Inorganic lightweight aggregate thermal mortar for steel structure

A technology of inorganic light aggregate and thermal insulation mortar, which is applied in the field of building materials, can solve the problems of poor fireproof performance of steel structures and high requirements for fireproof performance of enclosure structures, and achieve improved construction performance, construction performance and water retention performance, and improved and easy installation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of inorganic lightweight aggregate thermal insulation mortar for steel structure, comprising the steps of:

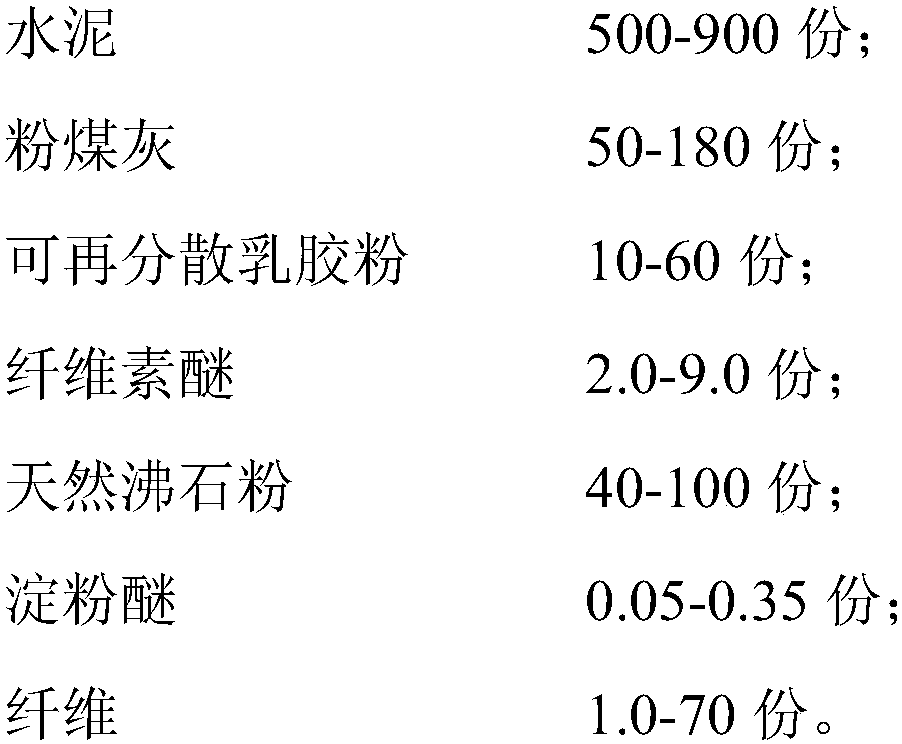

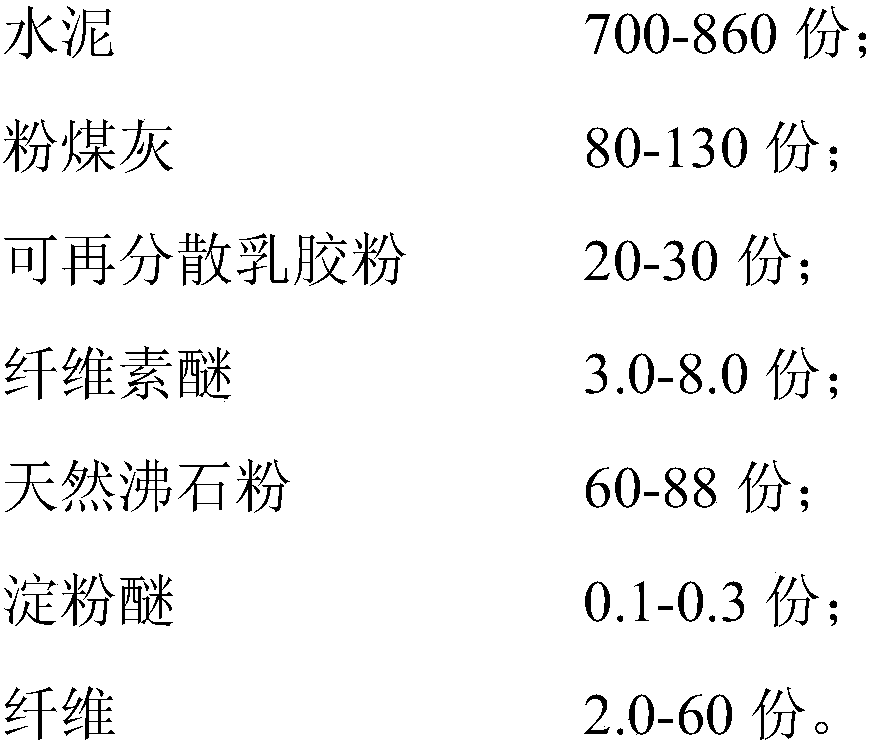

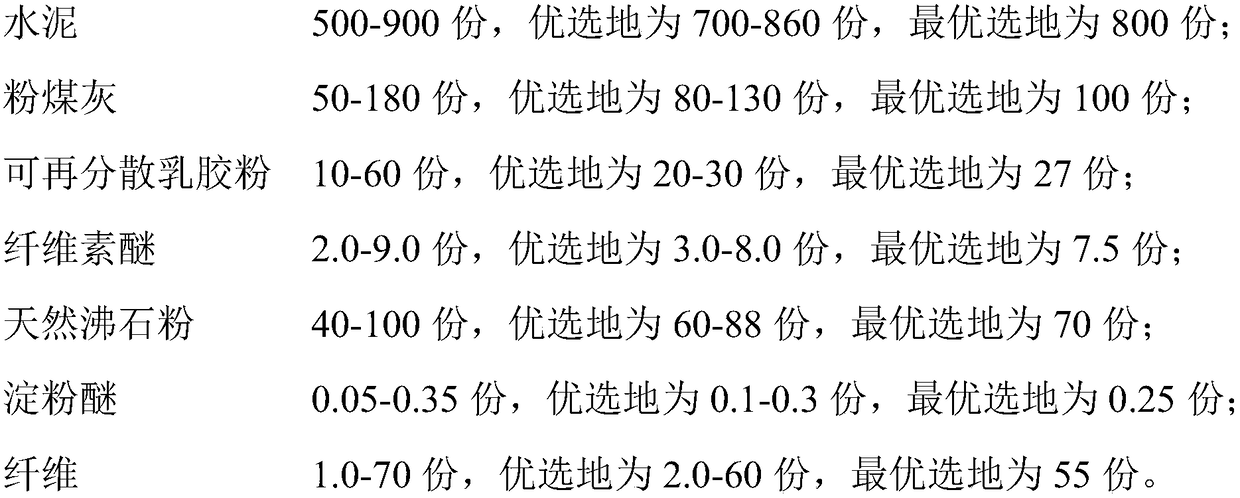

[0040] S1: Take 500-900 parts of cement, 50-180 parts of fly ash, 10-60 parts of redispersible latex powder, 2.0-9.0 parts of cellulose ether, 40-100 parts of natural zeolite powder, and starch ether in the following mass parts 0.05-0.35 parts and 1.0-70 parts of fiber, dry mixed and evenly prepared into powder;

[0041] S2: Take the lightweight aggregate according to the ratio of the mass (kg) of the powder to the volume (L) of the lightweight aggregate: 1:3.5-4.0;

[0042] S3: Mix lightweight aggregate and powder evenly to make insulating sand;

[0043] S4: Add water to the thermal insulation sand and stir until the consistency is 75-85mm to prepare mortar.

[0044] Among them, "consistency 75-85mm" refers to the cone penetration value of the mortar (also known as the penetration value), which means tha...

Embodiment 1

[0048] An inorganic lightweight aggregate thermal insulation mortar for steel structures, which consists of 42.5 grade ordinary Portland cement 750, fly ash 80, ethylene vinyl acetate latex powder 20, hydroxyethyl methyl Cellulose ether 6.0, natural zeolite powder 65, starch ether 0.2, and glass wool 45 parts are prepared into powder; then the mass (Kg) of the powder: the volume (L) of closed-cell perlite is 1:3.5. Closed-cell perlite, mixed to make mortar raw material. After adding water and mixing, the consistency of the mortar is controlled at (80±5)mm. The thermal conductivity of the obtained thermal insulation mortar is 0.094W / m·k, the compressive strength is 2.8MPa, and the tensile bond strength is 0.30MPa.

Embodiment 2

[0050]An inorganic lightweight aggregate thermal insulation mortar for steel structures, which consists of 42.5 grade ordinary Portland cement 790, fly ash 100, ethylene vinyl acetate latex powder 25, hydroxyethyl methyl Cellulose ether 7.0, natural zeolite powder 74, starch ether 0.2 and PP fiber 3.0 parts are prepared into a powder; then the mass (Kg) of the powder: the volume (L) of closed-cell perlite is 1:3.6. Closed-cell perlite, mixed to make mortar raw material. After adding water and mixing, the consistency of the mortar is controlled at (80±5)mm. The thermal conductivity of the obtained thermal insulation mortar is 0.096W / m·k, the compressive strength is 3.1MPa, and the tensile bond strength is 0.33MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com