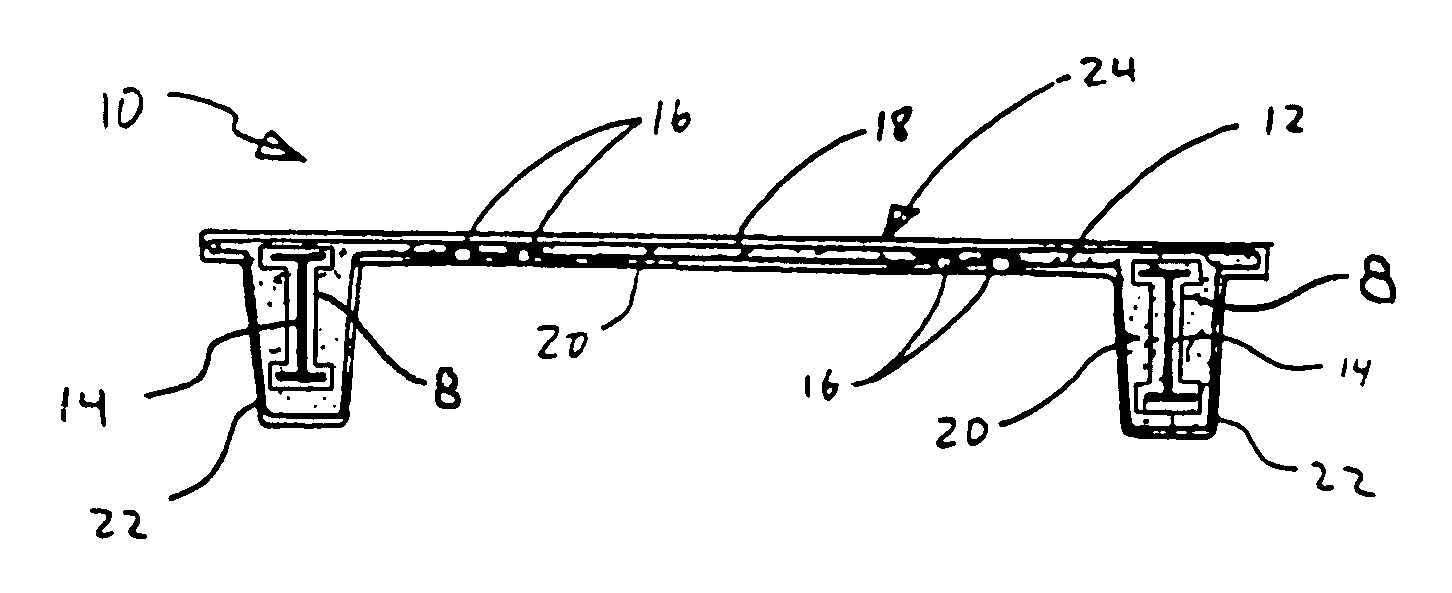

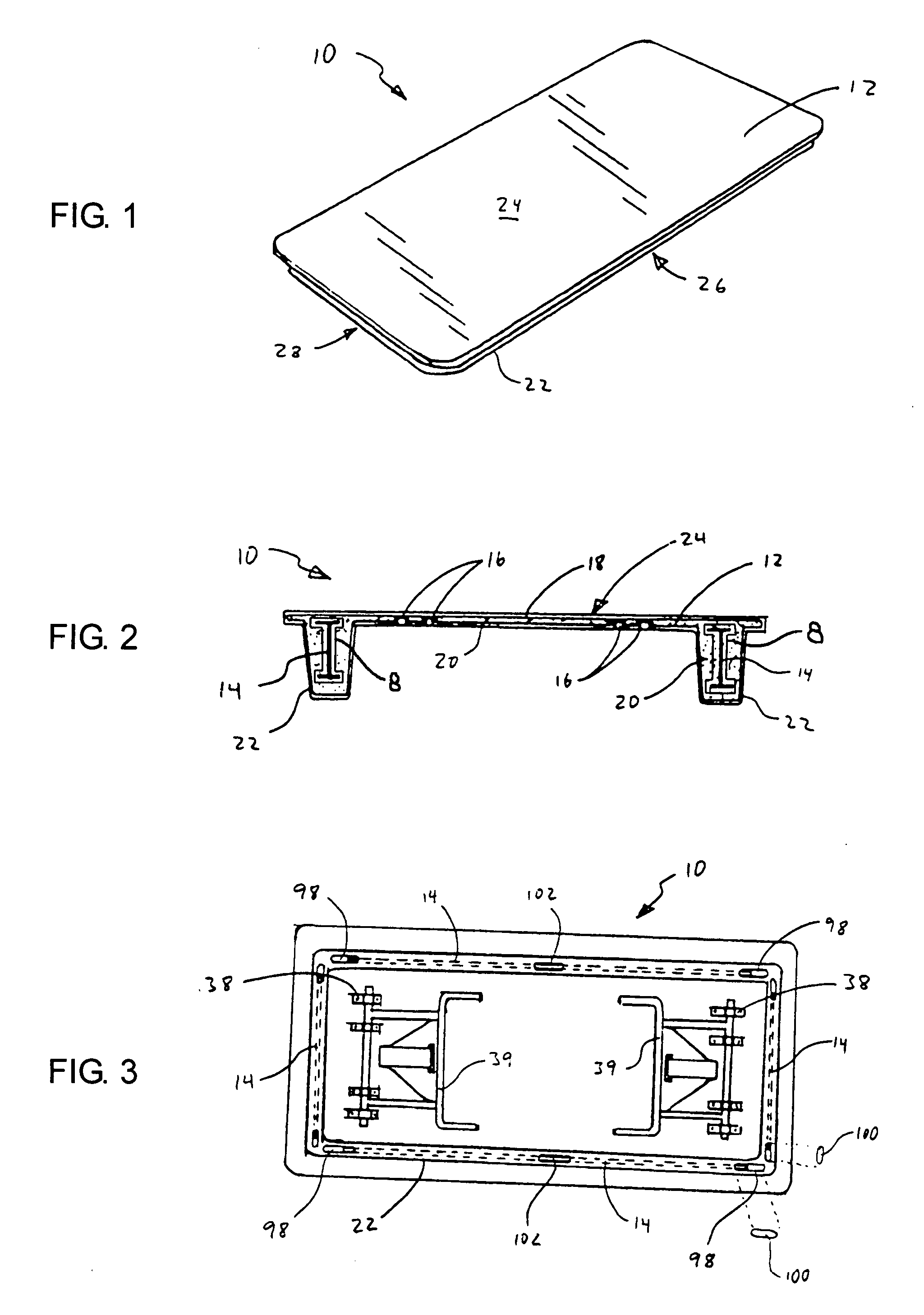

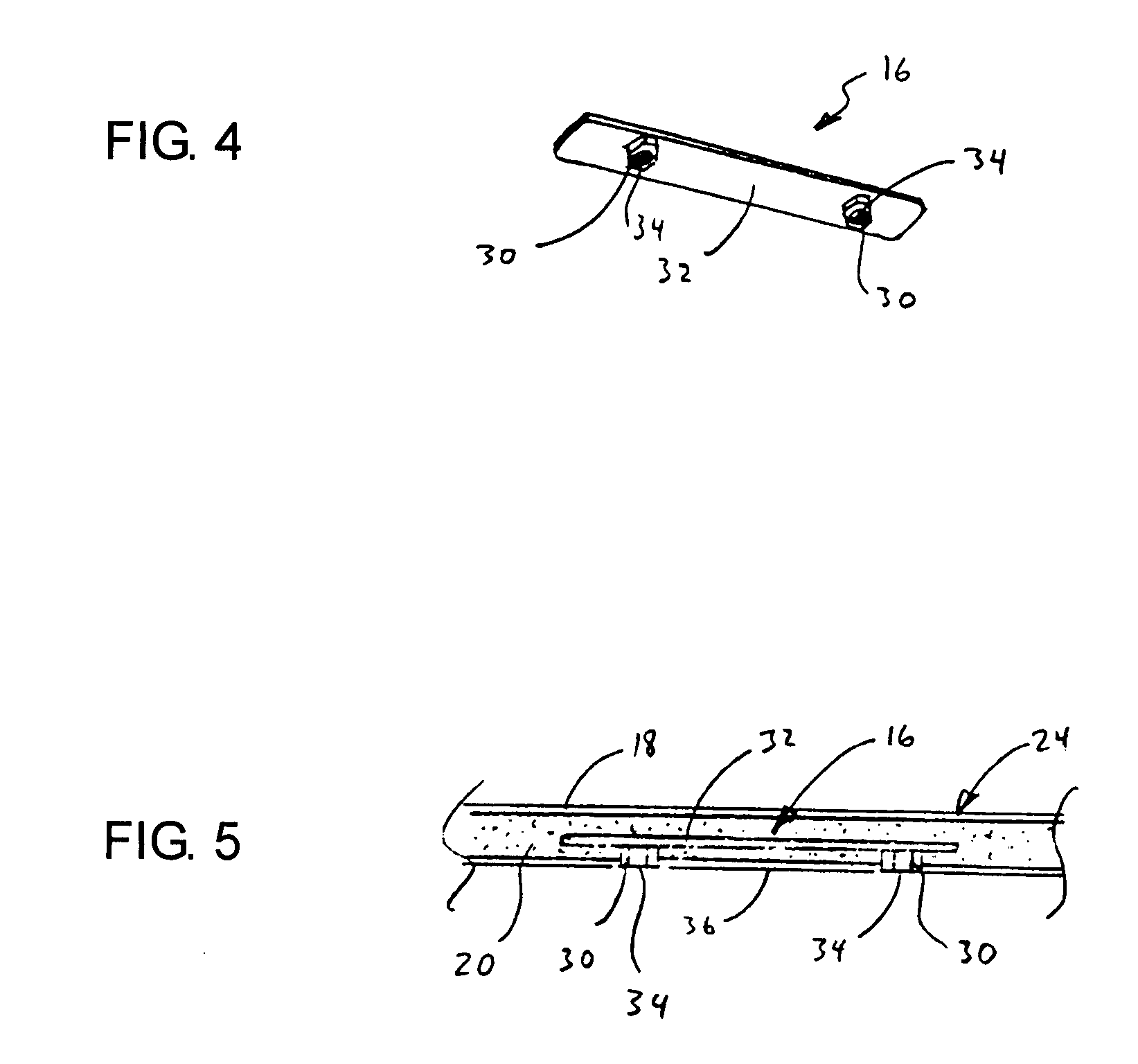

Molded article with foam-encased adhesion-resistant reinforcing member and method

InactiveUS20070275229A1Resistant to deformationMinimal internal stressLayered productsCeramic shaping apparatusPolymerSurface coating

A molded article includes a rotationally-molded body of polymer material, and a reinforcing member substantially encased within and in direct contact with the polymer material. Both the polymer material and the reinforcing member have their own unique post-molding shrinkage characteristics. A slip zone, defining a void in the body of polymer material, is formed around the end of the reinforcing member, such that post-molding shrinkage of the polymer material imposes substantially no stress on the end of the reinforcing member. The reinforcing member has a surface coating that substantially eliminates adhesion with the polymer material, so as to enable displacement of the reinforcing member with respect to contacting polymer material, and thereby reduce post-molding deformation of the molded article.

Owner:MFS

Absorbent core and absorbent article

InactiveUS20120115718A1Promote and inhibit gellingReduce the total massOther chemical processesAbsorbent padsOrganic acidScavenger

An absorbent core that can promote and / or inhibit gelling, and an absorbent article comprising it. The absorbent core includes a gelling agent that contains a polysaccharide capable of thickening in the presence of a polyvalent metal ion, a substance that can supply a polyvalent metal ion, and an organic acid and / or polyvalent metal ion scavenger.

Owner:UNI CHARM CORP

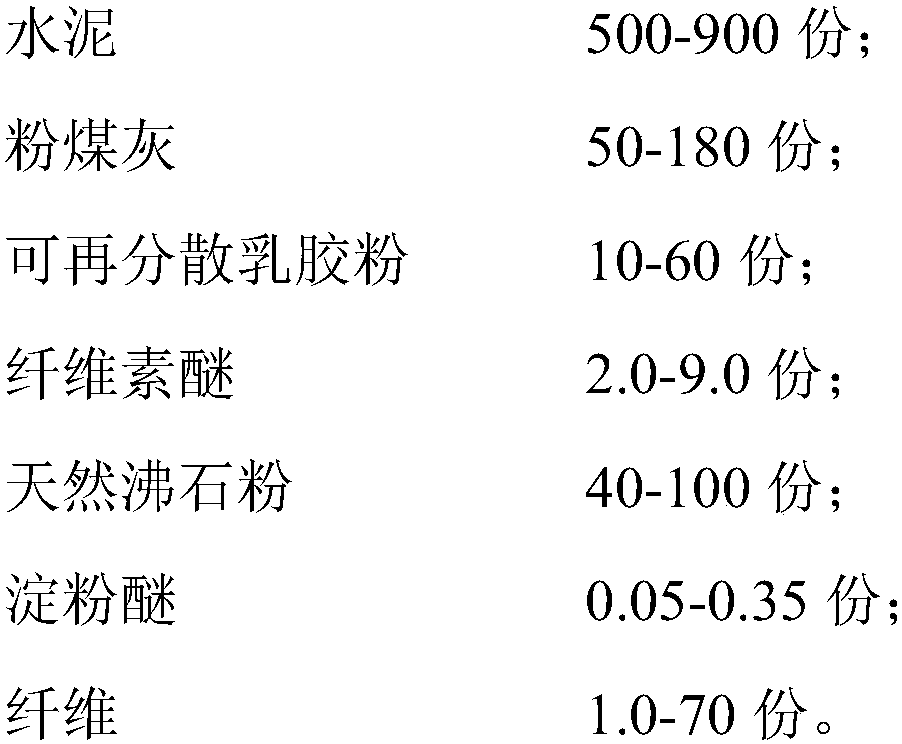

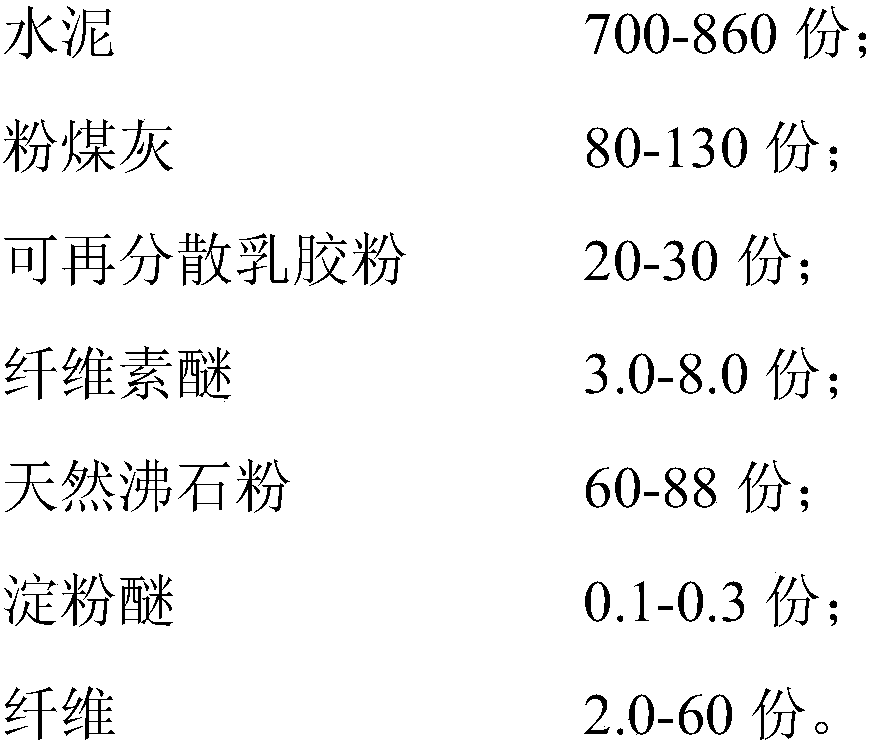

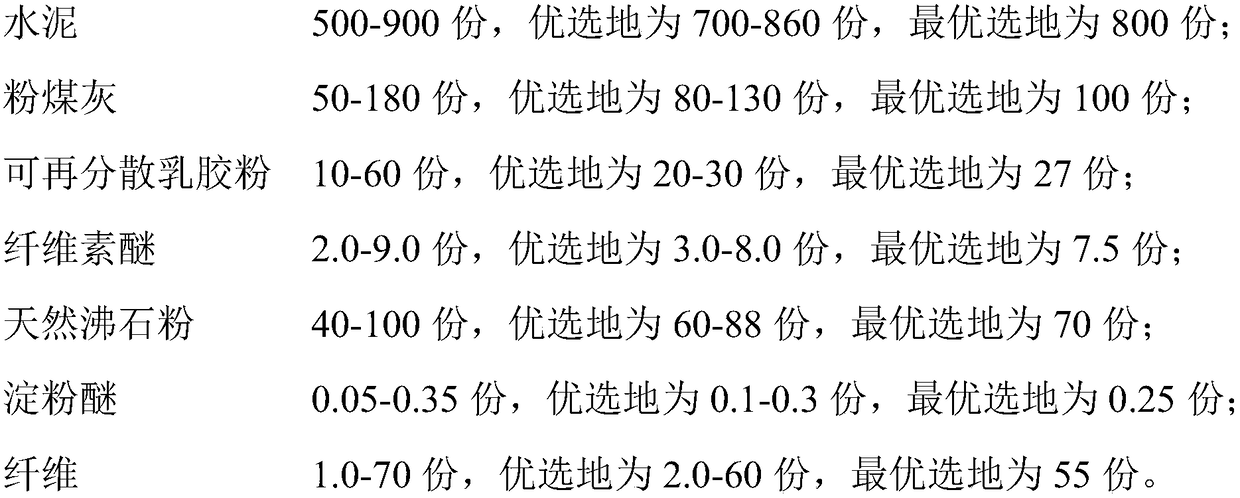

Inorganic lightweight aggregate thermal mortar for steel structure

The invention relates to inorganic lightweight aggregate thermal mortar for a steel structure. The inorganic lightweight aggregate thermal mortar for the steel structure is composed of powder and lightweight aggregate, wherein the power is prepared from the components, in parts by mass: 500-900 parts of cement, 50-180 parts of coal ash, 10-60 parts of redispersible latex powder, 2.0-9.0 parts of cellulose ether, 40-100 parts of natural zeolite powder, 0.05-0.35 part of starch ether and 1.0-70 parts of fiber. The cement, coal ash and redispersible latex powder jointly form a compound binding material system; the cement provides the initial bonding strength through preliminary rapid hydration; the coal ash replaces part of the cement to serve as a binding material to achieve the function ofimproving the anti-permeability of mortar while improving the peaceability of mortar; redispersible latex powder is in contact with water to be emulsified to be a film, and film and a hydrated productof cement form an inter-penetrating polymer network structure, so that mortar has the better bonding performance and the certain anti-deforming performance; cellulose ether and starch ether enhance the consistence of mortar, improves the construction performance and water retention capacity of mortar; and natural zeolite powder is used for improving the peaceability of a mortar mixture and improving the fireproof performance of thermal mortar.

Owner:HANGXIAO STEEL STRUCTURE

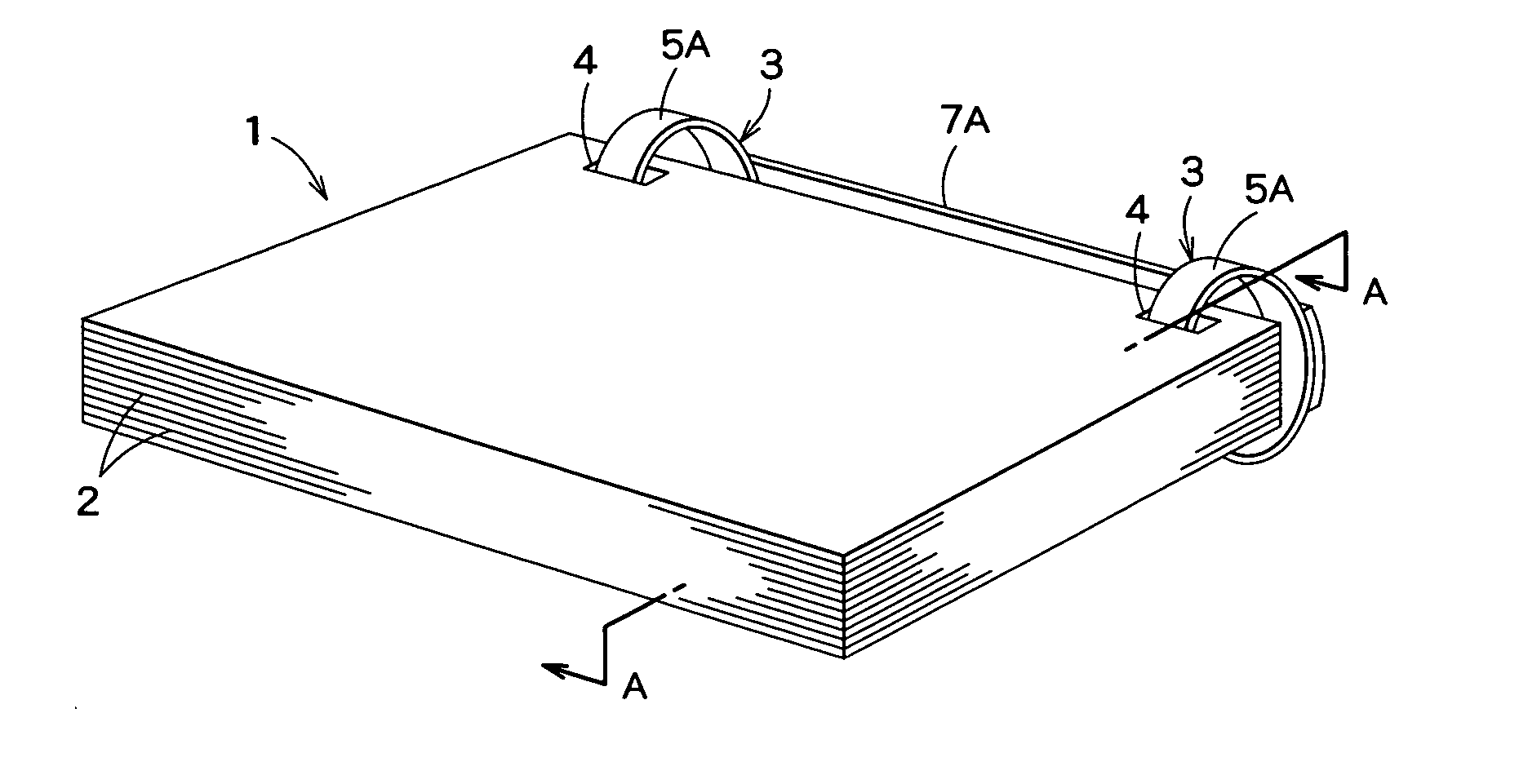

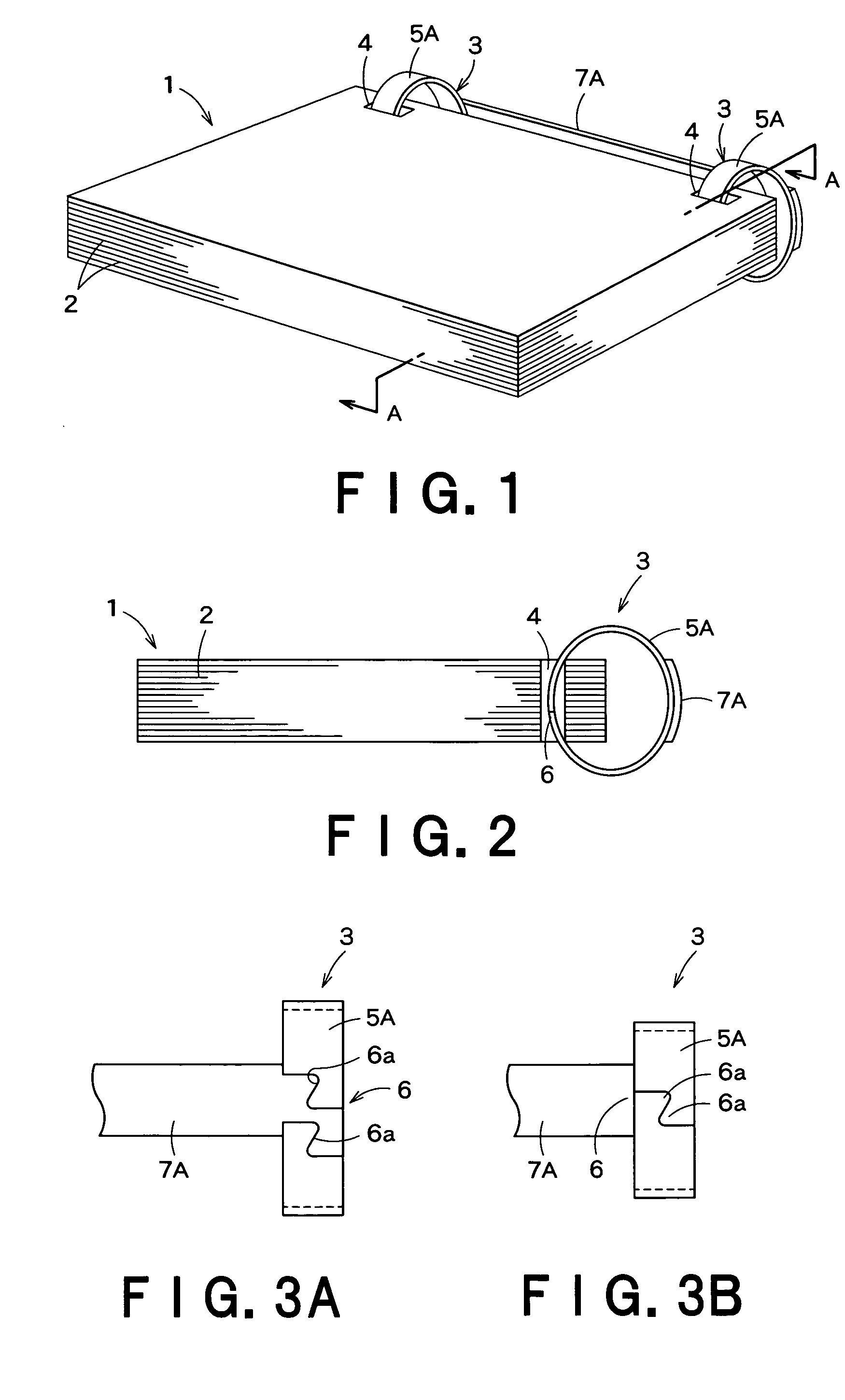

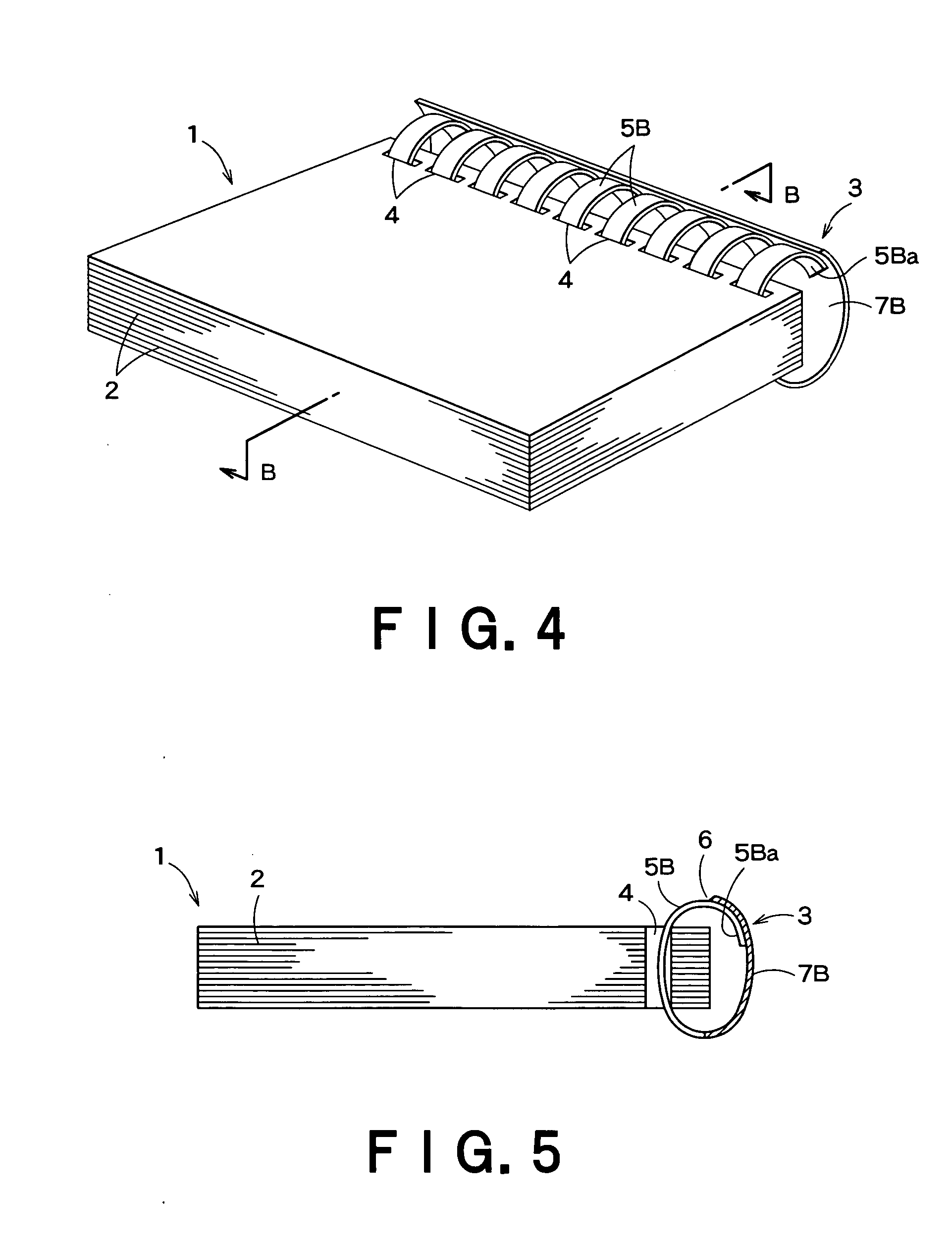

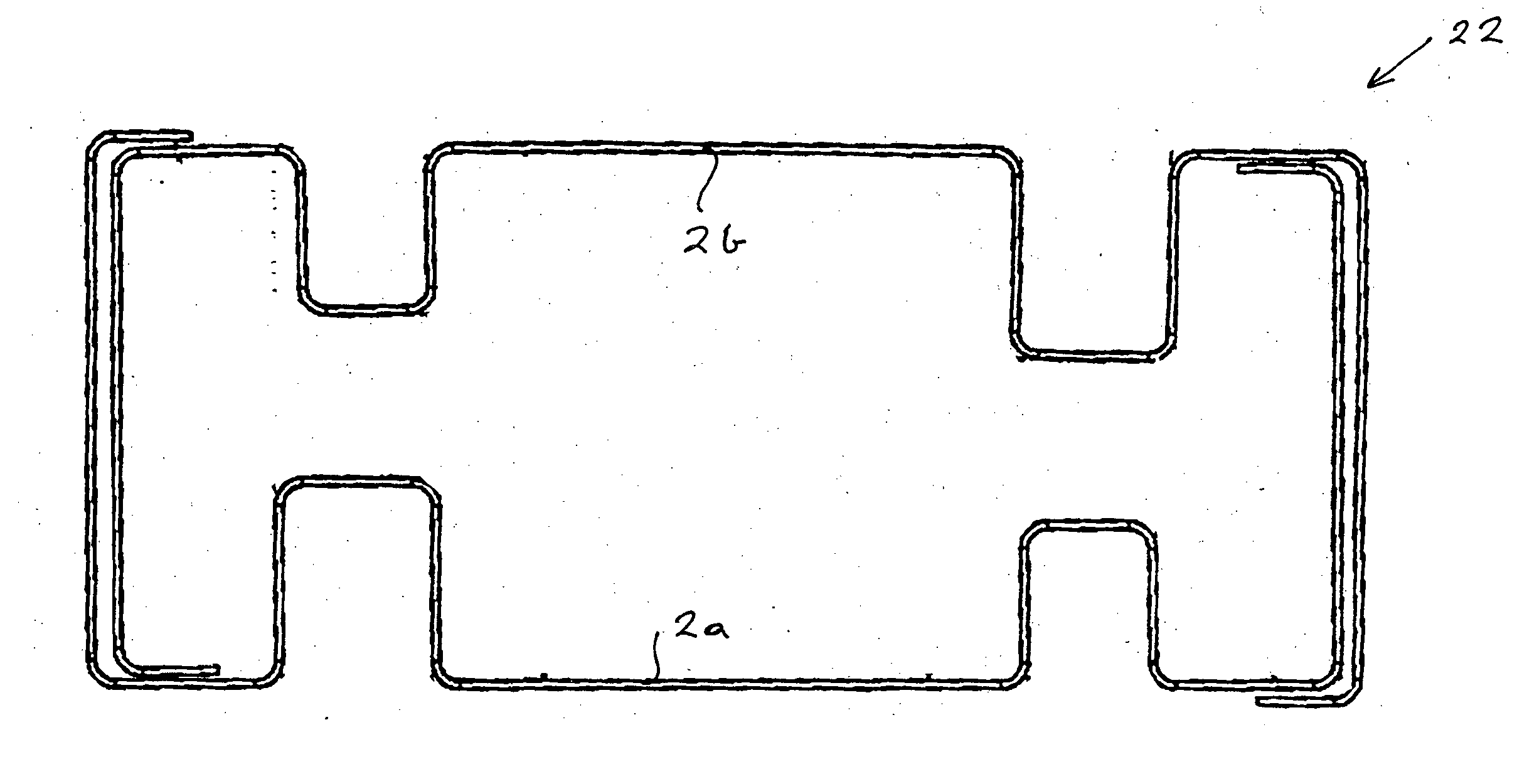

Waterproof book

InactiveUS20050230955A1Luxurious appearanceEasy to carryToysFiling appliancesEngineeringMaterial Perforation

A waterproof book can be read during bathing without trouble, is capable of maintaining its original shape, has leaves capable of maintaining the original shape and can be held by one hand for reading. The waterproof book includes: a necessary number of printed waterproof sheets forming leaves and each provided with a plurality of binding perforations on one edge thereof; and a binding member engaged in the binding perforations to bind the superposed waterproof sheets. The binding member has at least two binding loops capable of being closed after being loosely engaged in the two binding perforations of the superposed waterproof sheets, and a connecting part connecting the binding loops.

Owner:FRONTIER 2000

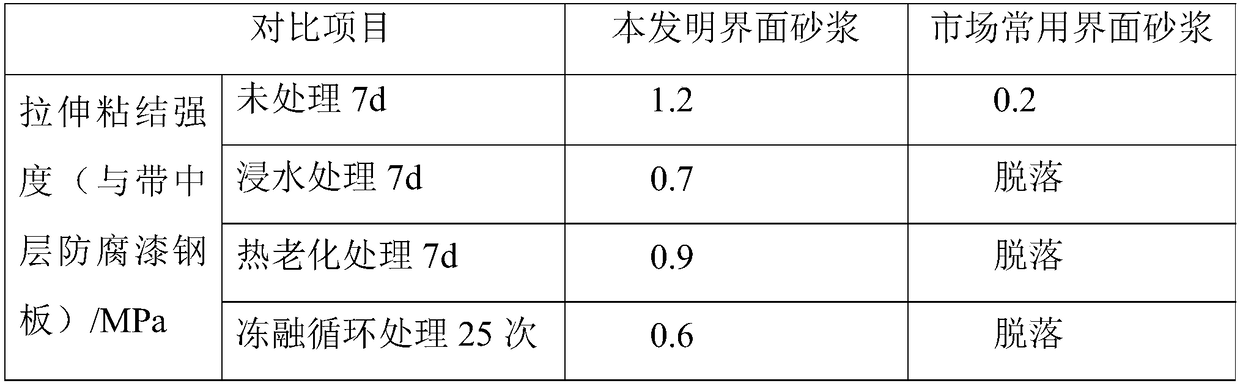

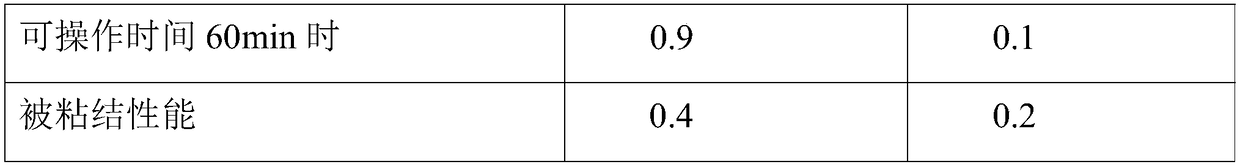

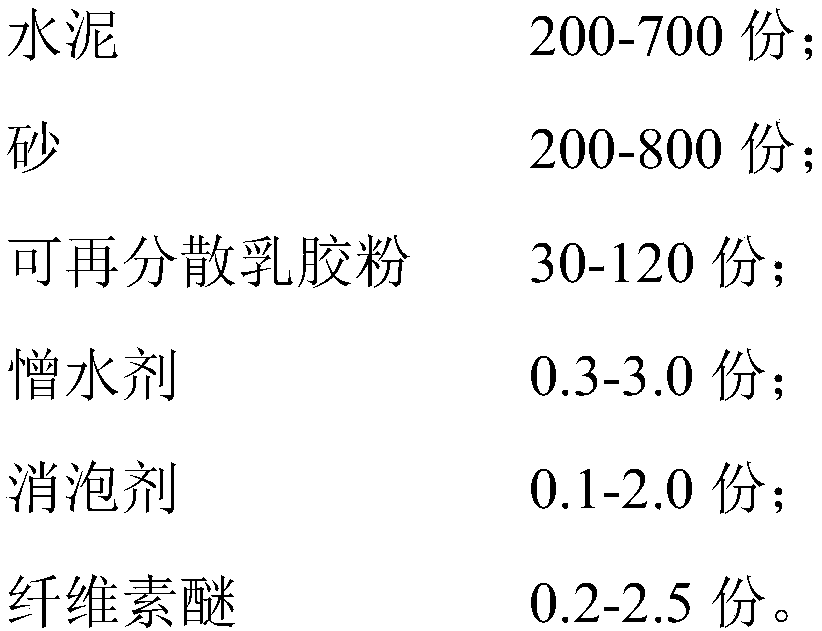

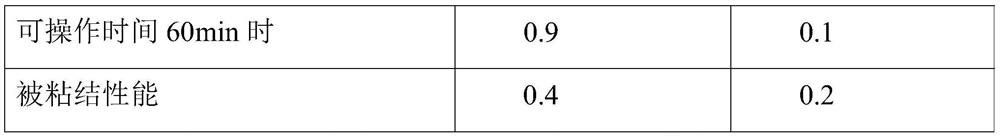

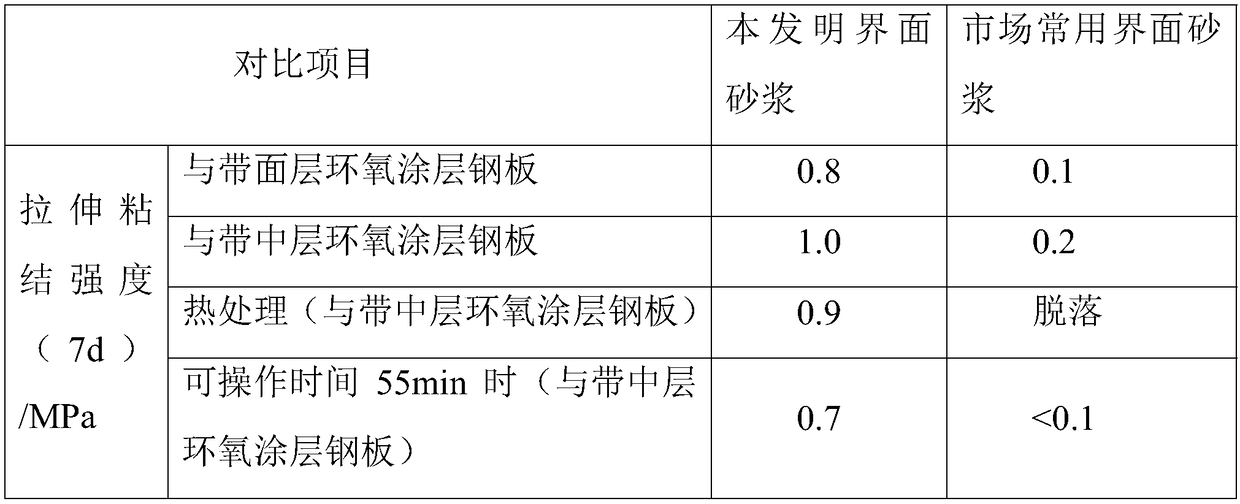

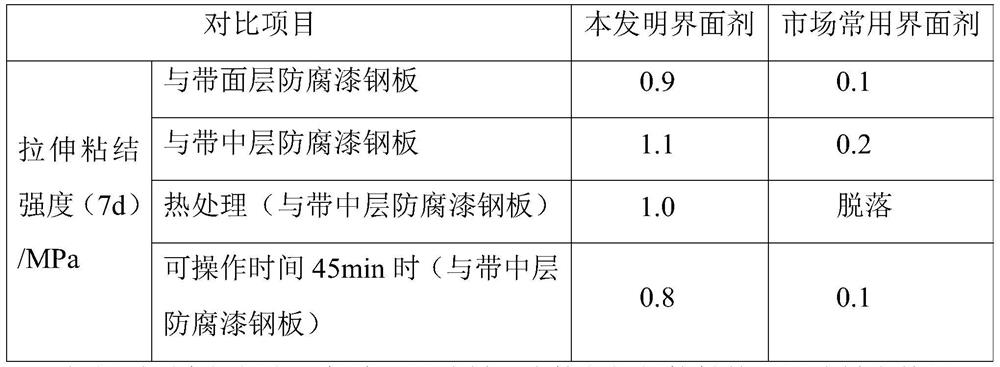

Interface mortar for steel structural exterior wall with anticorrosive coating layer

ActiveCN109020370AGood tensile bond strengthHigh tensile bond strengthCovering/liningsFreeze thawingCellulose

The invention relates to an interface mortar for a steel structure outer wall with an anticorrosive coating layer. The interface mortar comprises, by weight, 200-700 parts of cement, 200-800 parts ofsands, 30-120 parts of redispersible latex powder, 0.3-3.0 parts of a water repellent, 0.1-2.0 parts of a defoaming agent and 0.2-2.5 parts of cellulose ether. The interface mortar can effectively ensure the adhesion with the surface of a steel structure base layer with the anticorrosive coating layer, and has good bonded performance with a thermal insulation mortar, a bonding mortar, a plasteringmortar, a waterproof mortar and other mortars. Compared with traditional interface mortars for concrete and the masonry base layer, the interface mortar in the invention has the advantages of good affinity with the surface of the steel structure with the anticorrosive coating layer, high tensile bond strength, good bonded performance, small decrease of the tensile bond strength after water immersion, freeze-thawing and heat treatment, good durability, and meeting of the requirements of the use environment of the steel structure exterior wall with the anticorrosive coating layer.

Owner:HANGXIAO STEEL STRUCTURE

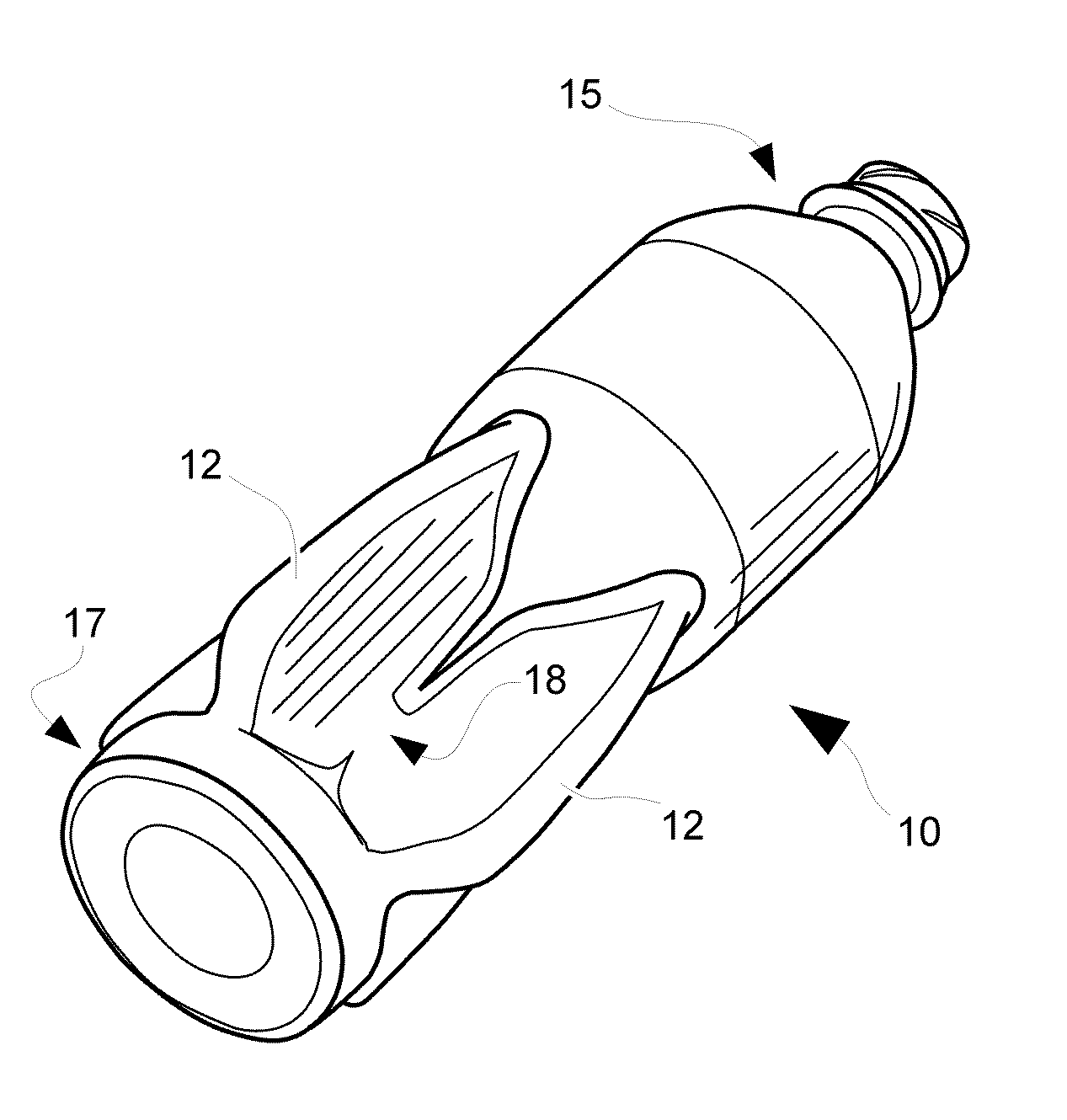

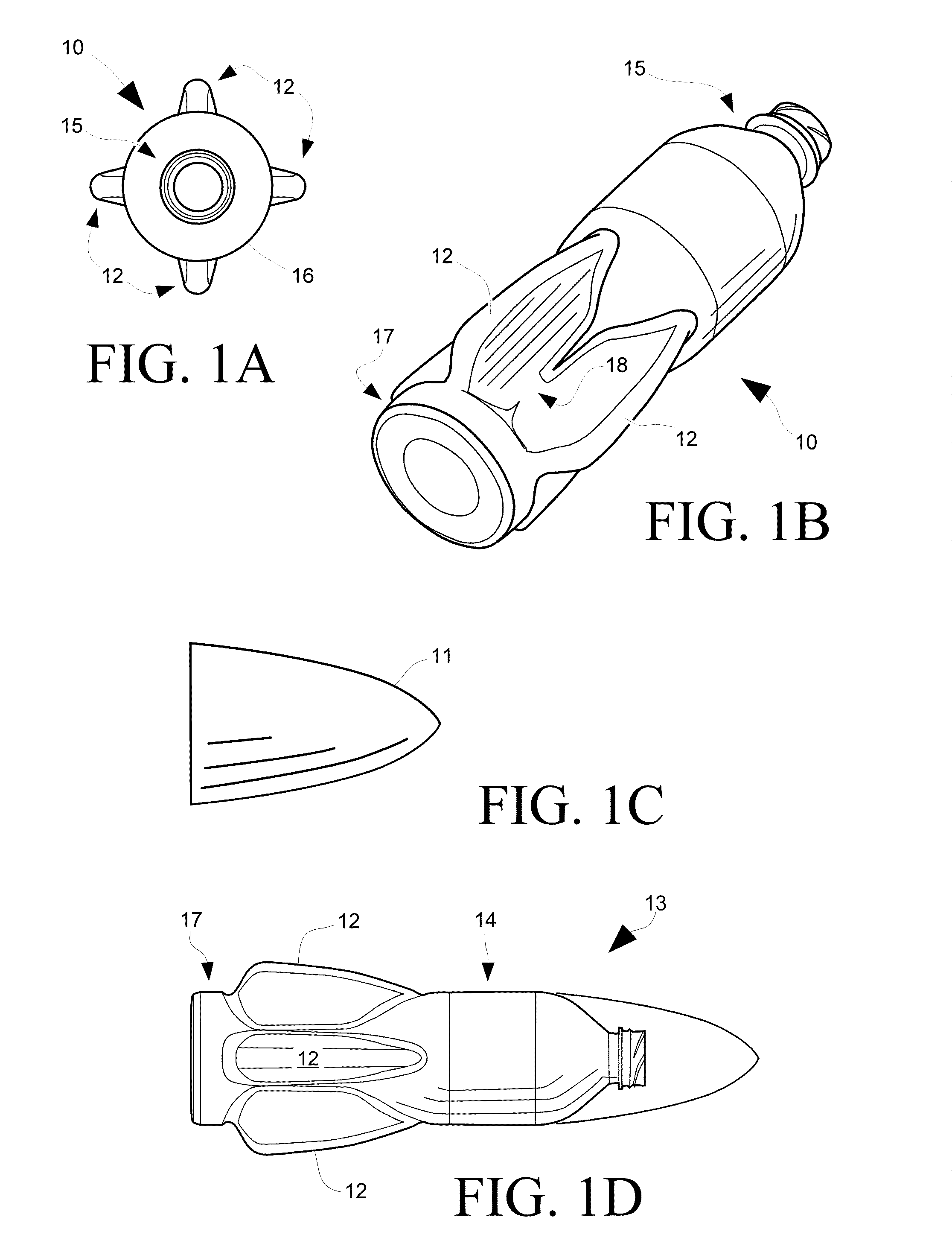

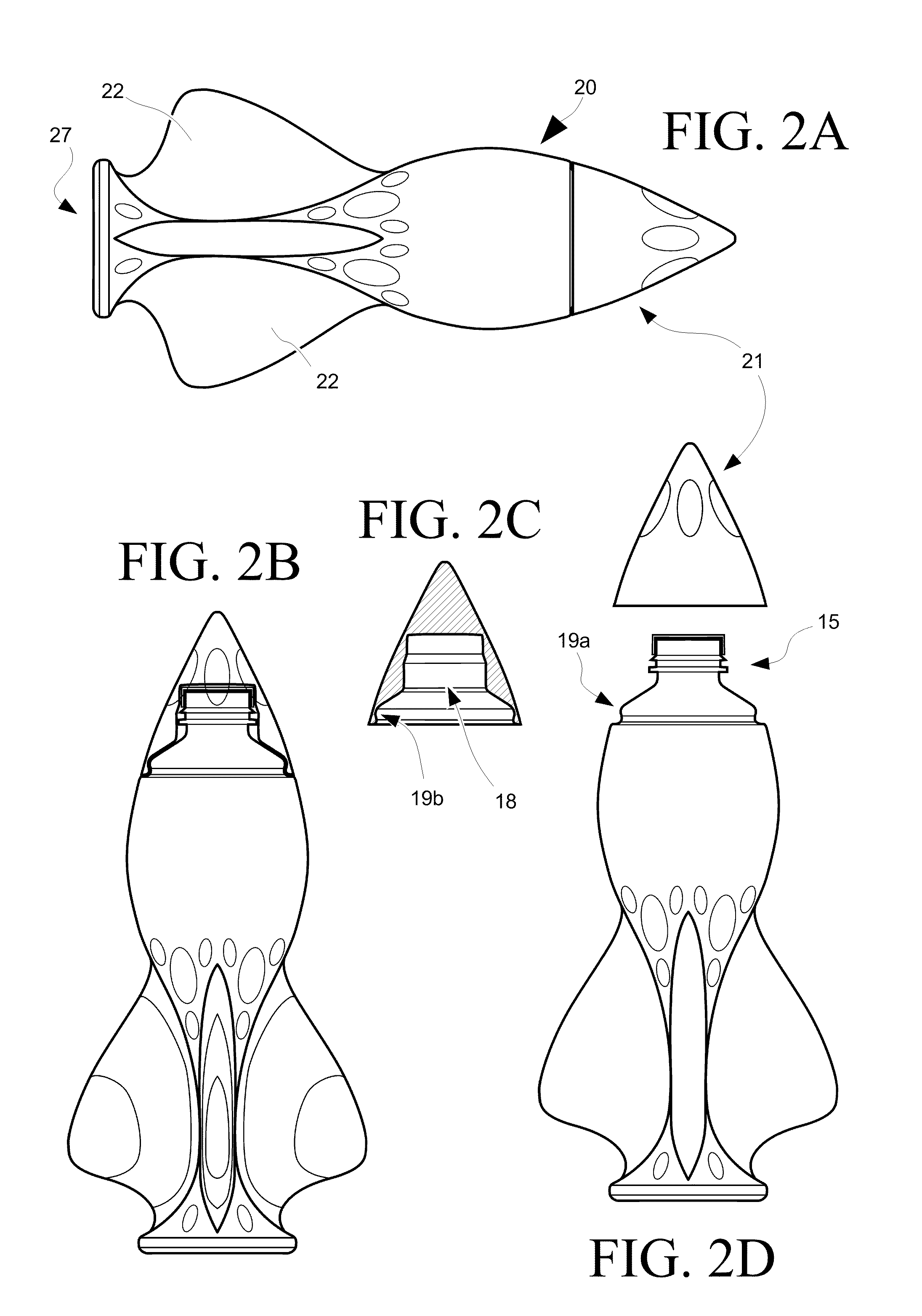

Thin-walled blow-formed tossable bottle with reinforced intra-fin cavities

Disclosed herein are aerodynamic beverage bottles that incorporate fins or protrusions that are molded in to a bottle sidewall, having concavities or valleys between those fins or protrusions that are reinforced to be stiff and otherwise resisting deformation from, for example, pressures generated within the bottle. The sidewall in the region of the fins, protrusions, valleys or concavities may be thinner than other parts of the bottle; fins may be located on one end of a bottle which is thinner than the other end. Such a bottle may have a cylindrical section to which a label may be attached. Such a bottle may be blow-molded. Detailed information on various example embodiments of the inventions are provided in the Detailed Description below, and the inventions are defined by the appended claims.

Owner:YARRO JUSTIN C +1

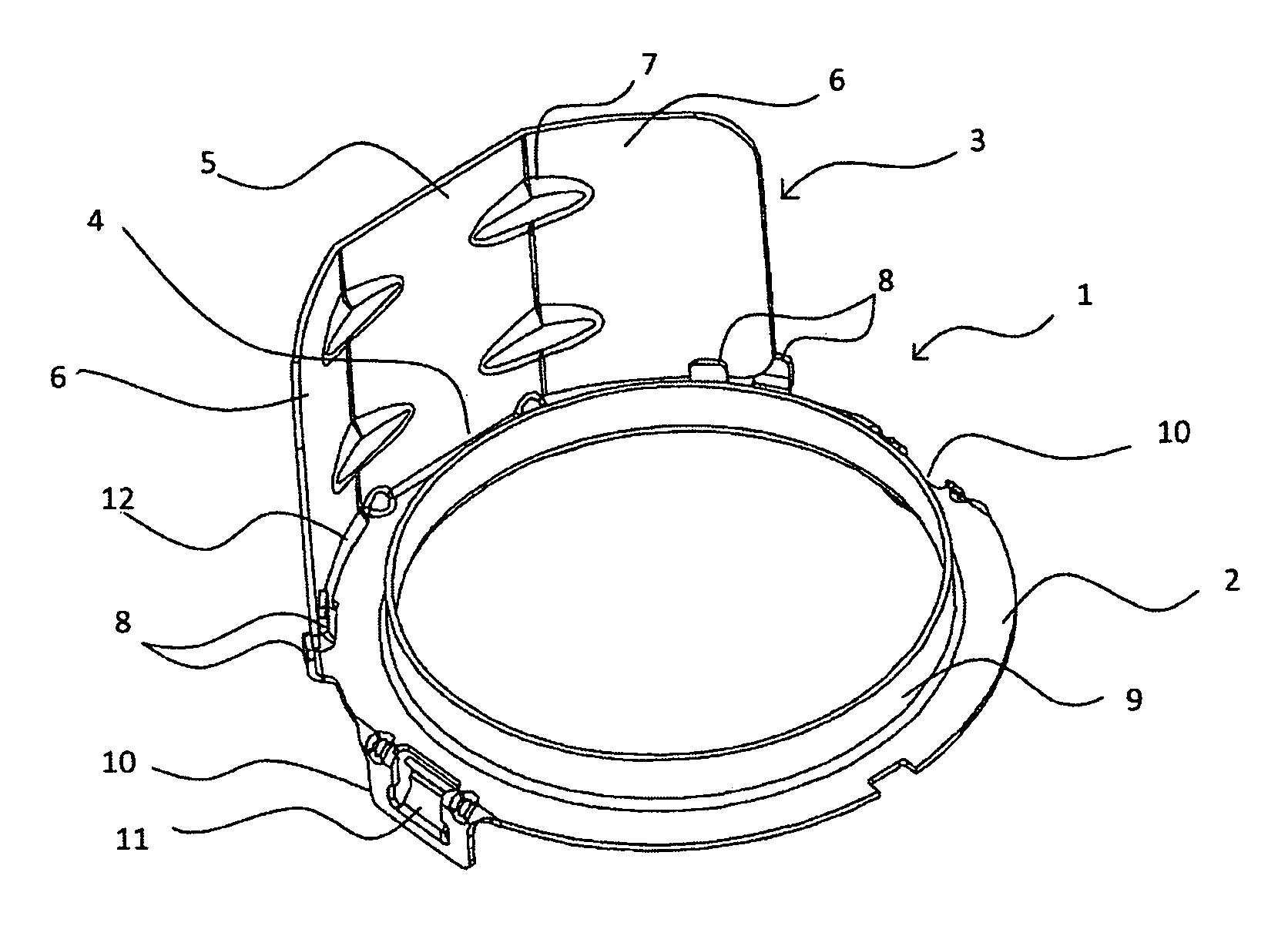

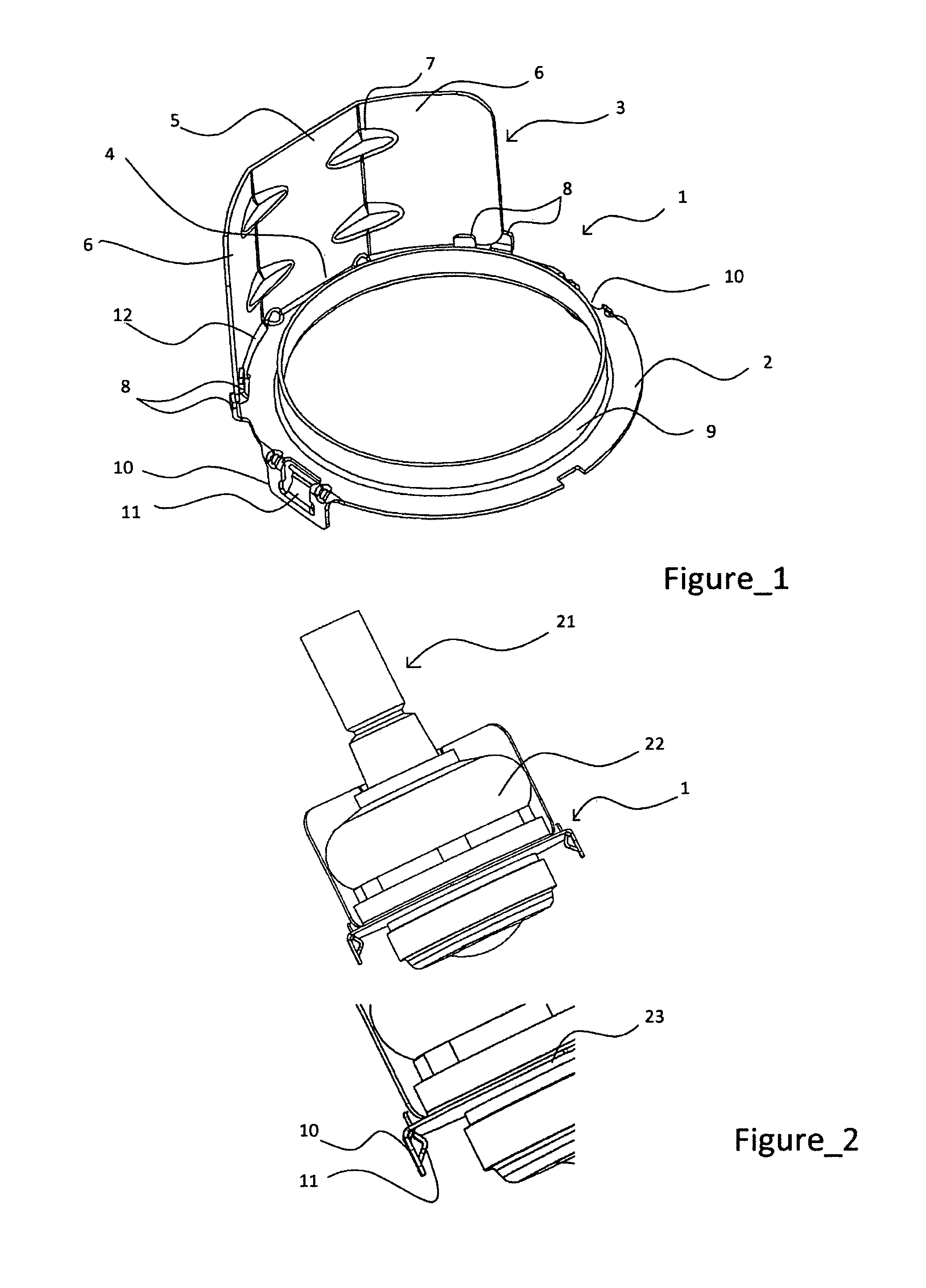

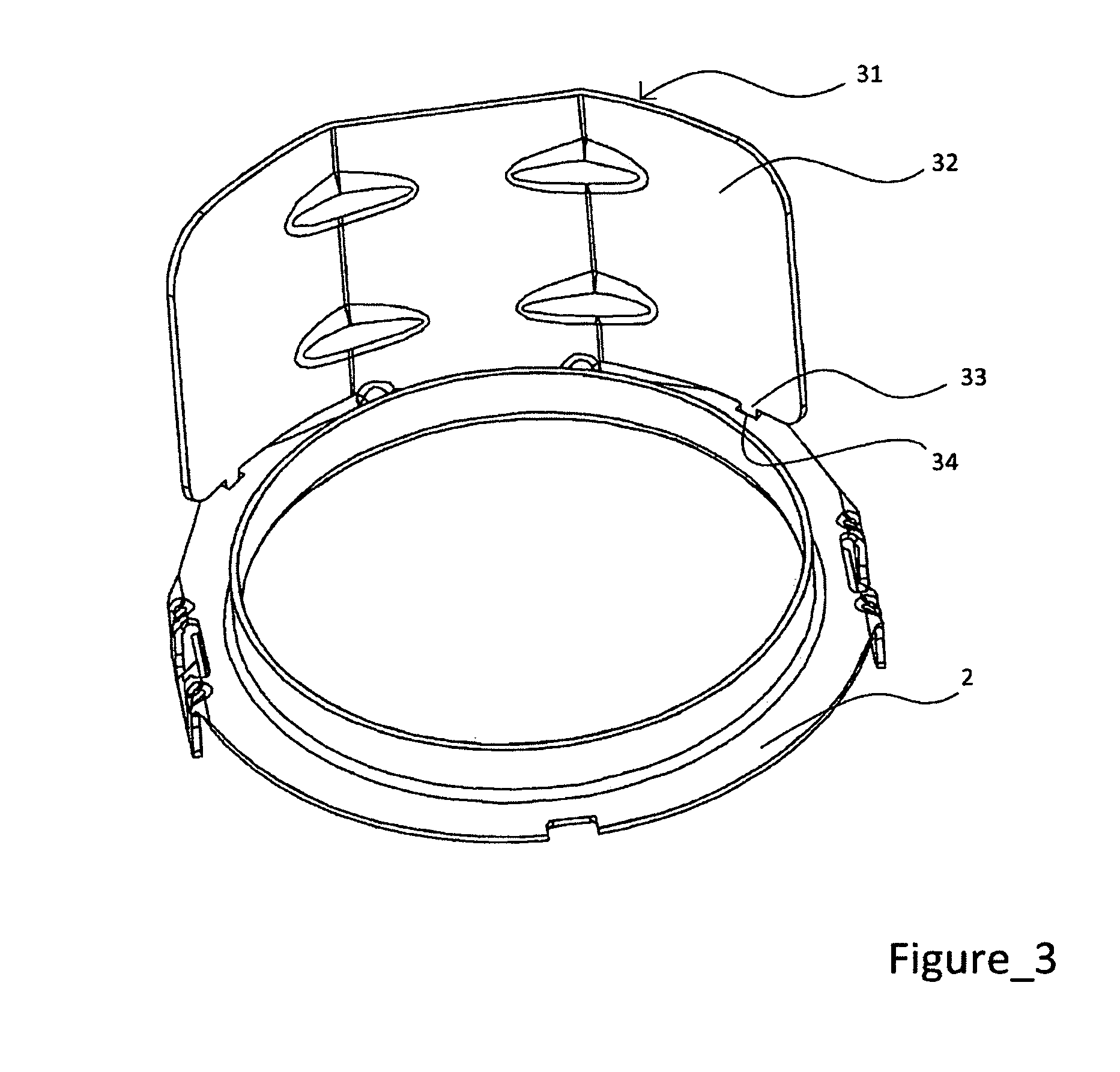

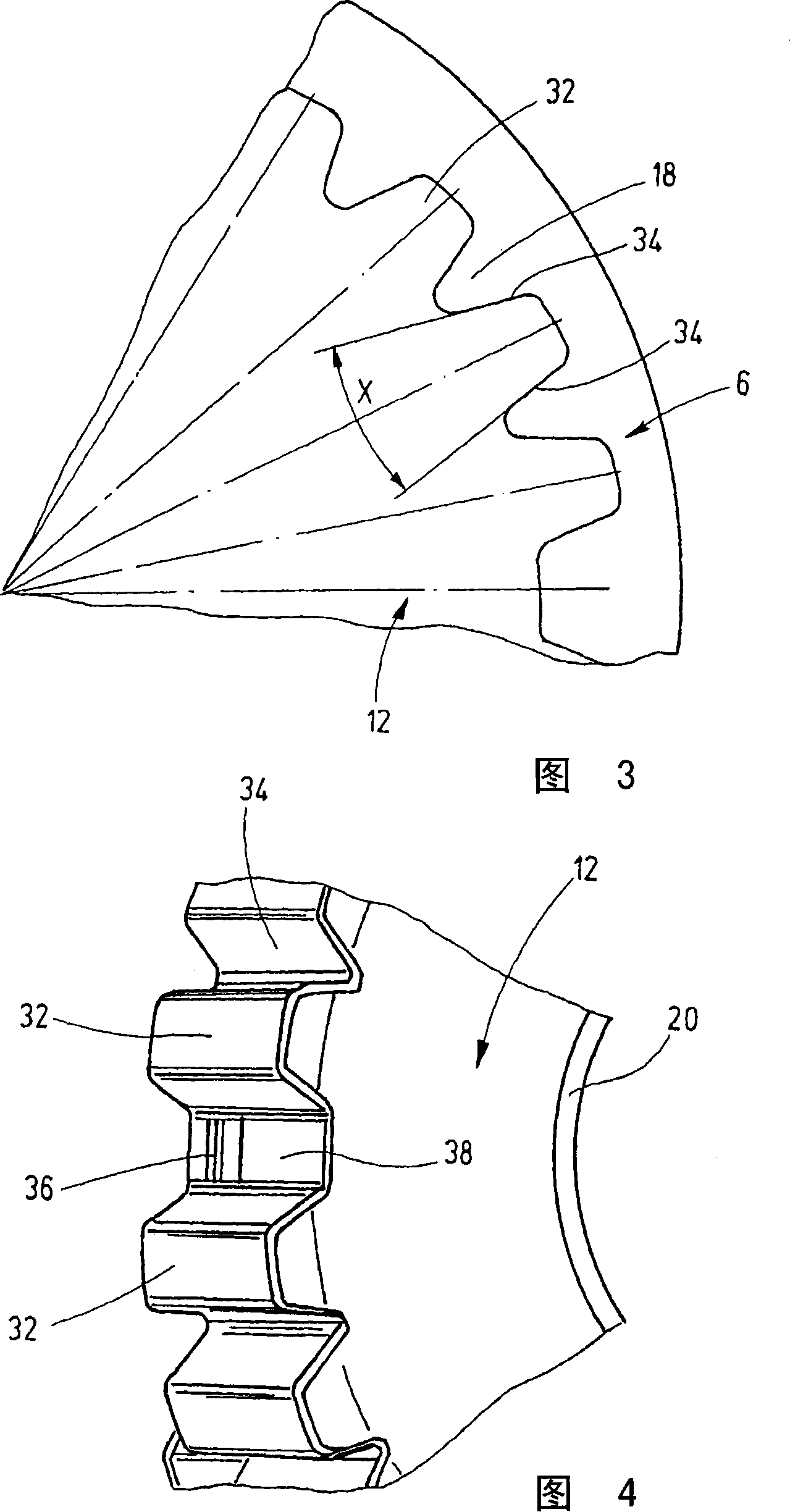

Knuckle protector for a vehicle

InactiveUS20110262211A1Easy to manufactureResistant to deformationPivotal connectionsSliding contact bearingsEngineeringMetal sheet

The invention relates to a protection device (1) for a knuckle joint (21) e.g. for the steering and / or suspension of a vehicle, which comprises an annular flange (2) for securing a thermal screen (3) to the knuckle joint, said screen extending lengthwise substantially perpendicular to the flange (2) and widthwise substantially along the, annular periphery of the flange. The screen and the flange are formed as a single part in a metal sheet that is folded in a linking area between the screen and the flange, the screen further including a surface portion in the form of a side tab (6) extending along the annular periphery of the flange, said side tab being separated from the flange by a notch (12) in the metal sheet, in the form of a slot.

Owner:A RAYMOND & CO

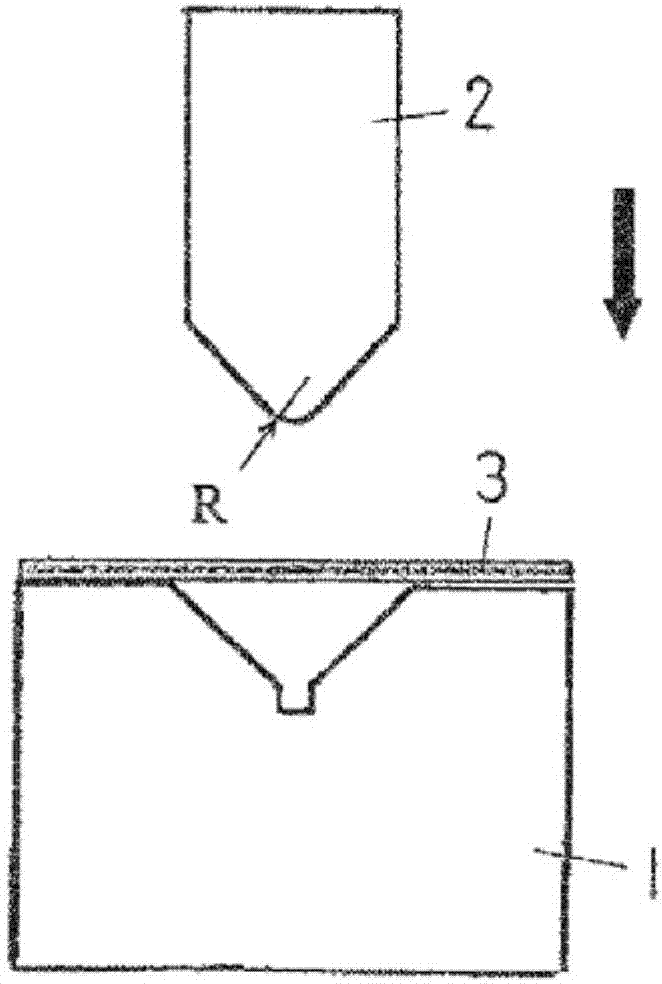

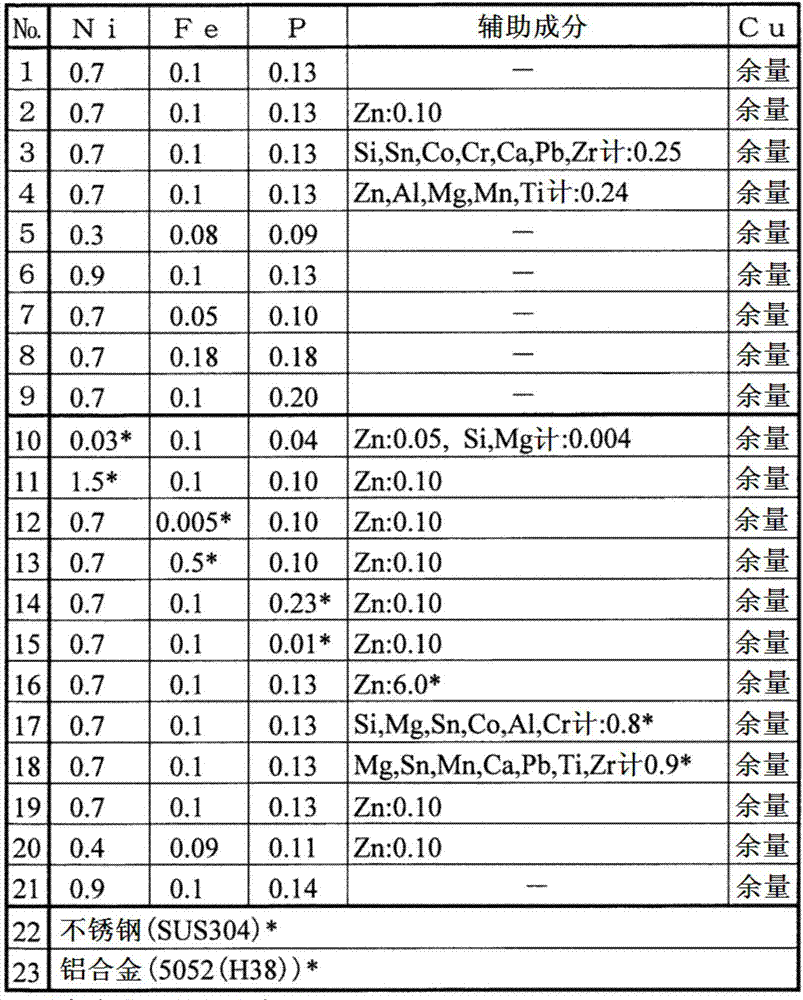

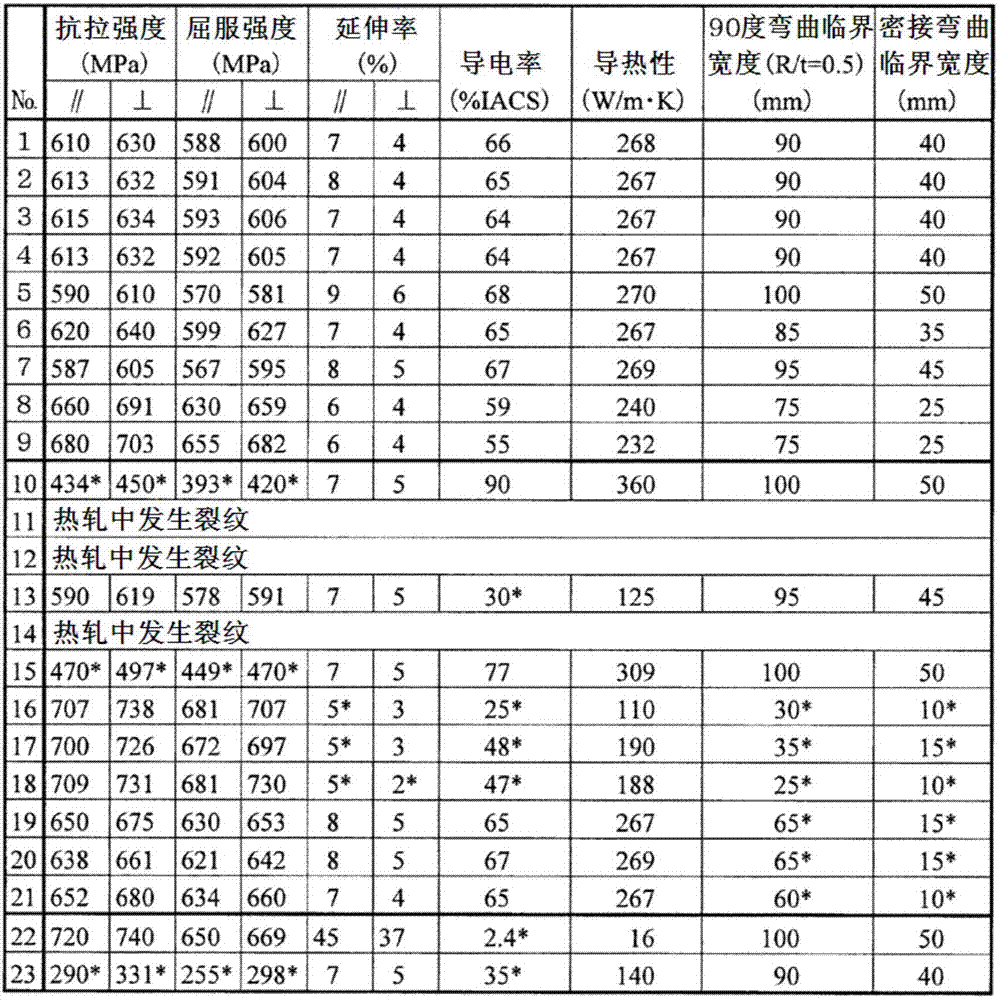

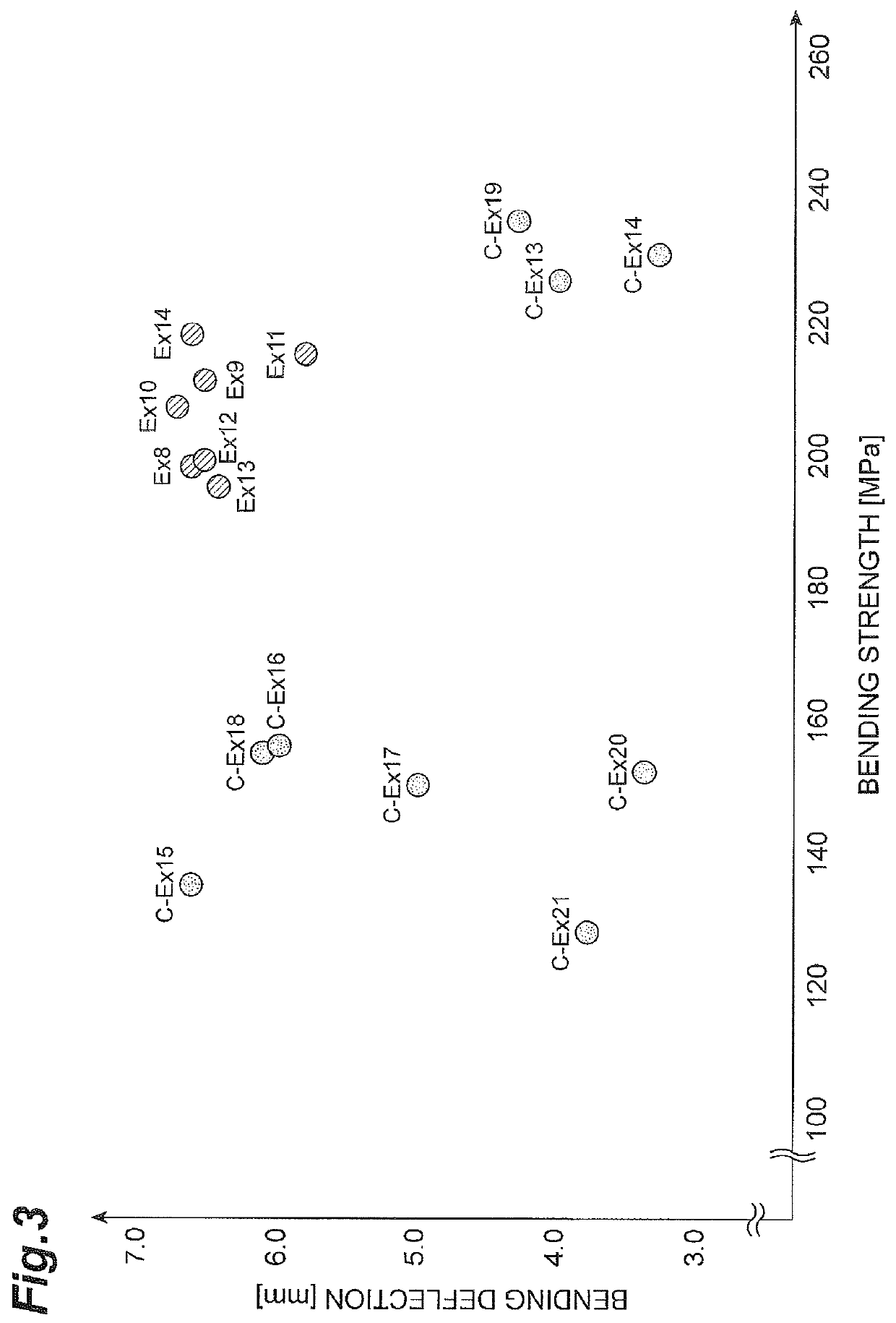

Copper alloy sheet for heat-dissipating component, and heat-dissipating component

InactiveCN107406916AImprove cooling effectAvoid performance degradationSemiconductor/solid-state device detailsSolid-state devicesMetallurgyBend radius

Provided is a copper alloy sheet for a heat-dissipating component that has high strength, excellent bending workability and heat-dissipating properties. The copper alloy sheet contains 0.1-1.0 mass % of Ni, 0.01-0.3 mass % of Fe and 0.03-0.2 mass % of P, with the remainder comprising Cu and unavoidable impurities. In a direction parallel to the rolling direction, the tensile strength is 580 MPa or higher, the proof stress is 560 MPa or higher, and the elongation is 6% or higher. In a direction perpendicular to the rolling direction, the tensile strength is 600 MPa or higher, the proof stress is 580 MPa or higher, and the elongation is 3% or higher. When the electrical conductivity is 50% IACS or higher, the ratio between the bending radius R and the sheet thickness t (R / t) is set to be 0.5, and the sheet is bent at an angle of 90-degree with the direction of the bend line being a direction perpendicular to the rolling direction, the bending limit width is 70 mm or more, and when the sheet is subjected to close-contact bending with the direction of the bend line being a direction perpendicular to the rolling direction, the bending limit width is 20 mm or more.

Owner:KOBE STEEL LTD

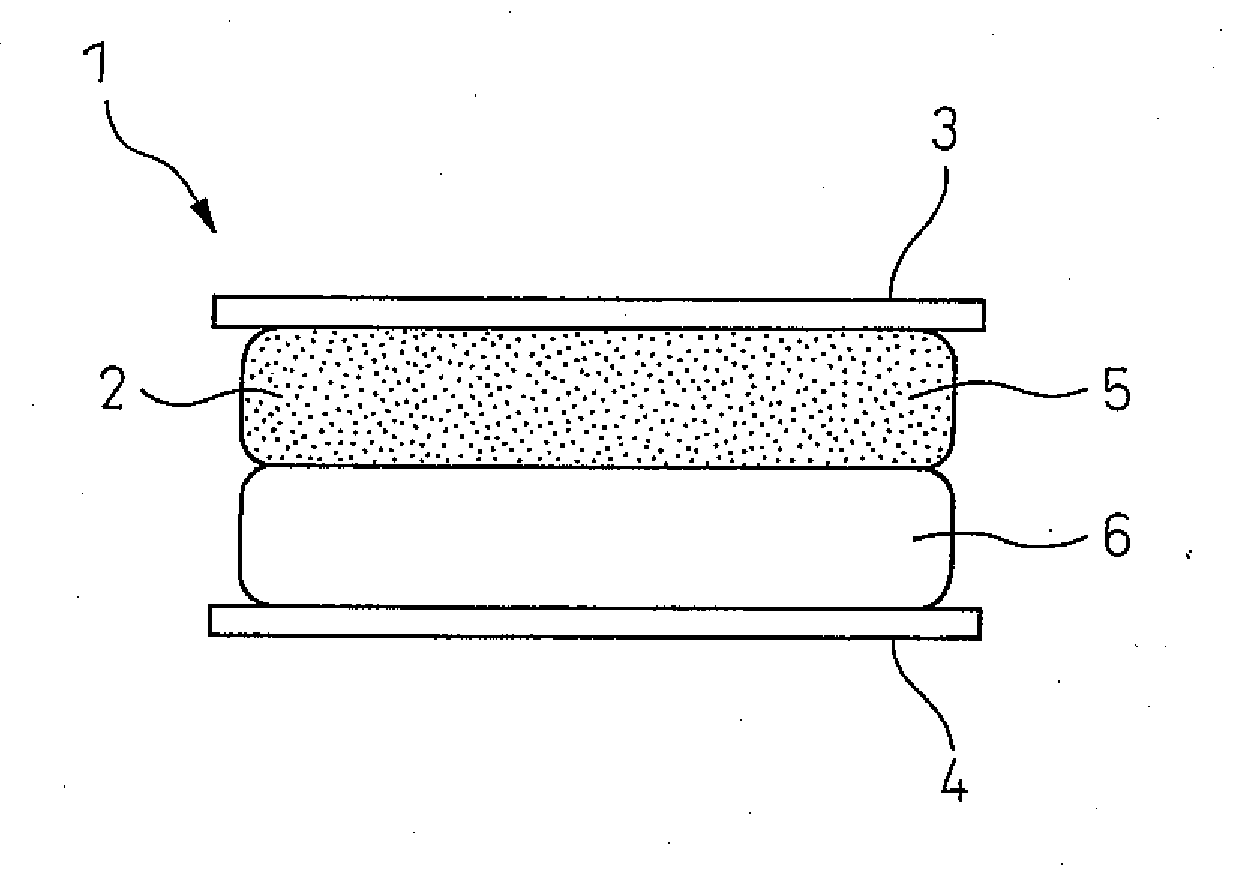

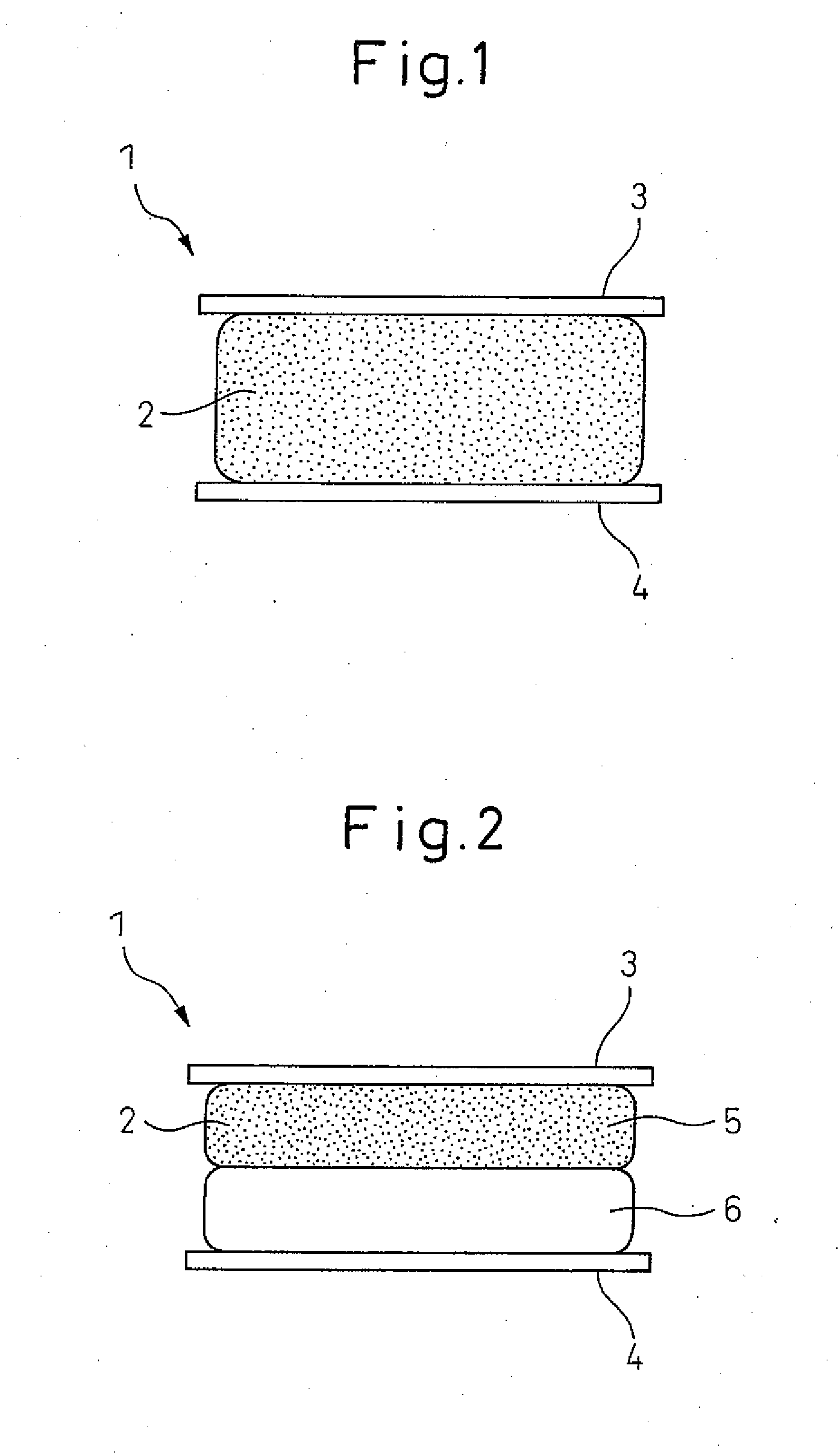

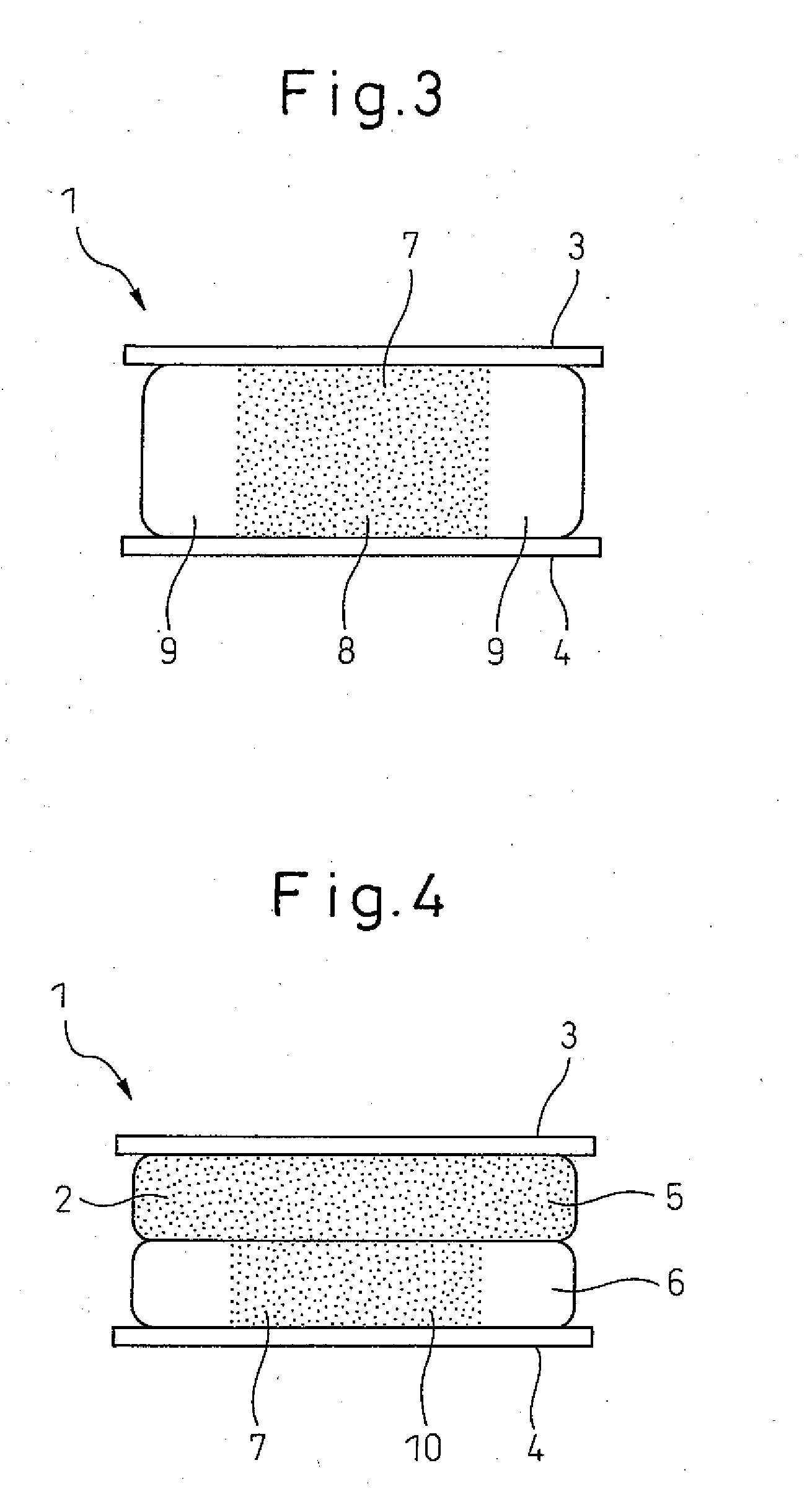

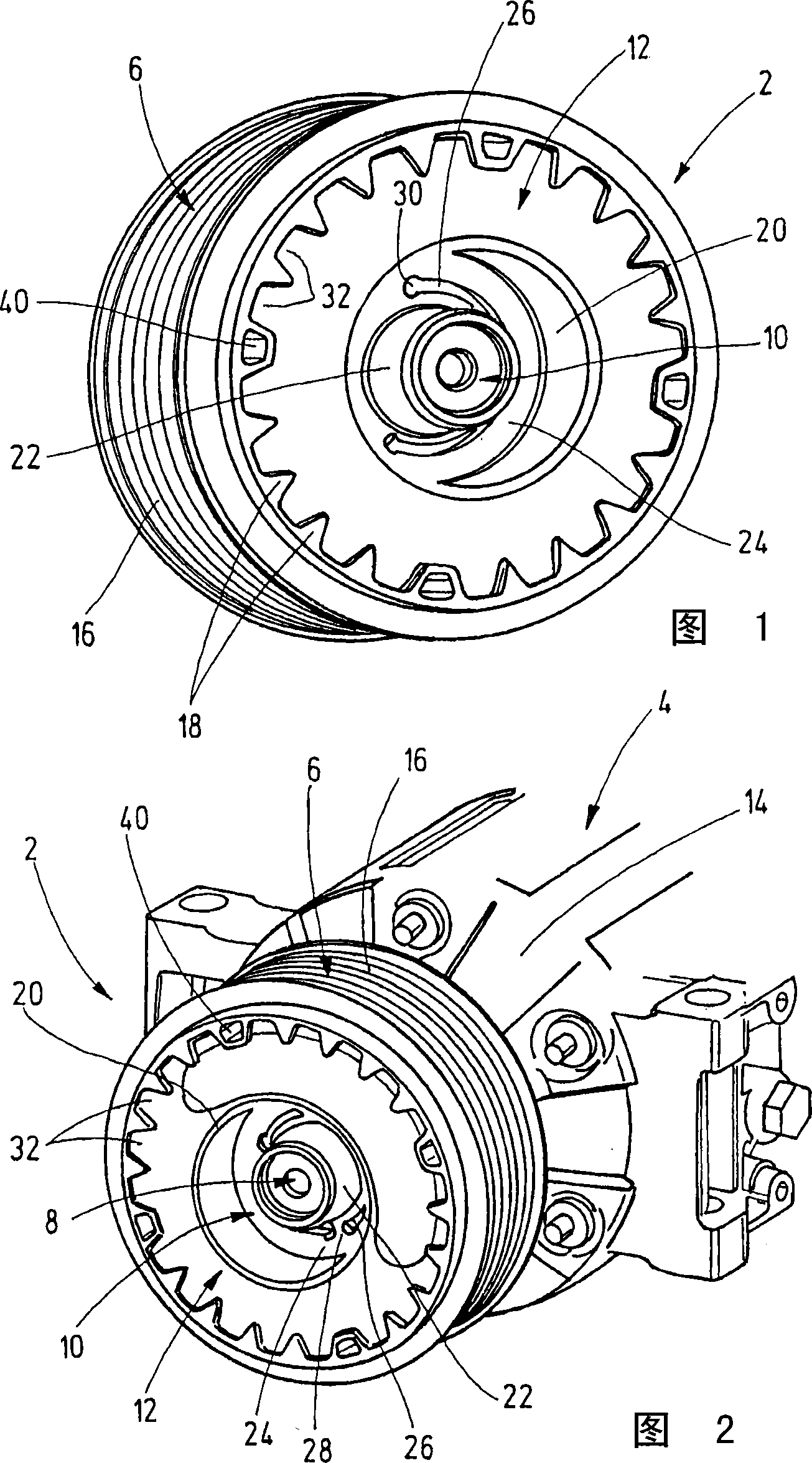

Device for transmitting torque

InactiveCN1993569AUnimpeded thermal expansionHigh strengthYielding couplingPortable liftingAutomobile air conditioningEngineering

The invention relates to a device for transmitting a torque from a belt pulley (6) to a hub (10) of a group to be driven, especially a compressor (4), for example an air-conditioning compressor of a motor vehicle. The inventive device comprises a vibration damping element (12) arranged between the belt pulley (6) and the hub (10). According to the invention, the vibration damping element (12) is connected to the hub (10) in a fixed manner on the inner periphery thereof, and is engaged with the belt pulley (6) in a positively locking manner on the outer periphery thereof.

Owner:ZEXEL VALEO COMPRESSOR EUROPE GMBH

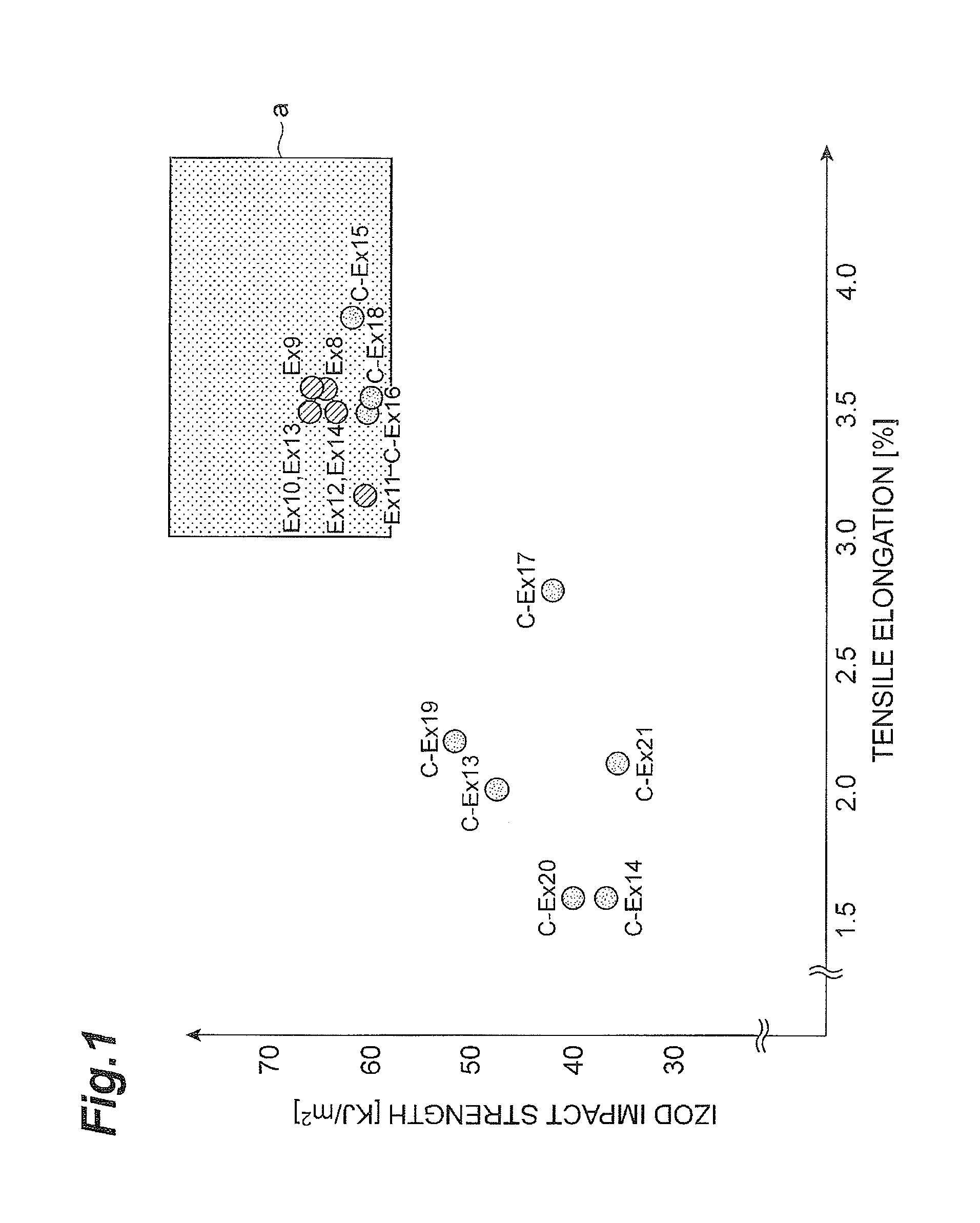

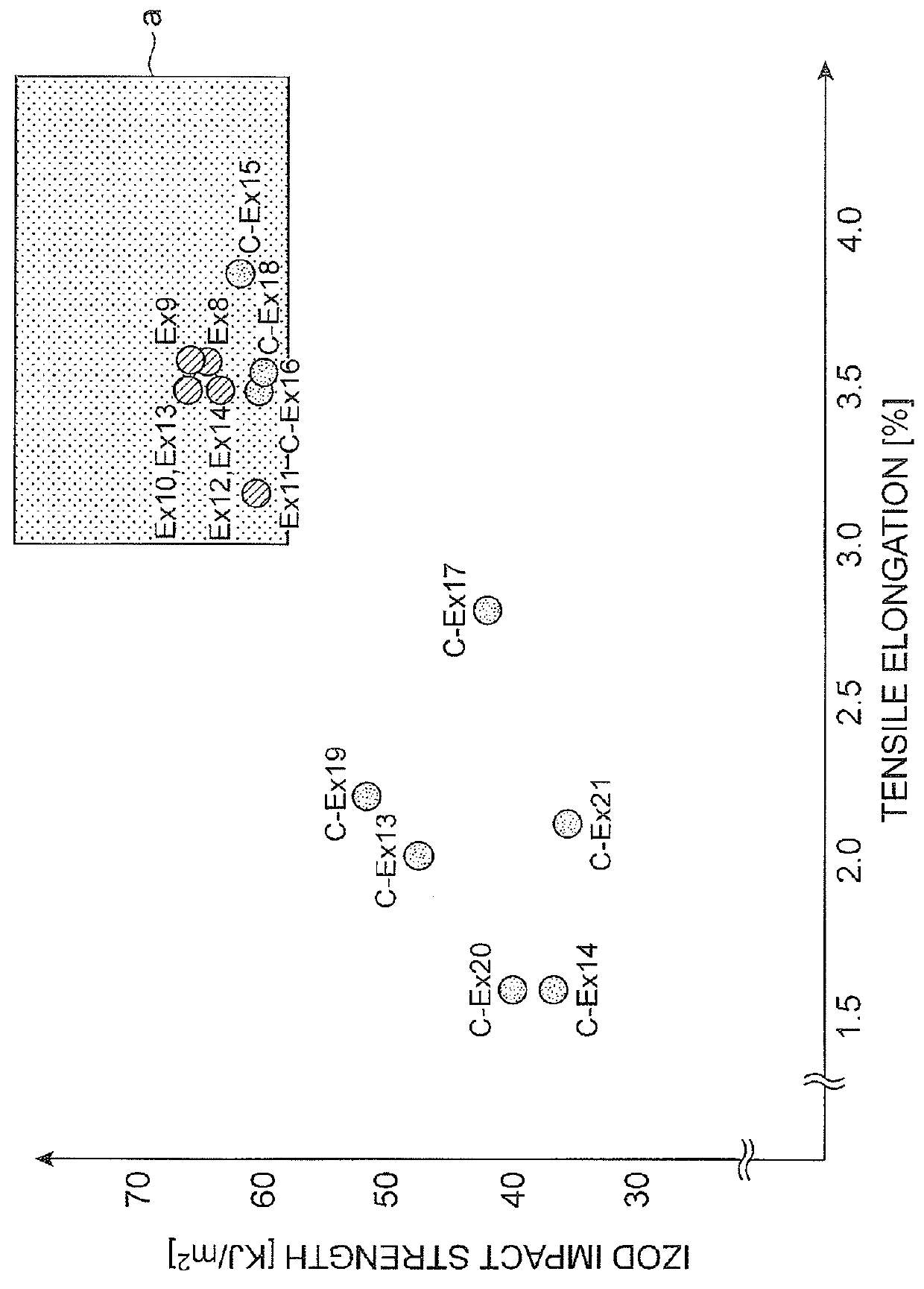

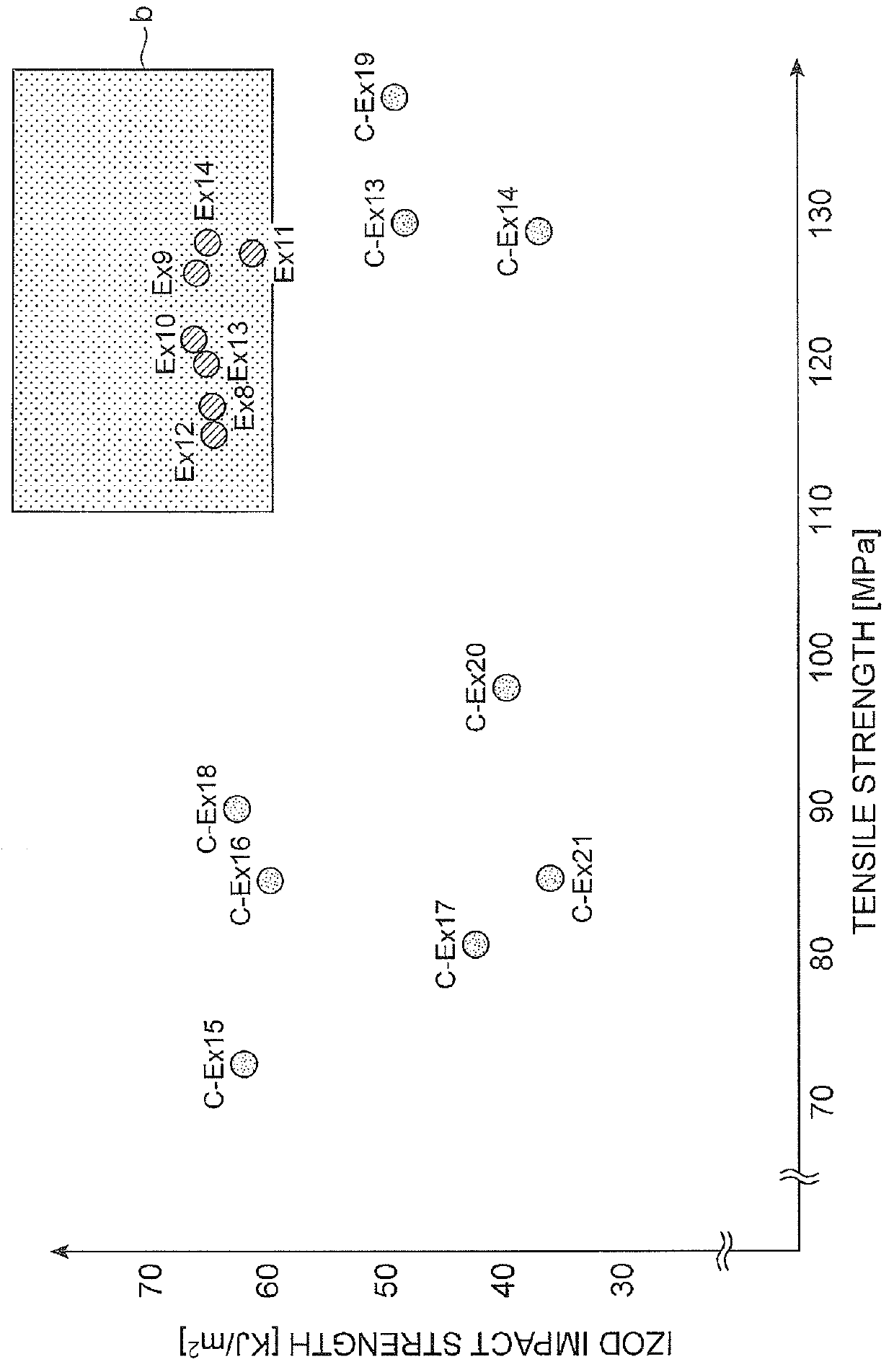

Liquid crystal polyester amide, liquid crystal polyester amide resin composition, and molded article

ActiveUS20150010744A1Improve liquidityOvercome lack of heat resistanceSynthetic resin layered productsPolyesterStructural unit

A liquid crystal polyester amide of the present invention includes 10 mol % to 65 mol % of a structural unit represented by the following formula (1), 3 mol % to 17.5 mol % of a structural unit represented by the following formula (2), 5 mol % to 20 mol % of a structural unit represented by the following formula (3), 7.5 mol % to 42 mol % in total of at least one of a structural unit represented by the following formula (4-1) and a structural unit represented by the following formula (4-2), and 2.5 mol % to 40 mol % in total of at least one of a structural unit represented by the following formula (5-1) and a structural unit represented by the following formula (5-2), and has a melting point of 300° C. or higher.

Owner:JX NIPPON OIL & ENERGY CORP

Light composite base material board and its manufacturing method

InactiveCN1651682AEasy to implementHigh strengthConstruction materialCeramic shaping apparatusAdhesive glueComposite substrate

The present invention relates to a light composite base material plate and it sproduction method. It includes base material layer, and the raw material composition of said base material layer includes (by volume portion) 25-45 portions of cement, 70-80 portions of rice husk, 30-60 portions of saw dust or fibrous debris and 20-30 portions of compound adhesive which is prepared by using (by volume portion) 100 portions of building glue and 15-30 portions of polyvinyl acetate emulsion. Said invention also provides its several advantages, and said product can be used as furniture plate, decorative ceiling plate, wall-enclosure plate and building form, etc.

Owner:陈舜荣

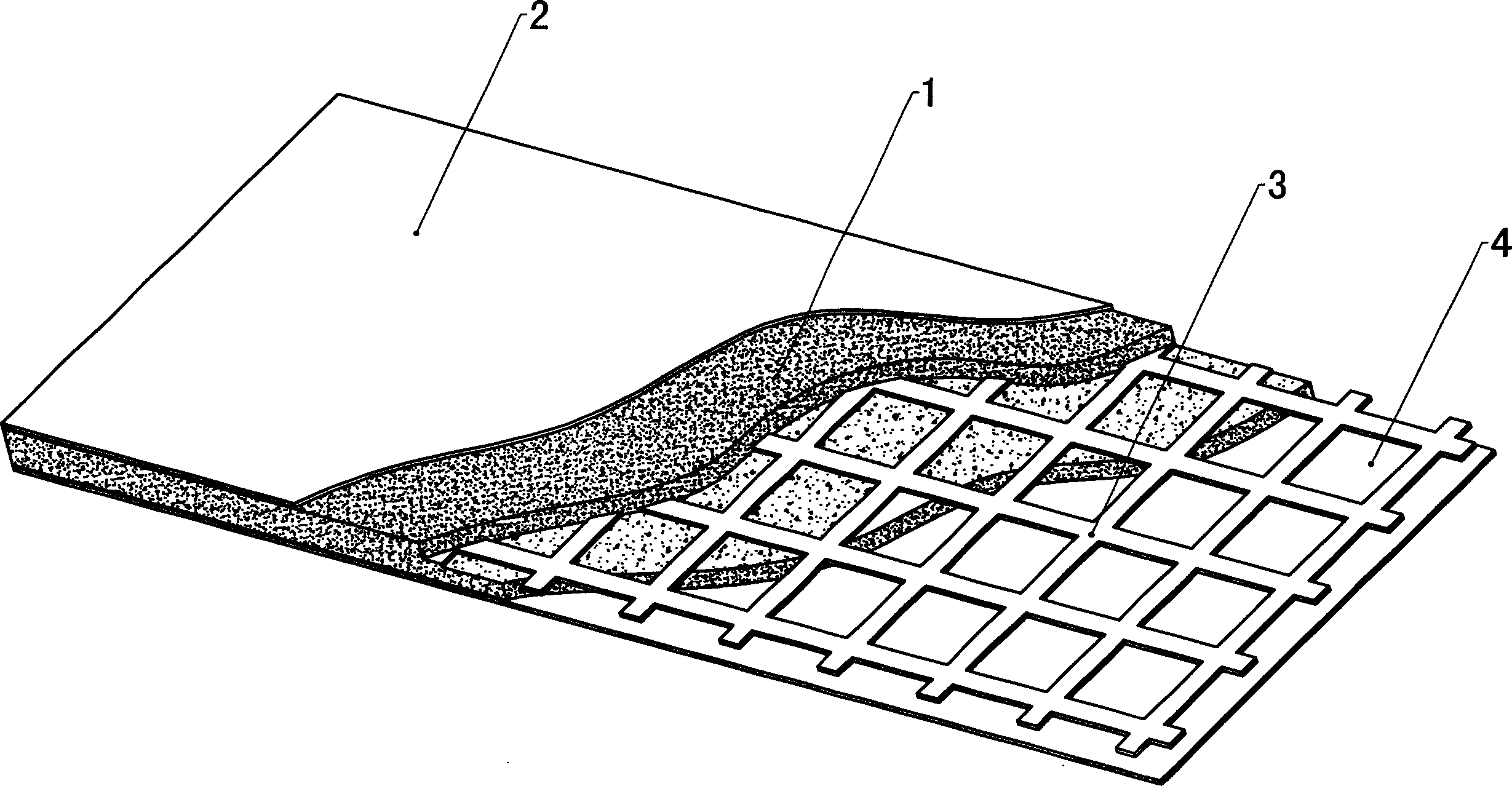

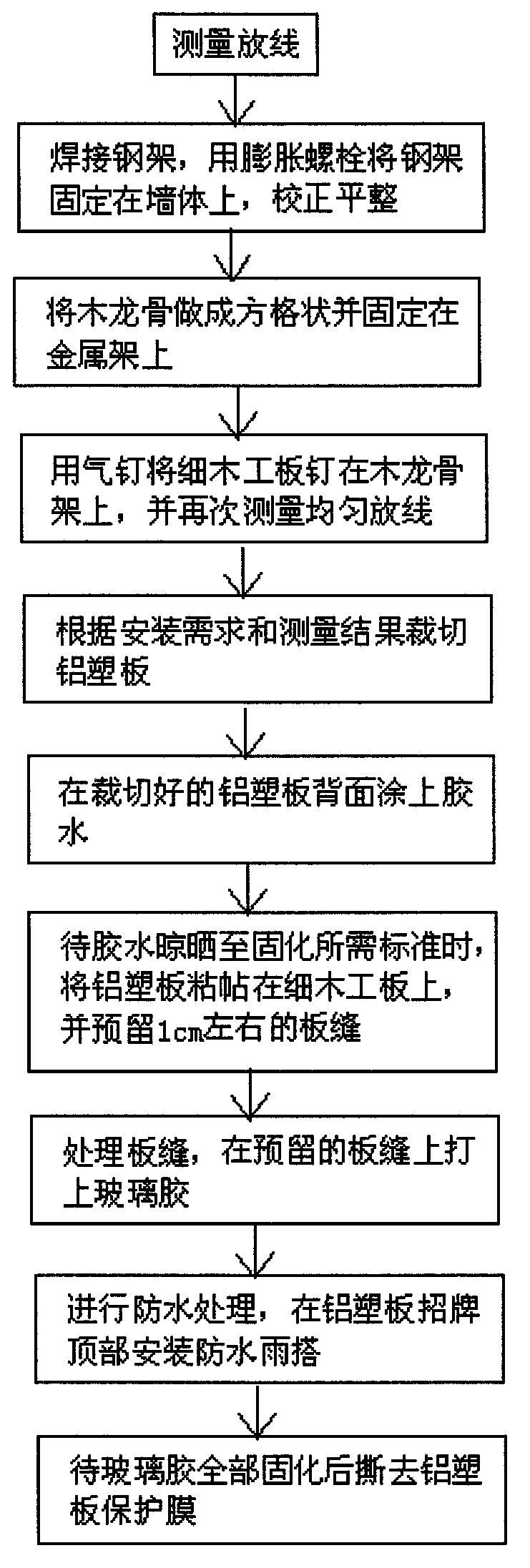

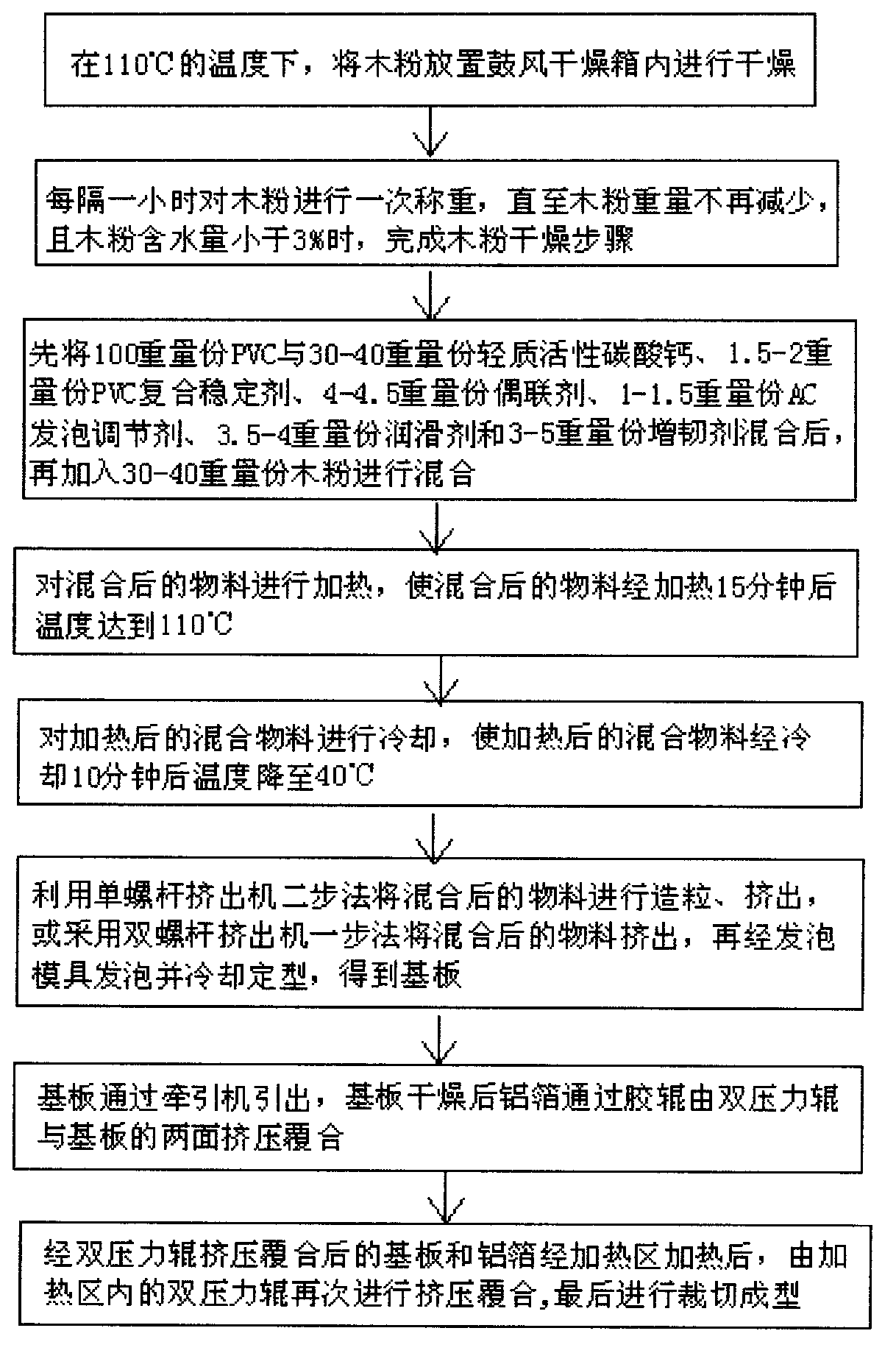

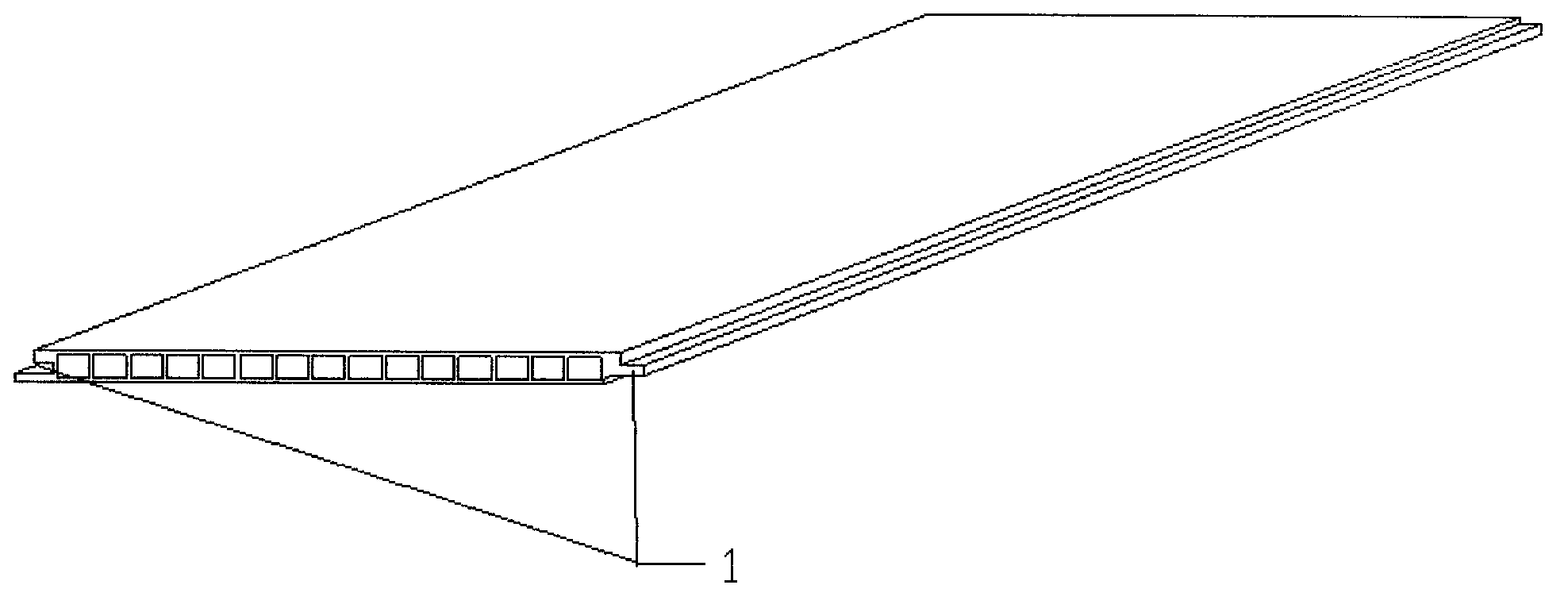

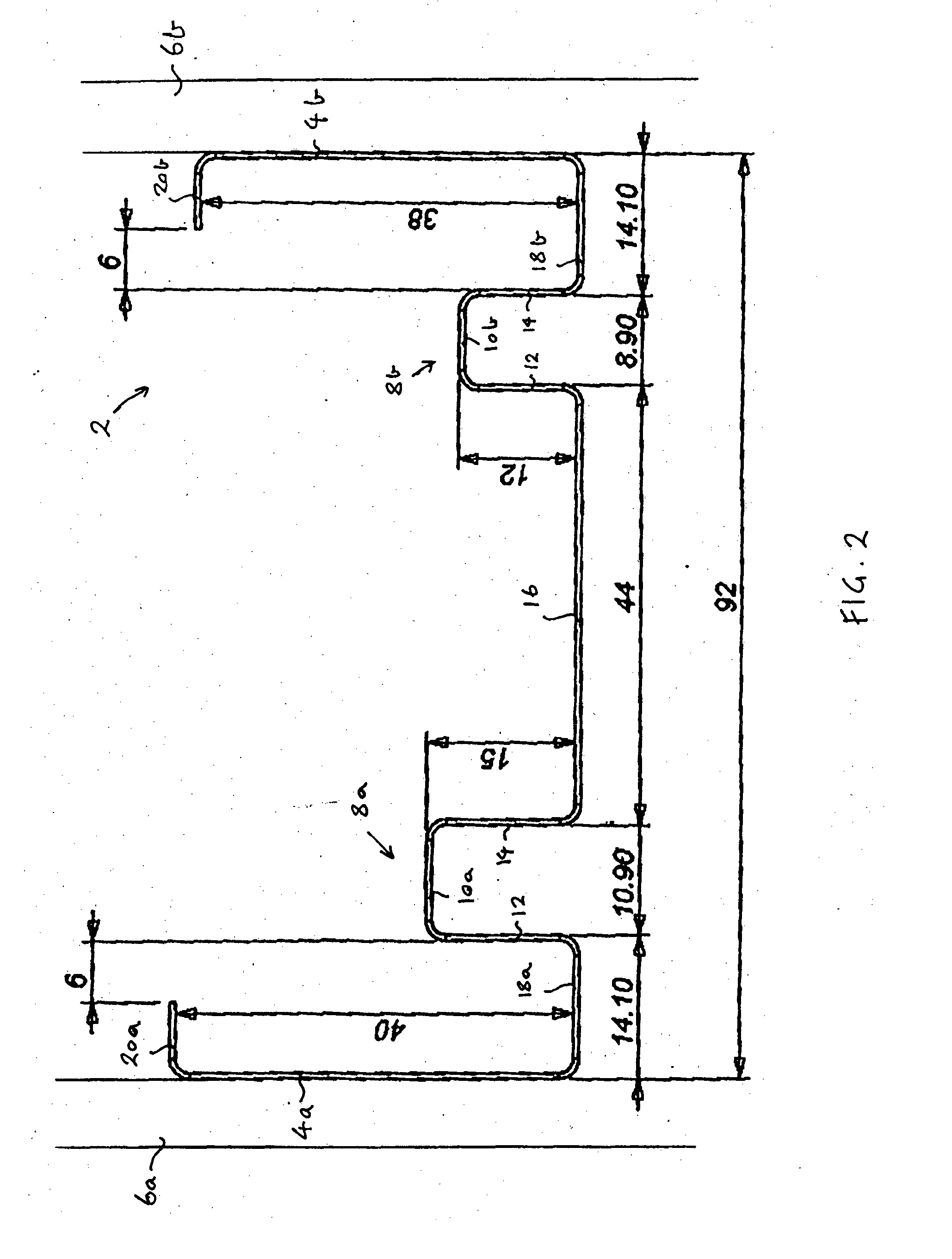

Aluminum-wood-plastic composite integrated decorative plate and preparation method thereof

InactiveCN103660457AAchieve decorative functionAchieve weather resistanceChemical industrySynthetic resin layered productsWeather resistanceSolid wall

The invention discloses an aluminum-wood-plastic composite integrated decorative plate and a preparation method thereof. The upper and lower surfaces of a base plate with a hollow I-shaped structure are thermally coated with aluminum foils, or the upper and lower surfaces of a base plate with a micro-foaming solid wall U-shaped structure are thermally coated with aluminum foils, so that the decorative function and surface weather resistance of an existing aluminum plastic plate can be realized, and the integrated decorative plate has the characteristics of damp-proofing effect, mothproofing effect and deformation resistance, the phenomena of glue failure, hollowing, deformation or drop of the decorative plate in the using process can be prevented, the potential safety hazard is reduced, the construction link can be simplified in the construction process, a great number of raw materials and labor can be saved, the integrated decorative plate has energy-saving and environment-friendly effects and is convenient to install, the construction efficiency can be improved, and the production cost is reduced.

Owner:潘建设

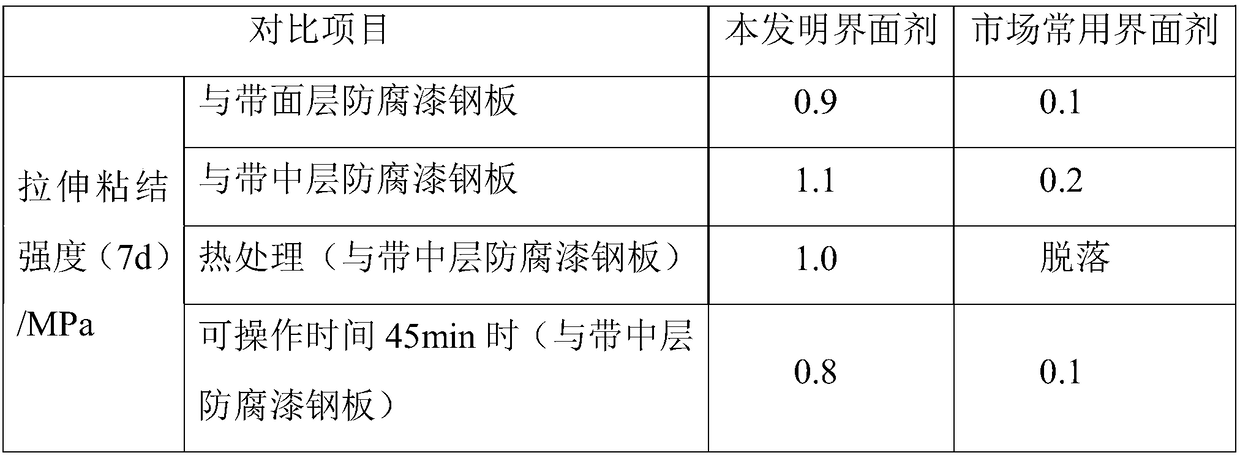

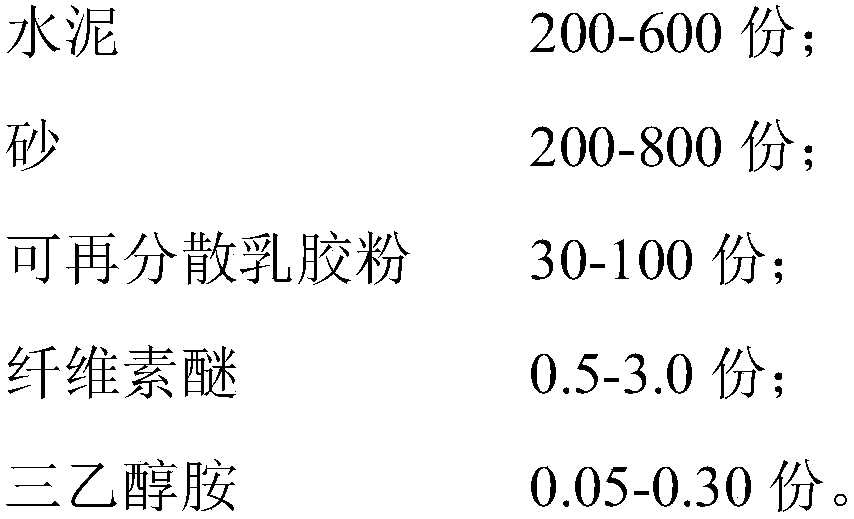

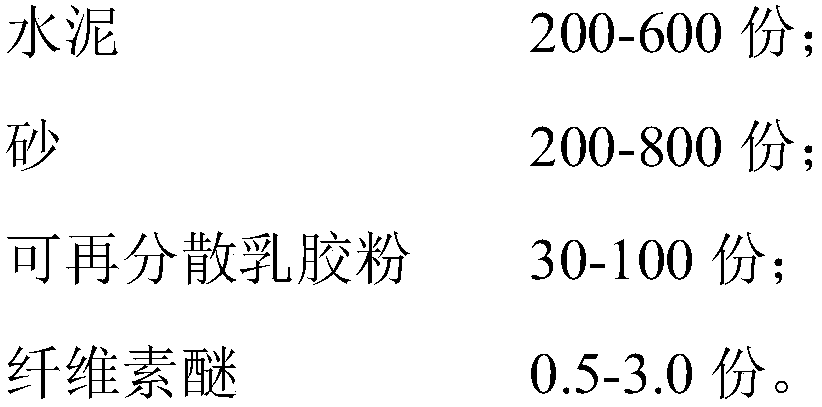

Interface agent for steel structure inner wall with anticorrosive coating

The invention relates to an interface agent for a steel structure inner wall with an anticorrosive coating. The interface agent is prepared from the following raw materials in parts by weight: 200-600parts of cement, 200-800 parts of sand, 30-100 parts of redispersible latex powder, 0.5-3.0 parts of cellulose ether and 0.05-0.30 part of triethanolamine. The interface agent has the beneficial effects that the interface agent can improve the adhesion performance between the steel structure with the anticorrosive coating and surface mortar and is better in affinity with the steel structure withthe anticorrosive coating and higher in adhesion strength; the cement and the redispersible latex powder form a composite cementing material system, the cement is used for initial rapid hydration to provide the initial adhesion strength, the redispersible latex powder is emulsified to form a film after being contacted with water, the film and a hydration product of the cement form an interpenetrating network structure, and good adhesion performance and a certain deformation resistance performance are formed on the steel structure with the anticorrosive coating; cellulose ether can improve theconstruction performance and the water retention performance of the interface agent and has the auxiliary effect to improvement of the adhesion performance of the interfacial agent; and triethanolamine can accelerate the strength growth speed and can also improve the adhesion performance of the interface agent.

Owner:HANGXIAO STEEL STRUCTURE

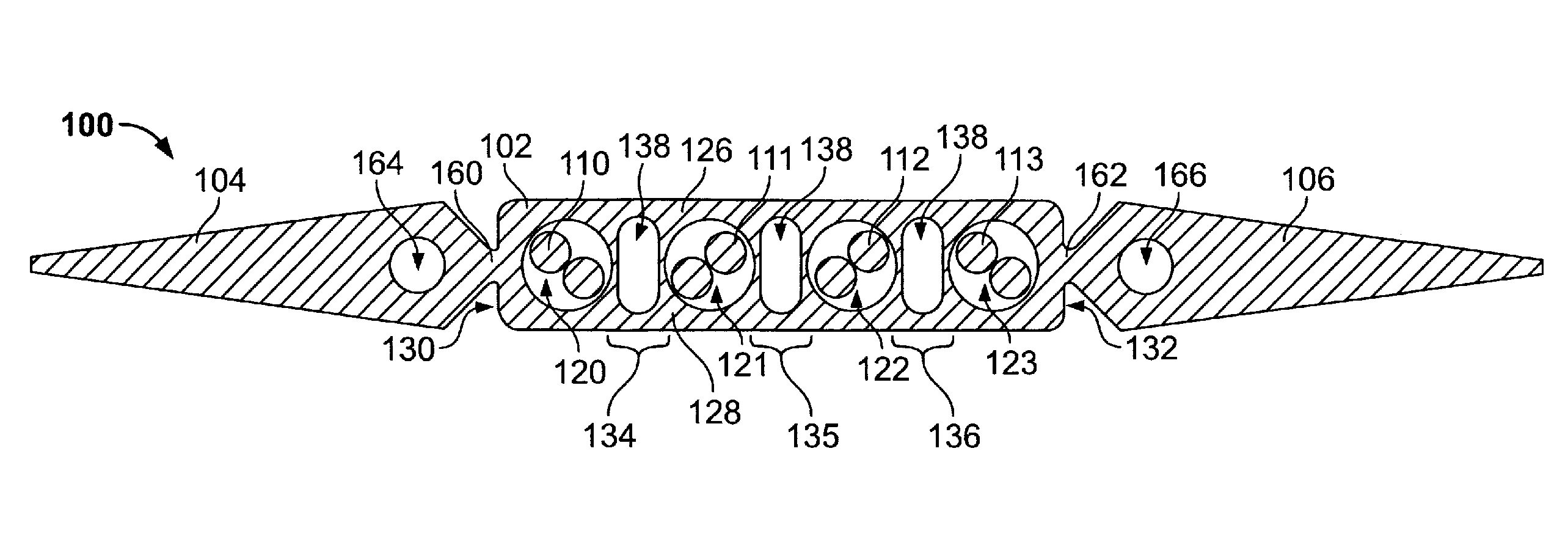

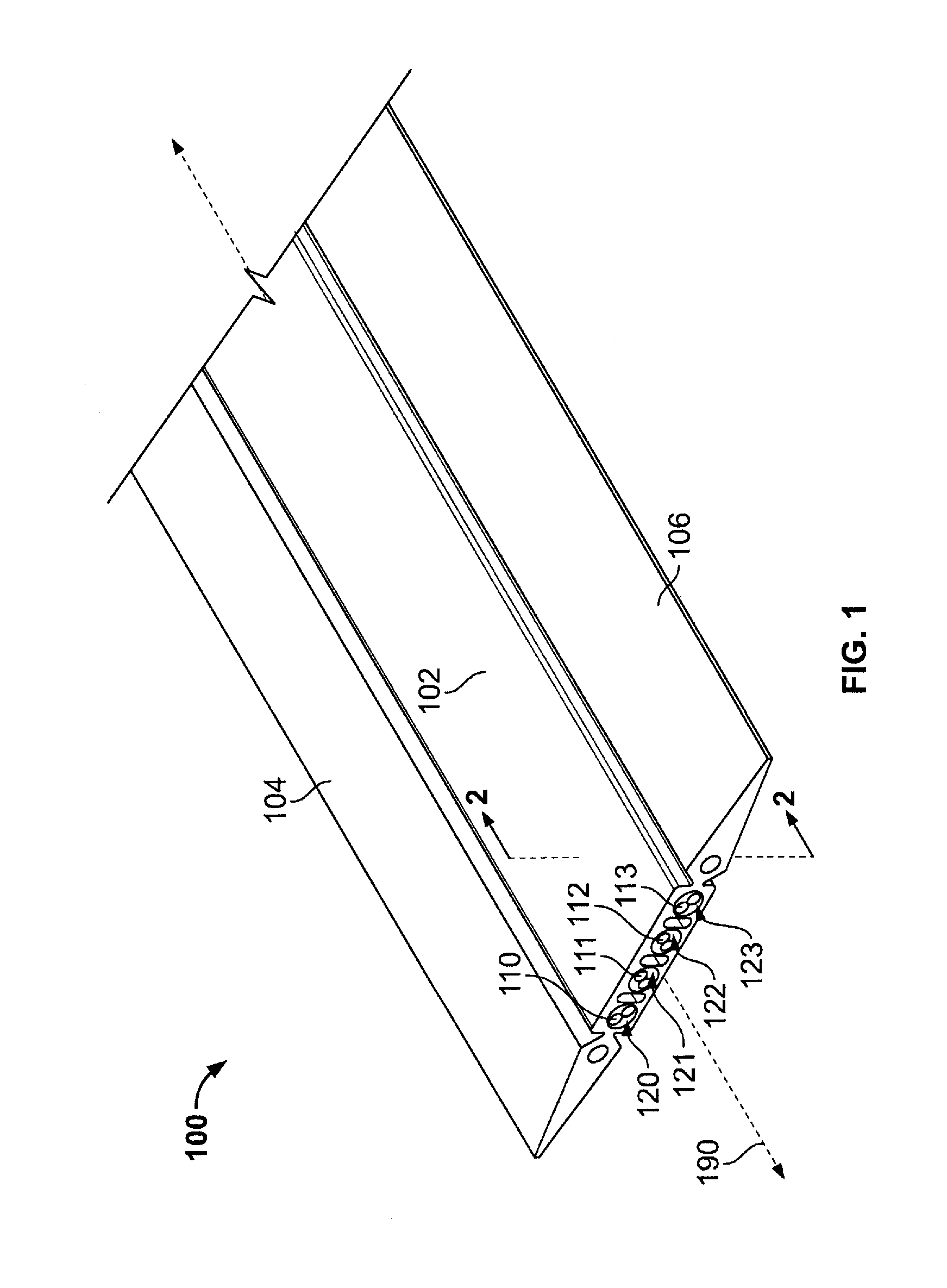

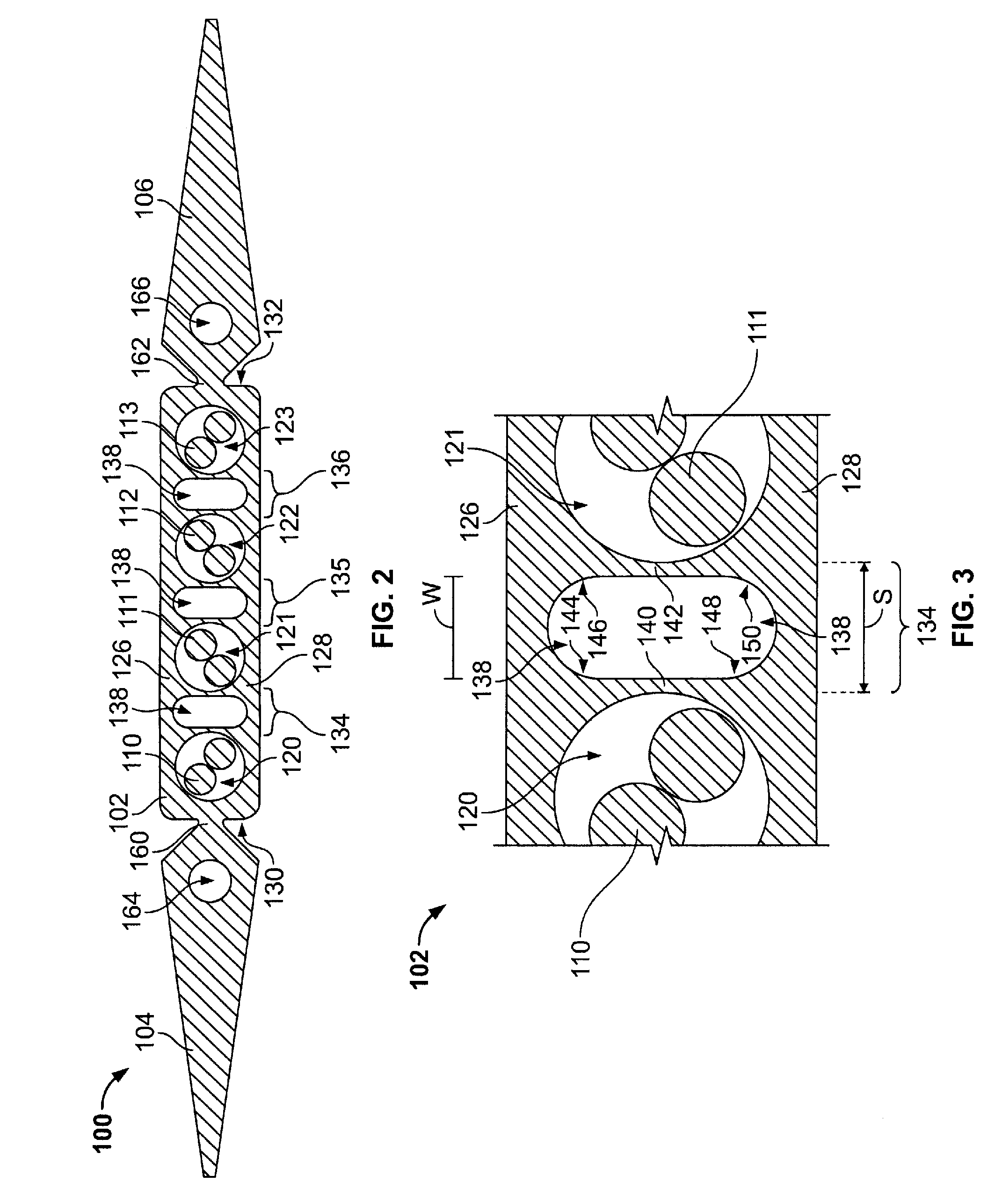

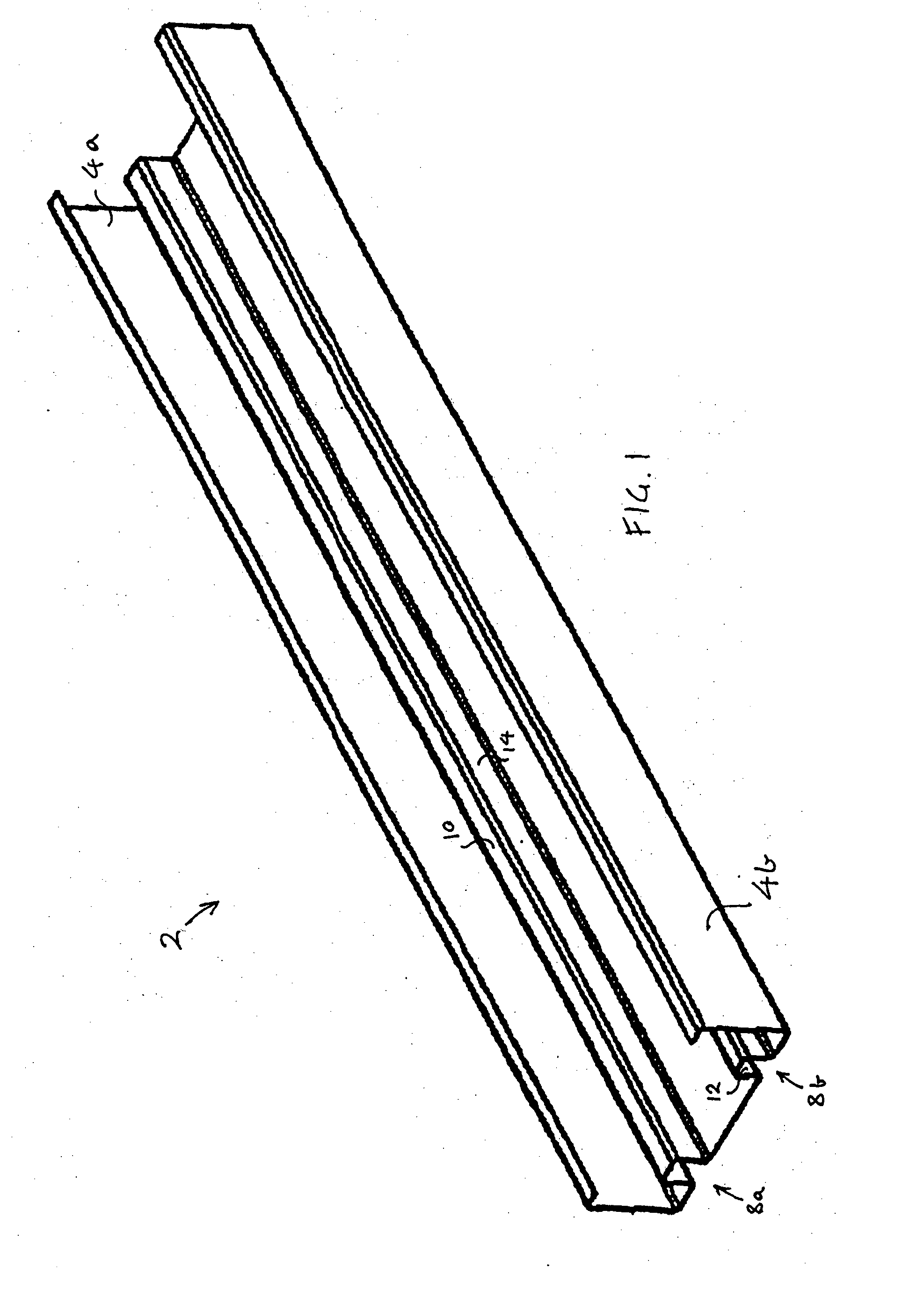

Low-profile cable

InactiveUS7534963B1Resistant to deformationExtend the length of the bodyFlat/ribbon cablesInsulated conductorsEngineeringTwisted pair

A low-profile cable is provided and includes a body having upper and lower portions that extend a length of the body and also having opposite sidewalls joining the upper and lower portions to one another. The cable also includes passages that are located between the sidewalls. The passages extend the length of the body and are configured to receive at least one twisted pair of conductors. Also, the cable includes a load-bearing structural section that spans between the upper and lower portions. The structural section includes opposing wall supports separated by a pocket channel therebetween. The structural section is configured to support the upper and lower portions and substantially resist deformation of the passages when external forces are induced onto at least one of the upper and lower portions.

Owner:COMMSCOPE TECH LLC

Sound Attenuation Stud

Owner:ETEX AUSTRALIA PTY LTD

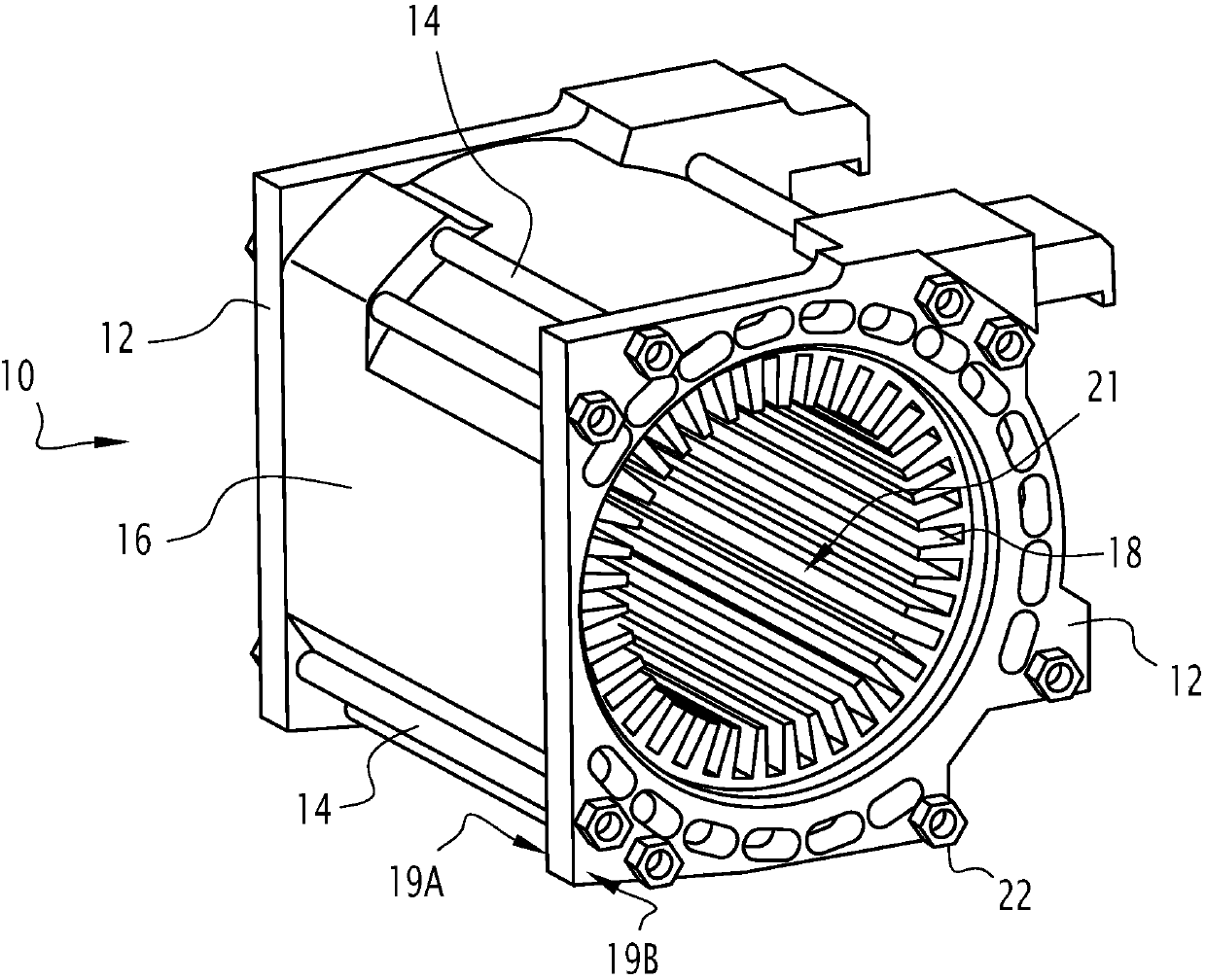

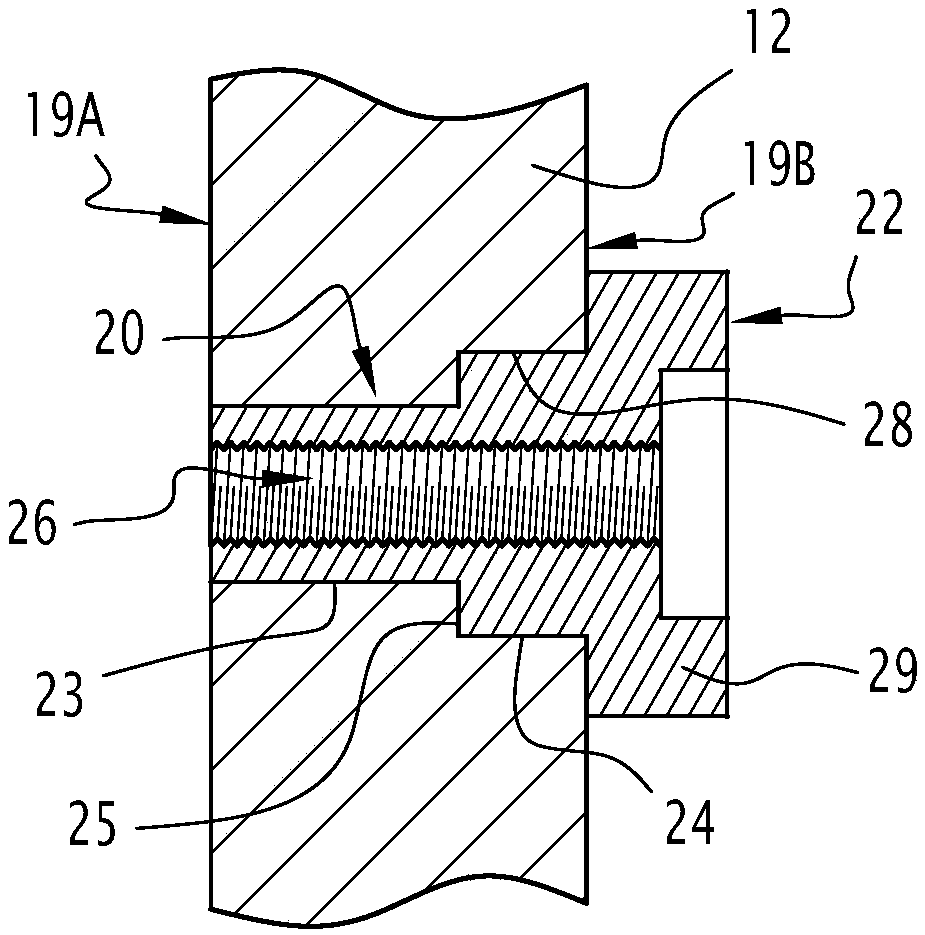

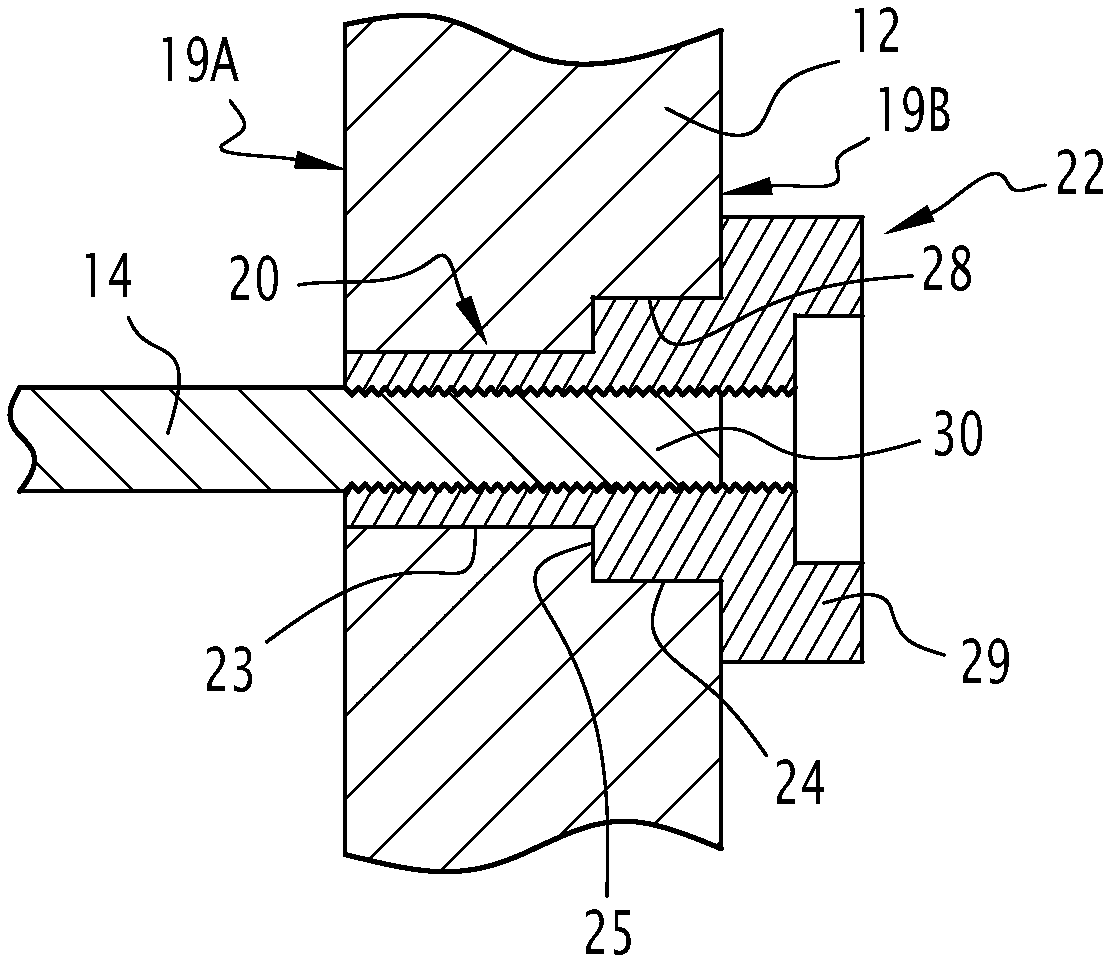

Screwed stator frame for an electric motor and associated manufacturing process

ActiveCN107645218AResistant to deformationReduce volumeMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineEngineering

A screwed stator frame for an electric motor and an associated manufacturing process are provided. A motor stator frame (10) including two plates (12) in cast iron; at least one steel bar (14) connecting both plates (12), each bar (14) having two threaded ends; and at least one threaded bushing (22). Wherein each of the plates (12) has at least one orifice being used as a seat for each threaded bushing (22) the threaded ends of each bar (14) being engaged into the threaded bushings (22).

Owner:ALSTOM TRANSPORT TECH SAS

A kind of interface mortar for steel structure exterior wall with anti-corrosion coating

ActiveCN109020370BGood tensile bond strengthHigh tensile bond strengthCovering/liningsCelluloseThermal insulation

The invention relates to an interface mortar for steel structure exterior walls with an anti-corrosion coating. The interface mortar includes cement, sand, redispersible latex powder, water-repellent agent, defoamer and cellulose ether, the weight of each component For example: 200-700 parts of cement, 200-800 parts of sand, 30-120 parts of redispersible latex powder, 0.3-3.0 parts of water repellent, 0.1-2.0 parts of defoamer, and 0.2-2.5 parts of cellulose ether. Its beneficial effect is: the interface mortar provided by the invention can effectively guarantee the bonding with the surface of the steel structure base layer with an anti-corrosion coating, and has a good relationship with plastering materials such as thermal insulation mortar, bonding mortar, plastering mortar, and waterproof mortar. Being bonded, compared with the interface mortar used for traditional concrete and masonry base, the interface mortar has better affinity with the surface of the steel structure with anti-corrosion coating, high tensile bond strength, and also has good bonded properties performance, and less decrease in tensile bond strength after water immersion, freeze-thaw and heat treatment, has good durability, and can meet the requirements of the use environment of steel structure exterior walls with anti-corrosion coatings.

Owner:HANGXIAO STEEL STRUCTURE

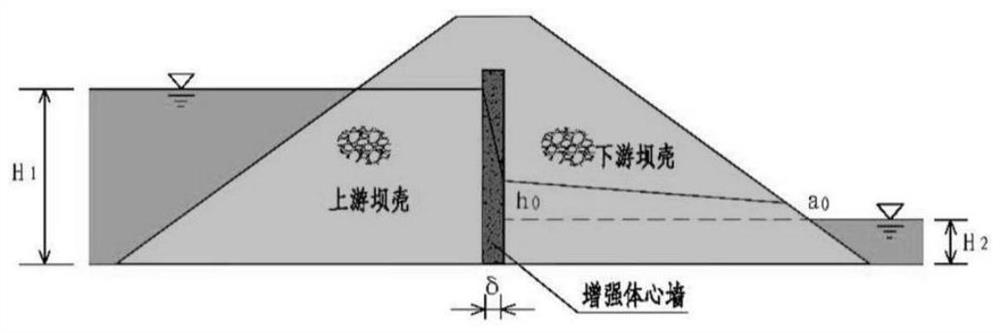

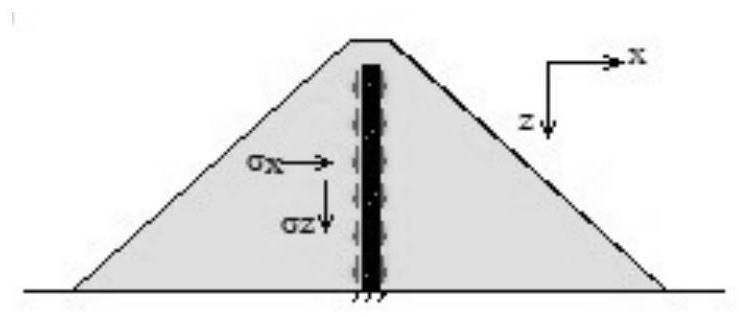

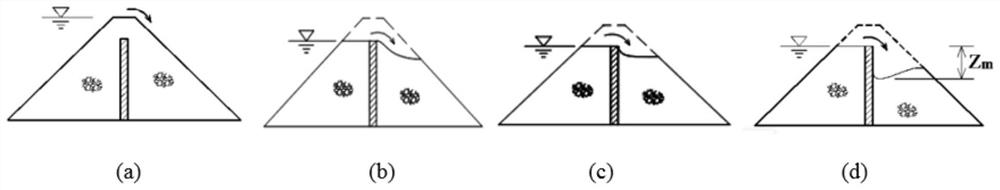

Parameter set of earth and rockfill dam longitudinal reinforcement and design method of earth and rockfill dam longitudinal reinforcement

PendingCN114491724AOvercoming birth defects prone to dam failureReasonable designGeometric CADDesign optimisation/simulationGeotechnical engineeringEmbankment dam

The invention discloses a parameter set of a longitudinal reinforcement of an earth and rockfill dam and a design method of the longitudinal reinforcement of the earth and rockfill dam. The design method of the longitudinal reinforcement of the earth and rockfill dam comprises the following steps: determining design parameters of the longitudinal reinforcement of the earth and rockfill dam; calculating the deformation resistance of the longitudinal reinforcement of the earth and rockfill dam; analyzing the stress of the longitudinal reinforcement of the earth and rockfill dam; carrying out hydraulic analysis when the longitudinal reinforcement of the earth and rockfill dam is overtopped by the flood; re-checking the strength of the longitudinal reinforcement of the earth and rockfill dam after being scoured; the longitudinal reinforcement of the earth and rockfill dam has the advantages of seepage prevention, stress resistance, deformation resistance and overtopping without collapse; the engineering investment can be effectively saved by 30-20%, and the economic benefit is obvious; and the conventional earth and rockfill dam is reinforced, so that the safety operation risk of a dangerous reservoir is greatly solved, the congenital defect that the earth and rockfill dam is easy to break is overcome, and the safe operation of the reservoir is guaranteed.

Owner:梁军

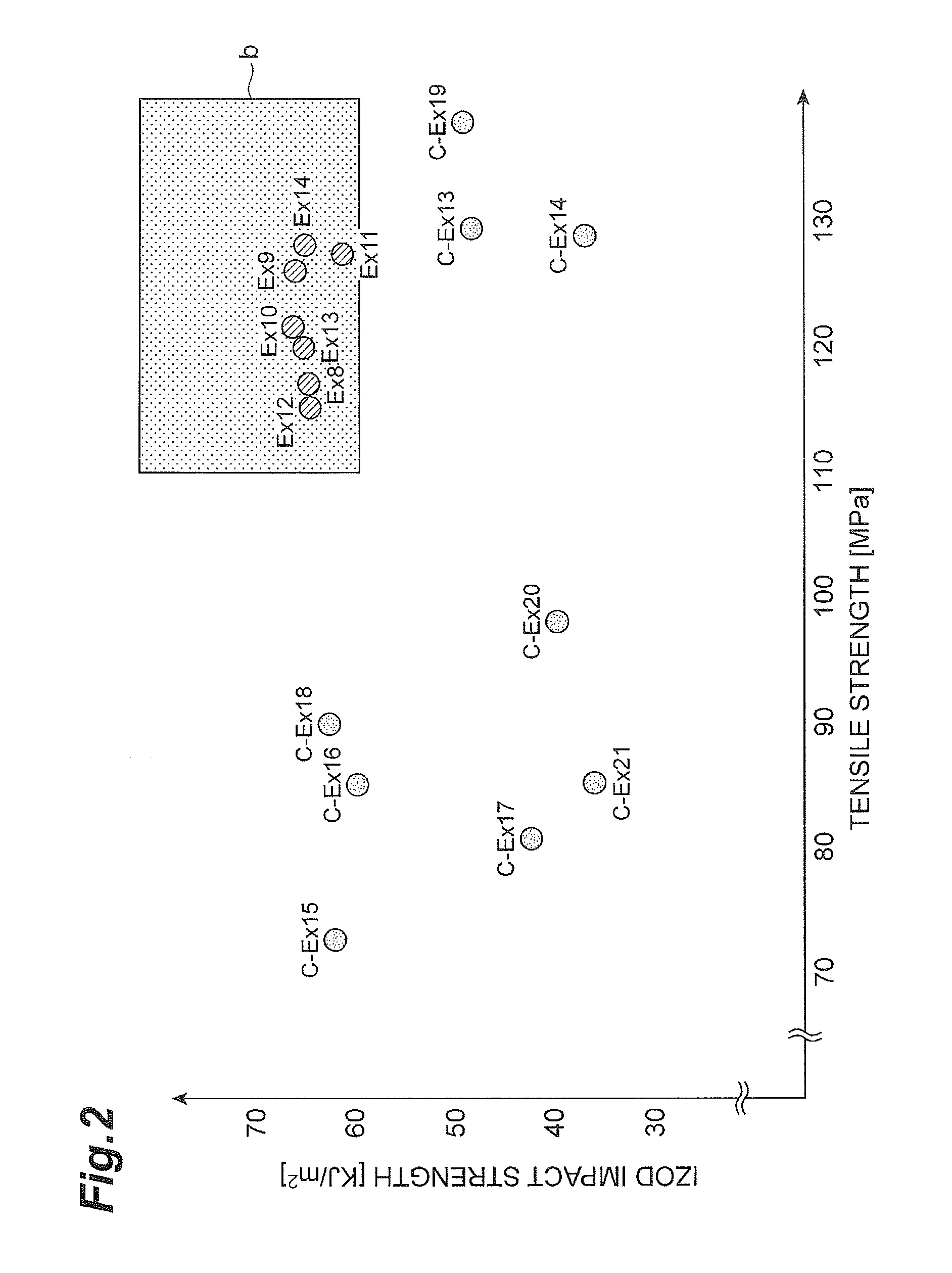

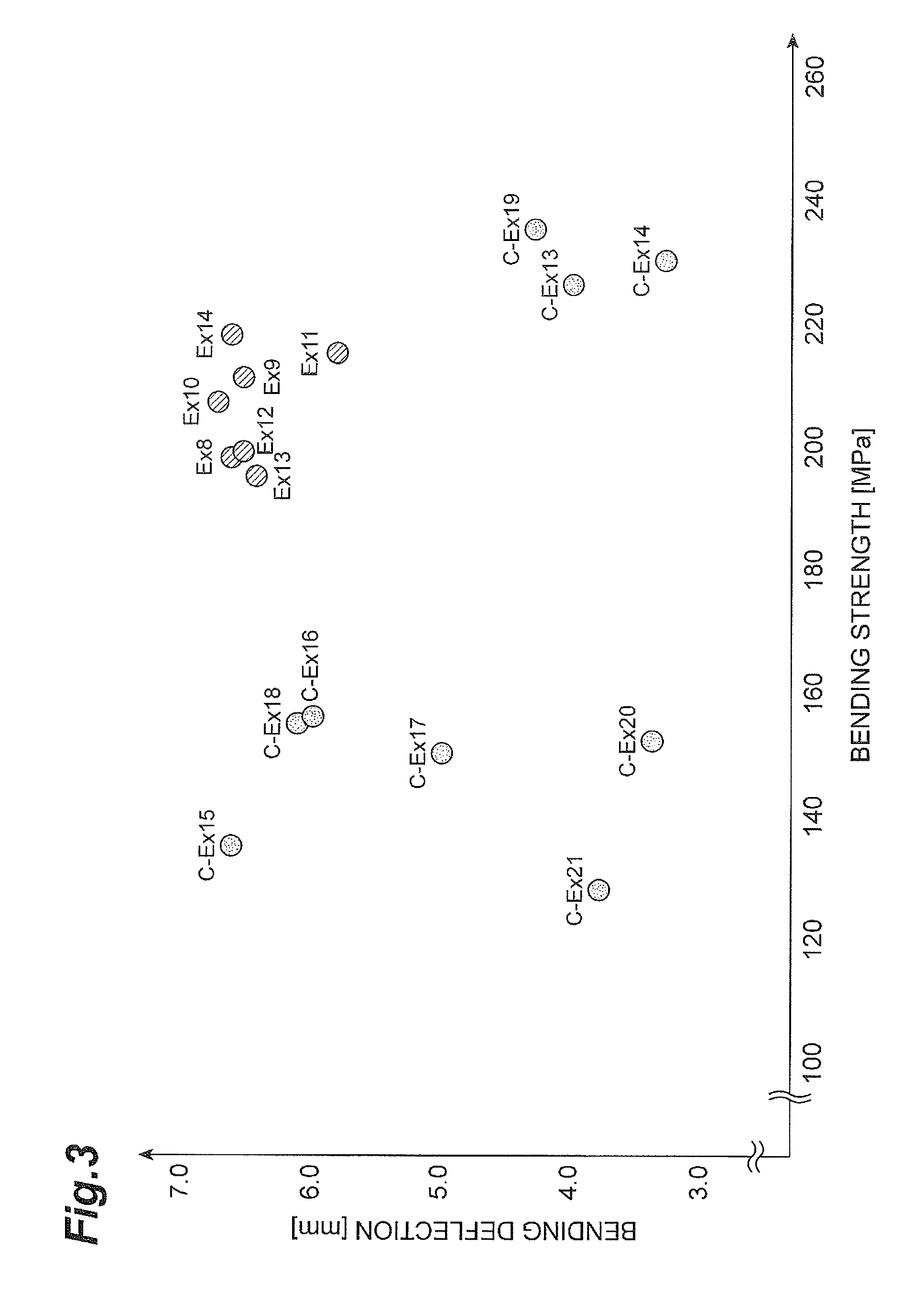

Liquid crystal polyester amide, liquid crystal polyester amide resin composition, and molded article

A liquid crystal polyester amide of the present invention includes 10 mol % to 65 mol % of a structural unit represented by the following formula (1), 3 mol % to 17.5 mol % of a structural unit represented by the following formula (2), 5 mol % to 20 mol % of a structural unit represented by the following formula (3), 7.5 mol % to 42 mol % in total of at least one of a structural unit represented by the following formula (4-1) and a structural unit represented by the following formula (4-2), and 2.5 mol % to 40 mol % in total of at least one of a structural unit represented by the following formula (5-1) and a structural unit represented by the following formula (5-2), and has a melting point of 300° C. or higher.

Owner:JX NIPPON OIL & ENERGY CORP

Interface mortar for steel-structured internal wall with epoxy coating

The invention relates to interface mortar for a steel-structured internal wall with an epoxy coating. The interface mortar is prepared from components in a weight ratio as follows: 200-600 parts of cement, 200-800 parts of sand, 30-100 parts of redispersible latex powder and 0.5-3.0 parts of cellulose ether. The interface mortar has the following beneficial effects: in the interface mortar for thesteel-structured internal wall with the epoxy coating, the cement and the redispersible latex powder jointly constitute a compound cementing material system, and the cement is used for providing initial bonding strength through early rapid hydration; the redispersible latex powder is emulsified into a film after being contacted with water, the film and a hydration product of the cement form an interpenetrating polymer network structure, good adhesion is formed on a steel structure with the epoxy coating, and certain deformation resistance is realized; cellulose ether can improve workability and water retention capacity of the mortar and has an auxiliary effect on improvement of bonding performance of the interface mortar.

Owner:HANGXIAO STEEL STRUCTURE

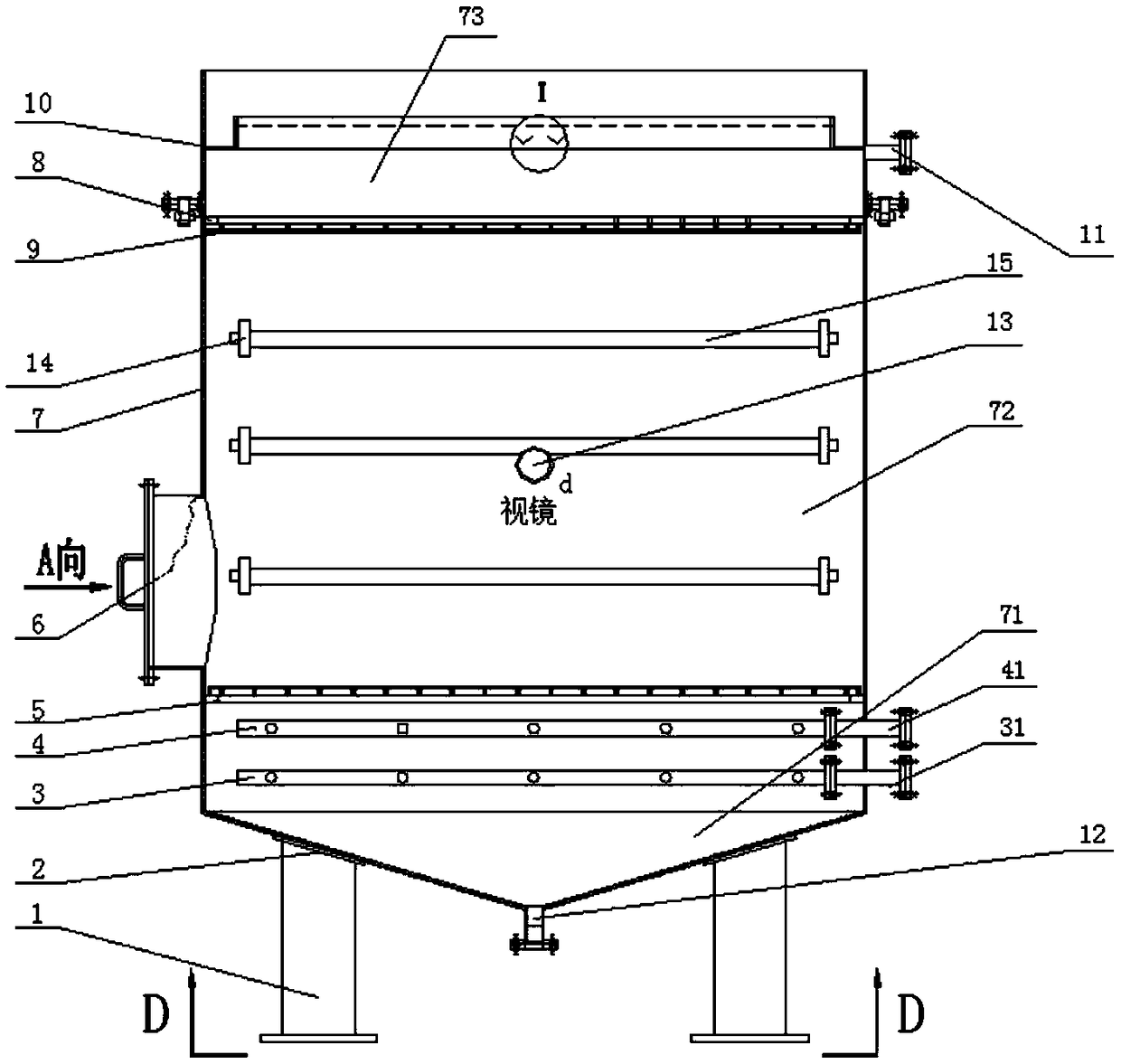

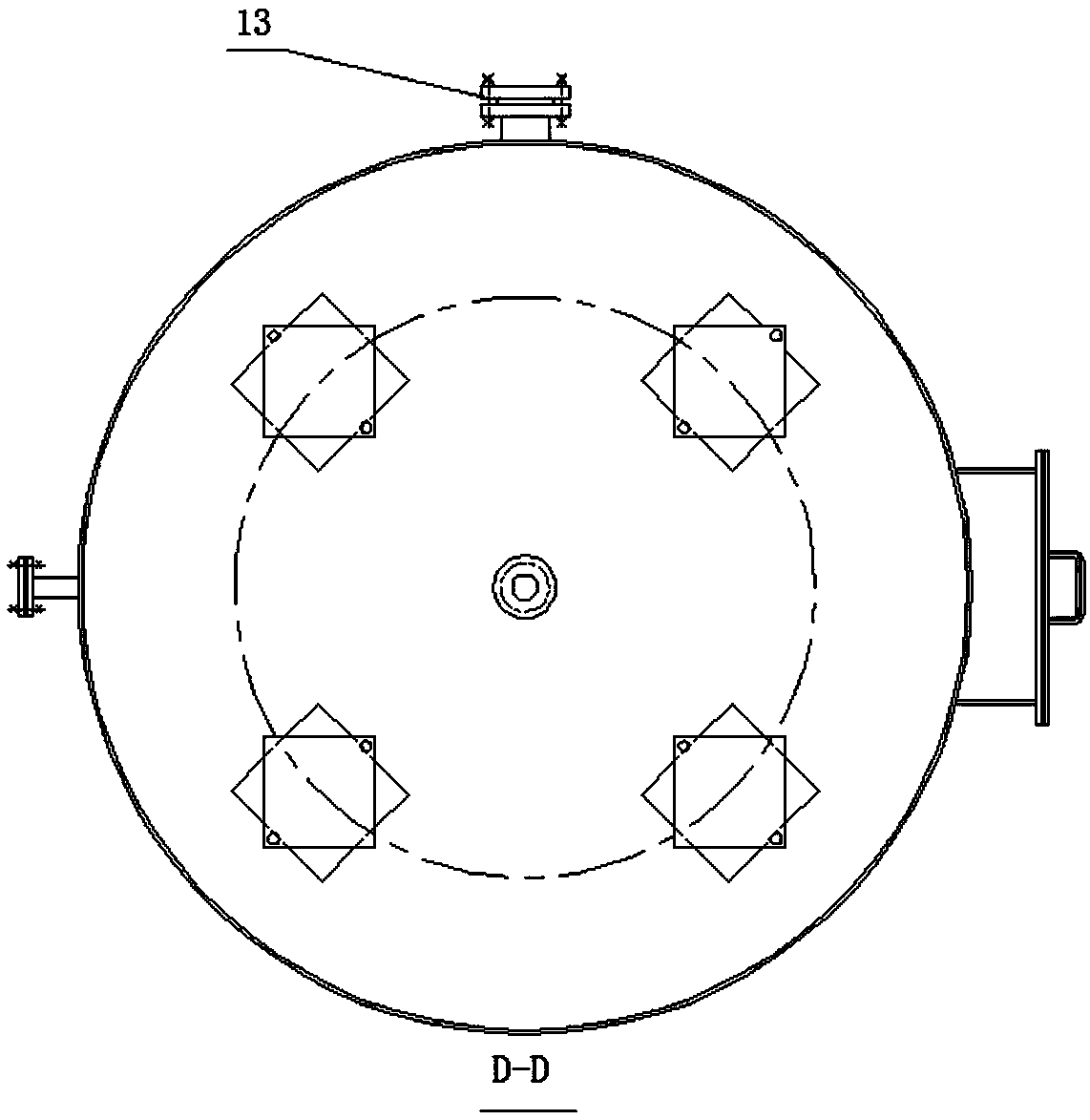

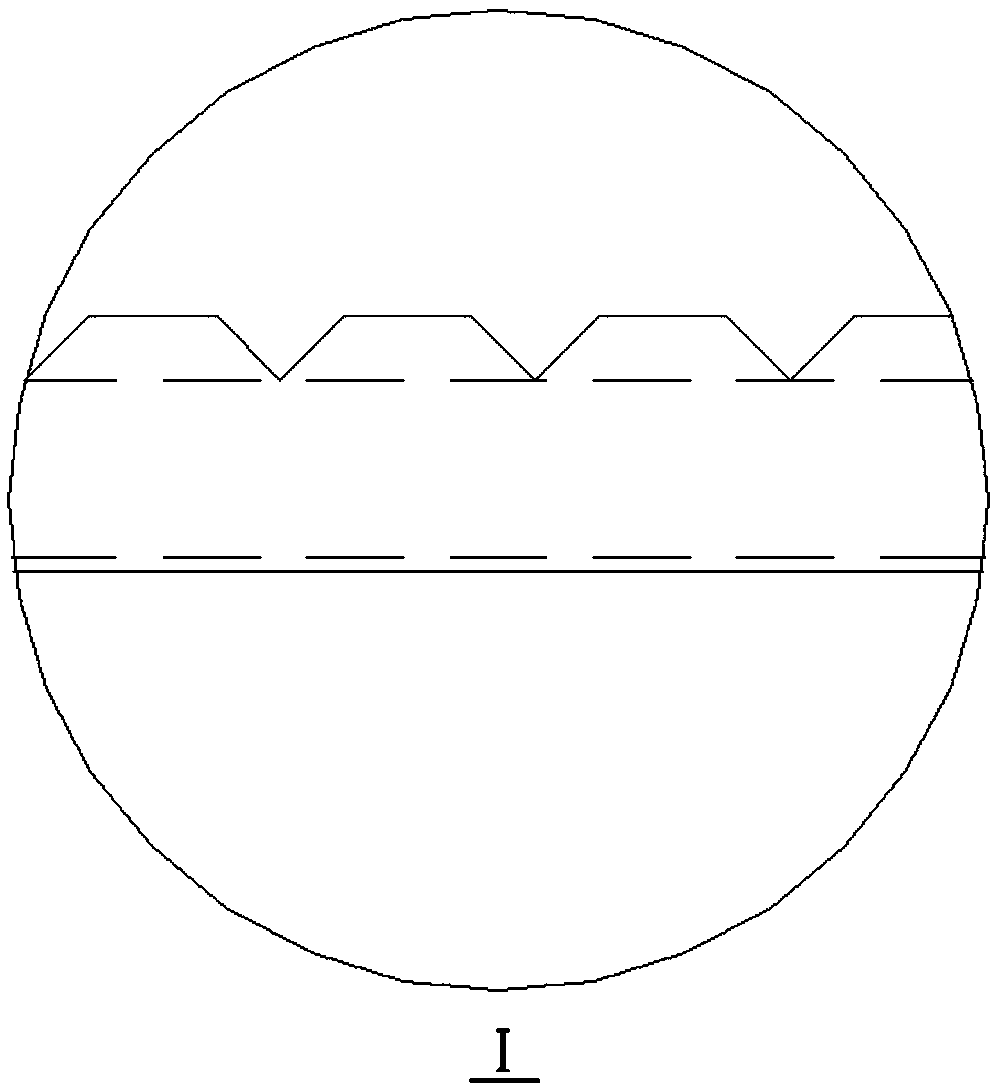

Photoreactor for efficient photosynthetic cultivation of spirulina

InactiveCN109439522AGuarantee the quality of trainingEasy to install and disassembleBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSpirodela

The invention discloses a photoreactor for efficient photosynthetic cultivation of spirulina. The photoreactor comprises support feet, a barrel and a barrel cover. The barrel is of tubular structure having an upward opening; the support feet are arranged at the lower periphery of the barrel through mounting pads; connection wing plates are connected to the periphery of the open end of the barrel and are integrated to the open end of the barrel; the open end of the barrel is provided with the barrel cover via a connection flange; the barrel cover is in convex type and is internally provided with an overflow weir; one side of the cover is provided with an overflow port. The photoreactor herein is convenient to maintain and wash at the premise that spirulina cultivation quality is guaranteed;therefore, it is effectively avoided that non-uniform distribution of nutrients in algae easily leads to non-uniform lighting for algae in deep and shallow tiers of the photoreactor, which causes optical damage and optical hunger.

Owner:XIAMEN CANCO BIOTECH CO LTD

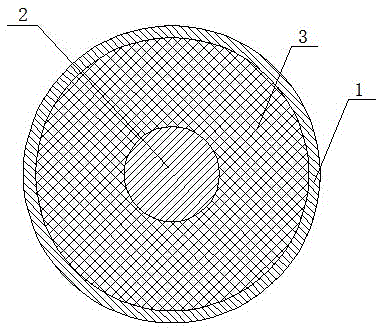

Automobile thin-wall thermoplastic insulation low-voltage cable

InactiveCN105632594AImprove insulation performanceResistant to deformationPlastic/resin/waxes insulatorsInsulated cablesThermoplasticEngineering

The invention discloses an automobile thin-wall thermoplastic insulation low-voltage cable. The automobile thin-wall thermoplastic insulation low-voltage cable comprises a tin-coated copper conductive core, a polyvinyl chloride thermoplastic elastomer wrapping the tin-coated copper conductive core and a sheath layer wrapping the polyvinyl chloride thermoplastic elastomer. According to the invention, an insulation layer employs the polyvinyl chloride thermoplastic elastomer which has quite good insulation performance, enables the cable to have the advantages of deformation resistance, high elasticity, high weatherability and the like, is plasticized and formed at a high temperature and has a thickness meeting the requirement for the thickness of the cable. The sheath layer ensures that the thin-wall cable has quite good flame-retardant fireproof performance and quite higher mechanical performance.

Owner:HEFEI XINGCHEN ELECTRIC WIRE & CABLE

A kind of interface agent for steel structure inner wall with anti-corrosion coating

The invention relates to an interface agent for steel structure interior walls with an anti-corrosion coating, comprising the following raw materials in parts by weight: 200-600 parts of cement, 200-800 parts of sand, 30-100 parts of redispersible latex powder, and cellulose ether 0.5-3.0 parts, triethanolamine 0.05-0.30 parts. The beneficial effect is: the interface agent can improve the bonding performance between the steel structure with anti-corrosion coating and the plastering mortar; and the interface agent has better affinity with the steel structure with anti-corrosion coating, and the bonding strength is higher; Cement and redispersible latex powder form a composite cementitious material system. Cement is used for rapid hydration at the initial stage to provide initial bond strength. Redispersible latex powder is emulsified into a film after contacting with water, and forms a hydration product with cement. The interpenetrating network structure forms good bonding performance and certain deformation resistance on the steel structure with anti-corrosion coating; cellulose ether can improve the construction and water retention performance of the interface agent, and assist the improvement of the bonding performance of the interface agent Effect; triethanolamine can accelerate the strength growth rate and improve the bonding performance of the interface agent.

Owner:HANGXIAO STEEL STRUCTURE

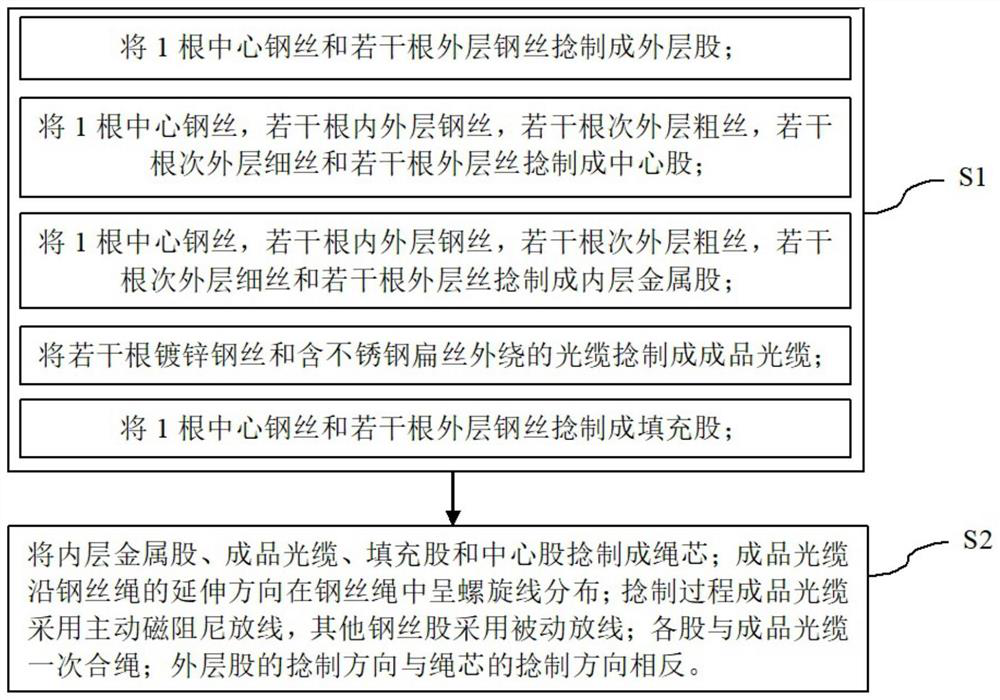

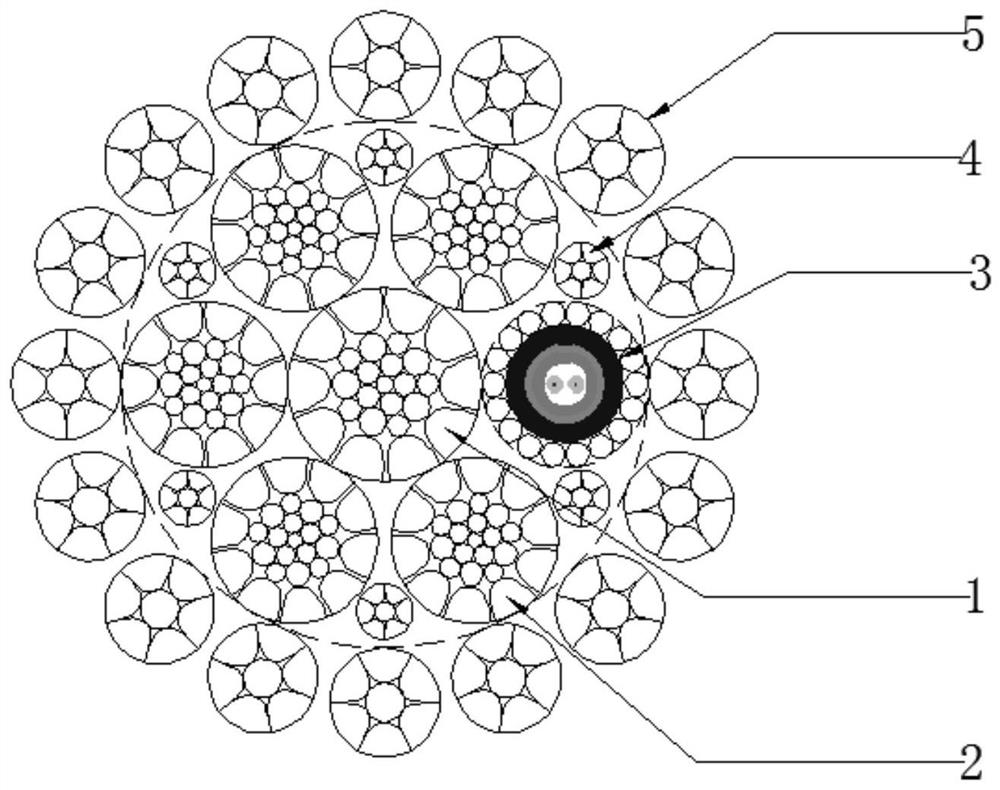

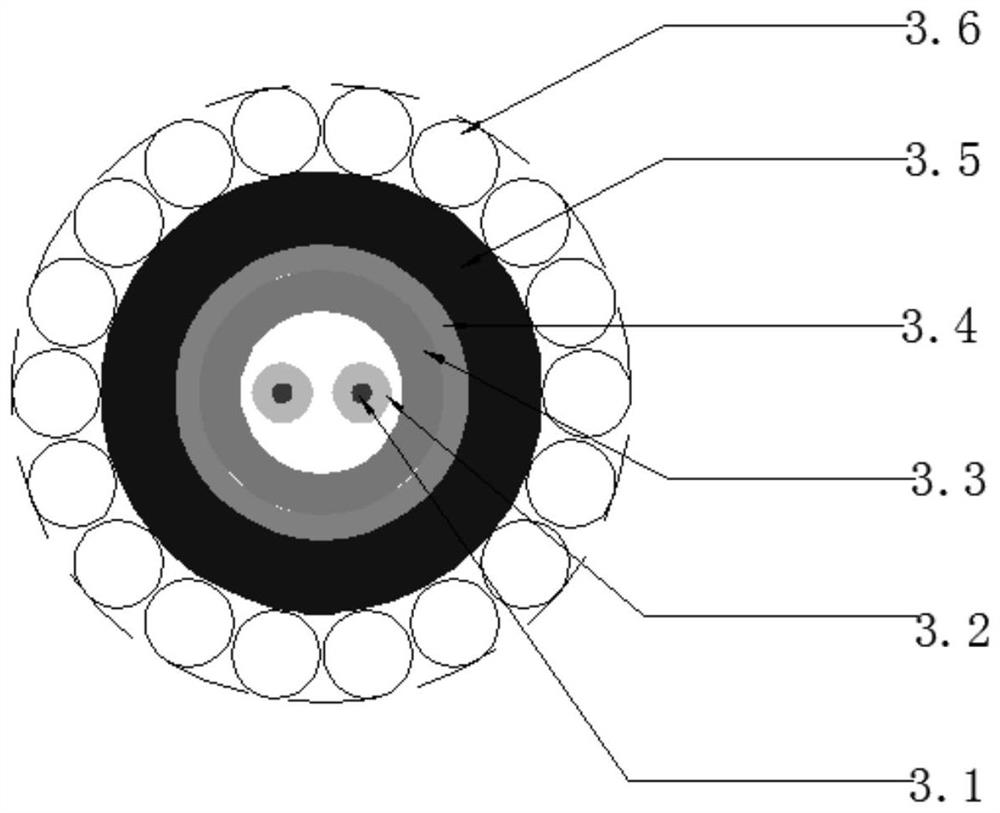

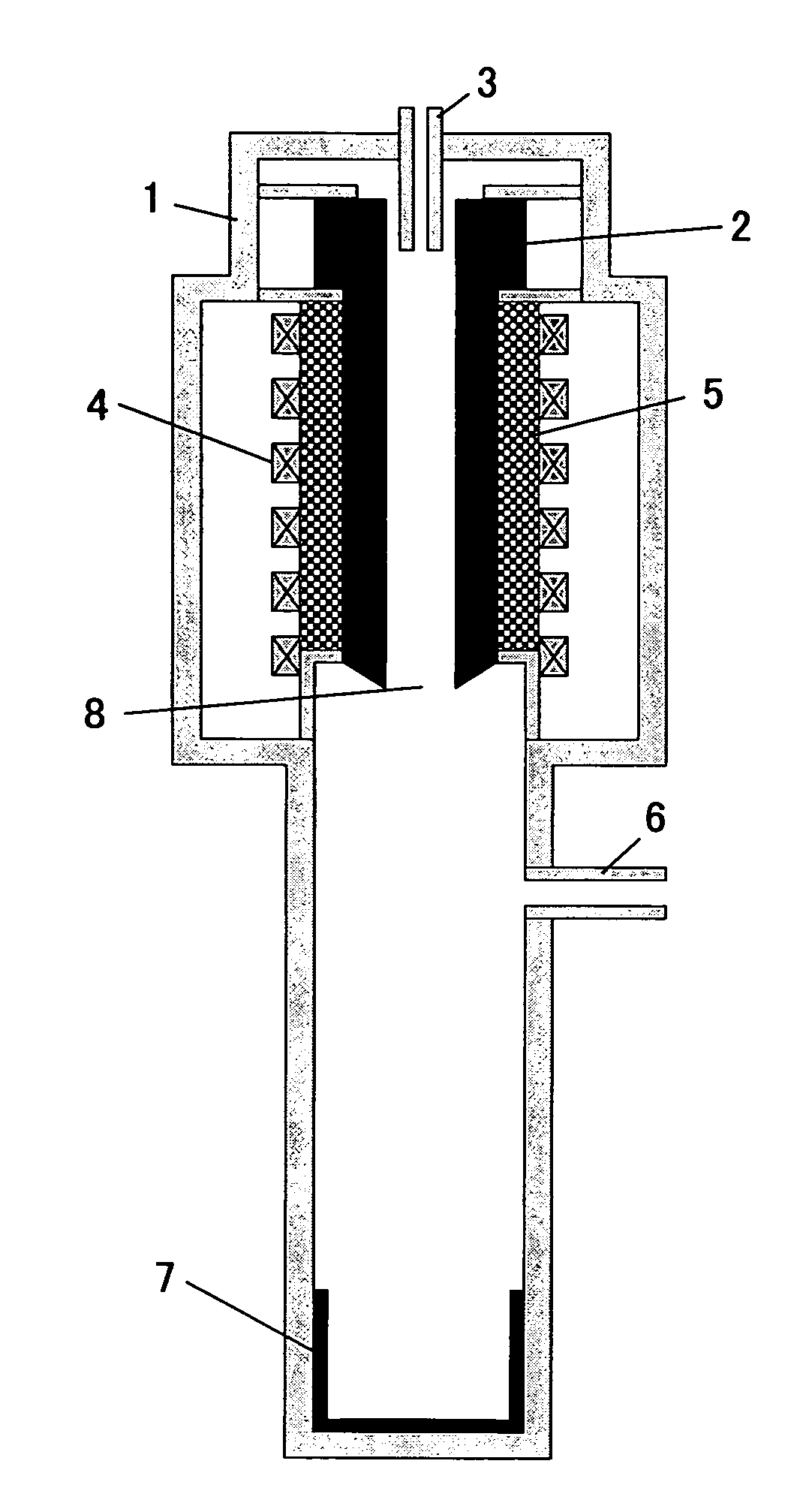

Production method of video deep well rescue steel wire rope

The invention discloses a production method of a video deep well rescue steel wire rope. The production method comprises the following steps of twisting an outer layer strand, twisting a central strand, twisting to form an inner-layer metal strand, twisting a plurality of galvanized steel wires and an optical cable containing a stainless steel flat wire into a finished optical cable, twisting filling strands, twisting the inner-layer metal strand, the finished optical cable, the filling strands and the central strand into a rope core, spirally distributing the finished optical cable in the steel wire rope along the extension direction of the steel wire rope, adopting active magnetic damping pay-off for the finished optical cable in the twisting process, adopting passive pay-off for other steel wire strands, performing one-time rope combination on each strand and the finished optical cable, and enabling the twisting direction of the outer layer strand to be opposite to that of the rope core. When the video deep well rescue steel wire rope is twisted, the finished optical cable and the steel wire strands are consistent in pay-off tension, the active magnetic damping pay-off is adopted for the finished optical cable, and the steel wire rope produced through the production method has the advantages of being high in bearing performance and capable of effectively transmitting video signals.

Owner:FASTEN HONGSHENG GRP CO LTD

Cylindrical vessel made of carbon and process for making silicon

InactiveUS8282904B2Resistant to deformationSuppress cracksMelt-holding vesselsSiliconHydrogenThermal expansion

A cylindrical vessel made of carbon is used in the production of silicon. The inner surface of the vessel comes into contact with a silicon melt, wherein the permeation with silicon melt is reduced, formation of SiC is suppressed, and the vessel is resistant to deformation even when volumetric expansion ascribable to silicon is brought about. The carbon-made cylindrical vessel is made of a carbon material having a bulk specific gravity of 1.8 or more. The thermal expansion coefficient of the carbon material at 350 to 450° C. is preferably 3.5×10−6 / ° C. to 6.0×10−6 / ° C. A process for producing silicon uses said vessel wherein a chlorosilane is reacted with hydrogen.

Owner:TOKUYAMA CORP

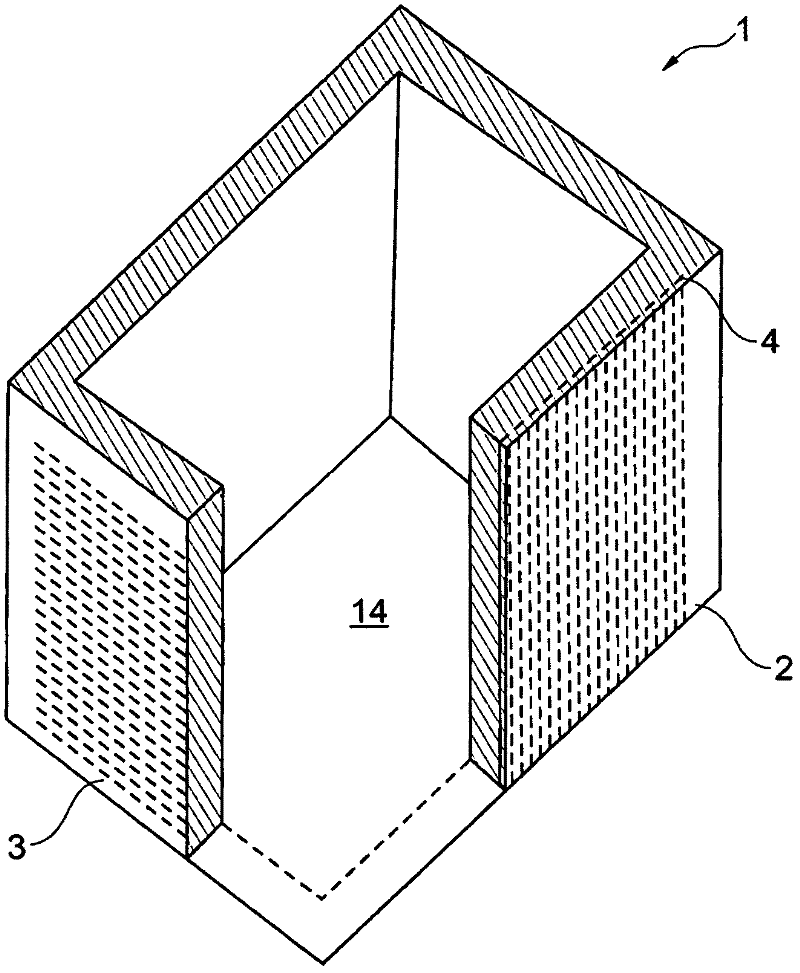

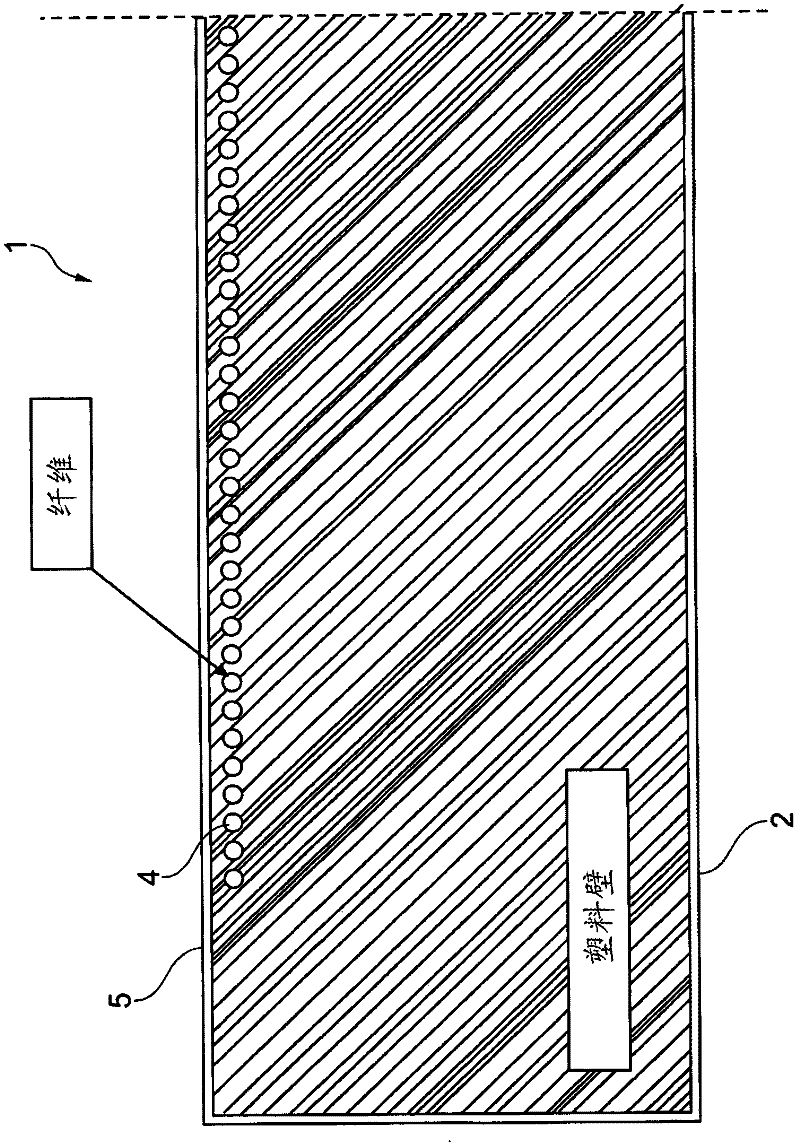

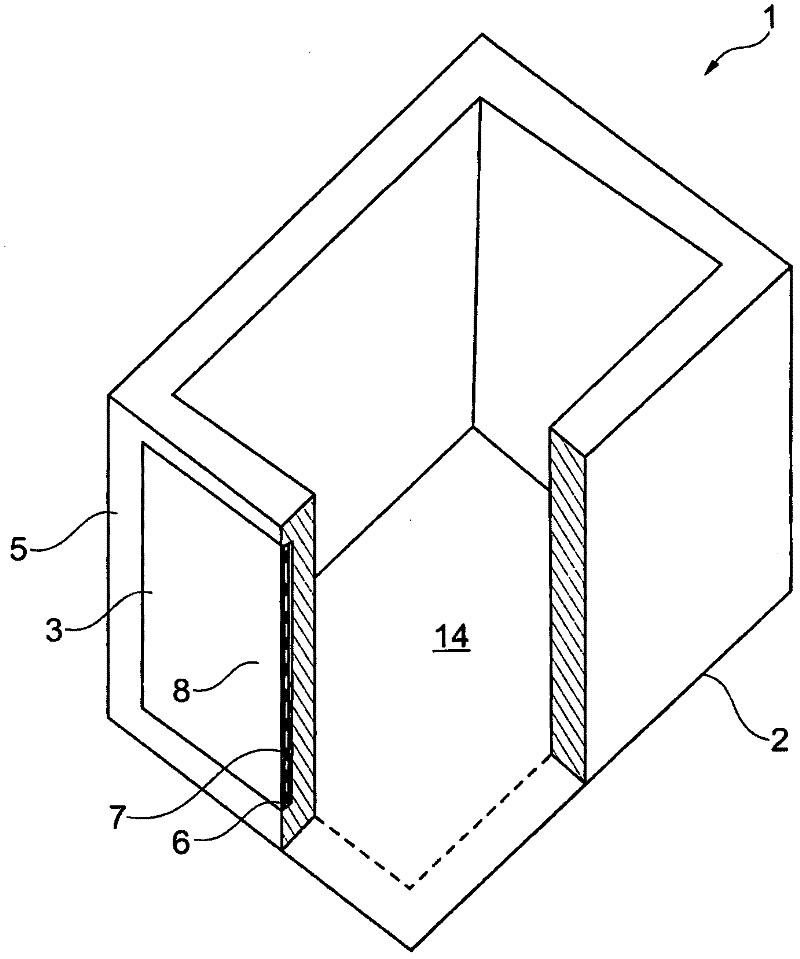

Plastic transport container for transporting and/or storing goods and similar items

InactiveCN102448837AHigh hardnessResistant to deformationBoxesThin material handlingFiberEngineering

The present invention relates to a plastics transport container for transporting and / or storing articles, having a container base (14) and side walls (2, 3) which are circumferentially arranged at the base of the container. Thus, it is provided that at least one flat section of the thin-walled container with a thickness ranging from 1.4 mm to 4 mm is reinforced by a braided or woven structure of fibers (4) embedded in the surface or proximal to the surface of the section.

Owner:SCHOELLER ARCA SYST

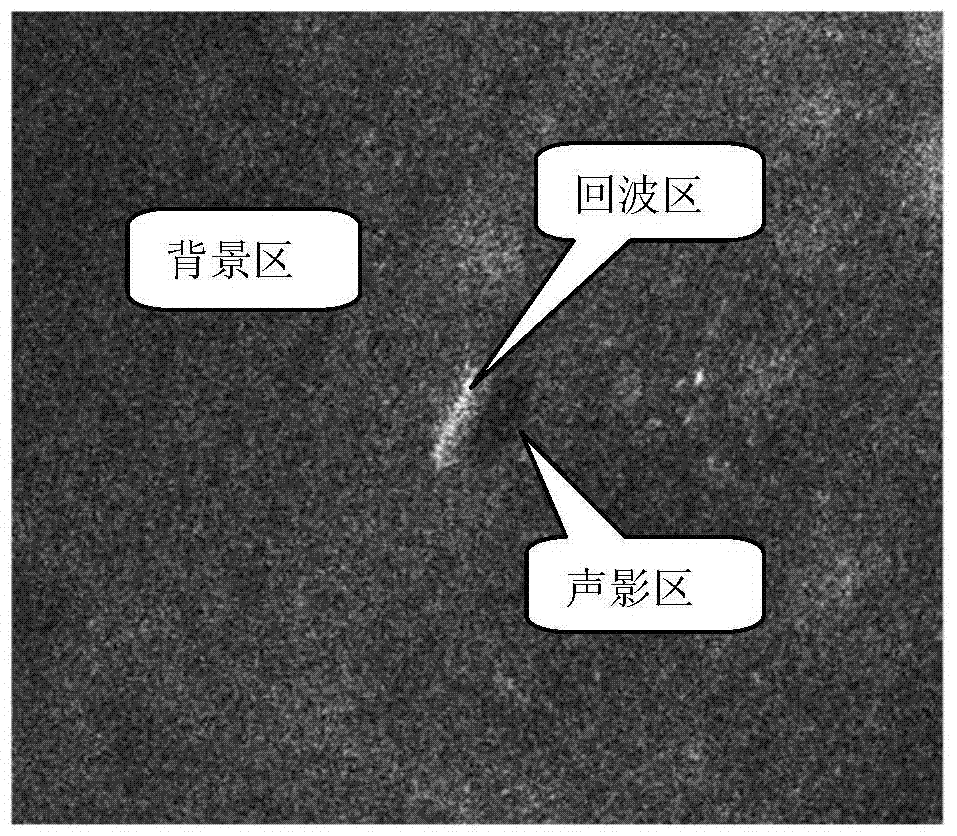

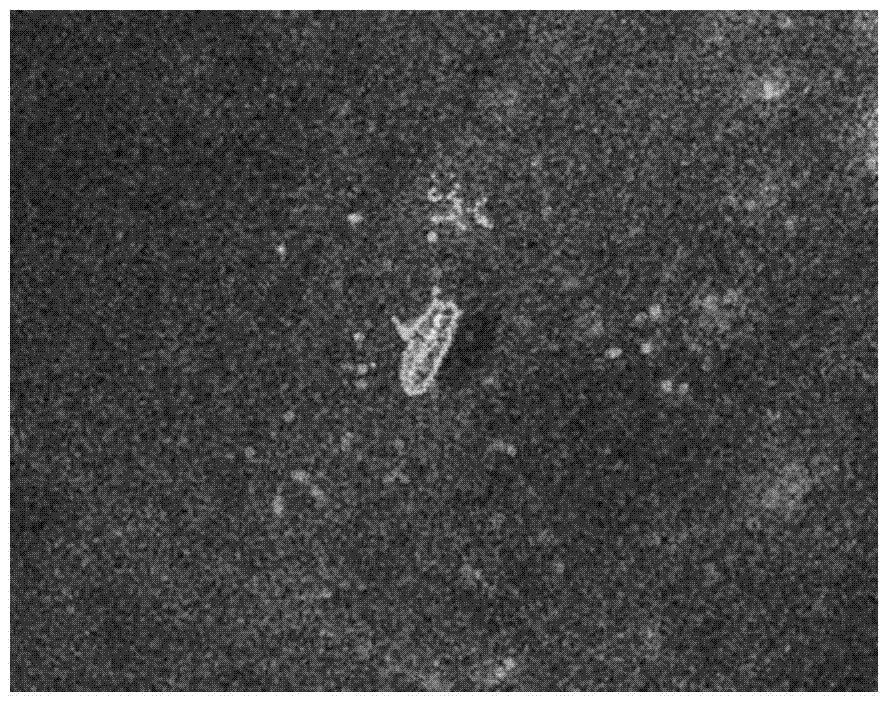

A Mine Target Recognition Method Based on Active Contouring in Sonar Images

ActiveCN104657736BFind exactlyImprove noise immunityCharacter and pattern recognitionSonarPattern recognition

The invention relates to the field of automatic target recognition of images, in particular to a mine target recognition method of sonar images. The invention includes proposing an active contour model constrained by a hyperellipse, an active contour model constrained by a multiphase level set, and a sonar image mine target recognition method based on the active contour model. Compared with the general target recognition method, the present invention has the advantages that it can still meet the requirement of identifying the mine target in the noisy sonar image, and can still obtain the accurate outline of the mine target under the condition that the image of the mine target is blurred.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com