Patents

Literature

30results about How to "Luxurious appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

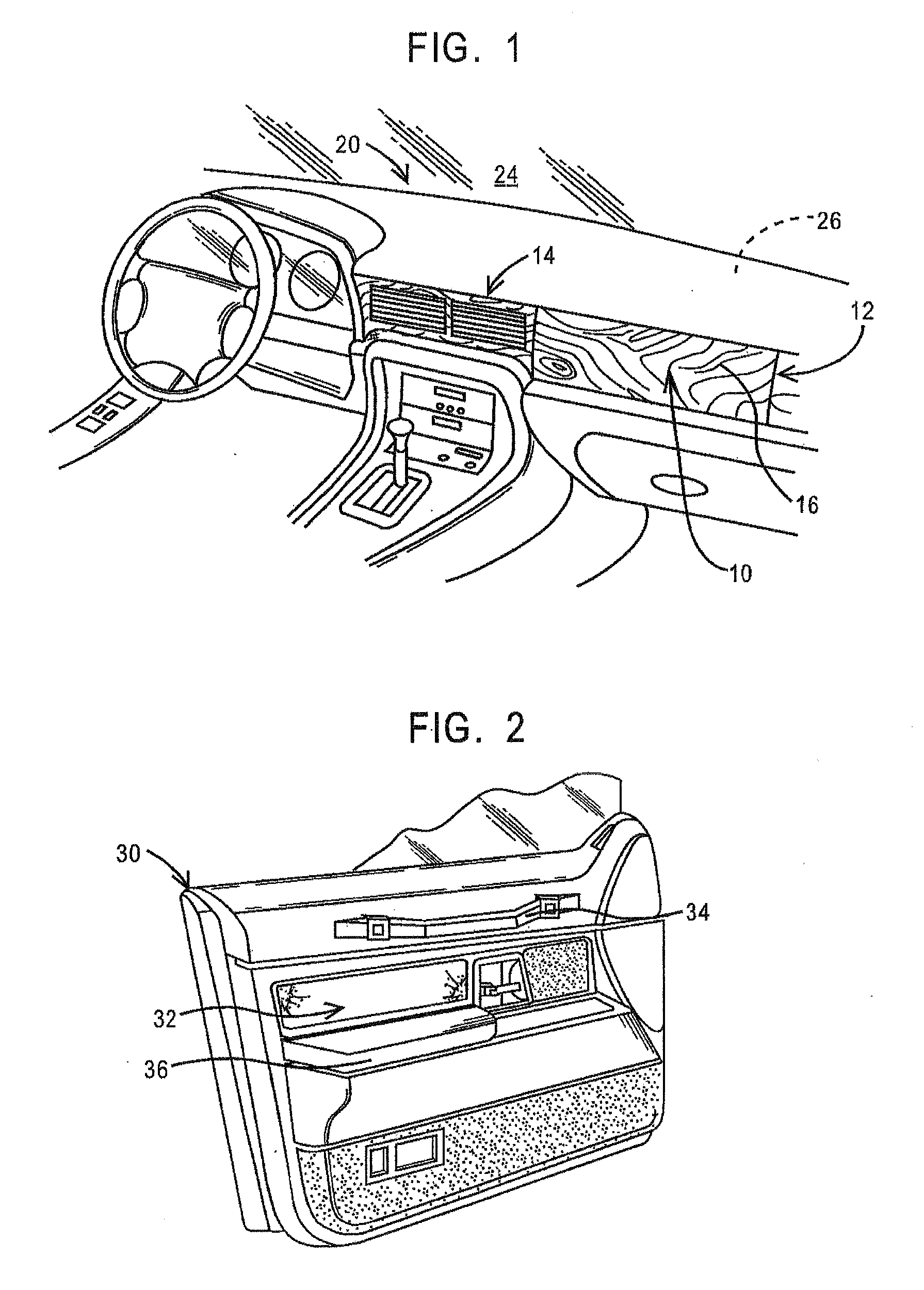

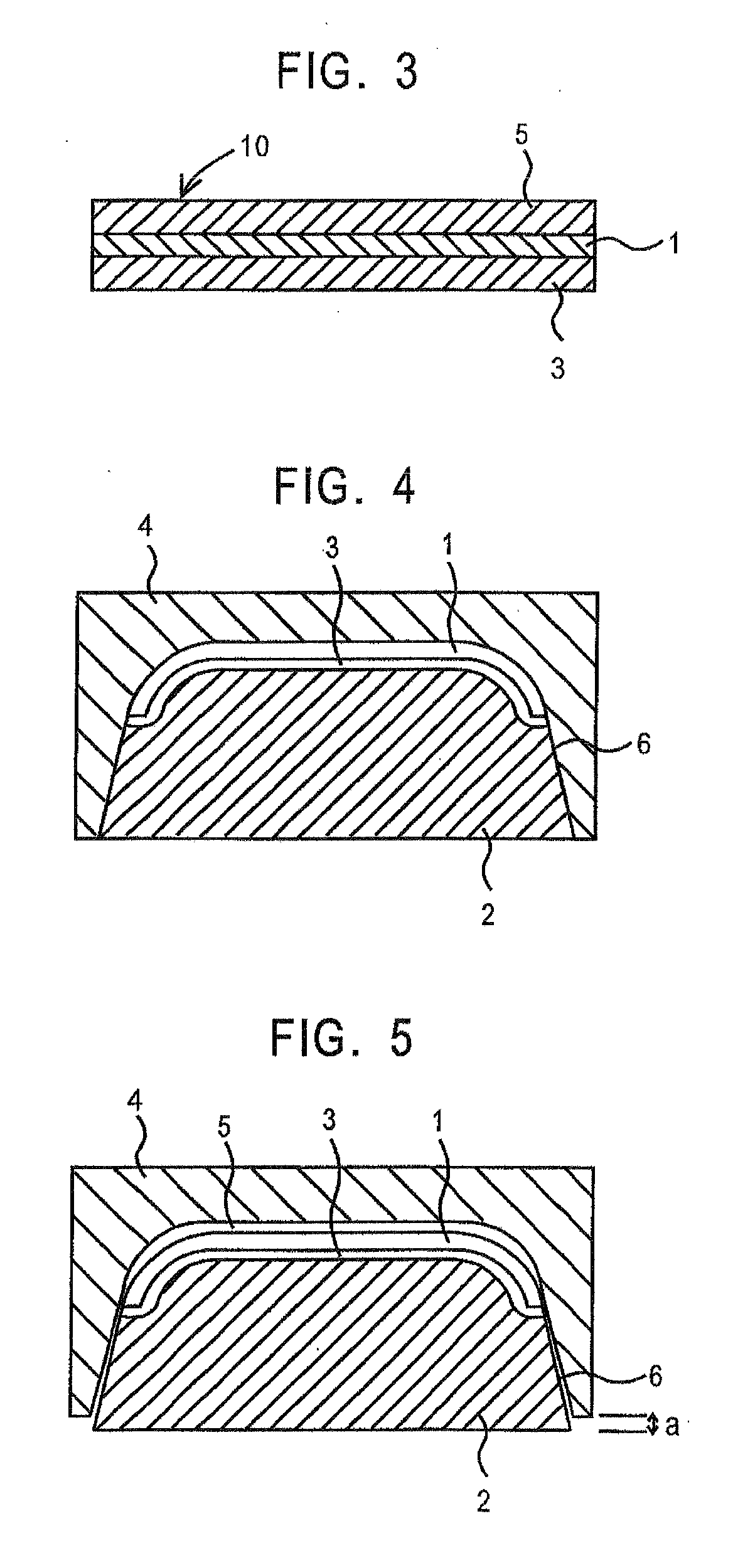

In-Mold Lamination Of Decorative Products

InactiveUS20090174121A1Luxurious appearanceExceptional depth of imageMouldsSynthetic resin layered productsEngineeringDecorative product

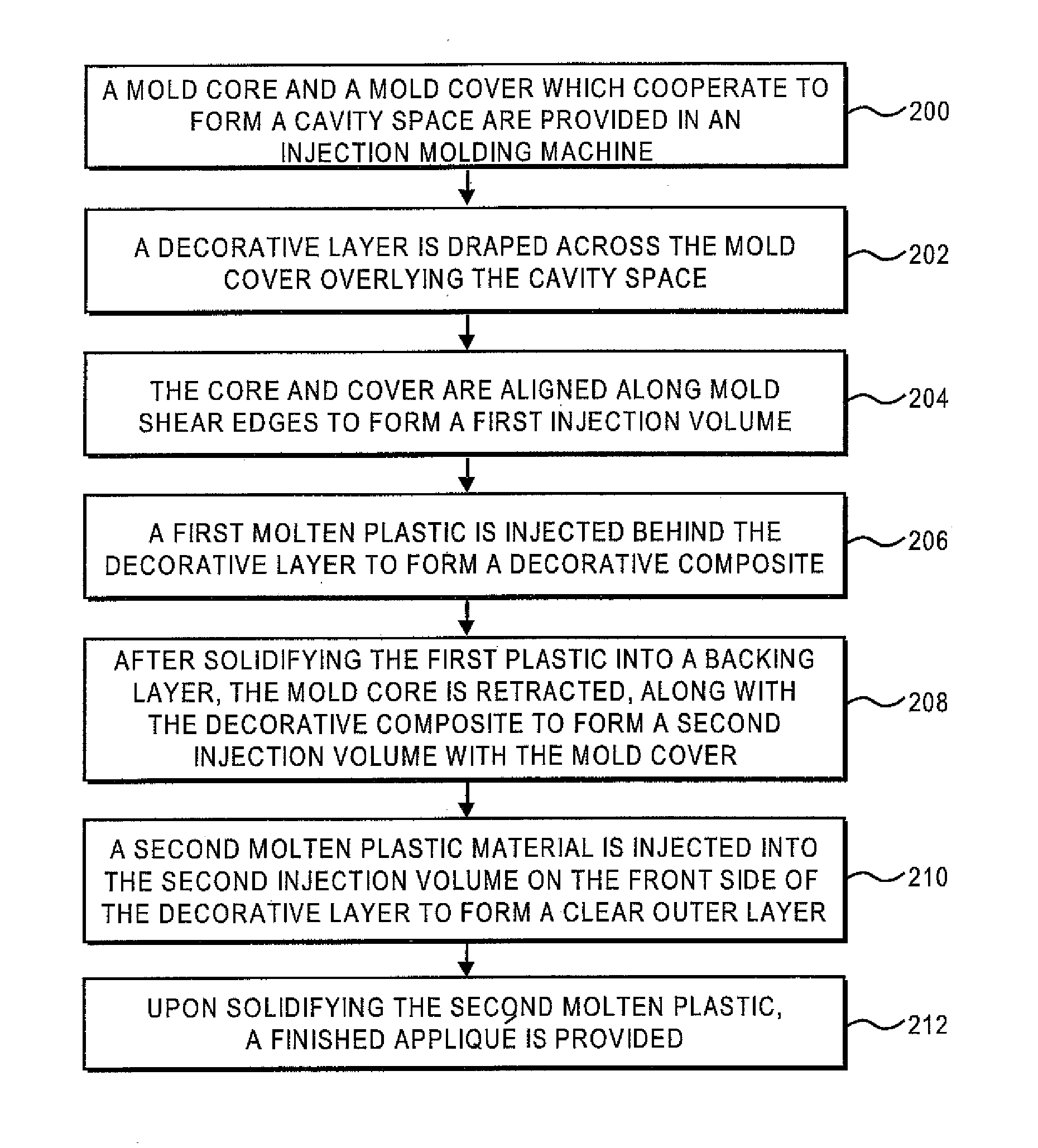

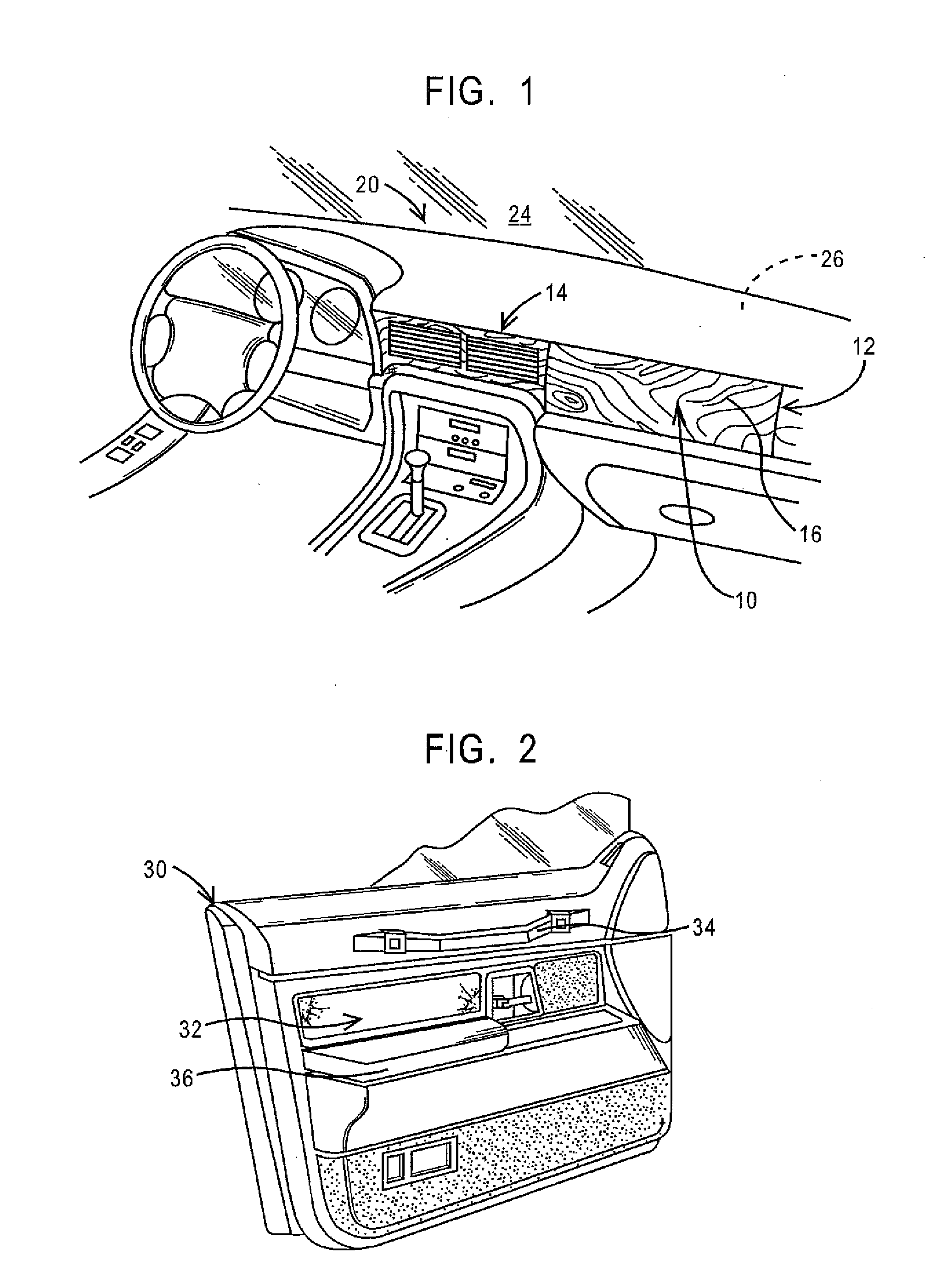

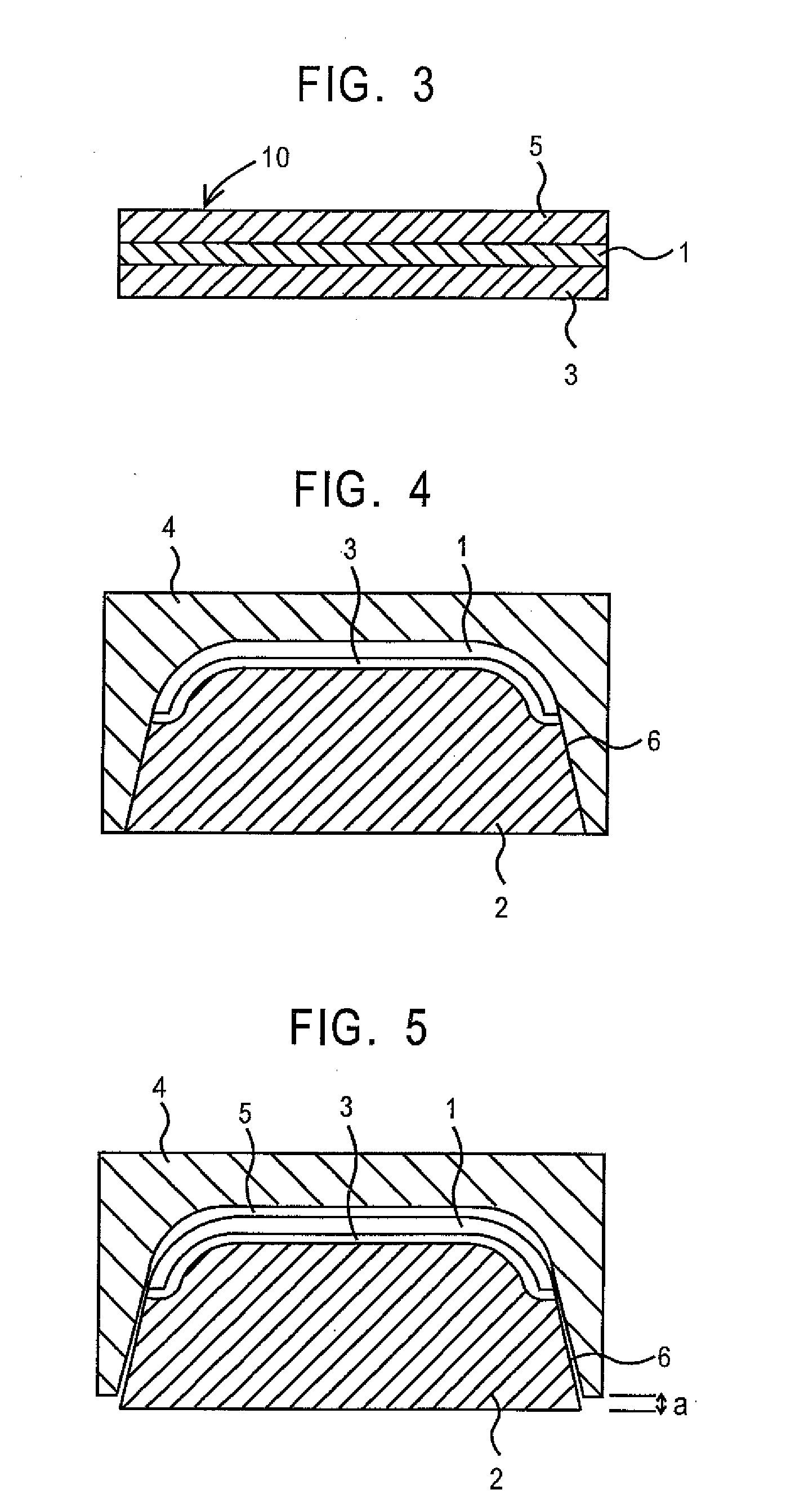

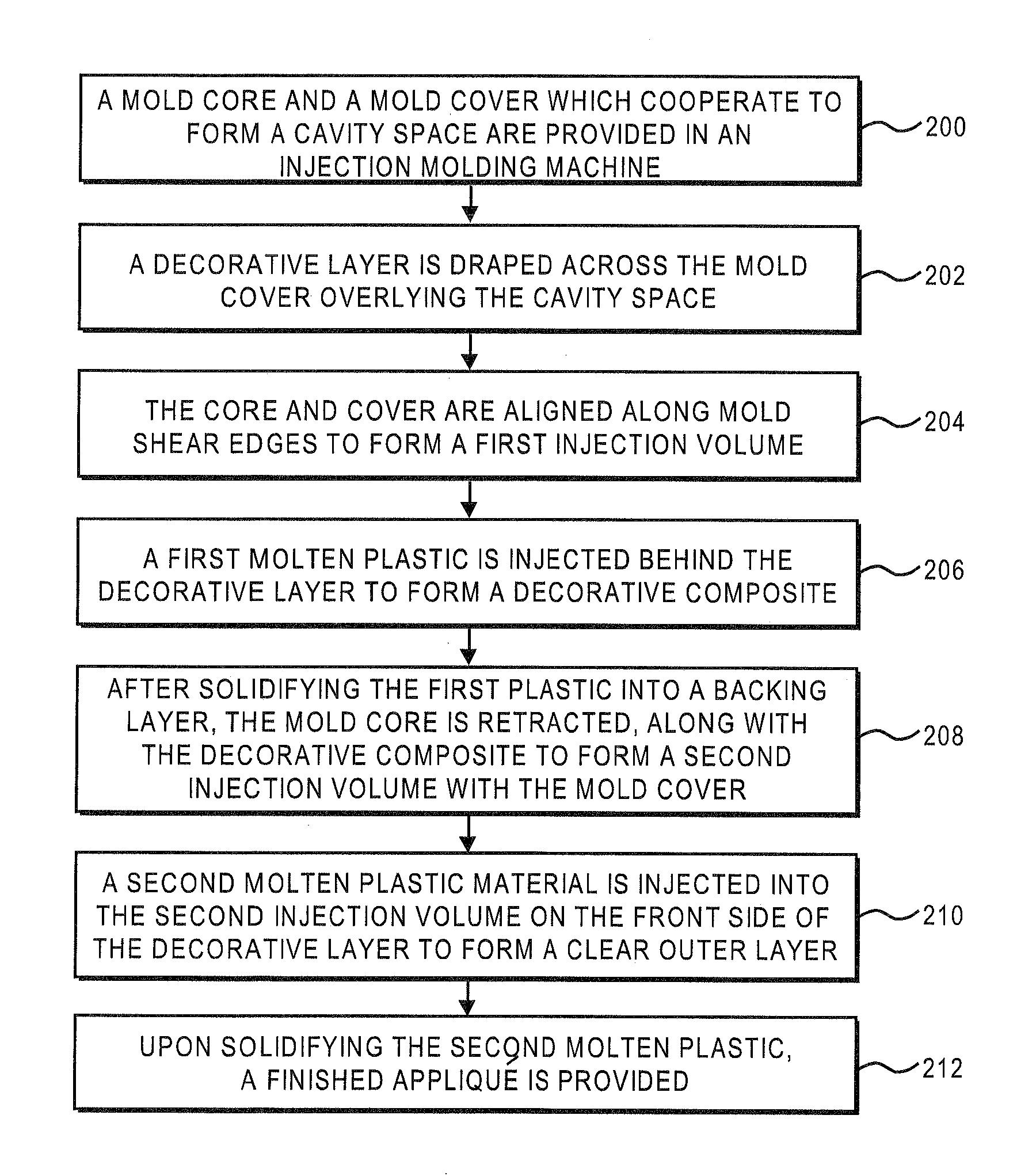

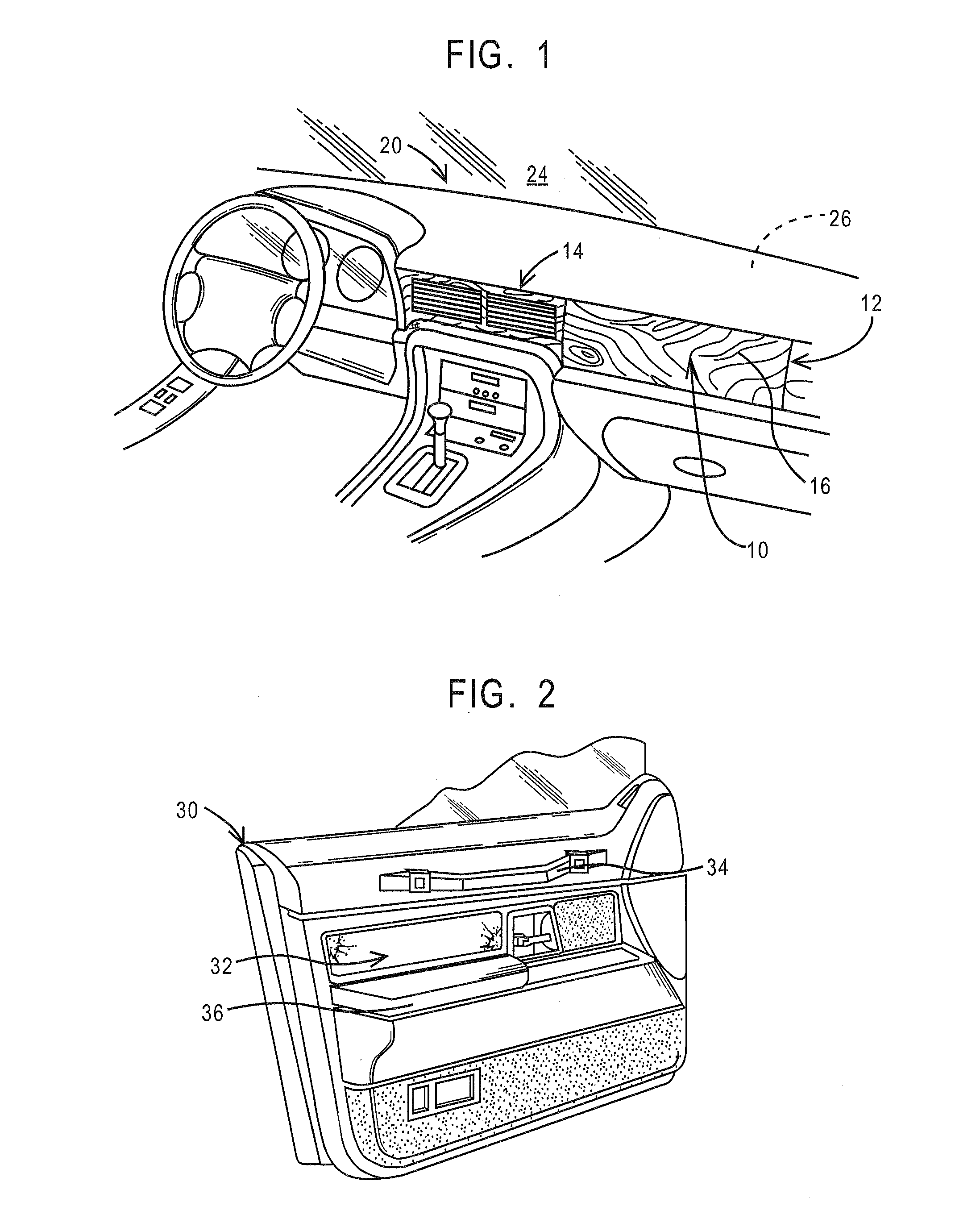

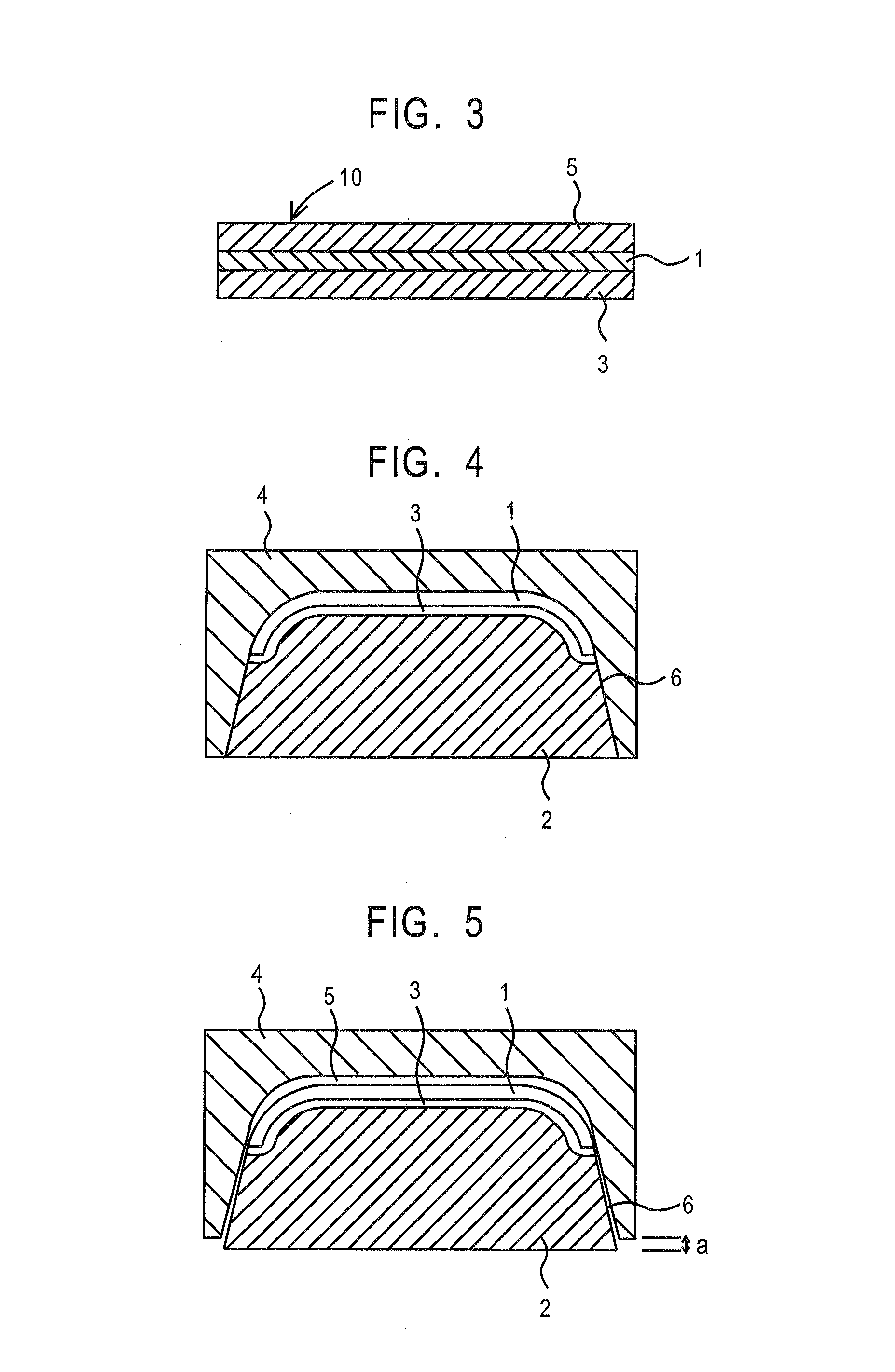

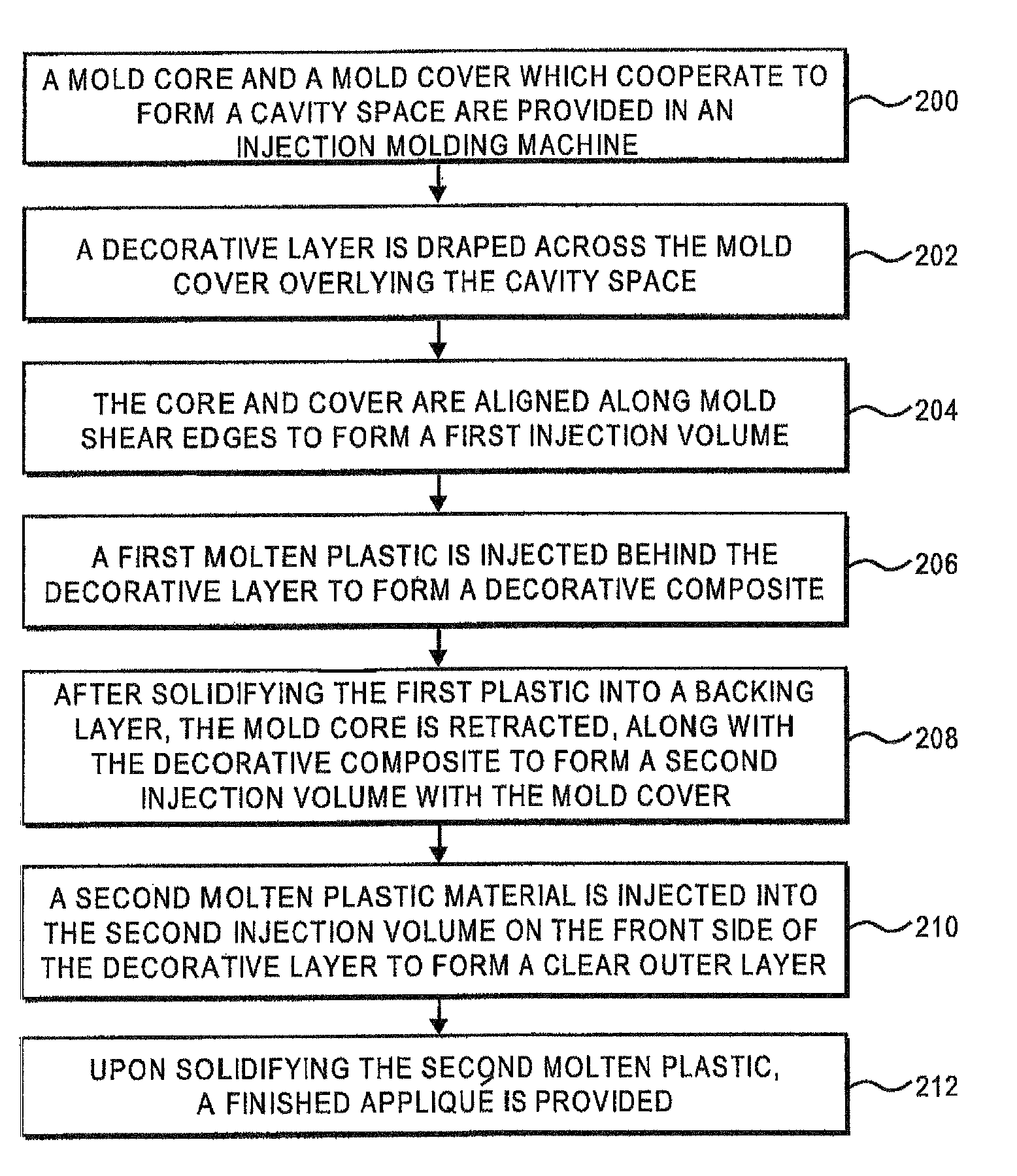

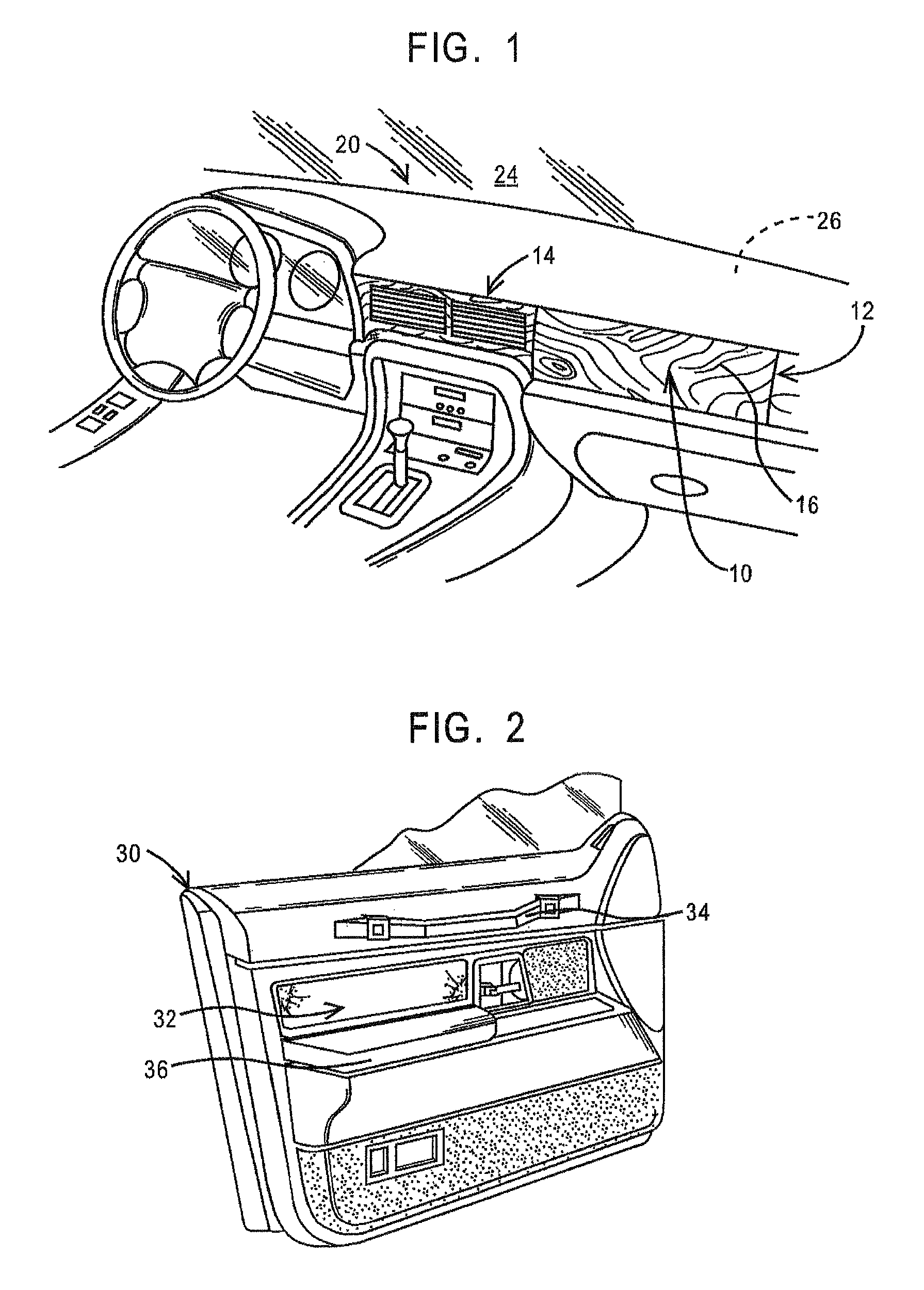

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer. A method is also disclosed for coating the exposed surface of the decorative layer between injection of the backing and outer layers to impart a desired visual effect or repair the surface. Use of multiple layers of decorative film, clear plastic and colored / opaque plastic is also disclosed to provide distinguishing visual effects.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

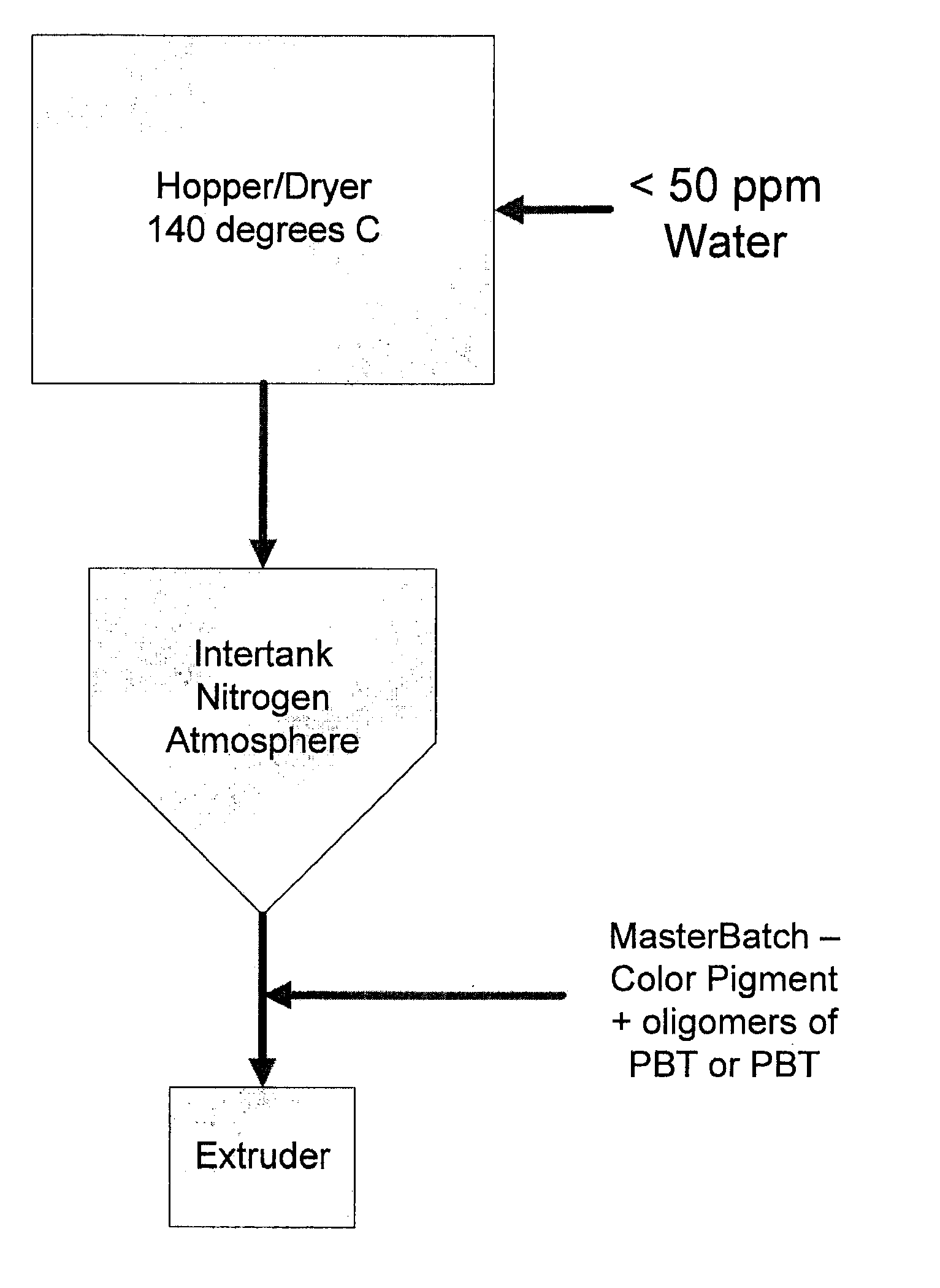

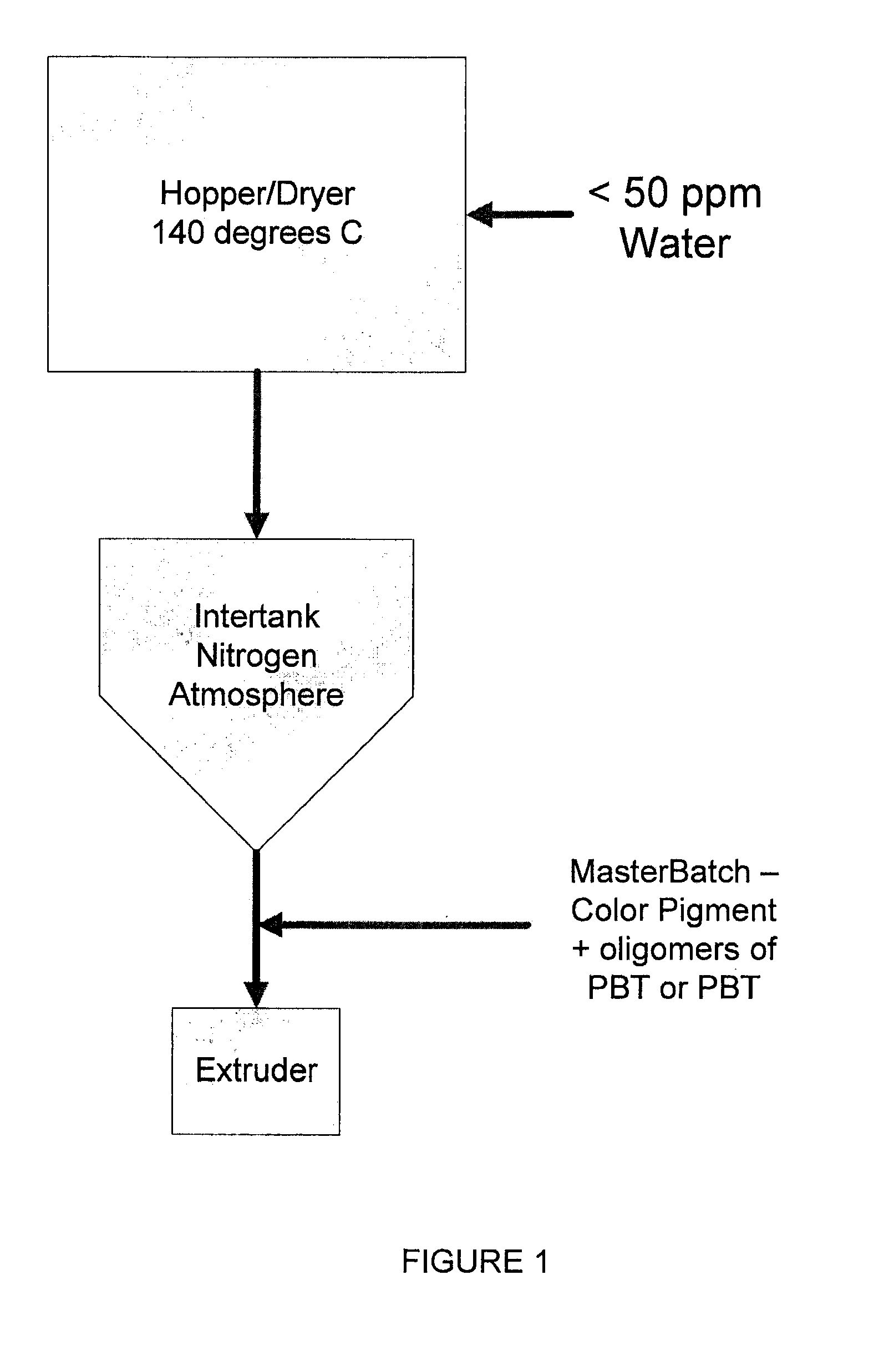

PET Carpet With Additive

InactiveUS20110177283A1Improvement be eliminateLuxurious appearanceLayered productsMelt spinning methodsWater contentFiber

A method of forming PET fiber for carpet is disclosed. The method includes drying PET material so it has a water content of less than 50 ppm. Adding color to the PET material, heating the PET material to a temperature less than 330° C. so the PET has a viscosity between about 0.68 and 0.86, and extruding the PET through a spinneret to form fibers.

Owner:FUTURIS AUTOMOTIVE INTERIORS US

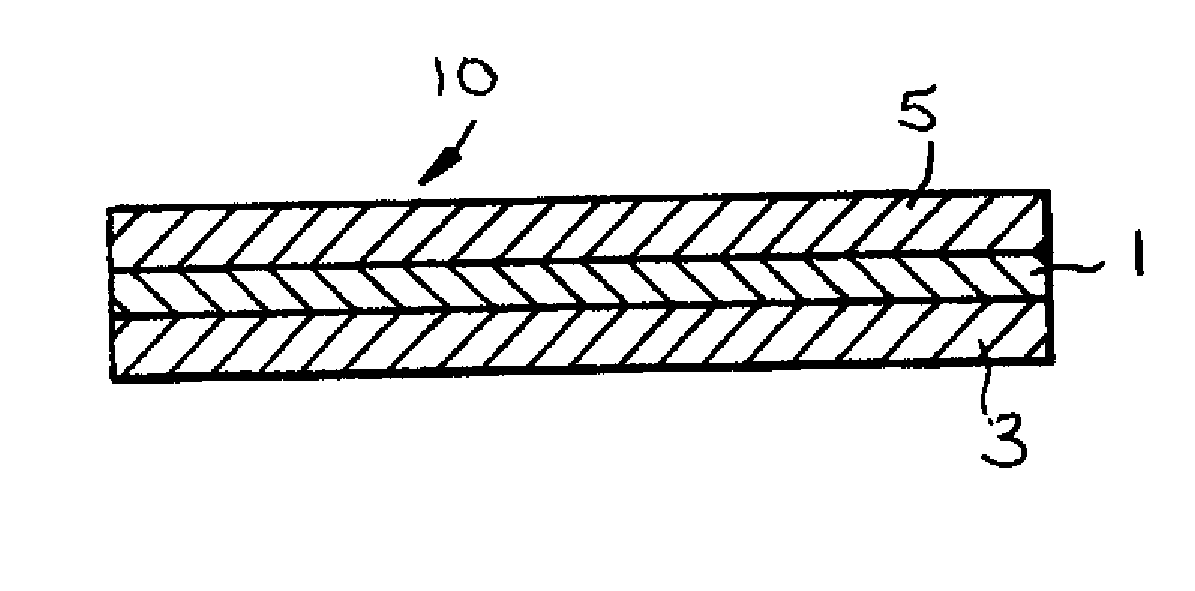

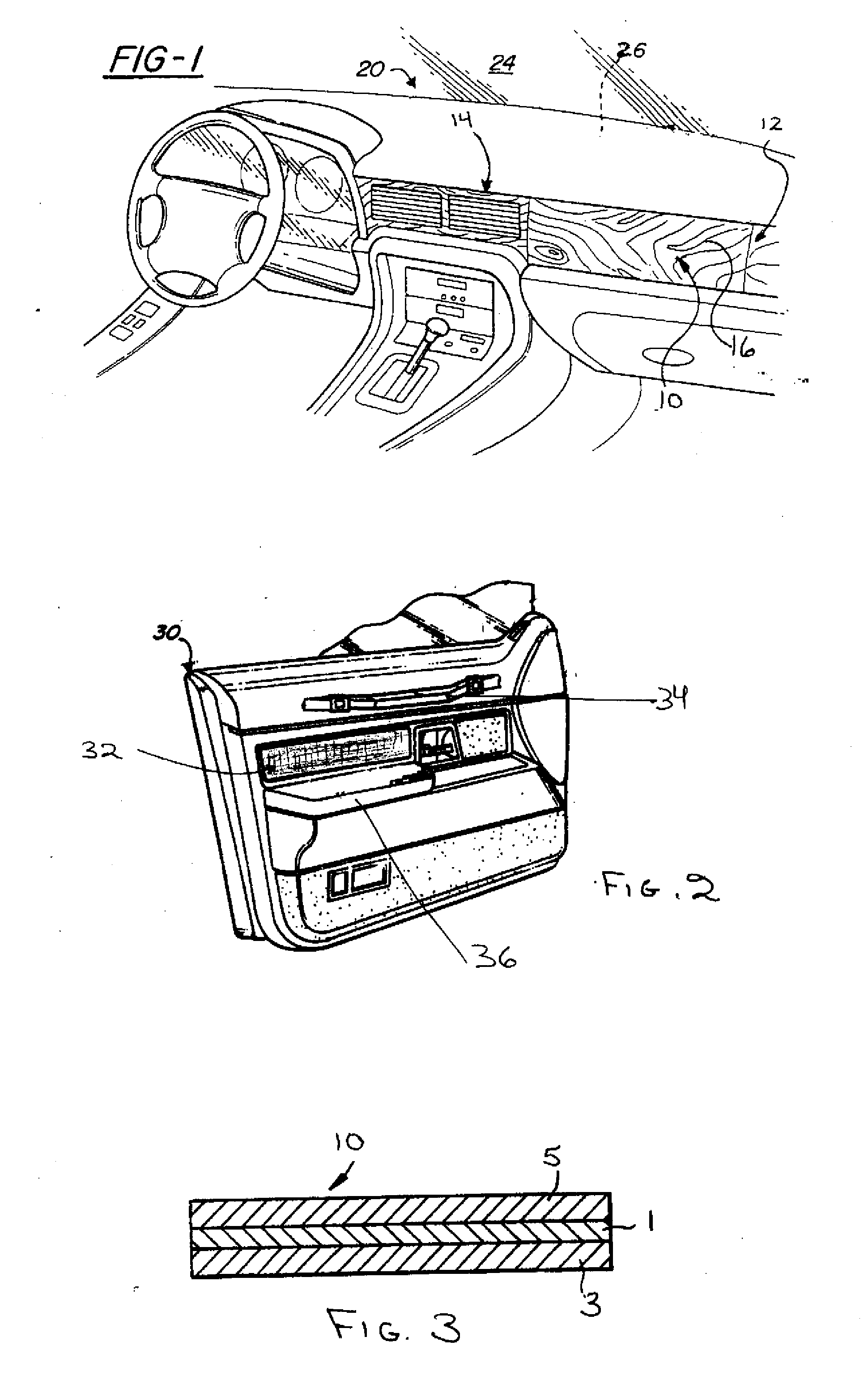

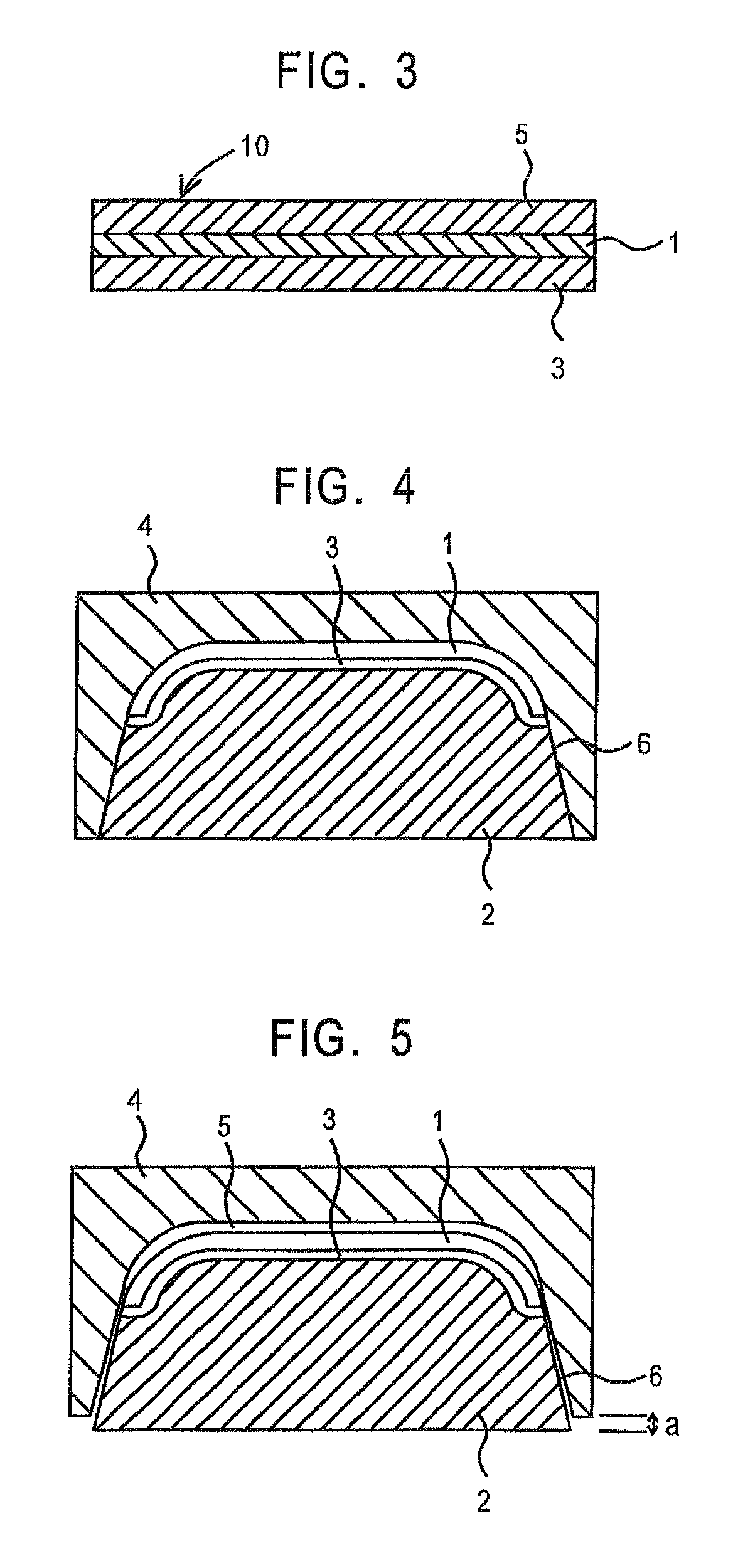

In Mold Lamination Of Decorative Products

InactiveUS20070141353A1Exceptional depth of imageThinner cross-sectionMouldsSynthetic resin layered productsDecorative productElectrical and Electronics engineering

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

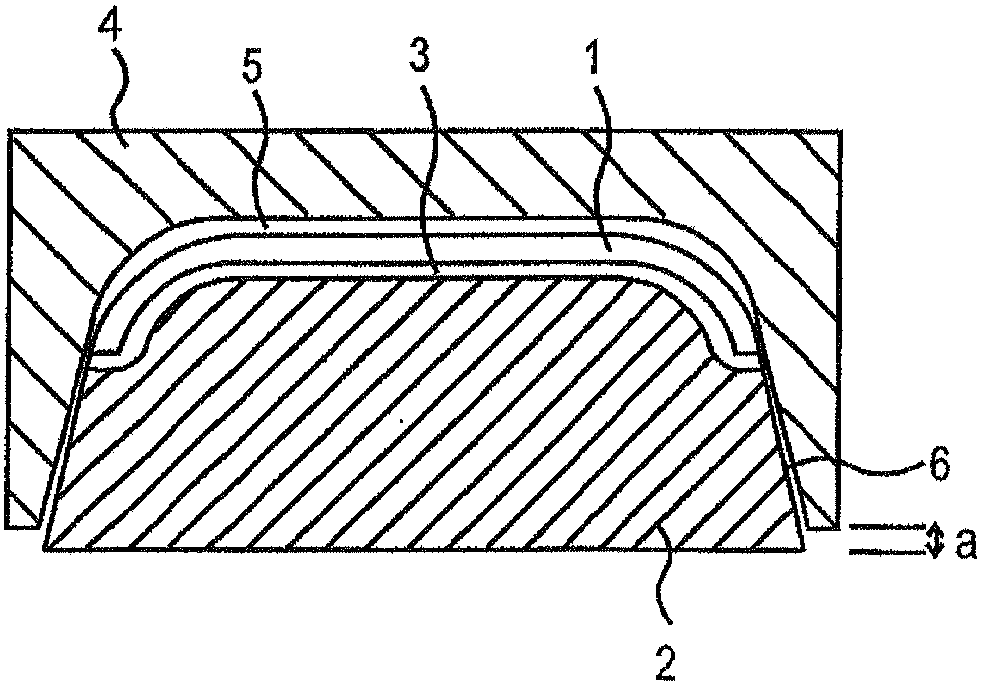

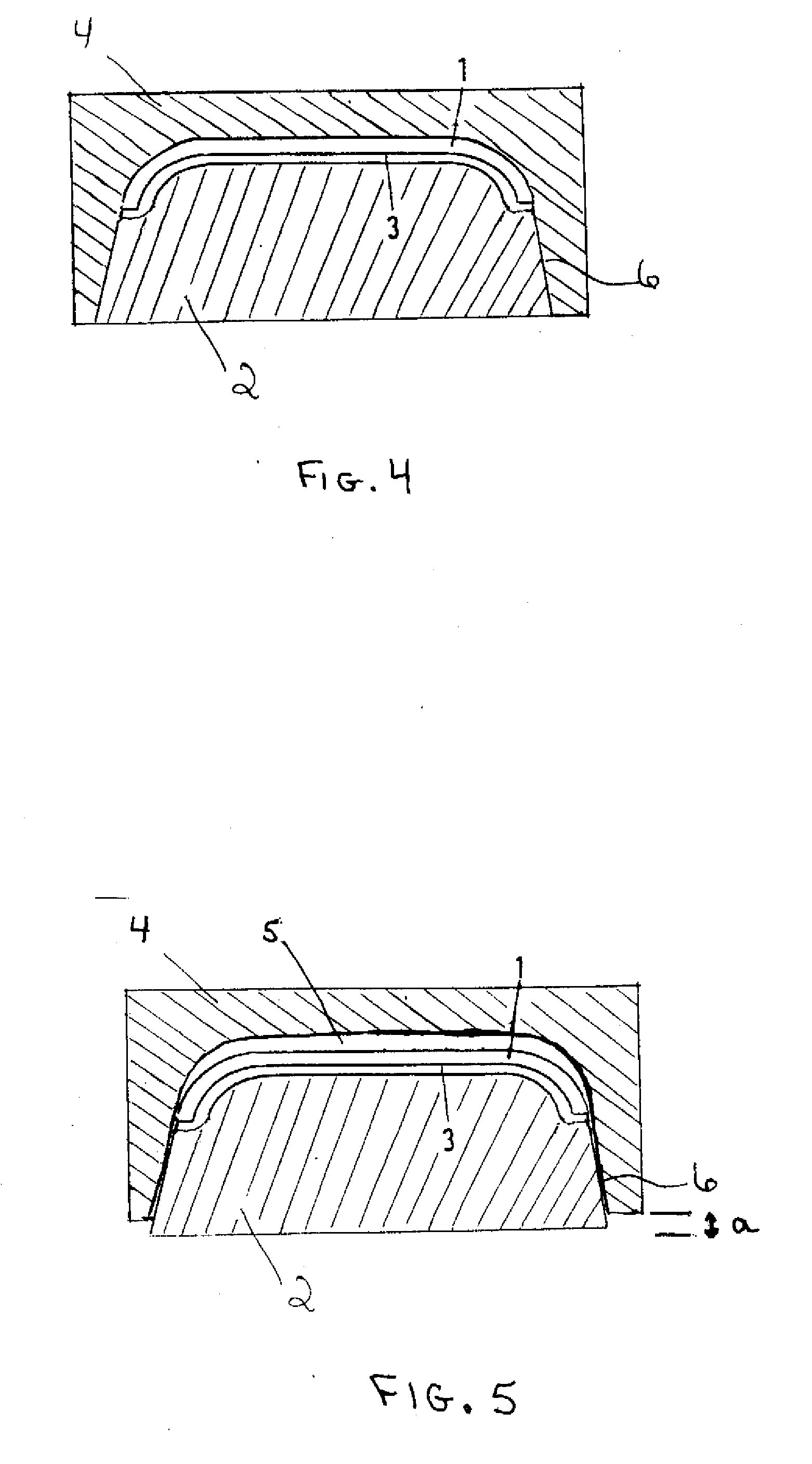

In-Mold Lamination Of Decorative Products

InactiveUS20070194487A1Exceptional depth of imageThinner cross-sectionMouldsSynthetic resin layered productsDecorative productElectrical and Electronics engineering

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer. A method is also disclosed for coating the exposed surface of the decorative layer between injection of the backing and outer layers to impart a desired visual effect or repair the surface.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

In mold lamination of decorative products

InactiveUS7674414B2Exceptional depth of imageLuxurious appearanceMouldsSynthetic resin layered productsEngineeringDecorative product

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

In-mold lamination of decorative products

InactiveUS7981342B2Exceptional depth of imageLuxurious appearanceMouldsSynthetic resin layered productsDecorative laminateMultiple layer

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer. A method is also disclosed for coating the exposed surface of the decorative layer between injection of the backing and outer layers to impart a desired visual effect or repair the surface. Use of multiple layers of decorative film, clear plastic and colored / opaque plastic is also disclosed to provide distinguishing visual effects.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

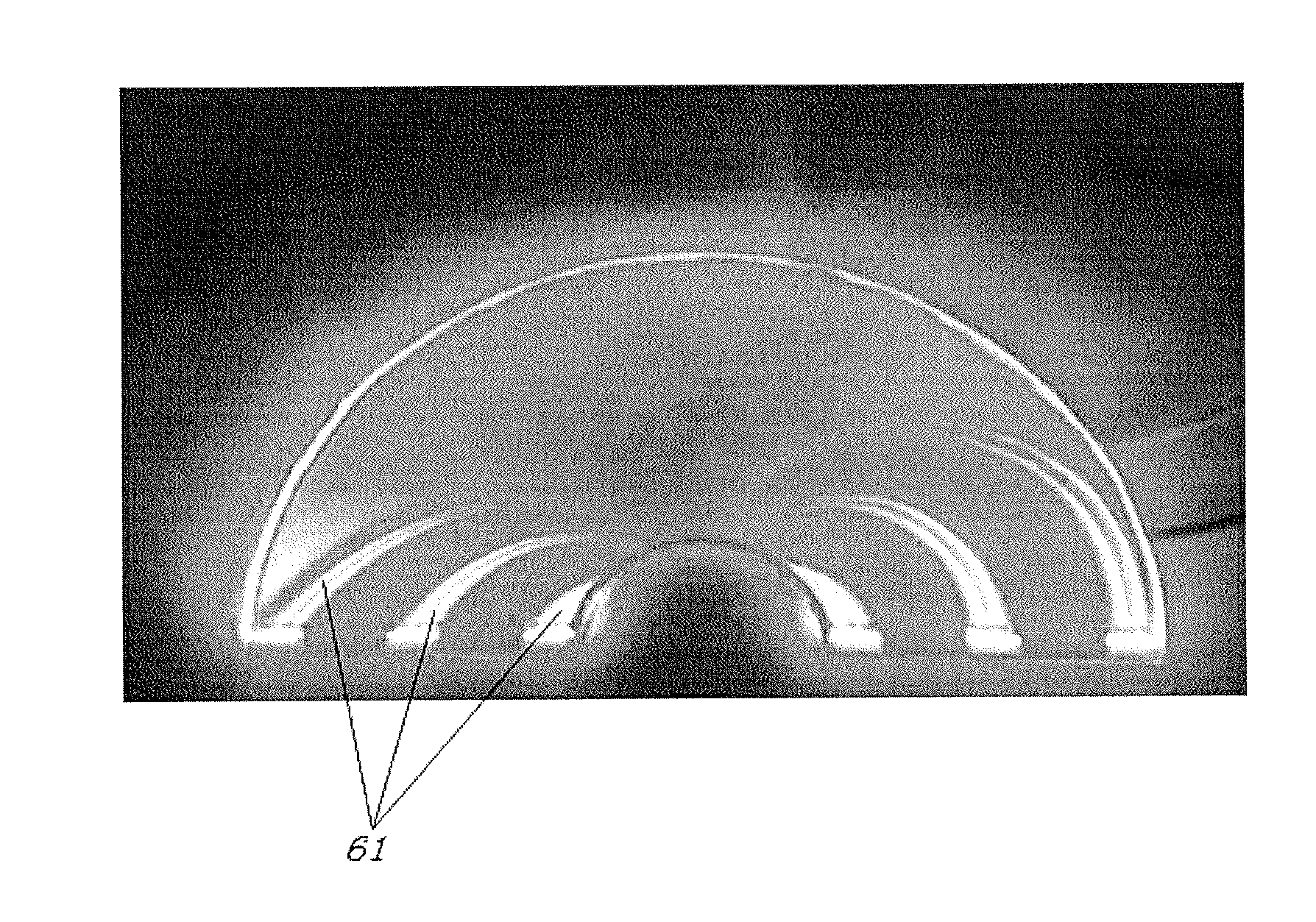

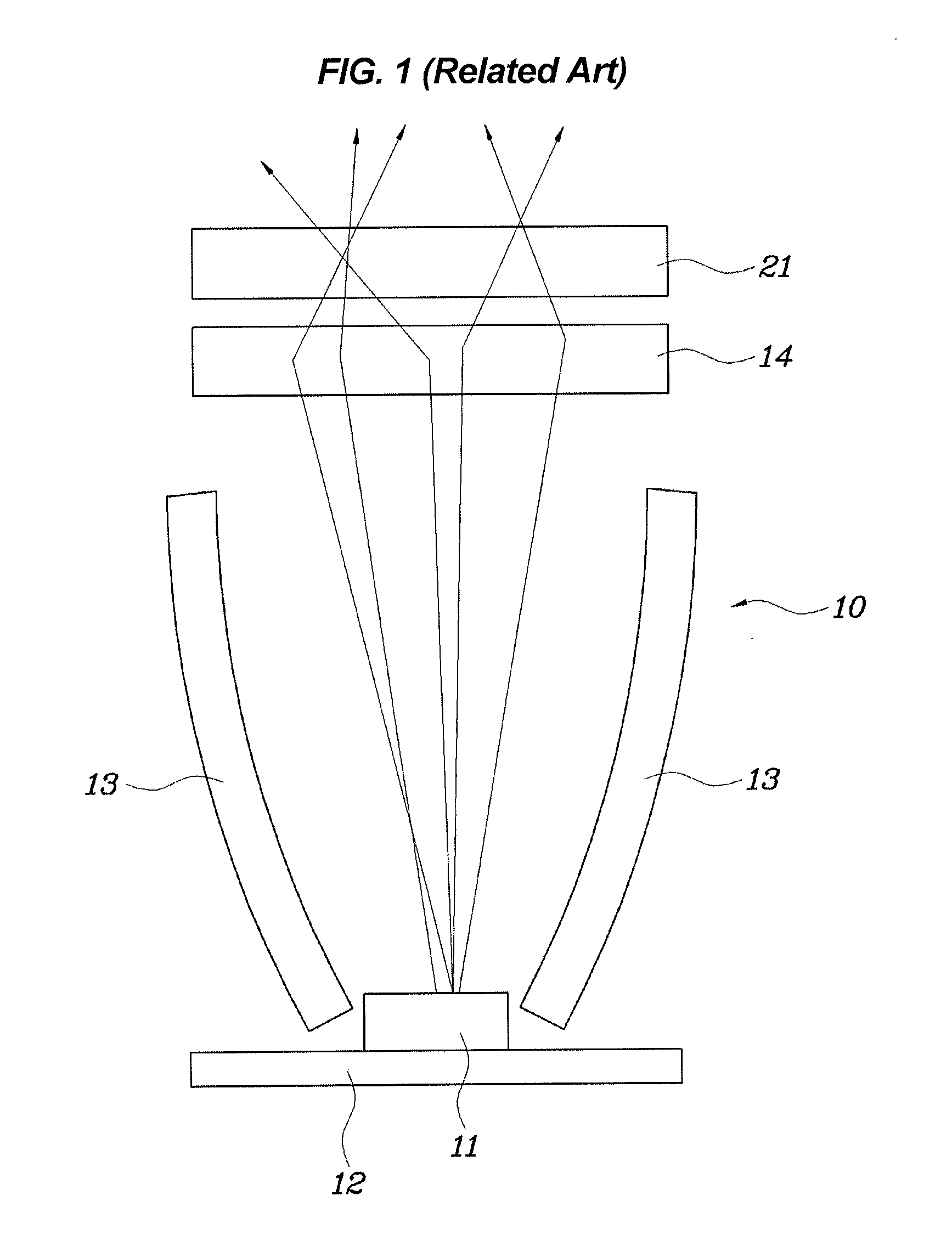

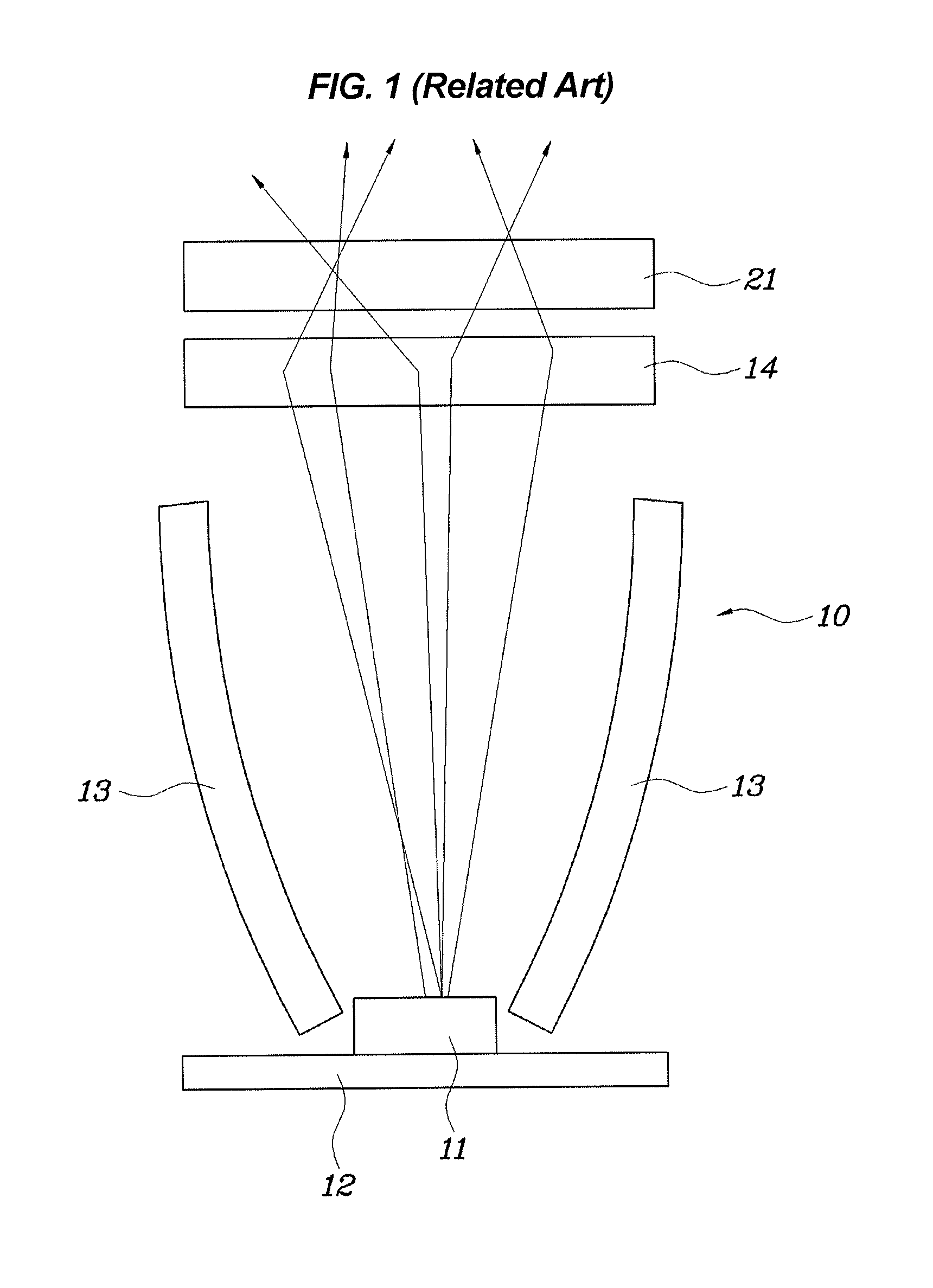

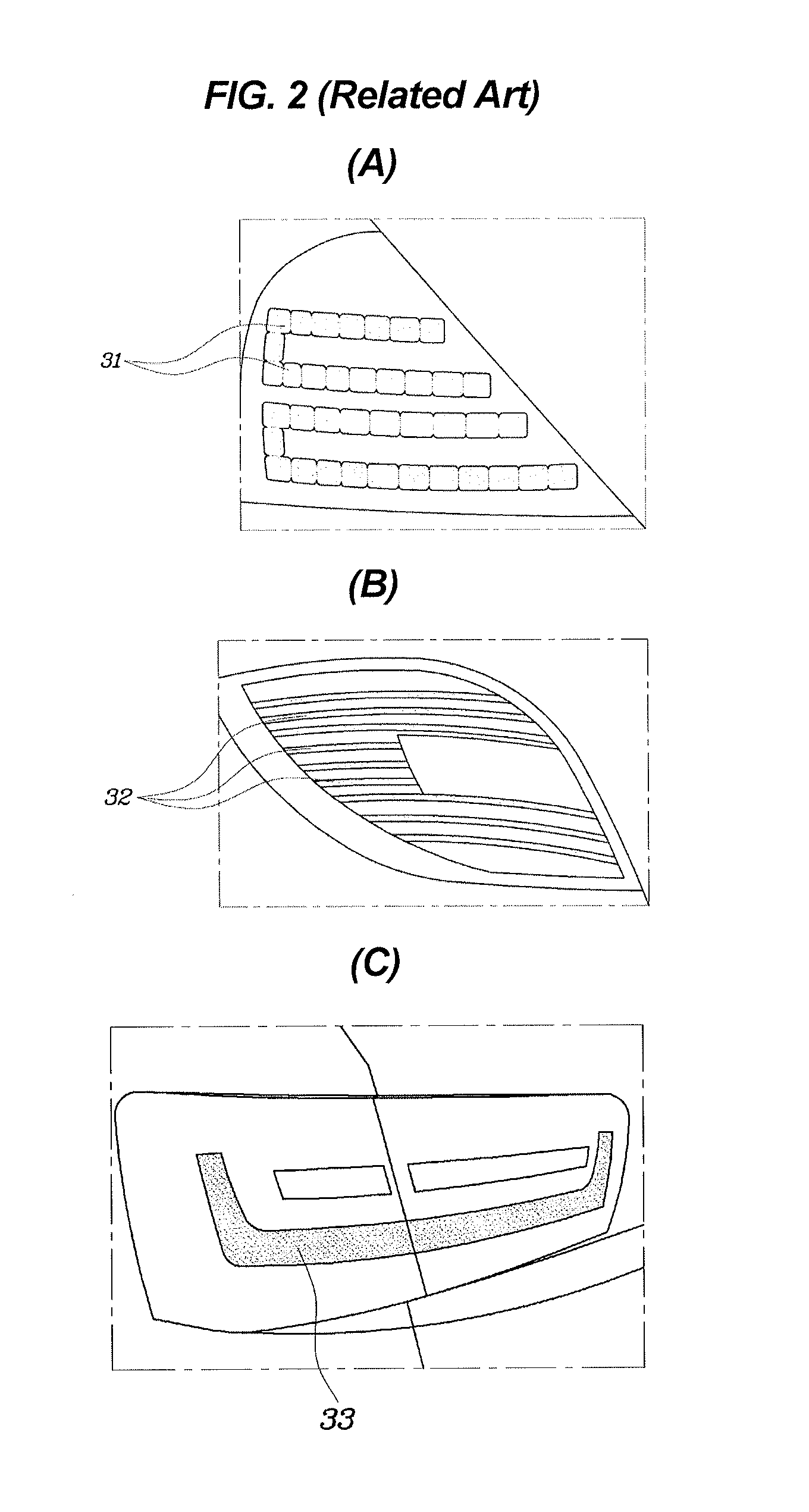

Light source module of lamp for vehicle

ActiveUS20150167918A1Increasing costIncrease awarenessPlanar light sourcesPoint-like light sourceVisibilityLight source

Disclosed is a light source module for a vehicle. The light source module includes an LED light source, a PCB that controls supply of current to the LED light source, a patterned film disposed on the PCB and provided with an optical pattern which enables a stereoscopic light-emission image of a desired pattern to be formed when light from the LED light source is emitted thereto, and optical resin that is disposed on the patterned film and uniformly transmits the light from the LED light source to the entire range of the patterned film. The light source module improves visibility of the LED light source and makes a lamp using the light source module look luxurious by using a hidden effect of a deposited film even when the LED light source is not turned on.

Owner:HYUNDAI MOTOR CO LTD

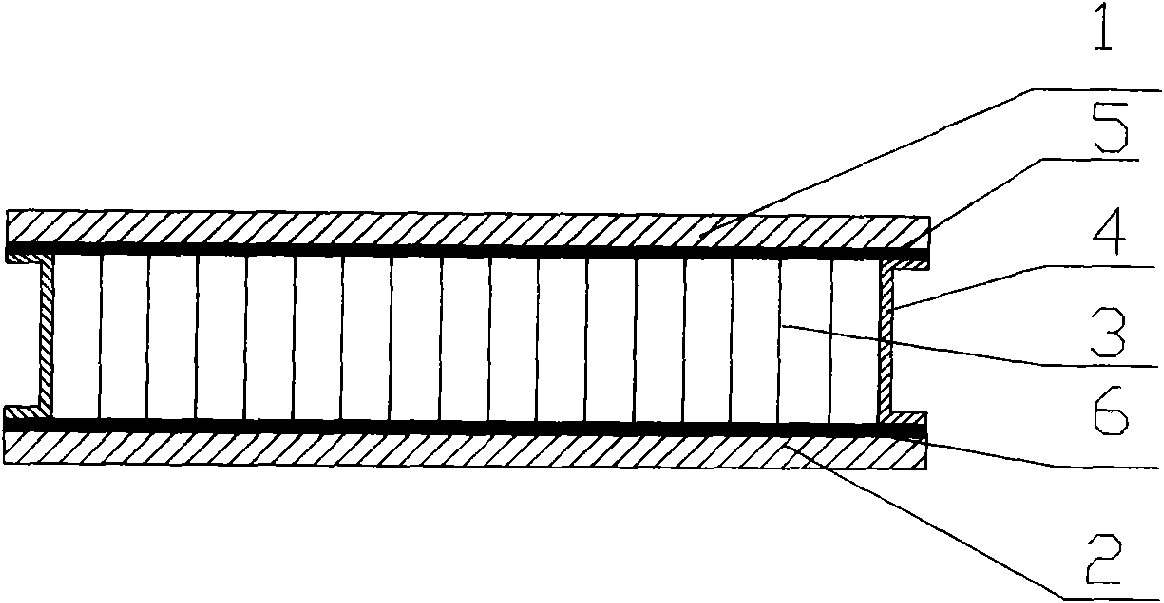

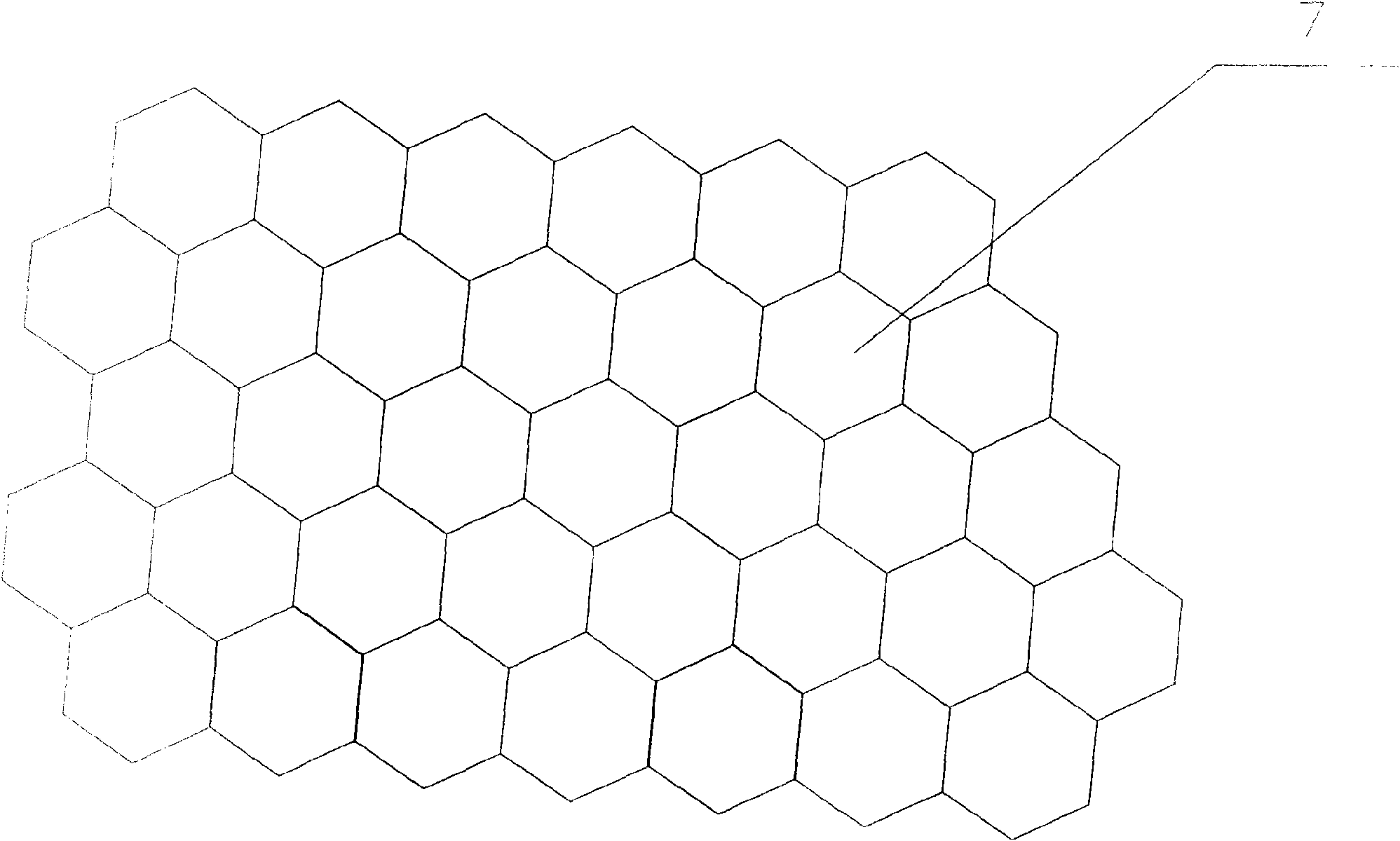

Honeycomb composite clean wall plate

The invention discloses a honeycomb composite clean wall plate, comprising a panel and a soleplate, wherein at least one layer of honeycomb core layer is arranged between the panel and the soleplate; the external edge of the honeycomb layer between the panel and the soleplate is provided with a circle of metal keel. The honeycomb composite clean wall plate has light specific weight, high strength, large rigidity, stable structure and good wind load resistance performance. The honeycomb composite clean wall plate has clean surface and is pressurized and combined to complete by an environment-protective adhesive and by totally sealed dustless operation and the honeycomb plate composite equipment at high temperature, has no smell, no toxicity and no three wastes during the production and application process, leads the honeycomb plate to be firmer, more rigid, more straight, fireproof, waterproof and electrostatic-proof, and is a green environment-protective wall material which has high quality, light weight, high strength and luxurious surface.

Owner:北京中玉仁技术有限公司

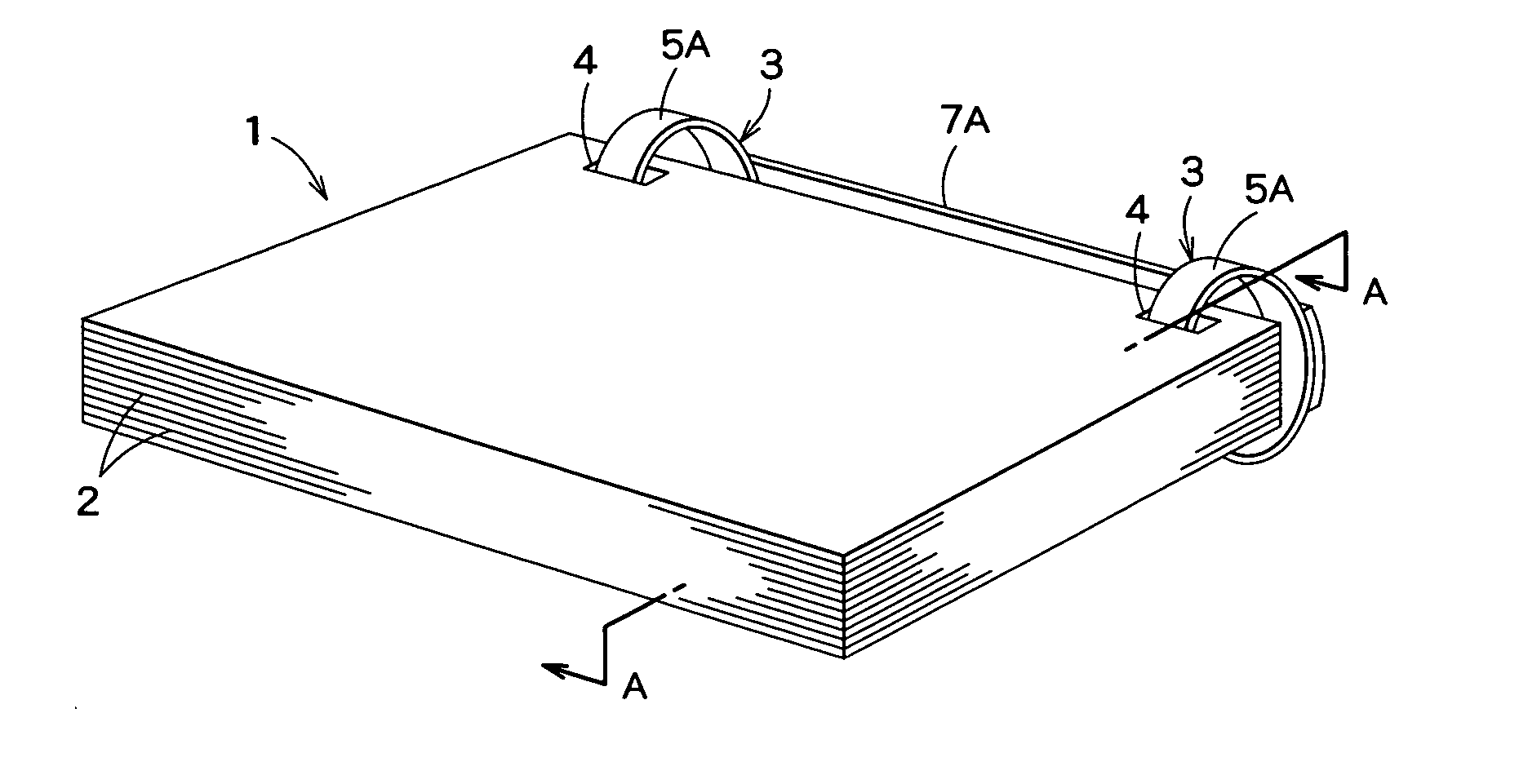

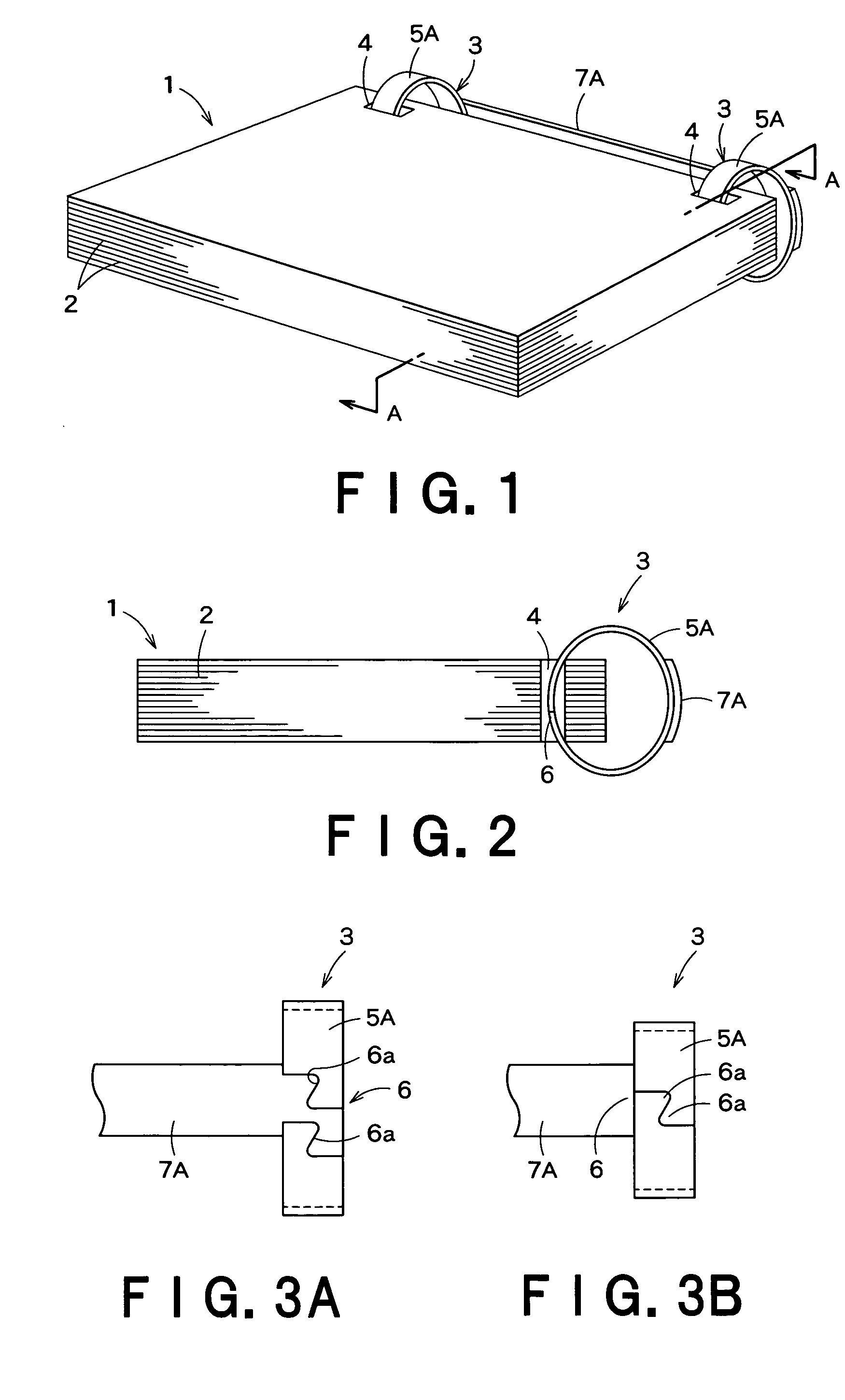

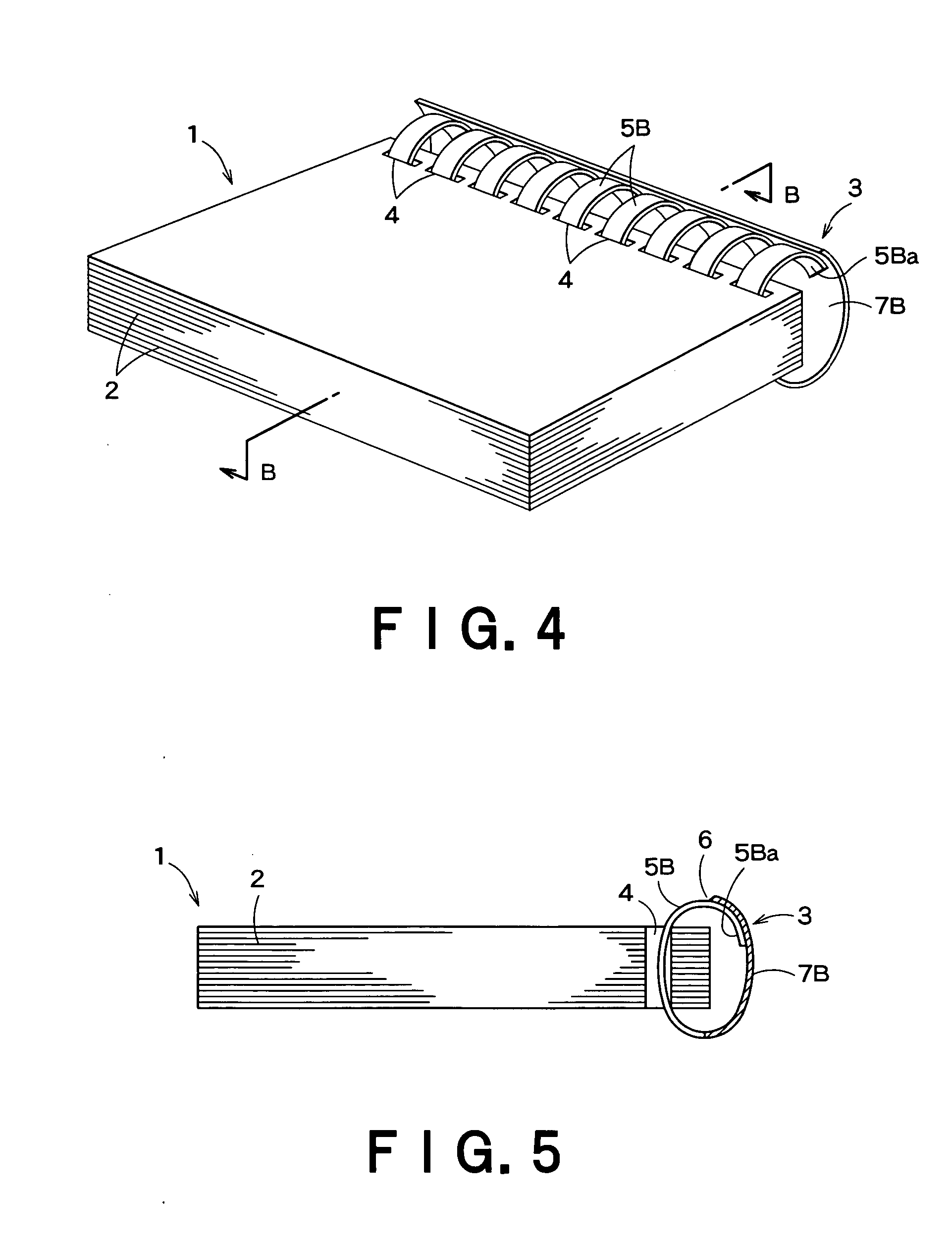

Waterproof book

InactiveUS20050230955A1Luxurious appearanceEasy to carryToysFiling appliancesEngineeringMaterial Perforation

A waterproof book can be read during bathing without trouble, is capable of maintaining its original shape, has leaves capable of maintaining the original shape and can be held by one hand for reading. The waterproof book includes: a necessary number of printed waterproof sheets forming leaves and each provided with a plurality of binding perforations on one edge thereof; and a binding member engaged in the binding perforations to bind the superposed waterproof sheets. The binding member has at least two binding loops capable of being closed after being loosely engaged in the two binding perforations of the superposed waterproof sheets, and a connecting part connecting the binding loops.

Owner:FRONTIER 2000

Ecological shell powder embossment coating and interior wall embossment construction method

InactiveCN106630747AUnique decorative effectUnique embossed effectBuilding constructionsWear resistantCarvacryl acetate

The invention relates to environmental-friendly coating, in particular to an ecological shell powder embossment coating and an embossment construction method. The ecological shell powder embossment coating comprises shell powder, hydrated magnesium silicate, vinyl acetate, hydroxyethyl cellulose, polyvinyl alcohol, polydimethylsiloxane, titanium dioxide, propyl alcohol ether, coating wear-resistant hardening agent-aluminum oxide, a nano TiO2 (titanium dioxide) / white carbon black composite photocatalytic material. The ecological shell powder embossment coating has the advantages that the pollution problem caused by 'formaldehyde, benzene, ammonia, radon, an organic compounds TVOC (total volatile organic compound) and alkylphenol ethoxylates' is solved; the problems of yellowing, mildewing, swelling, discolouring, dusting, cracking, low hardness, short service life and generation of large amounts of bacteria after getting damp of a traditional interior wall material are solved. The embossment construction method has the advantages that skin textures of an embossment can reach to a 3D (three-dimensional) effect with bright color, solid figures are realistic and lifelike, people have a feel of be personally on the scene, and a high artistic appreciation value is obtained.

Owner:佟朝富

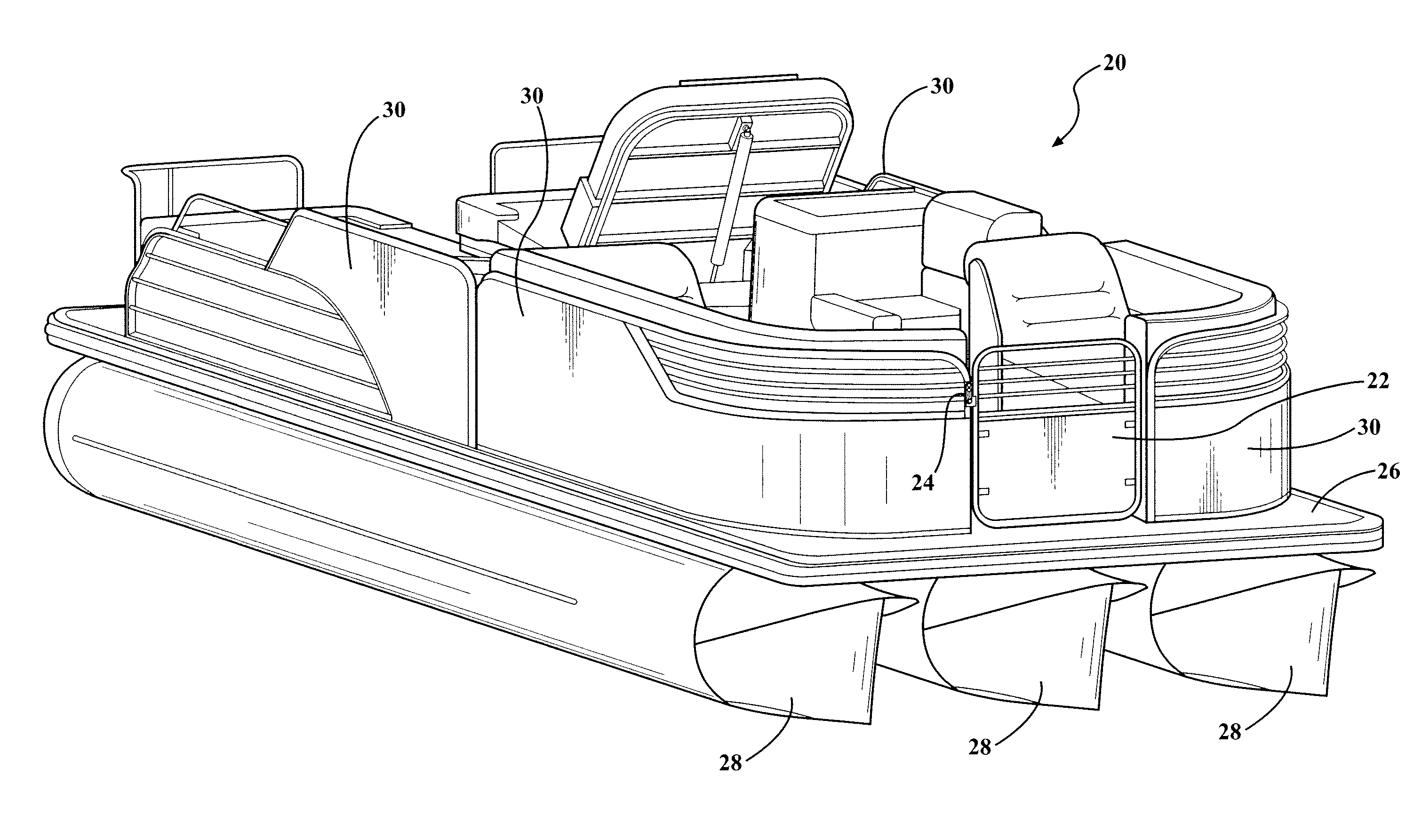

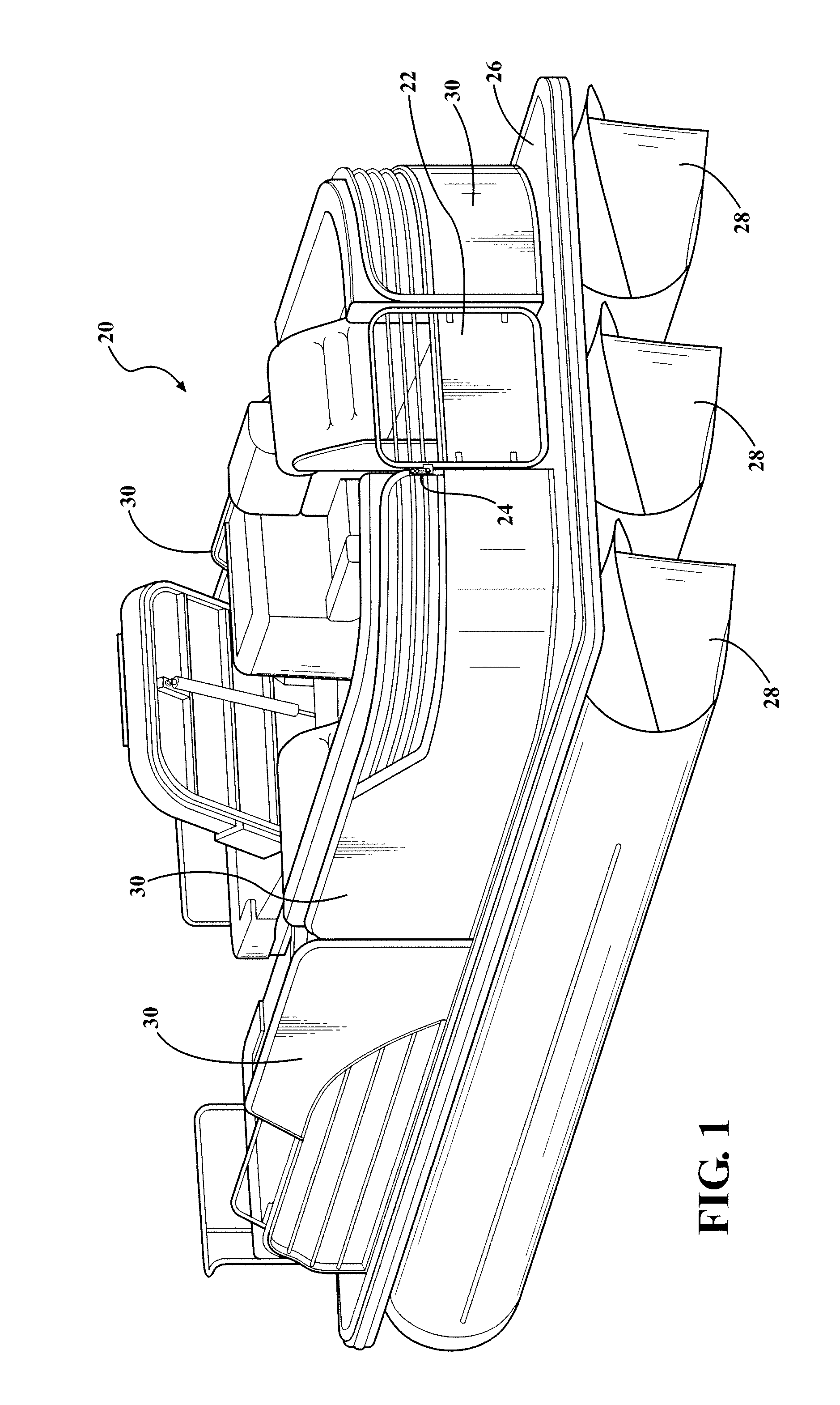

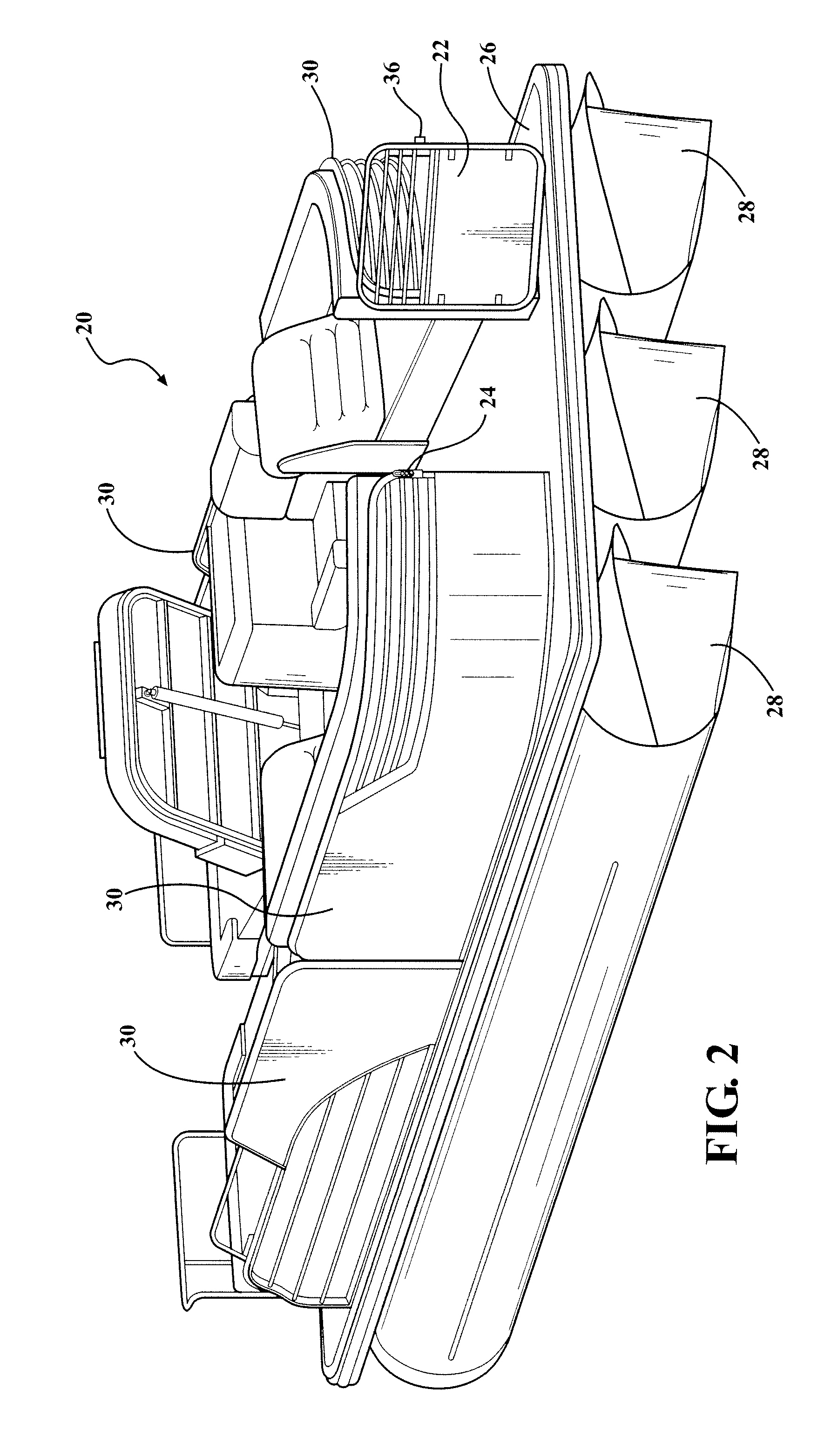

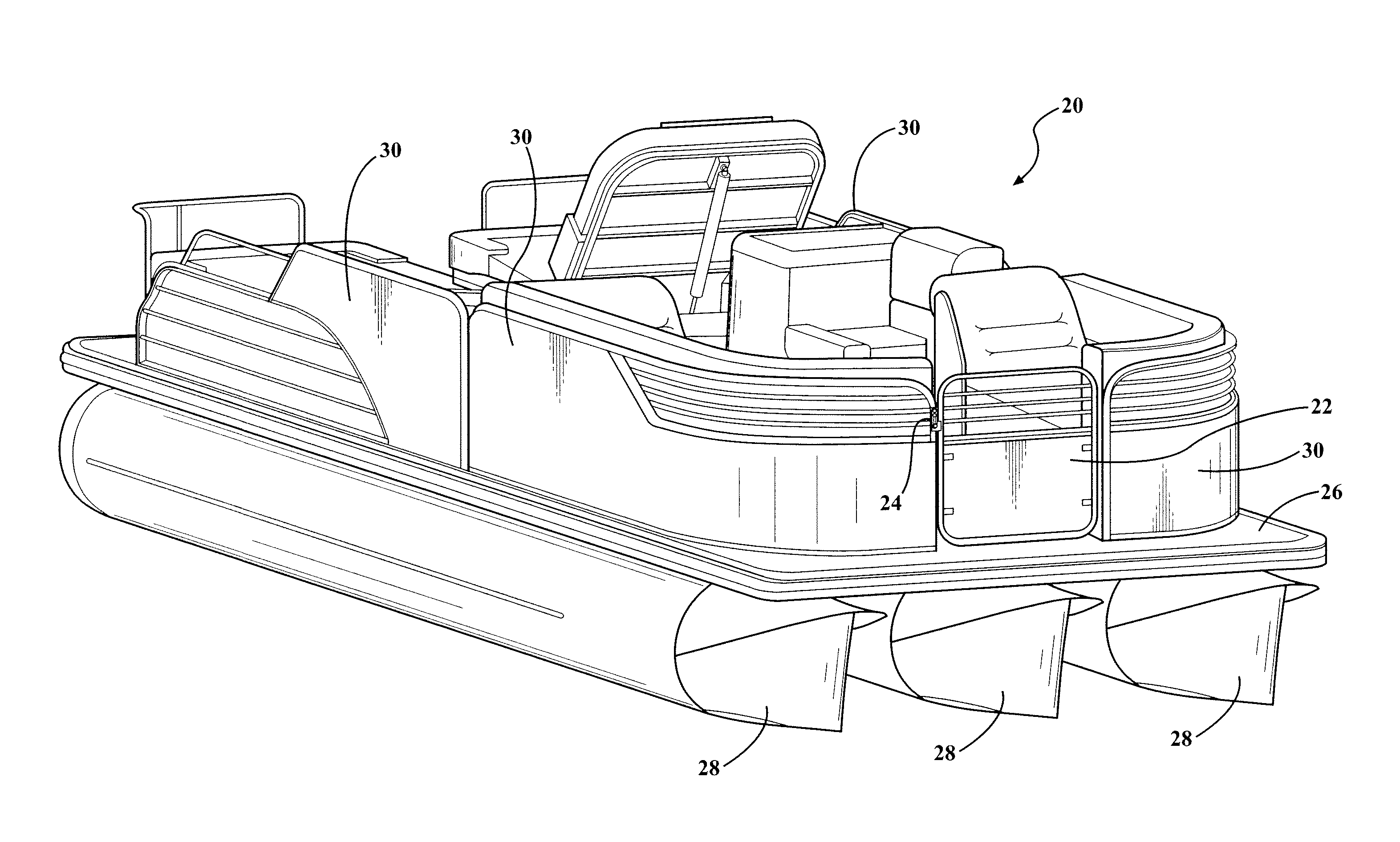

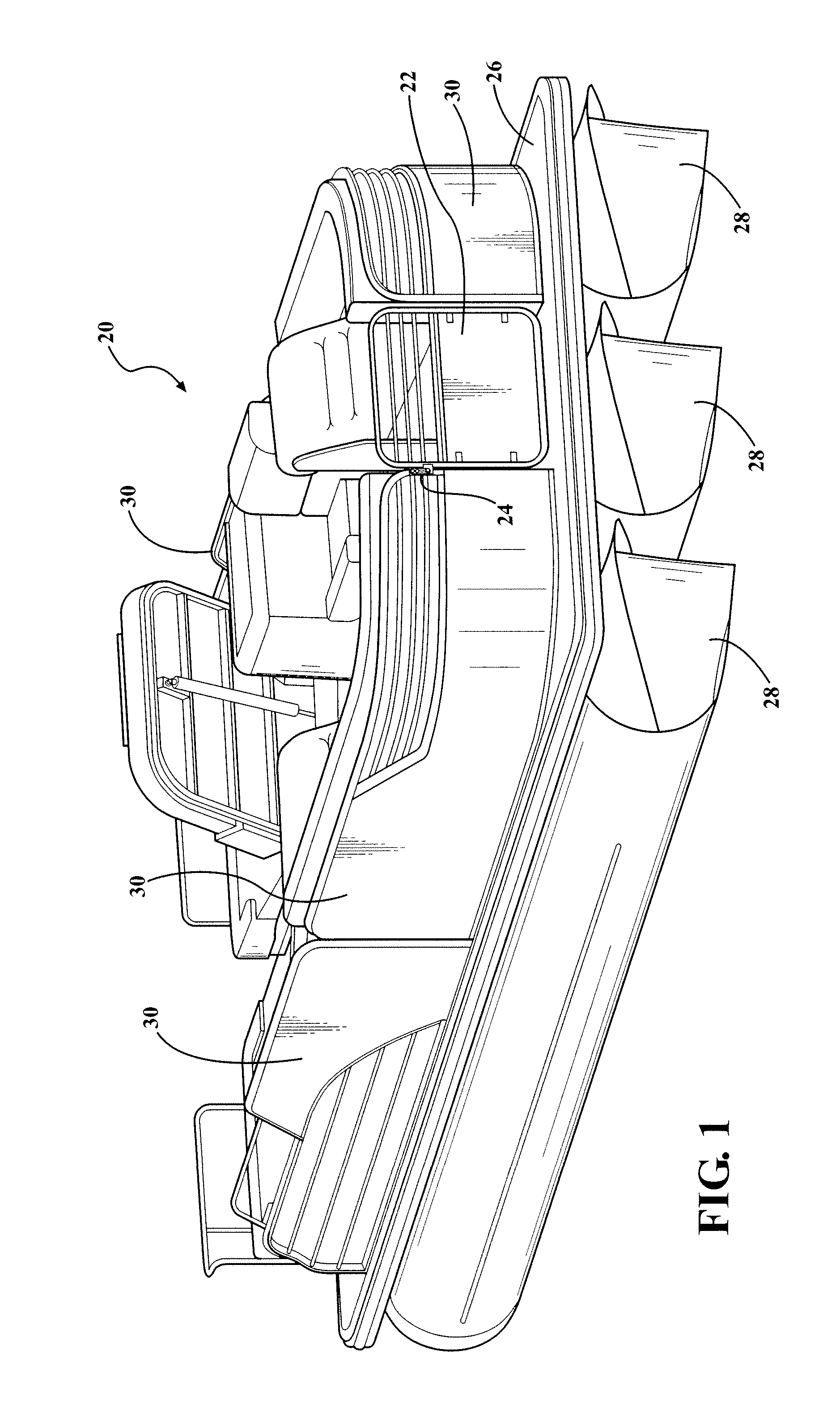

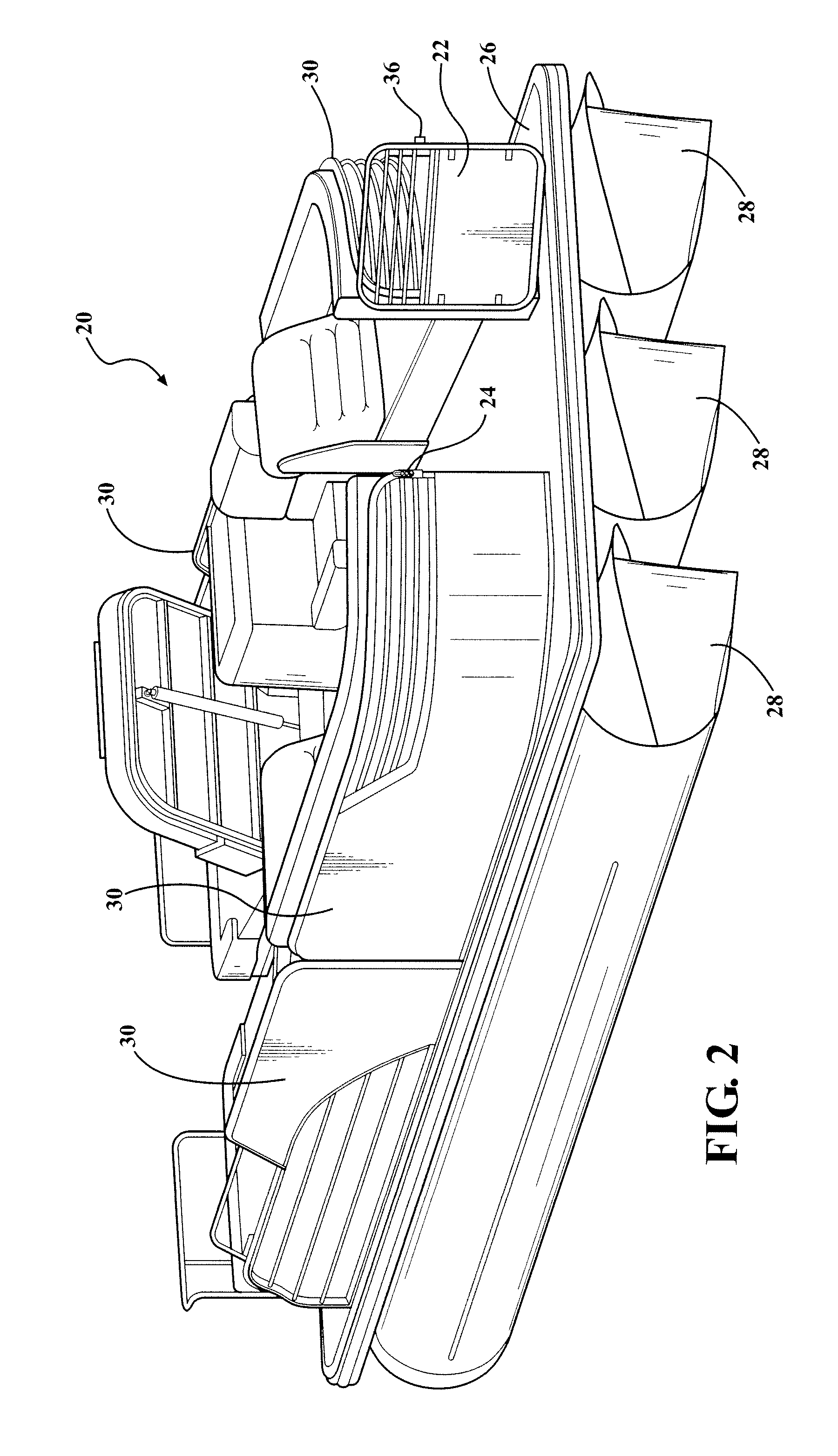

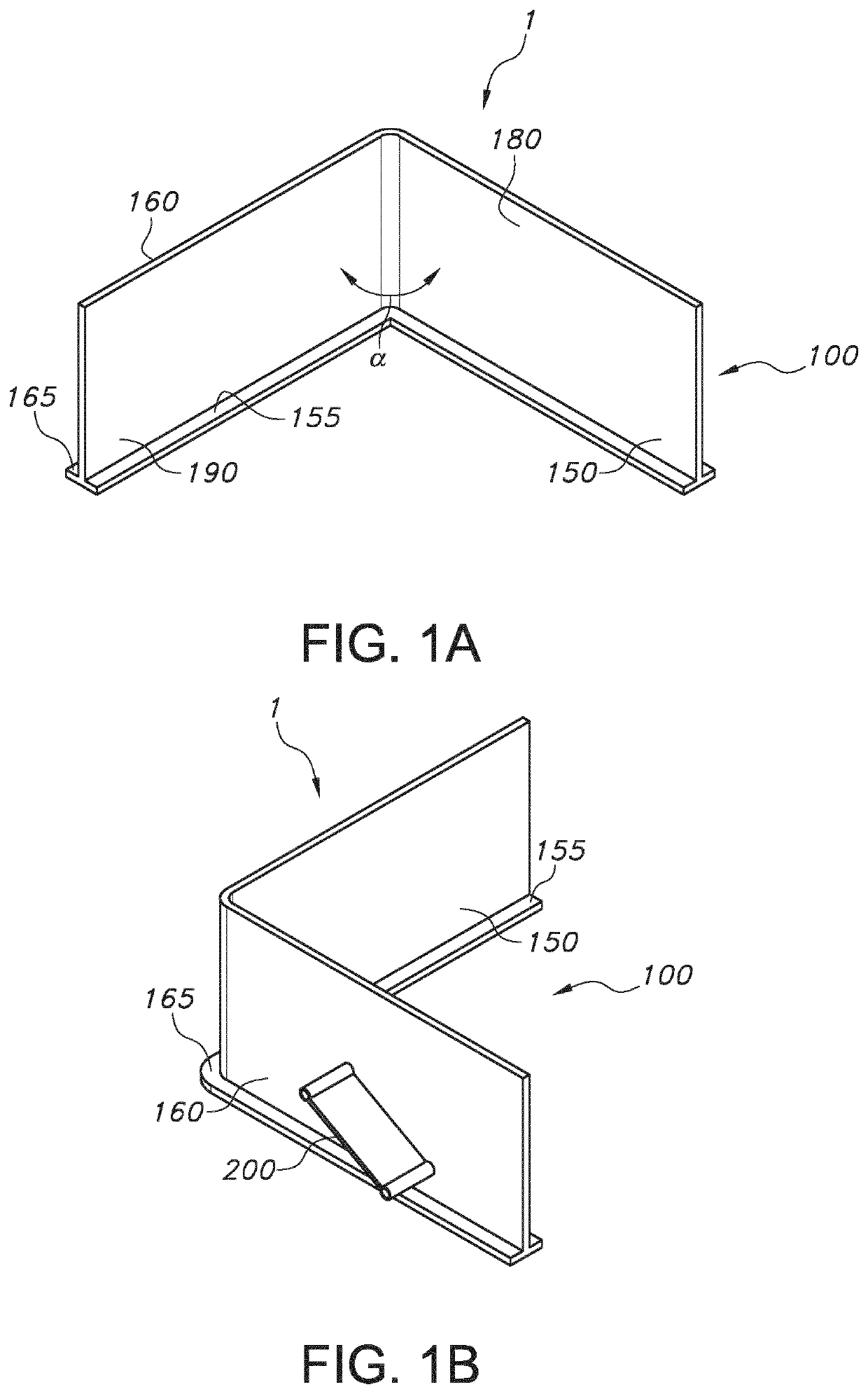

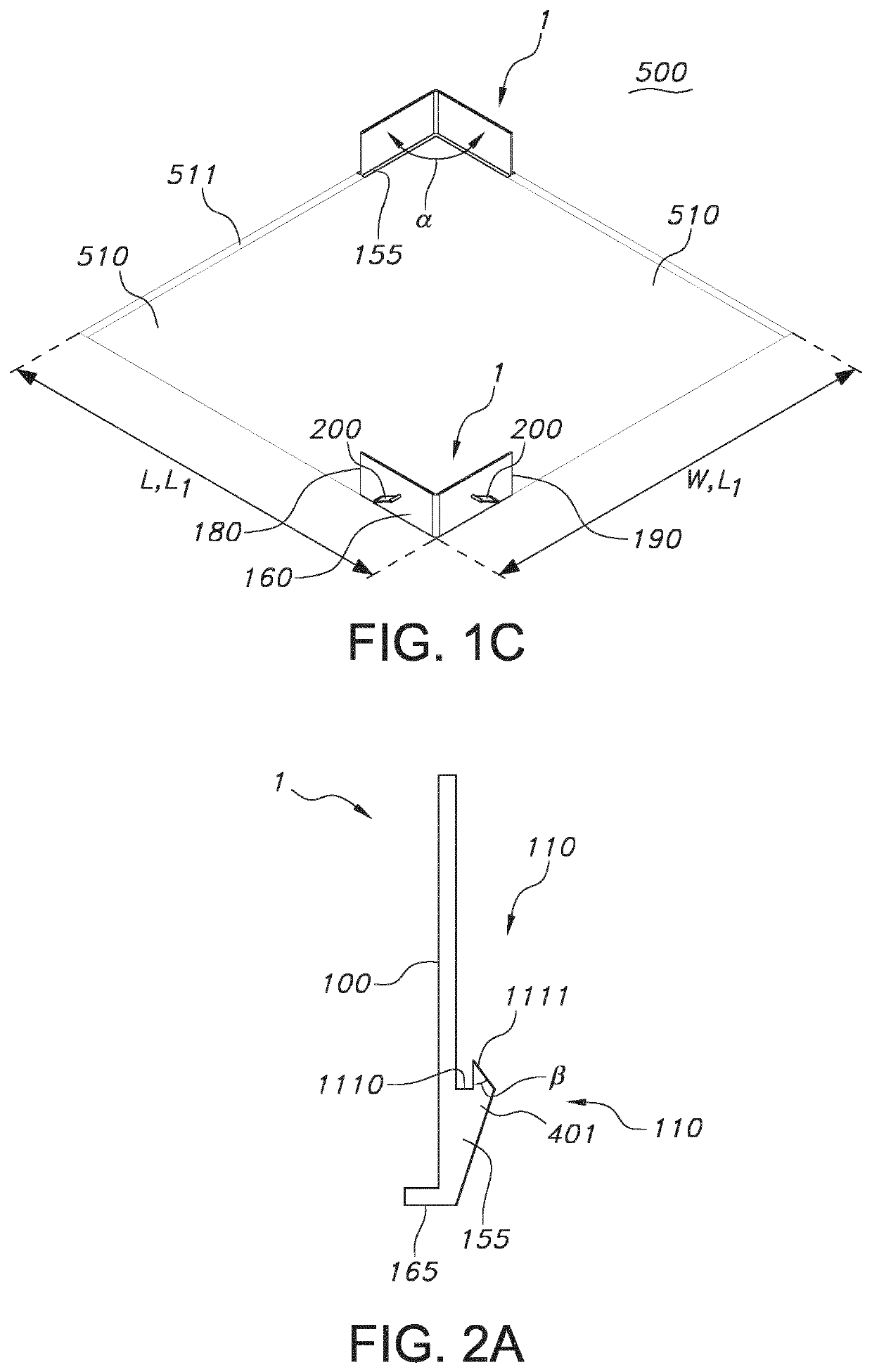

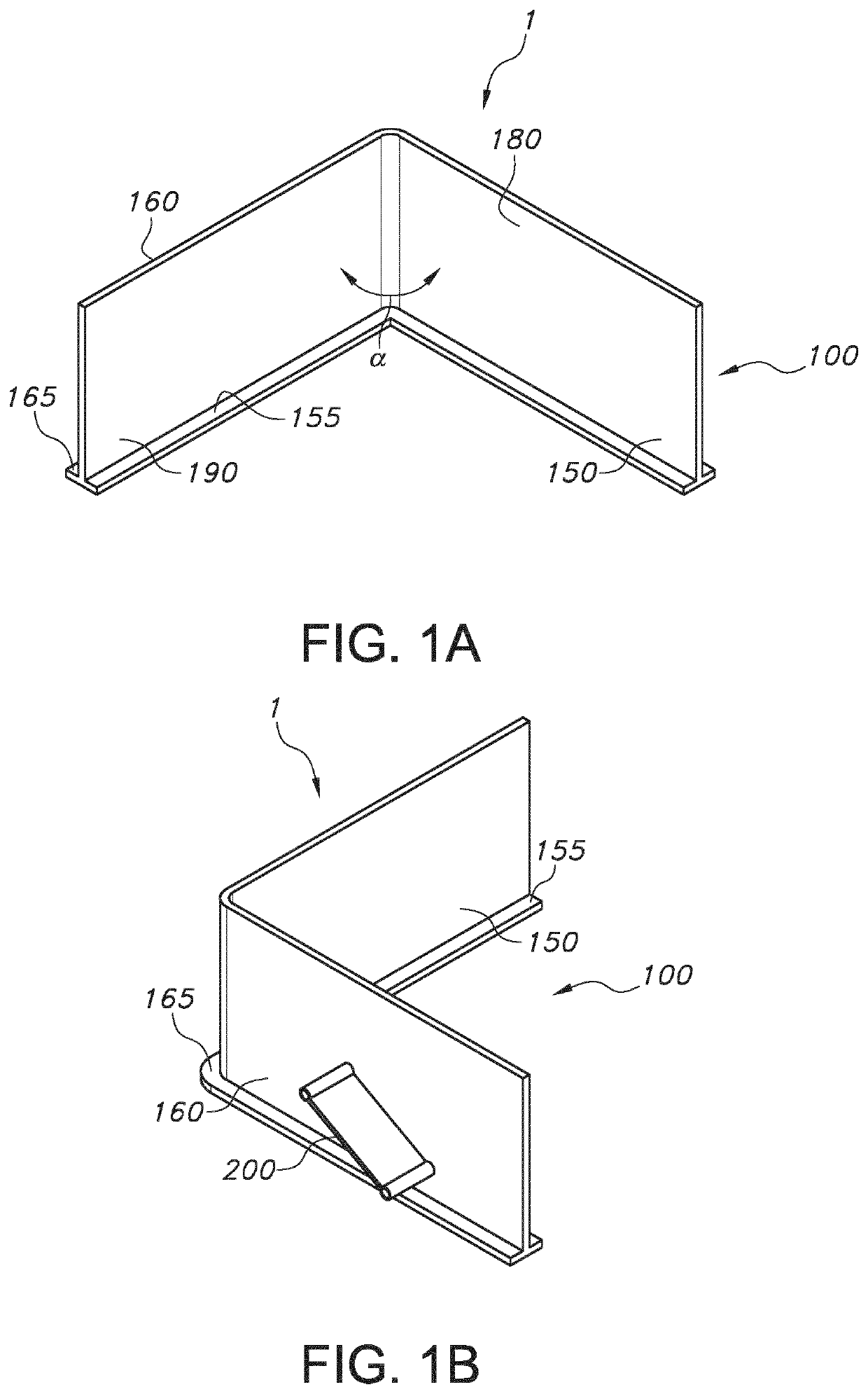

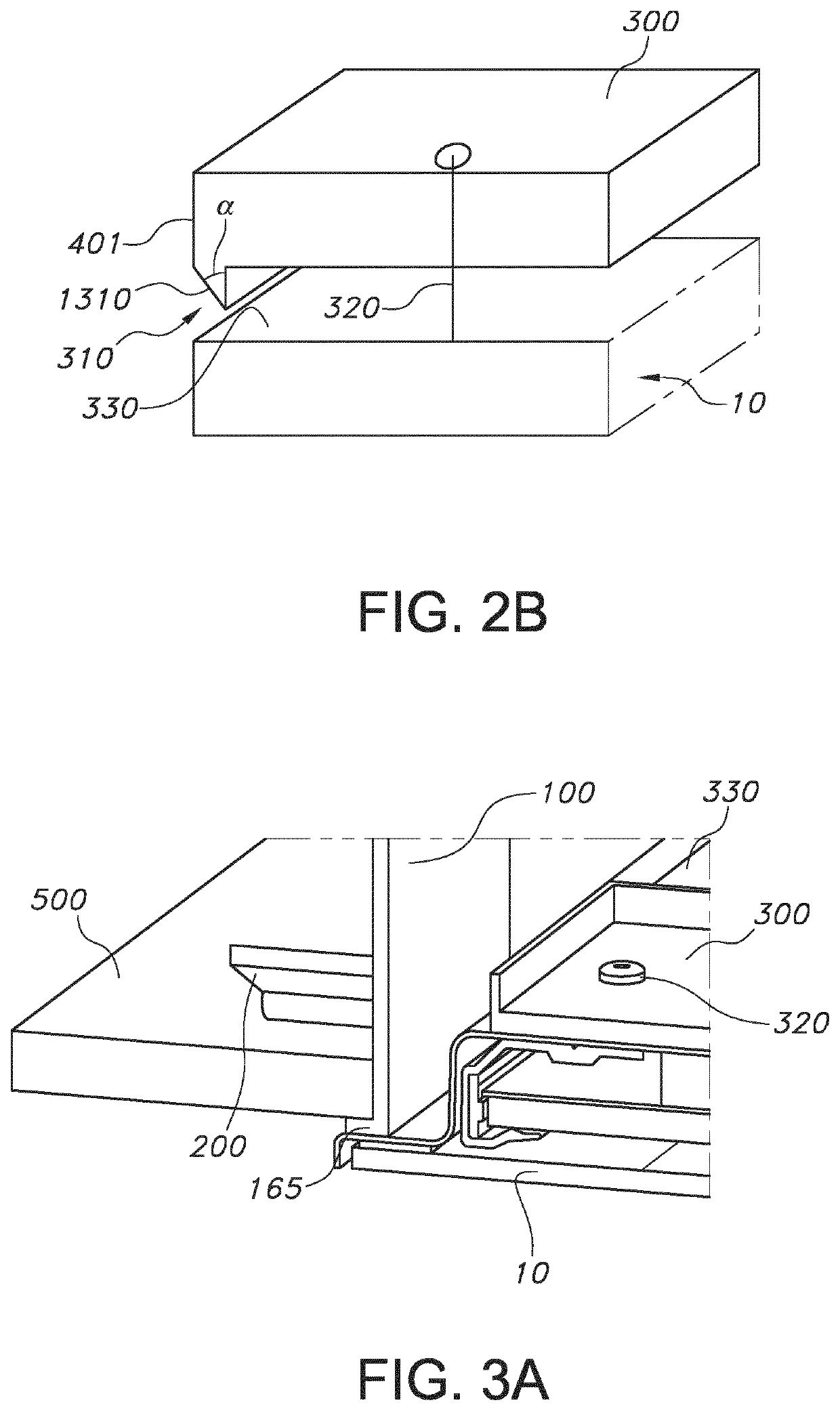

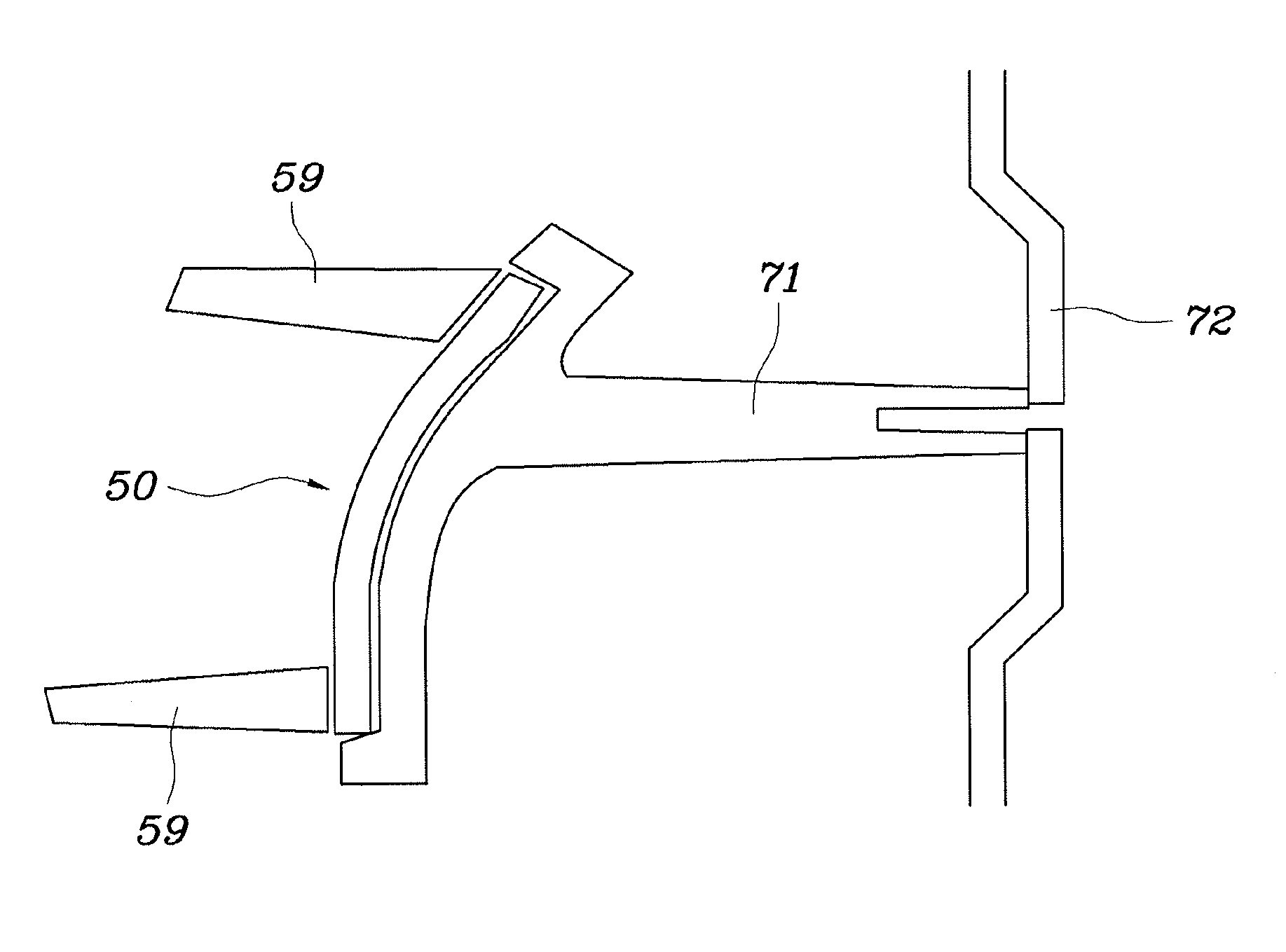

Boat with a latch assembly

InactiveUS20130025524A1Easy to useReduce forceBuilding locksConstruction fastening devicesInterior spaceEngineering

A boat including at least two wall segments extending generally upwardly from a deck to define an interior space. The wall segments are spaced from one another to define a passage for allowing passengers to enter and exit the interior space. A gate is secured to one of the wall segments for controlling access to the interior space. A latch assembly including base and sliding members is coupled to an end of one of the wall segments. The sliding member is movable between a latched position for trapping a portion of the gate and an unlatched position for releasing the gate. At least one glide plate of a low-friction material is disposed between the base and sliding members. Additionally, when the sliding member is in the unlatched position, the base member presents a strike surface for receiving contact from the gate to protect the wall segment.

Owner:AVALON PONTOONS

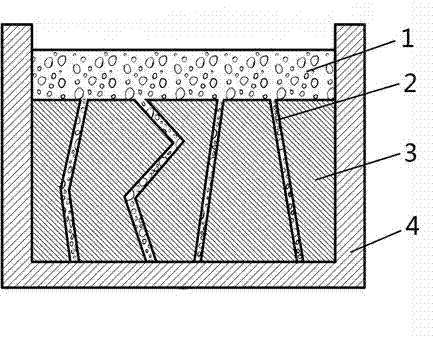

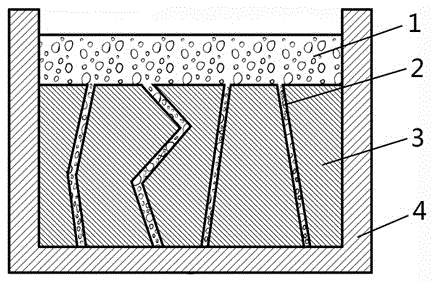

Production method for artificial stone composite boards

InactiveCN103240790ACuring shrinkage is smallHigh densityCeramic shaping apparatusEpoxyArchitectural engineering

The invention belongs to the field of building and ornament materials, and particularly relates to a production method for artificial stone composite boards. The method includes placing monoblock base boards or jointed boards in moulds, fully mixing with low-shrink unsaturated polyester resin or low-shrink epoxy resin and auxiliary materials to obtain mixtures after grading artificial stone packing, directly spreading the mixtures on the base boards, trowelling and vibrating the mixtures to enable material surfaces to be smooth, placing the base boards into vacuum equipment to remove bubbles, performing natural or heating solidification, and optionally polishing surfaces to obtain artificial stone composite board products. The production method is simple in process and low in cost, and composition is firm; abandoned defective products such as ceramic, stone and artificial stone can be effectively utilized, and one-time forming is realized without bonding; and the products are attractive in surface and not slippery when touching water, have high strength and wear-resisting properties, are easy and convenient to pave like floor tiles, and are widely applied to the field of the building and ornament materials.

Owner:成都汇玉科技产业有限公司

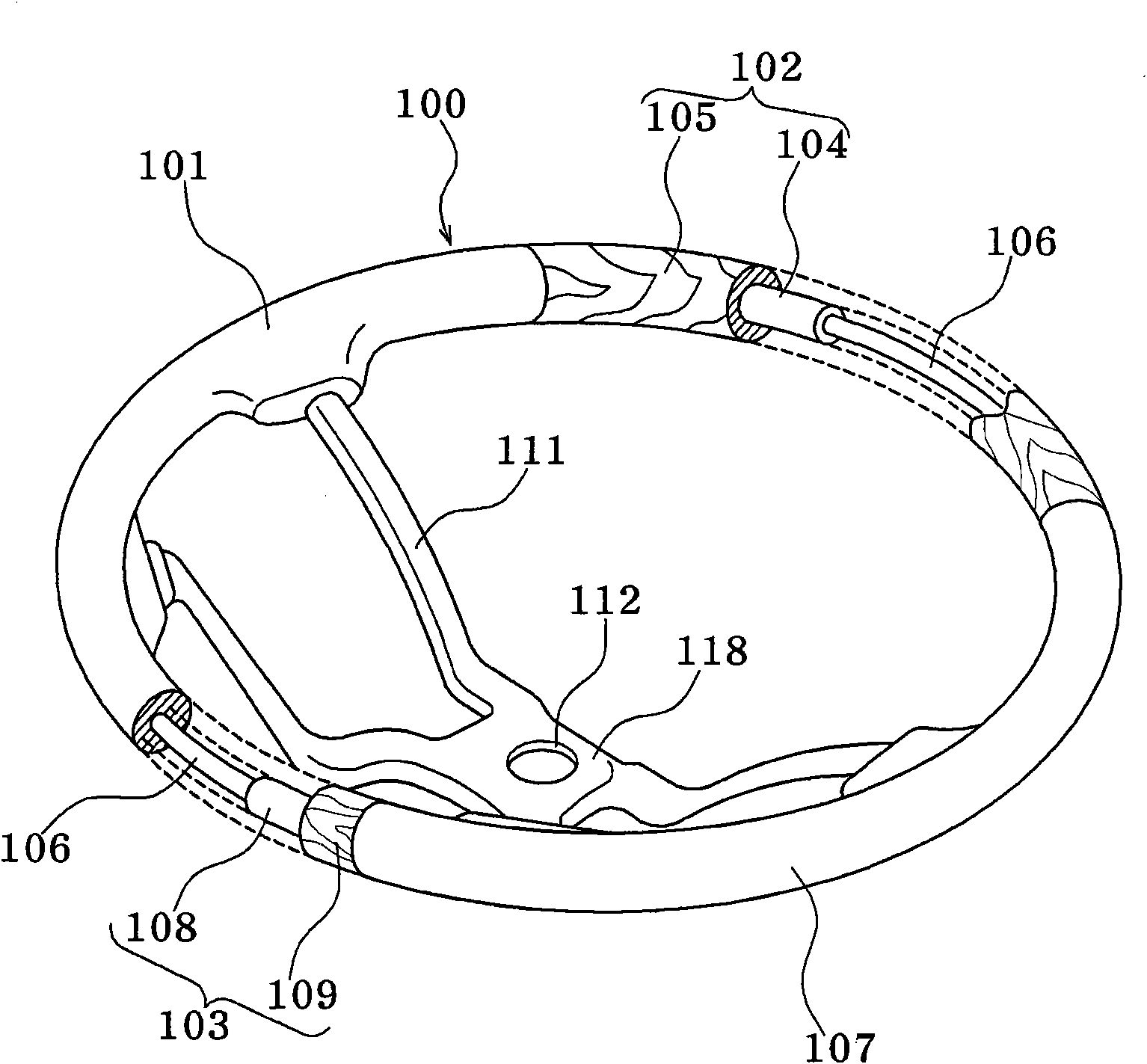

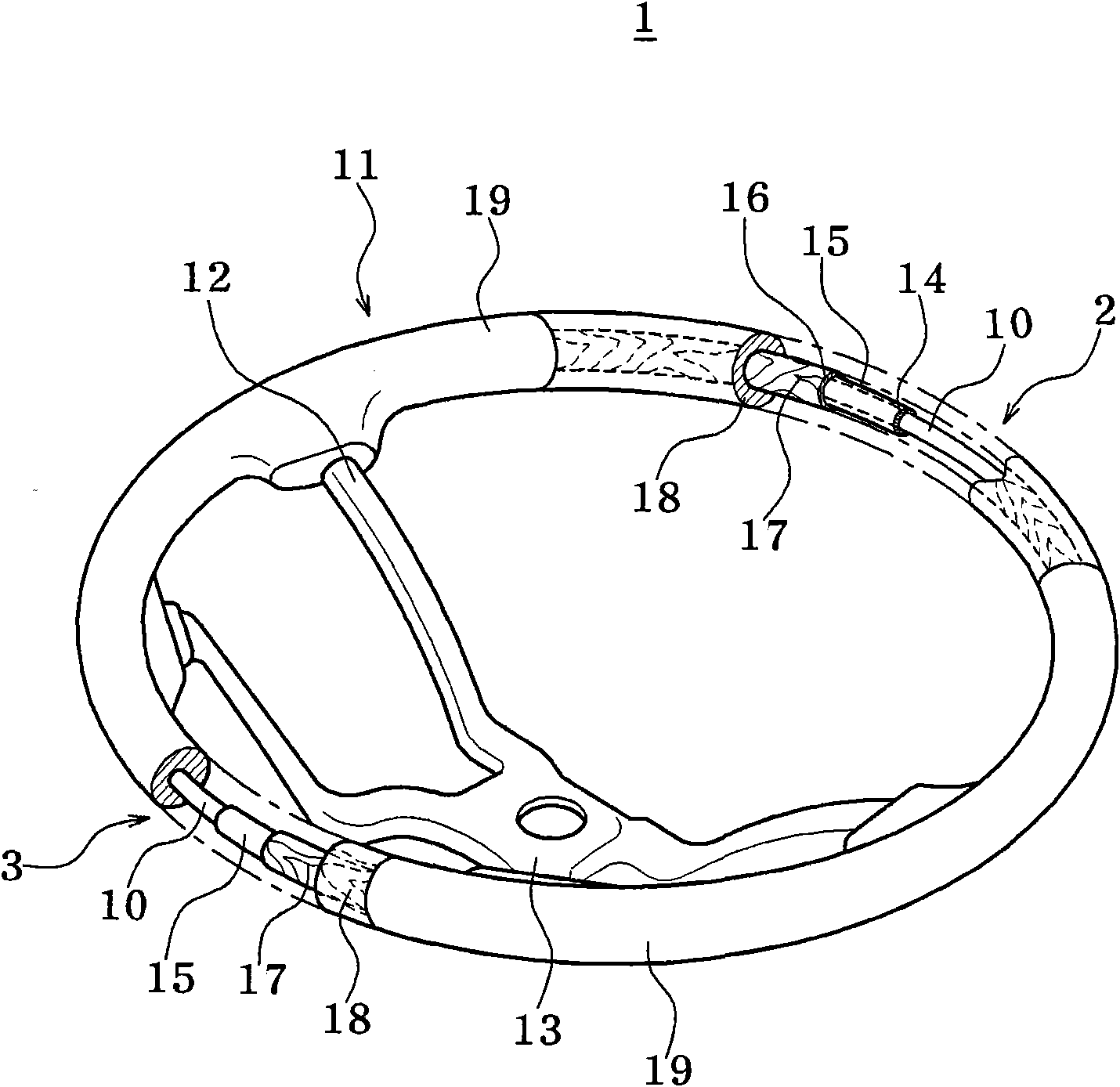

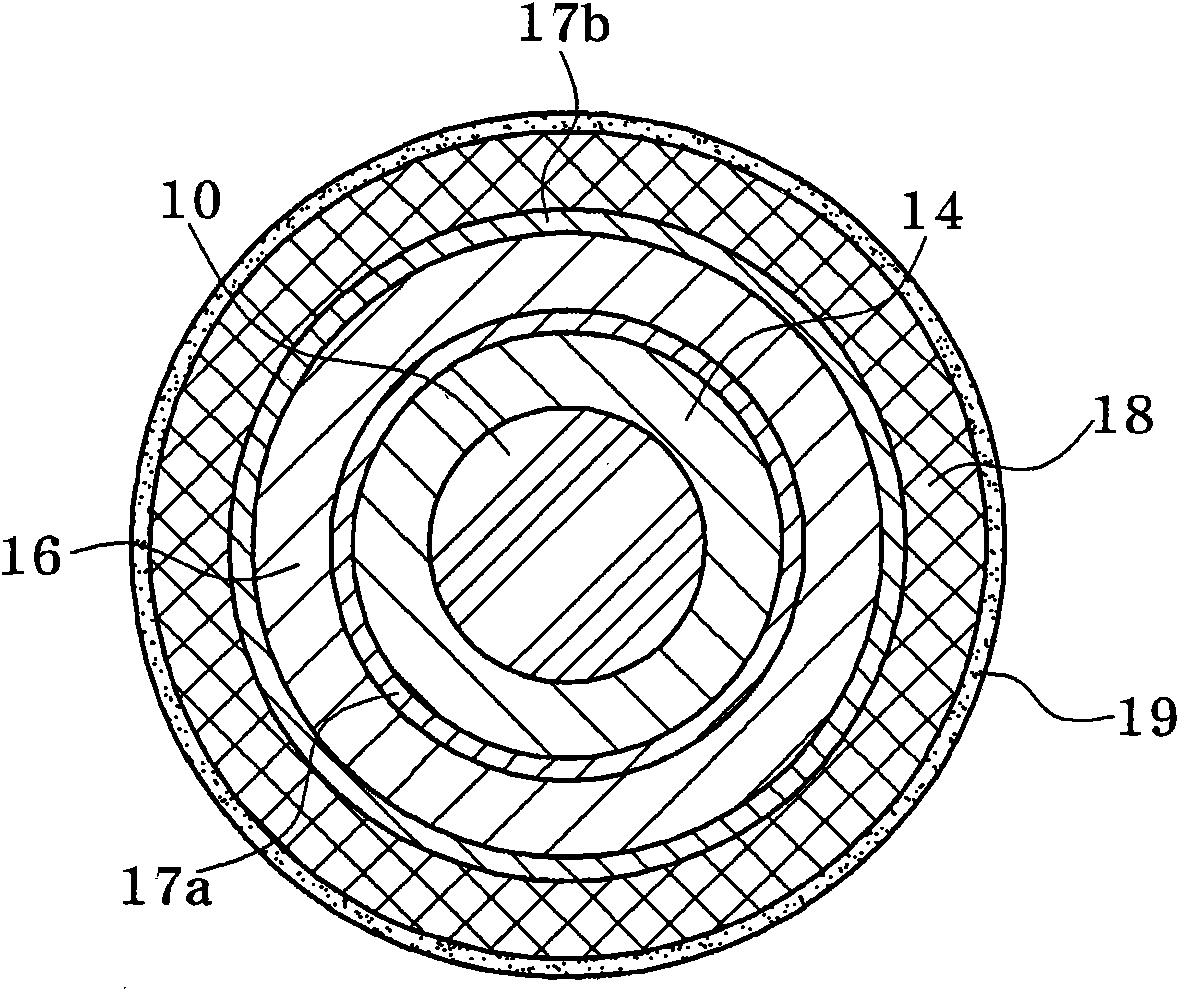

Steering wheel for automobile and method of fabricating the same

InactiveCN101885347ALuxurious appearanceSolve the real problemMechanical apparatusDecorative surface effectsPad printingSteering wheel

The present disclosure relates to a steering wheel for automobiles and a method of fabricating the same. The steering wheel is formed in multiple layers having a thickness difference of 2-3 mm by multi-stage injection molding and has a pattern or picture between the layers to provide a luxurious and pleasant appearance. In the method, after being preheated in a dryer to remove moisture, a metal frame is subjected to primary to tertiary injection molding in a mold to form the multiple layers. Here, drying is performed to remove moisture from the surface of injection-molded parts to prevent deterioration in adherence and quality during the process. Here, the pattern or figure is inserted between the layers by pad printing or a combination of pad printing and vacuum deposition. The multi-stage injection molding allows various colors, patterns, and figures to be printed on injection-molded parts excluding the uppermost layer.

Owner:MIRAETEC CO LTD

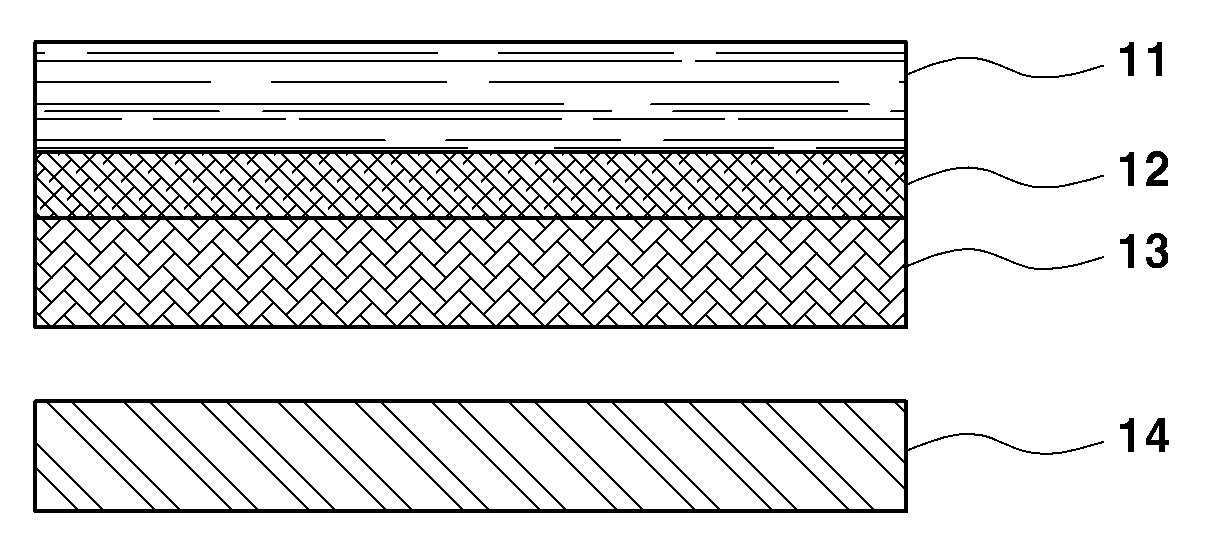

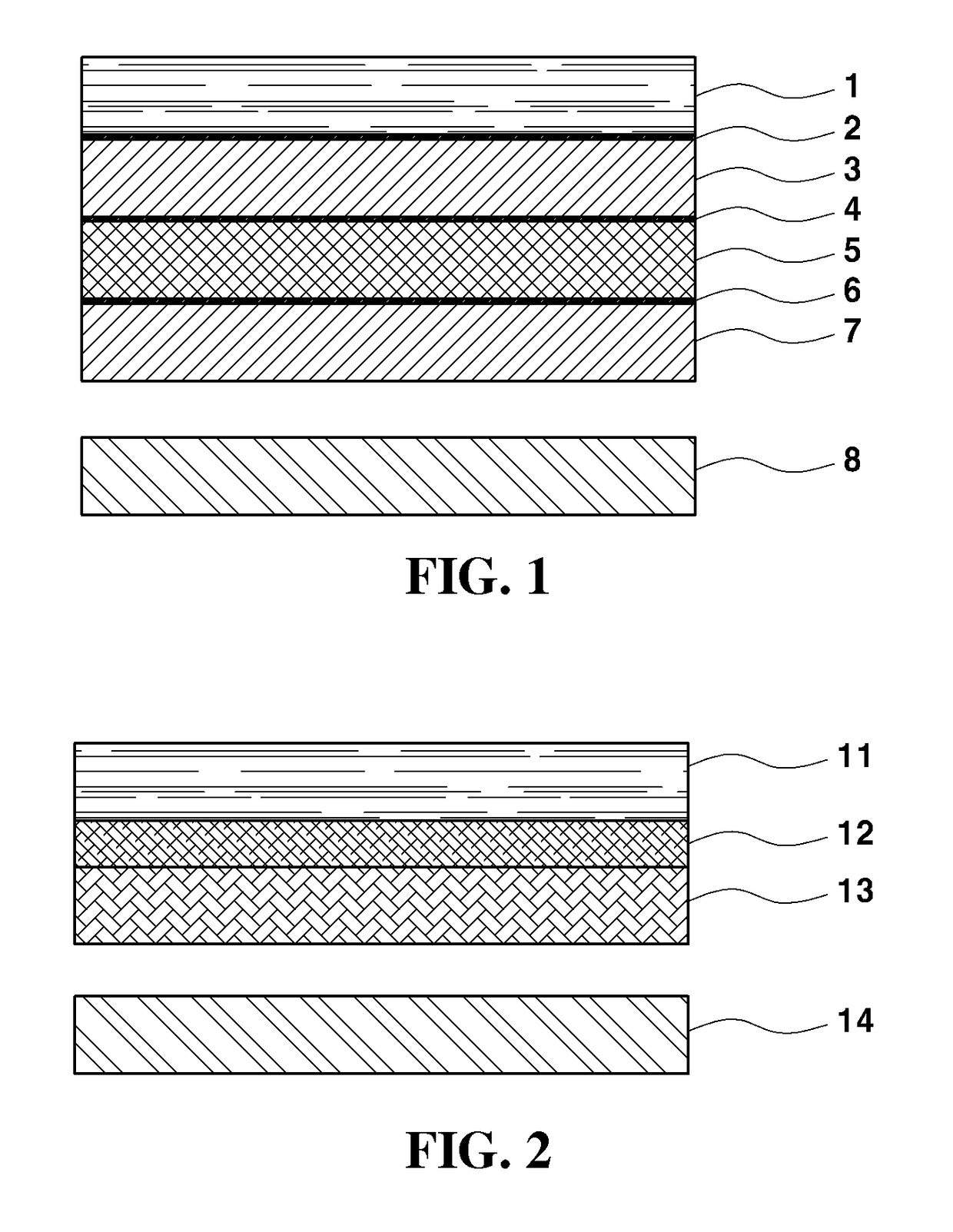

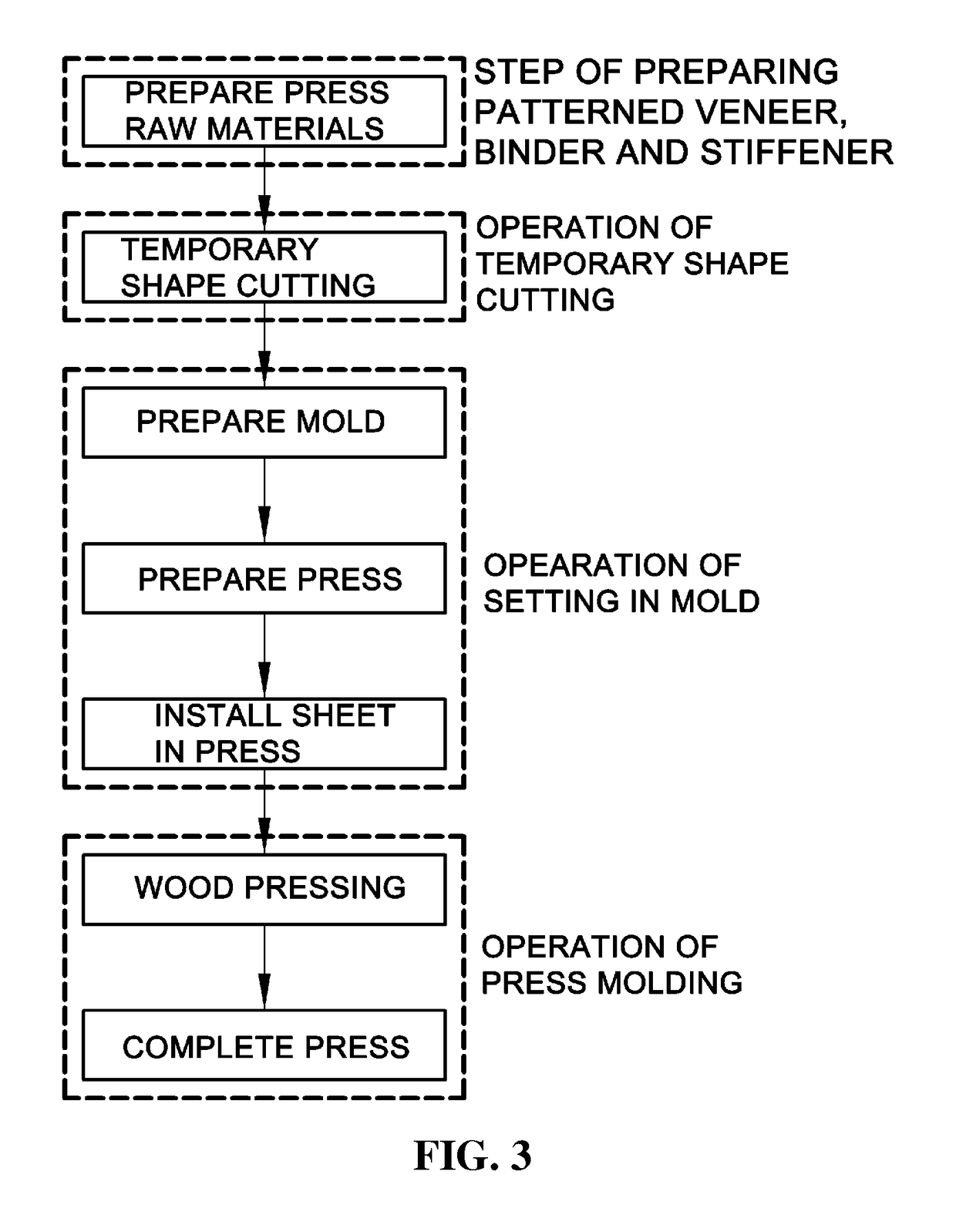

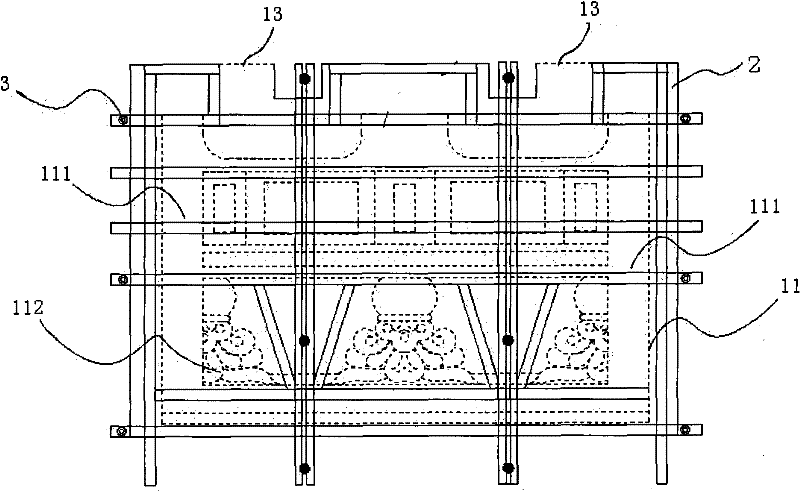

Wood sheet and method for manufacturing the same

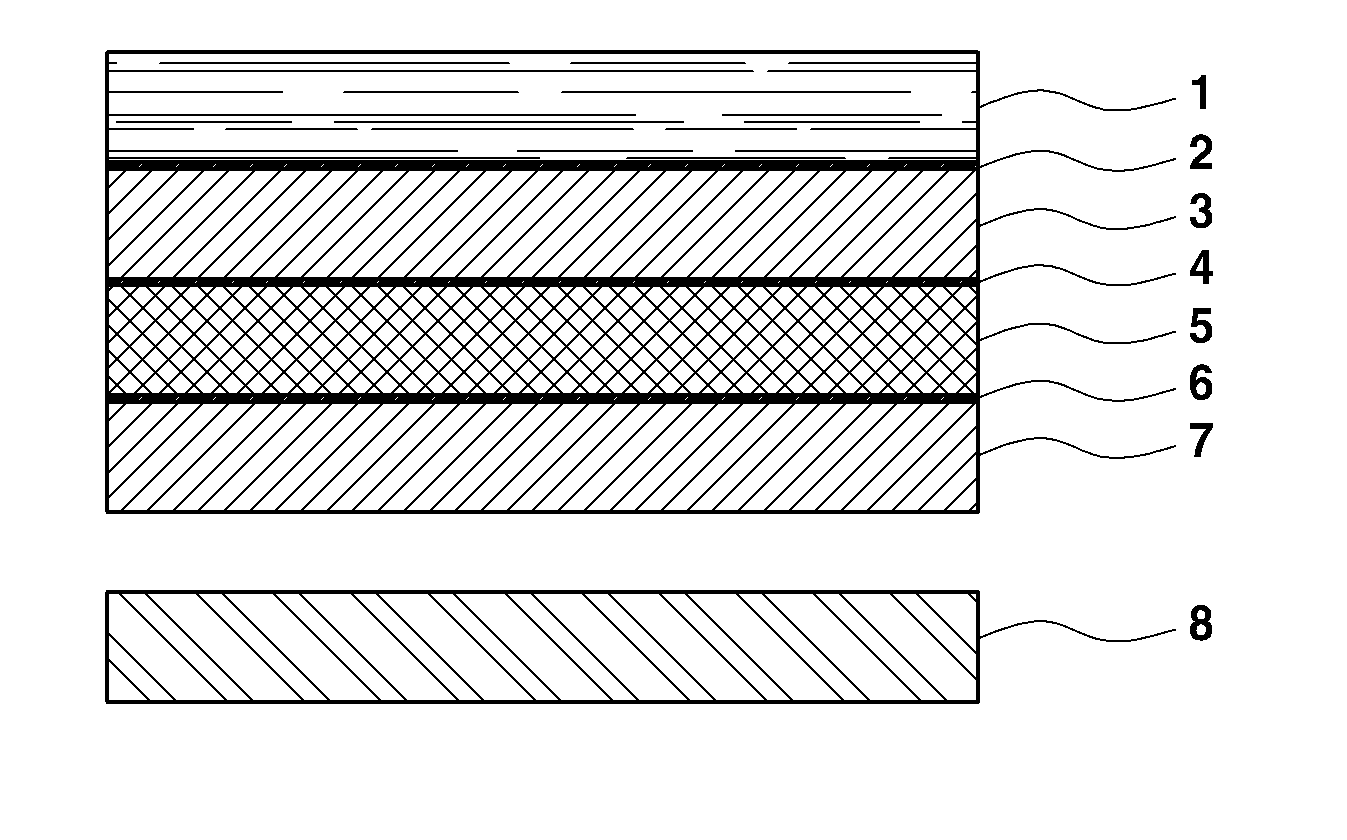

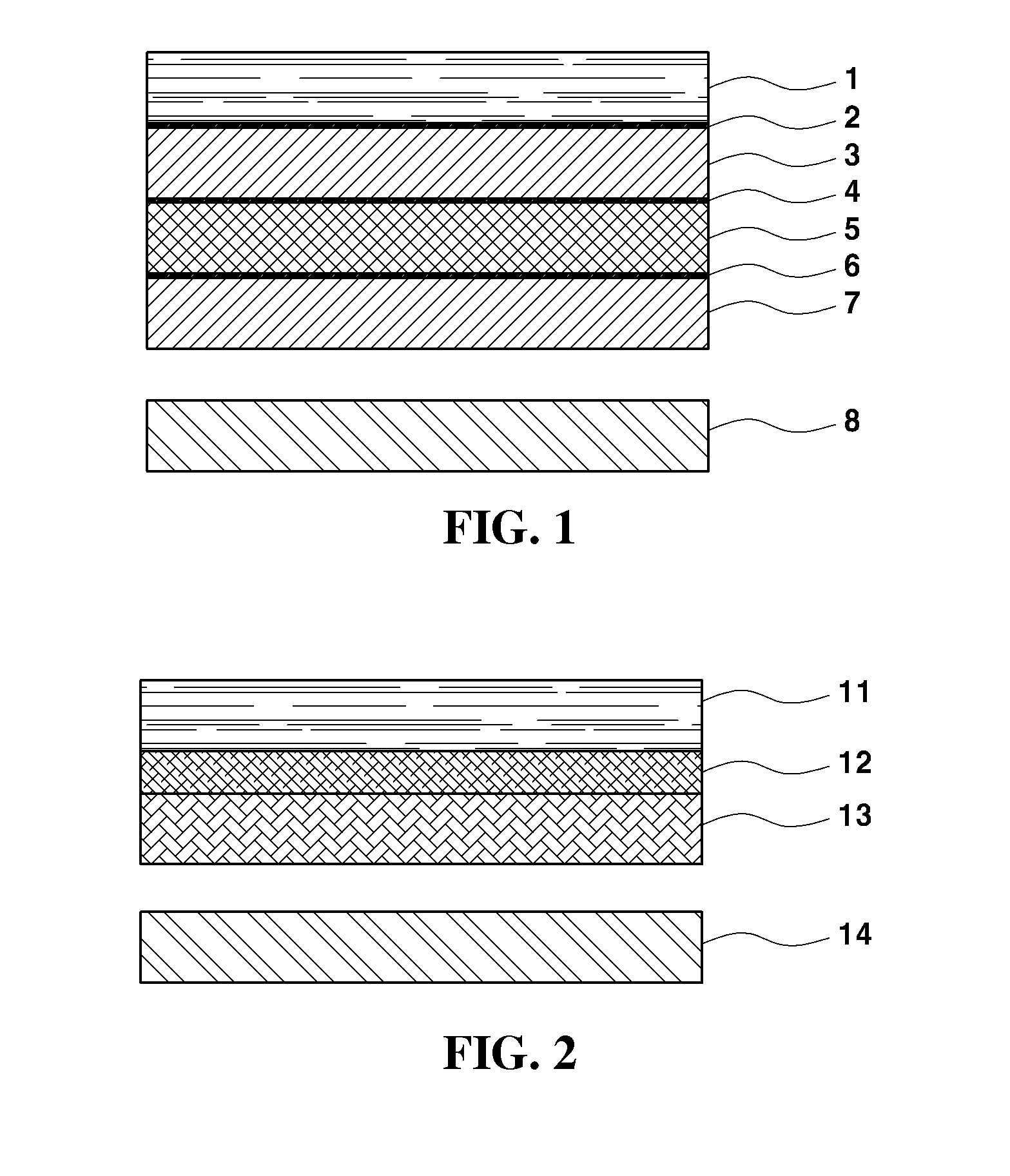

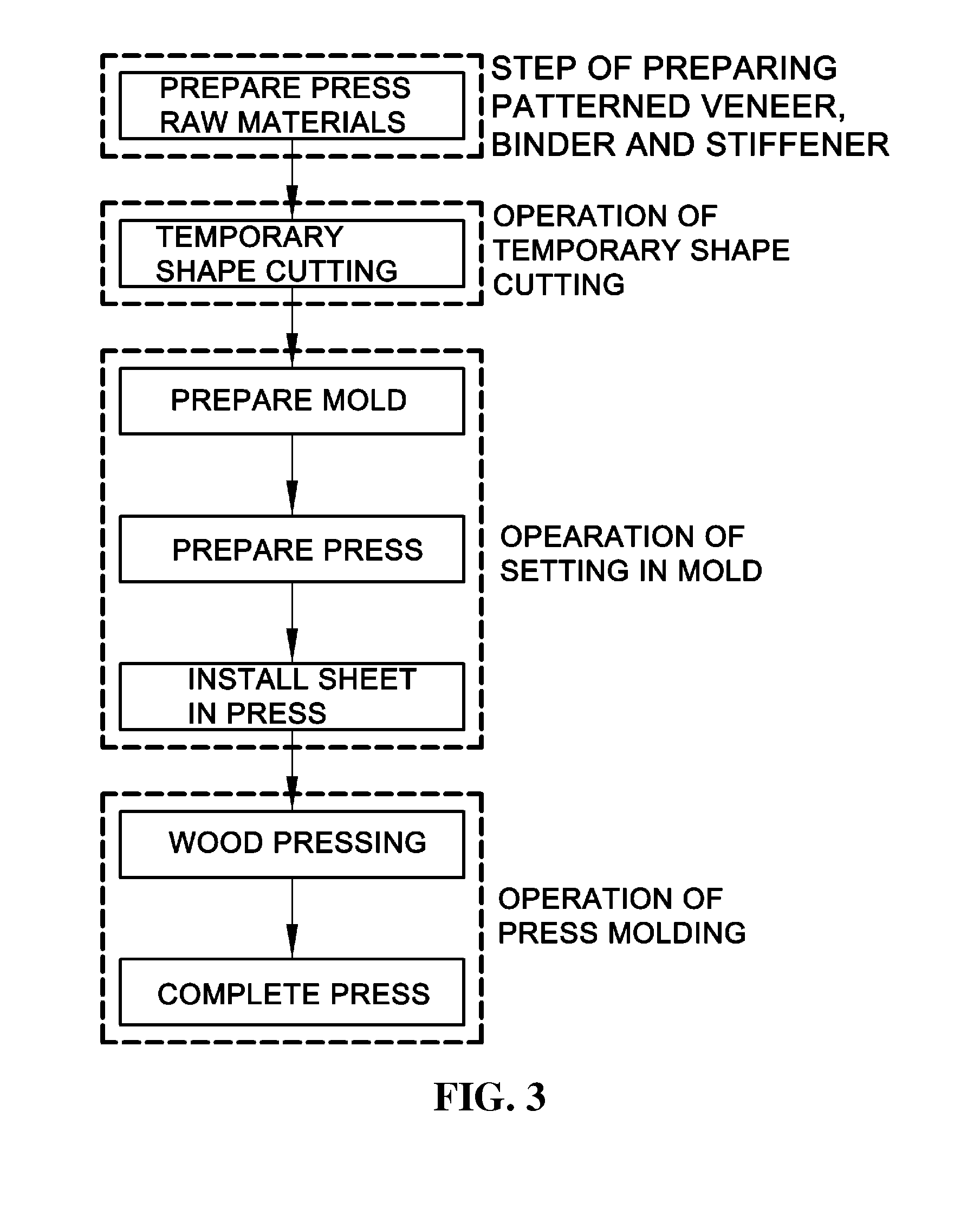

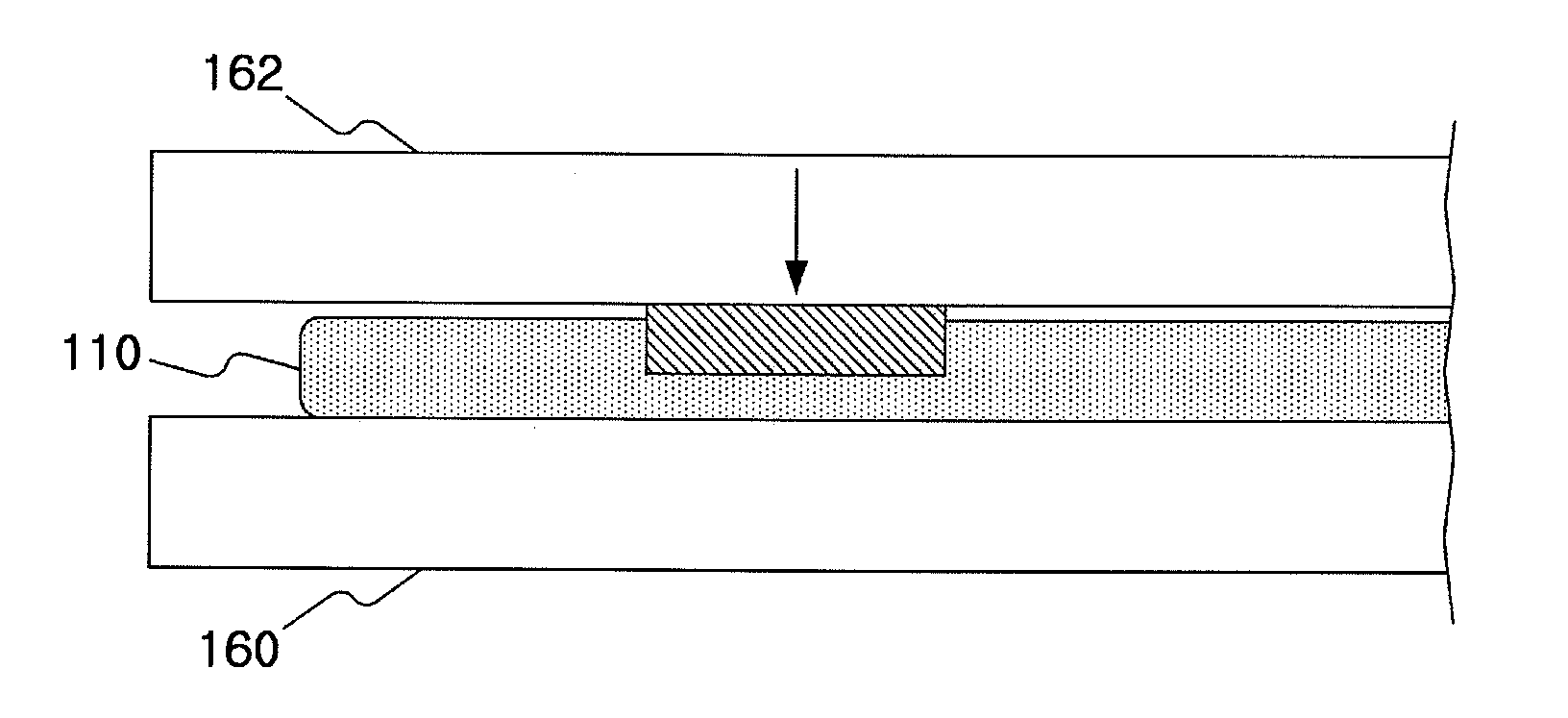

ActiveUS20150165732A1Good physical propertiesReduce weightDecorative surface effectsDuplicating/marking methodsEngineeringPhysical property

Disclose are a wood sheet and a method for manufacturing the wood sheet. In particular, the real wood sheet is prepared with natural wood sheets used for interior and exterior materials, a binder and a stiffener, thereby providing patterned veneer appearance. Further, the wood sheet may have improved physical properties and reduced weight and be manufactured with reduced cost.

Owner:HYUNDAI MOTOR CO LTD +1

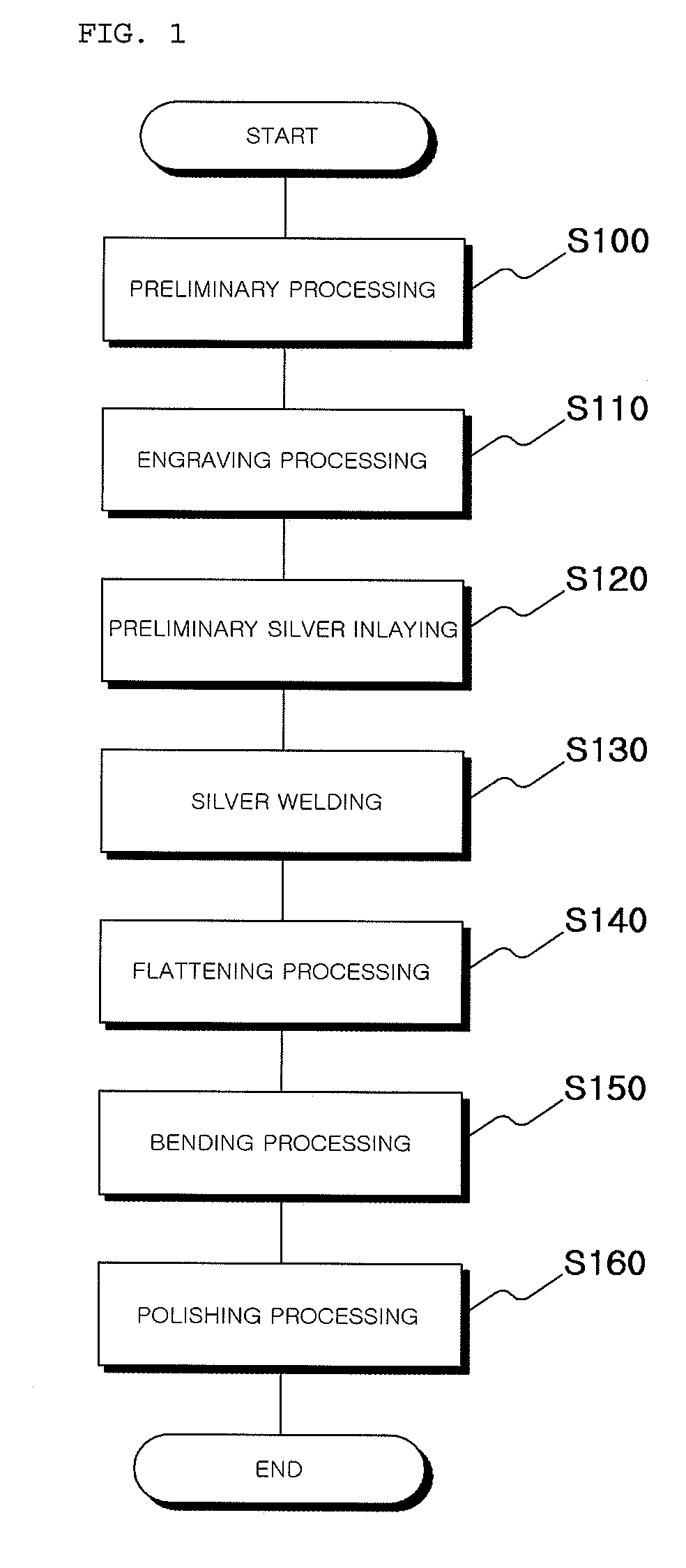

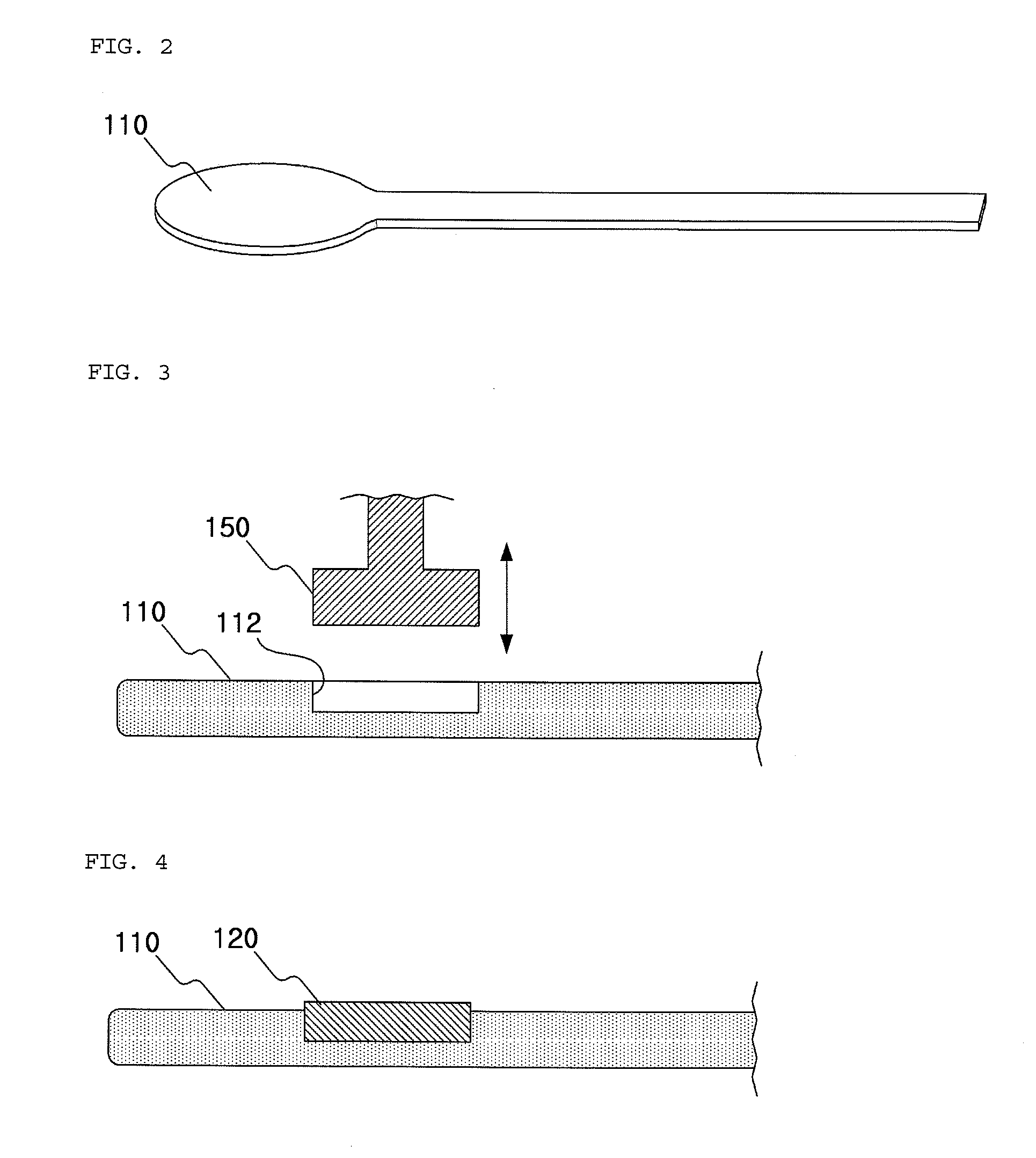

Silver inlaid product and a production method therefor

InactiveUS20120107638A1Reduce expensesHigh strengthDecorative surface effectsMetal rolling stand detailsMetalBrass

Disclosed is a silver inlaid product and a method of manufacturing the silver inlaid product, in which silver having the aesthetic appeal and the sterilizing ability is inlaid into metal, such as stainless steel and brass, having the durability and convenience in use, to provide tableware having the property of both metal and silver. method of inlaying silver includes: a first step of preliminarily processing stainless steel into a stainless steel plate according to a shape of a finished product; a second step of engraving a top surface of the preliminarily processed stainless steel plate in a shape for inlaying silver to form an engraved part; a third step of inlaying silver into the engraved part to form a preliminarily inlaid part; a fourth step of pressing the top surface in which the inlaid part is formed and welding the silver; a fifth step of flattening processing the top surface of the stainless steel plate and removing the silver protruding beyond the stainless steel plate; a sixth step of bending processing the flattening processed stainless steel plate in one direction; and a seventh step of polishing processing the top surface of the bending processed stainless steel plate.

Owner:LEE MOON HYUN

Boat with a latch assembly

Owner:AVALON PONTOONS

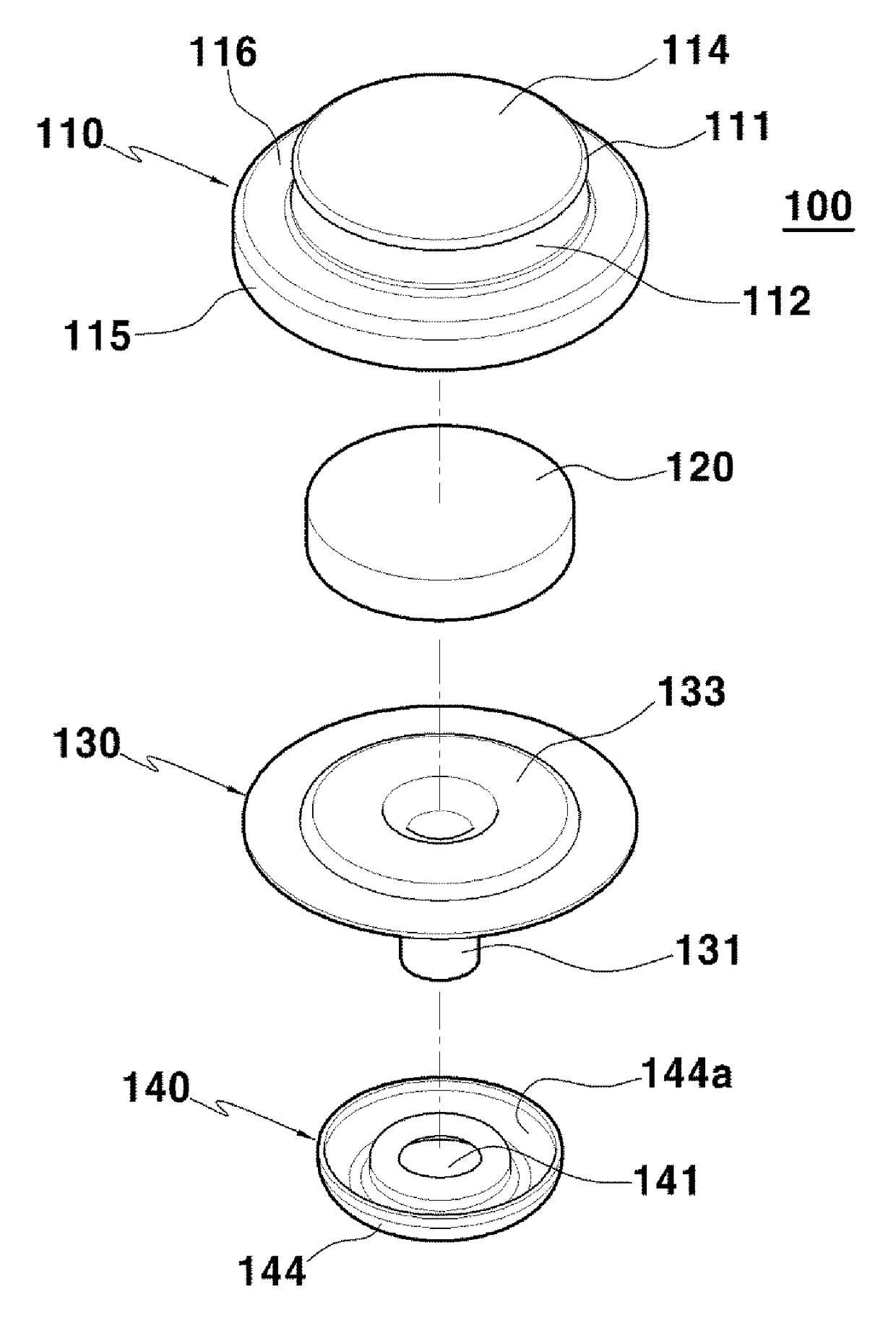

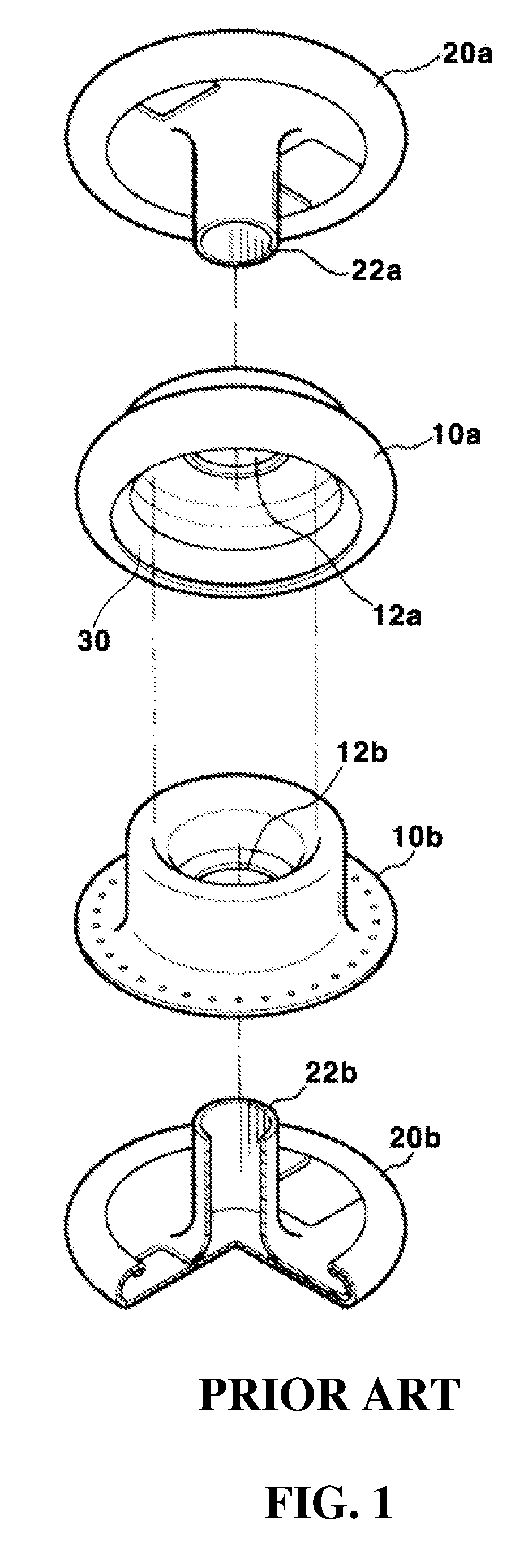

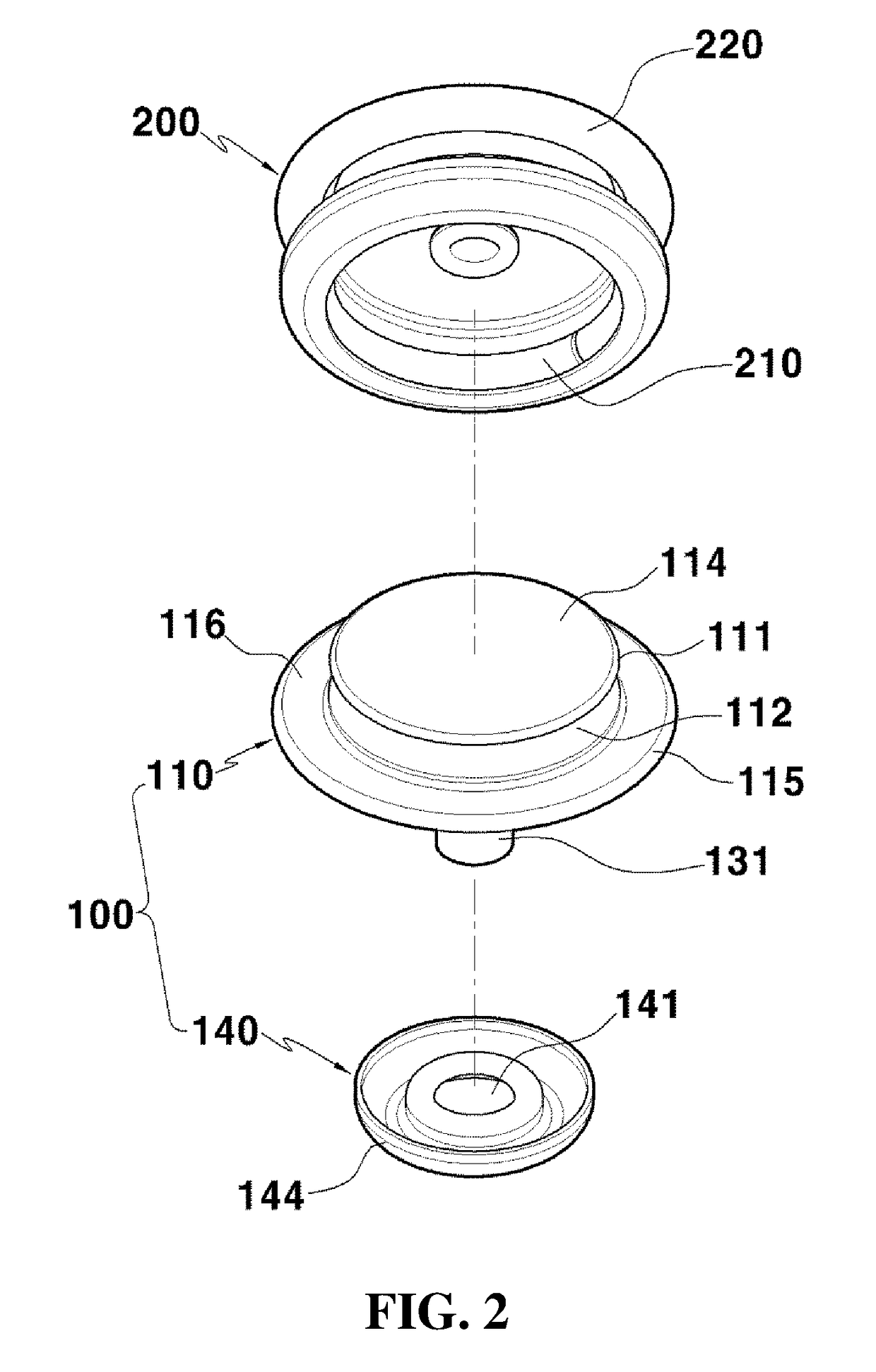

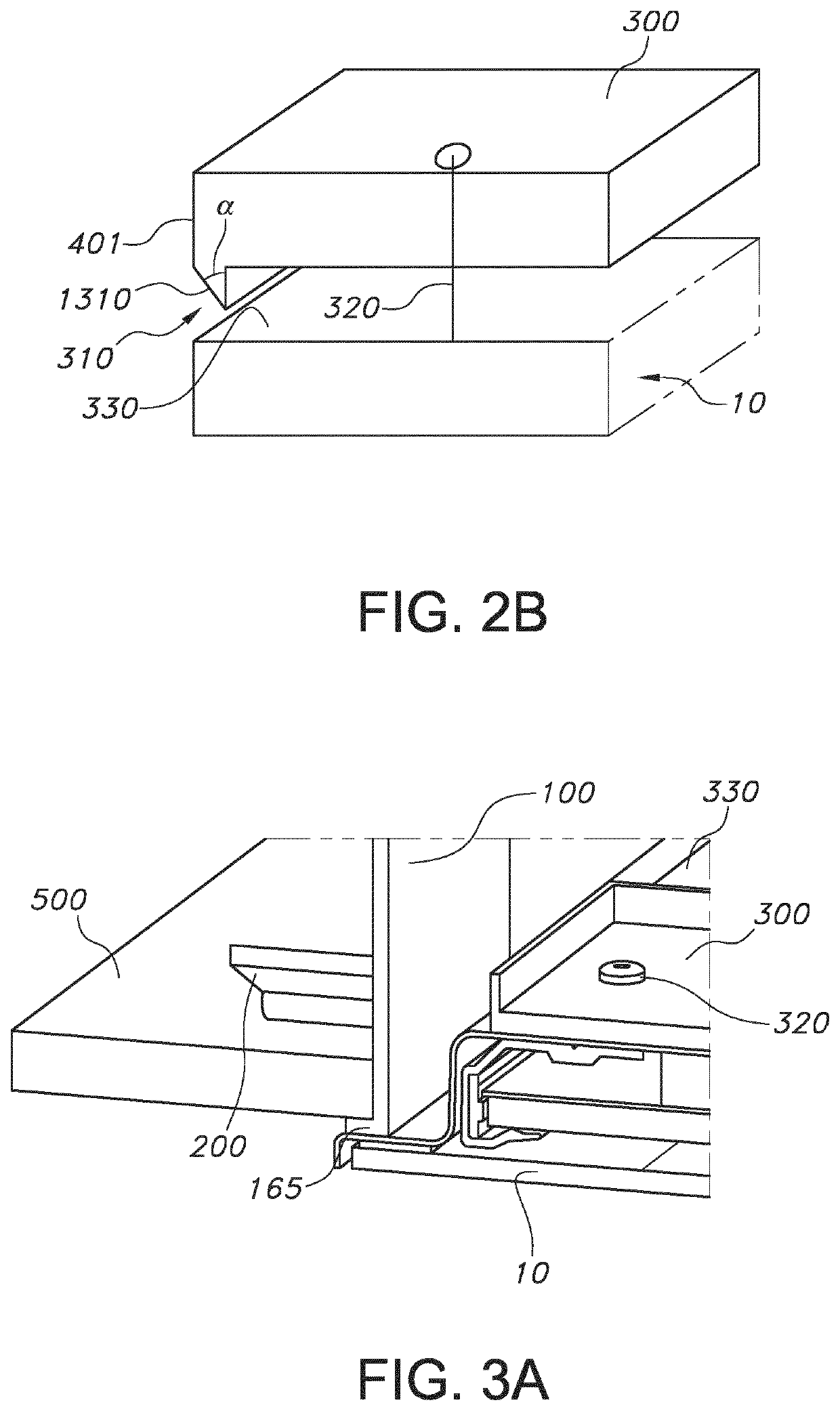

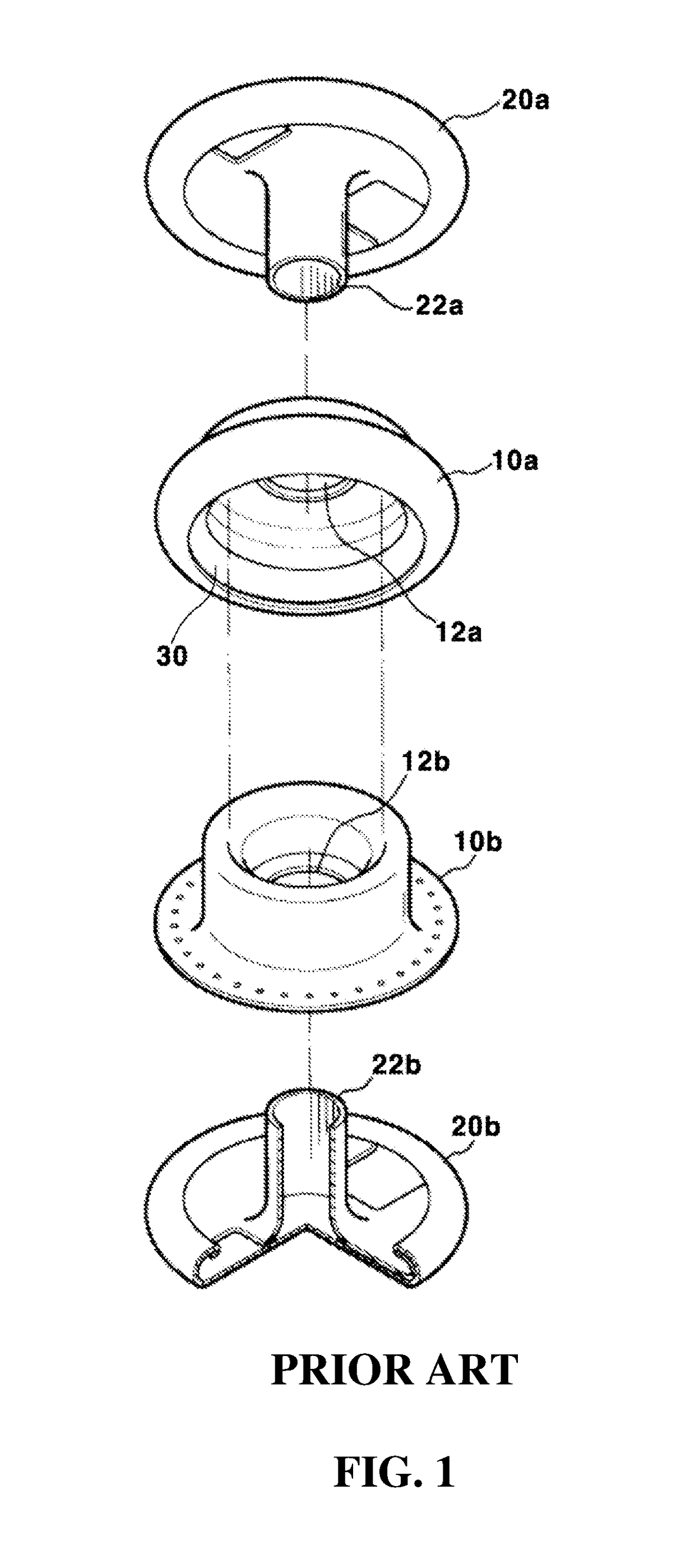

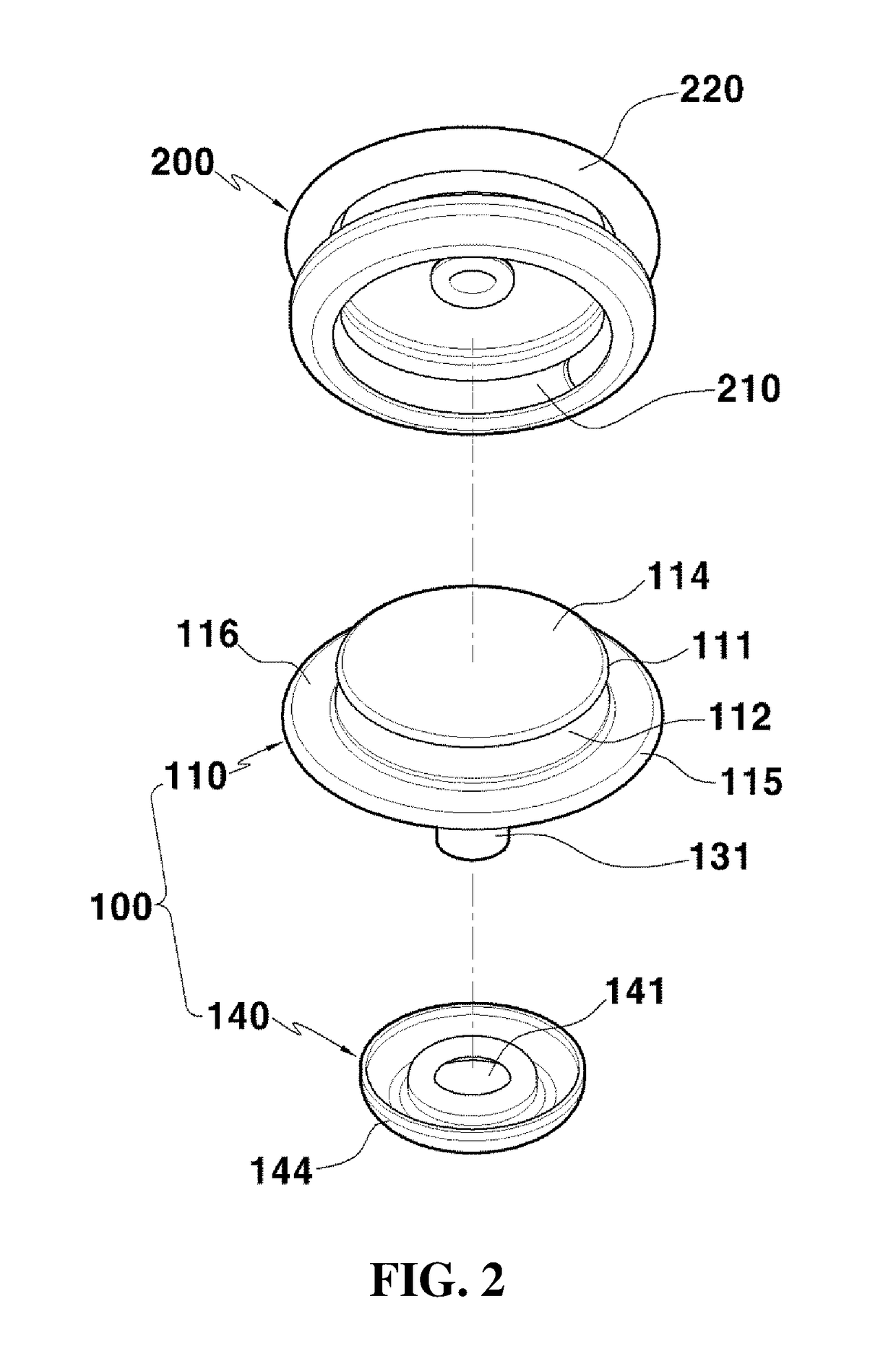

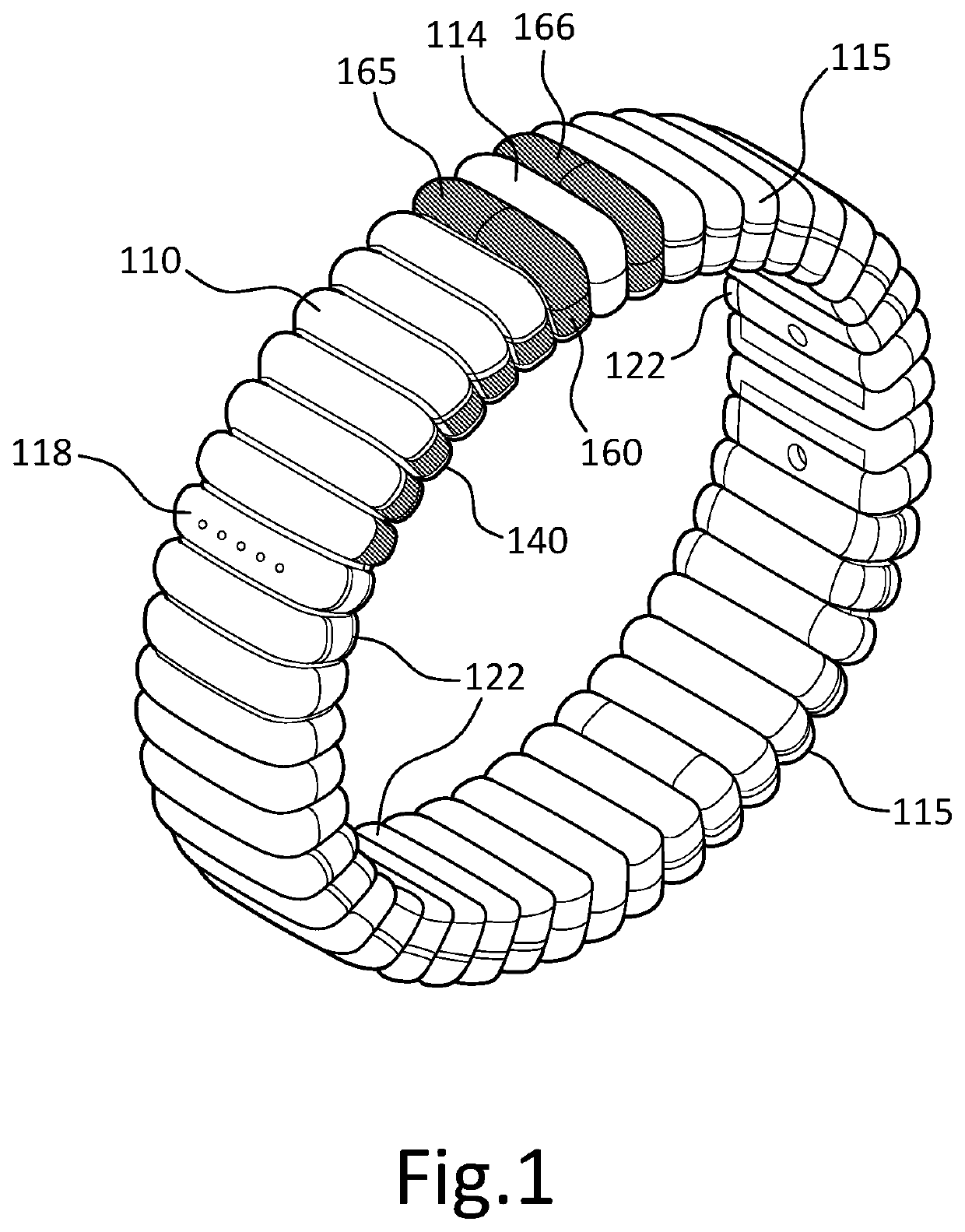

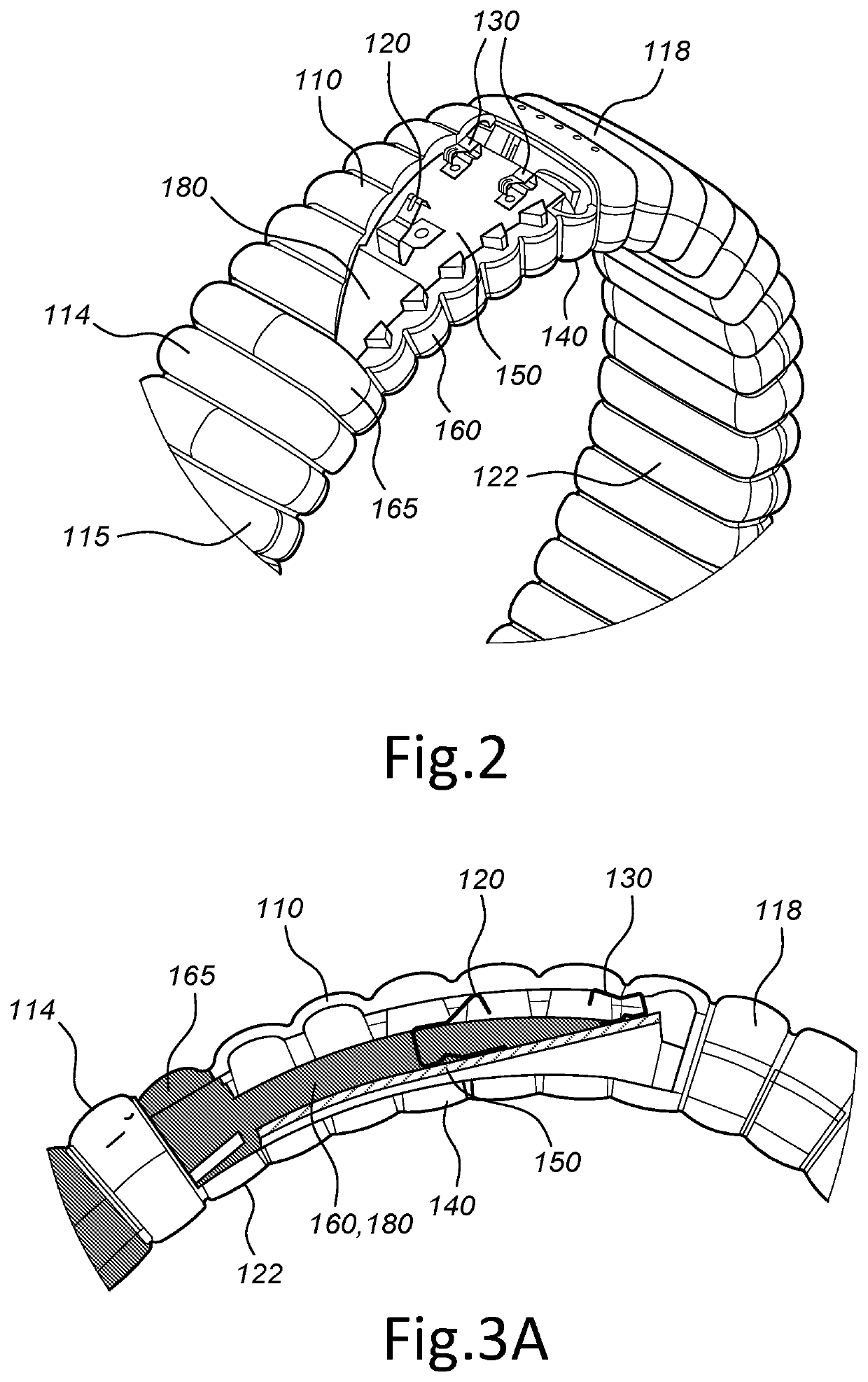

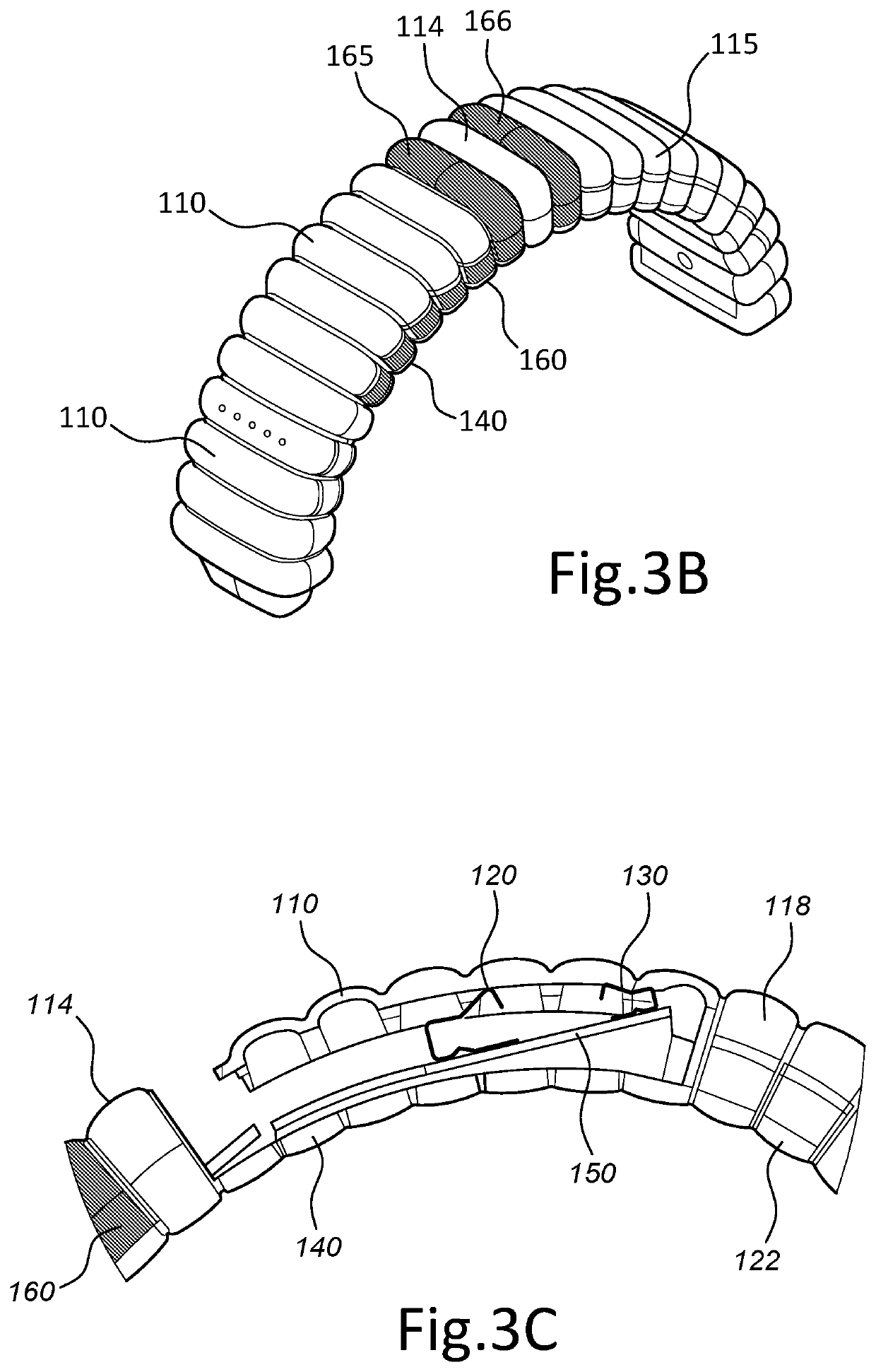

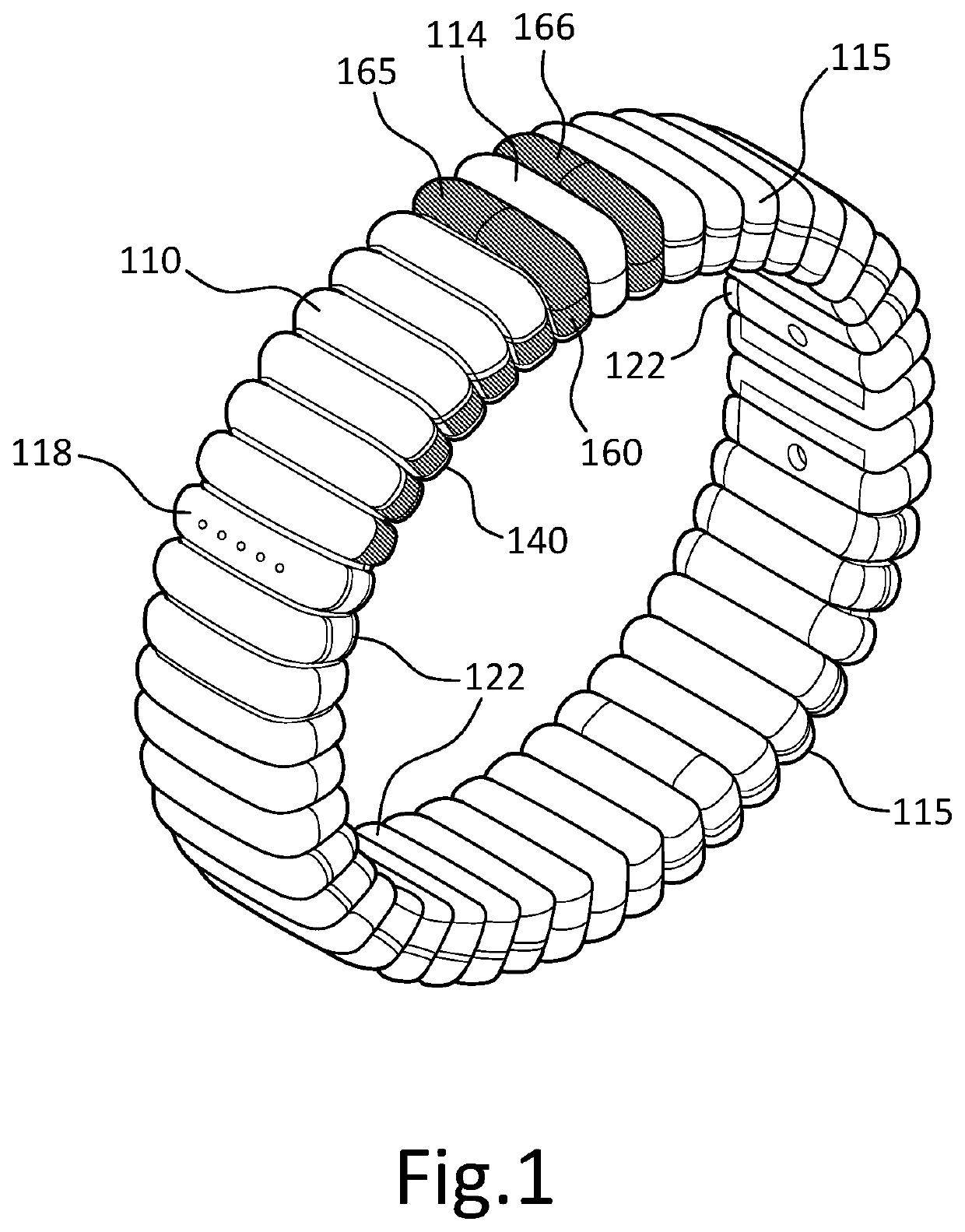

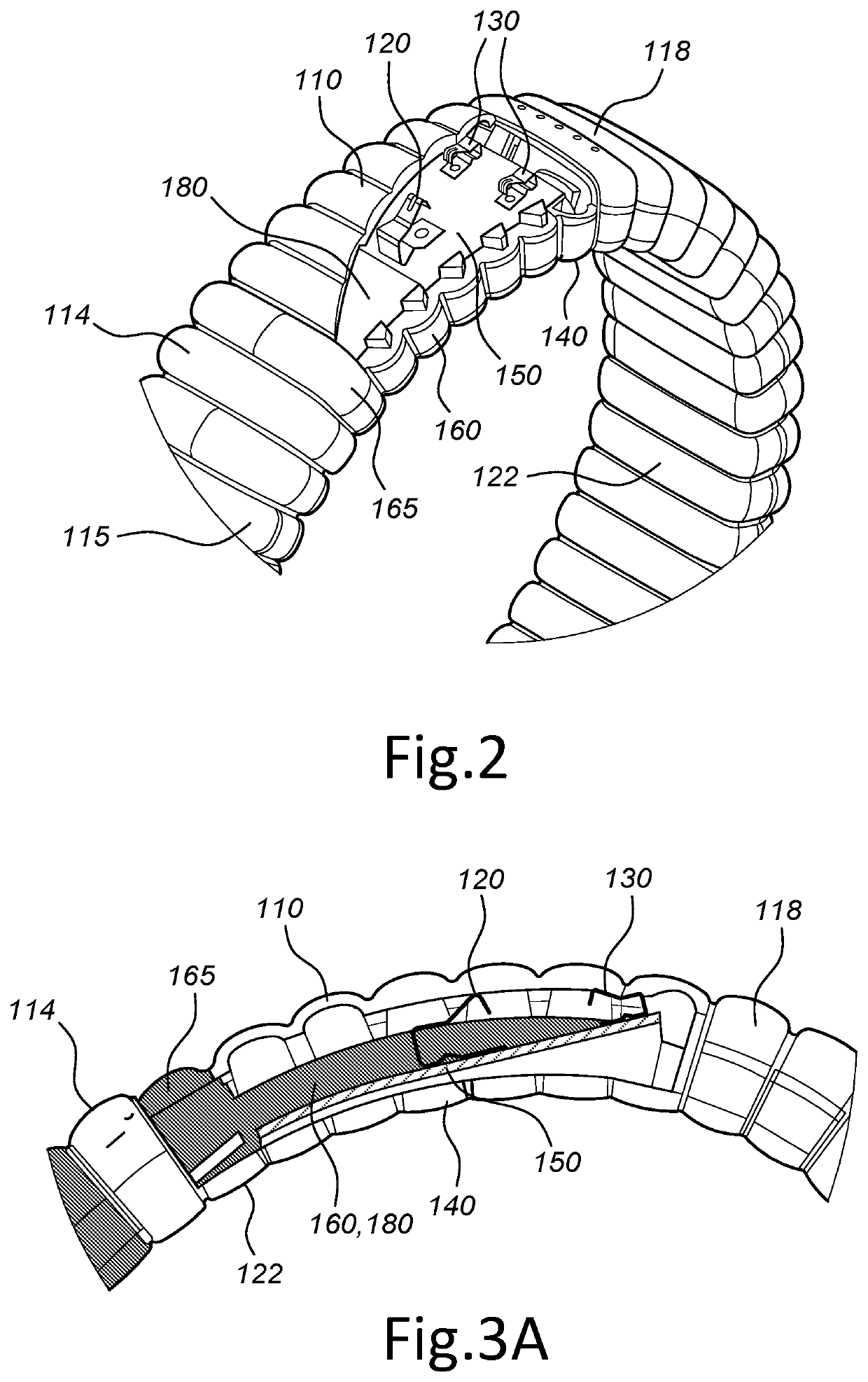

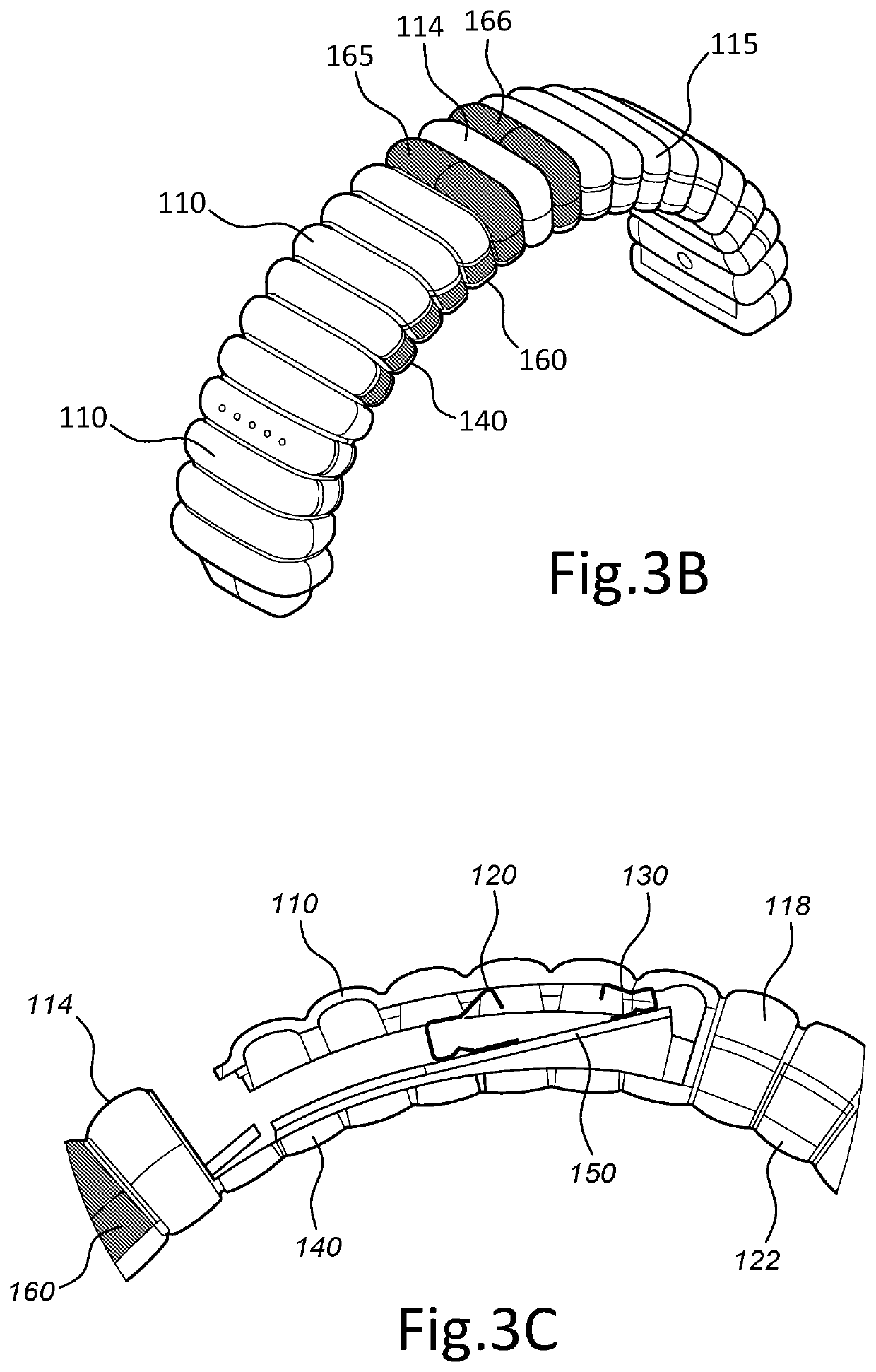

Male button for a snap button

InactiveUS20170265601A1Good lookingImprove marketabilitySnap fastenersPress-button fastenersEngineeringForeign substance

A male button for a snap button is provided that can have an enhanced appearance and that can obtain an advertising effect and a decoration effect while representing a luxurious appearance and that can prevent foreign substances from being entered therein. The male button for a snap button includes: a main body 110 having a surface portion 114 and a press fixing portion 115 having closed front surfaces in order to form a receiving space 113 within a fitting protrusion 111 and a concave peripheral portion 112 protruded in a cylindrical shape; a deformation prevention device 120 received at the receiving space 113 of the main body 110; a snap 130 having a coupling rod 131 and fixed to the press fixing portion 115 of the main body 110; and a snap fixing plate 140 inserted and fixed to the coupling rod 131 of the snap 130.

Owner:SHIN MAL SOON +2

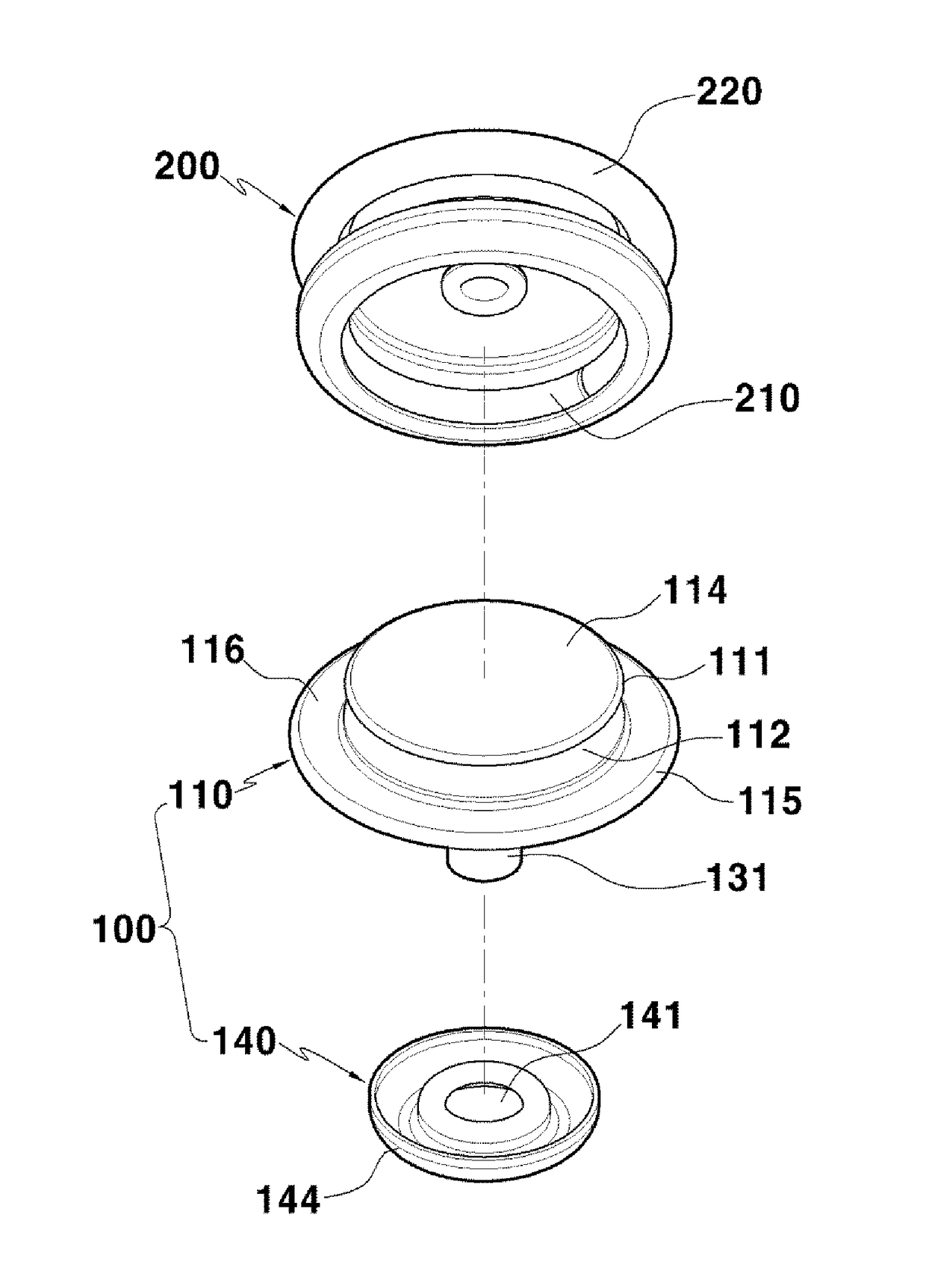

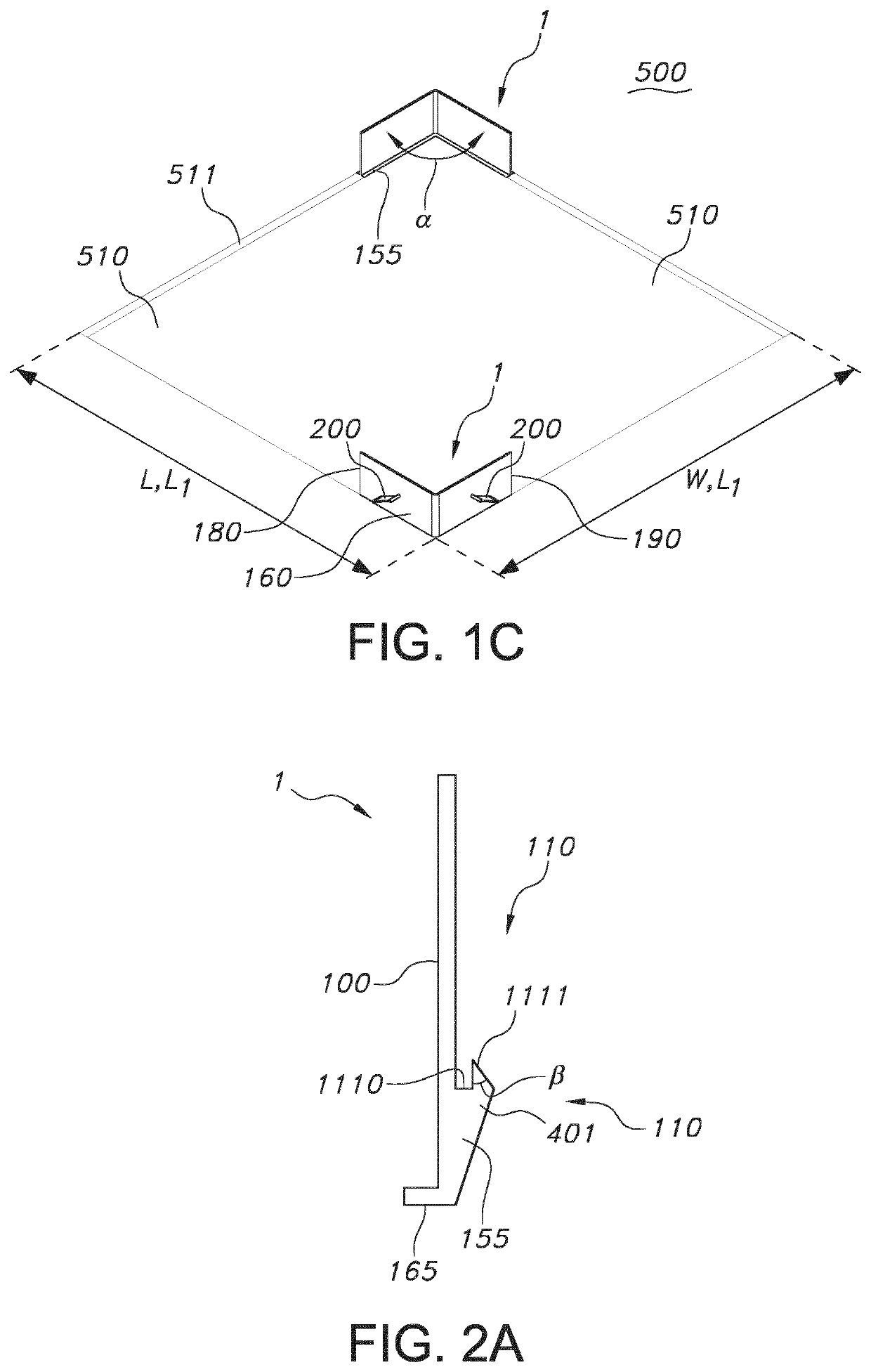

Ceiling interface for luminaires

ActiveUS10801706B2Improve acousticsImprove the climateLighting support devicesFixed installationEngineeringPhysics

Owner:SIGNIFY HLDG BV

Male button for a snap button

InactiveUS9781978B1Good lookingImprove marketabilitySnap fastenersPress-button fastenersCouplingEngineering

A male button for a snap button is provided that can have an enhanced appearance and that can obtain an advertising effect and a decoration effect while representing a luxurious appearance and that can prevent foreign substances from being entered therein. The male button for a snap button includes: a main body having a surface portion and a press fixing portion having closed front surfaces in order to form a receiving space within a fitting protrusion and a concave peripheral portion protruded in a cylindrical shape; a deformation prevention device received at the receiving space of the main body; a snap having a coupling rod and fixed to the press fixing portion of the main body; and a snap fixing plate inserted and fixed to the coupling rod of the snap.

Owner:SHIN MAL SOON +2

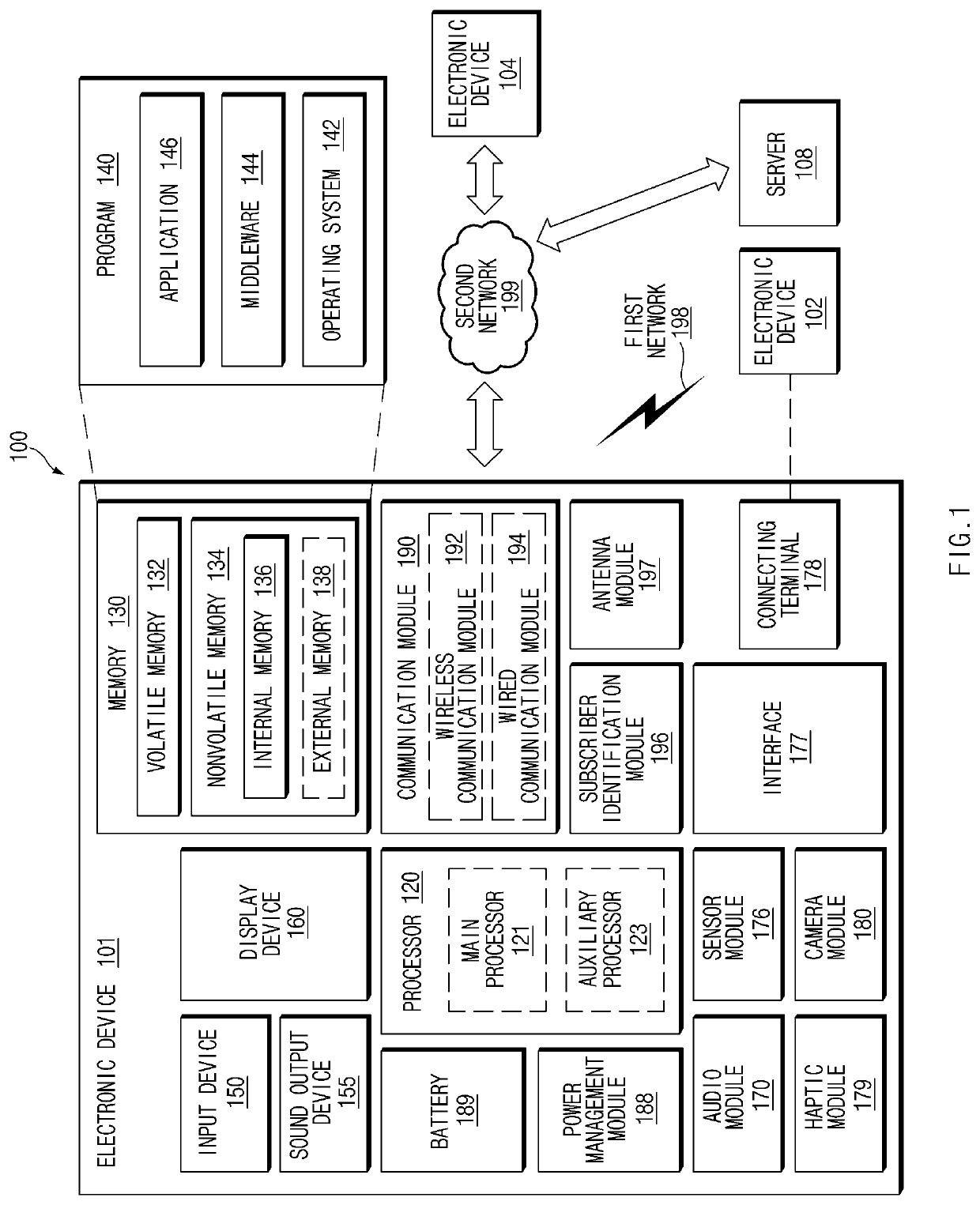

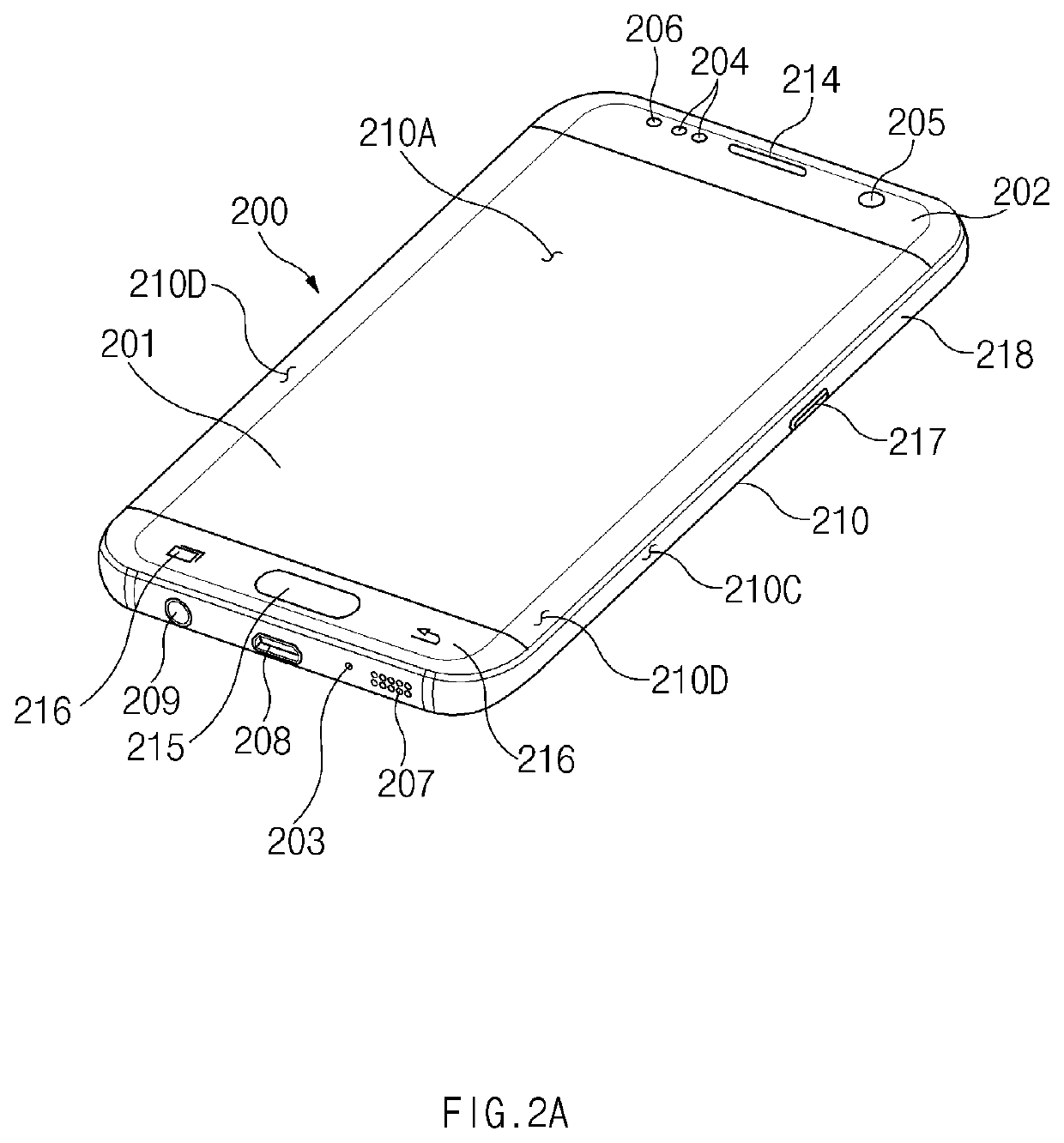

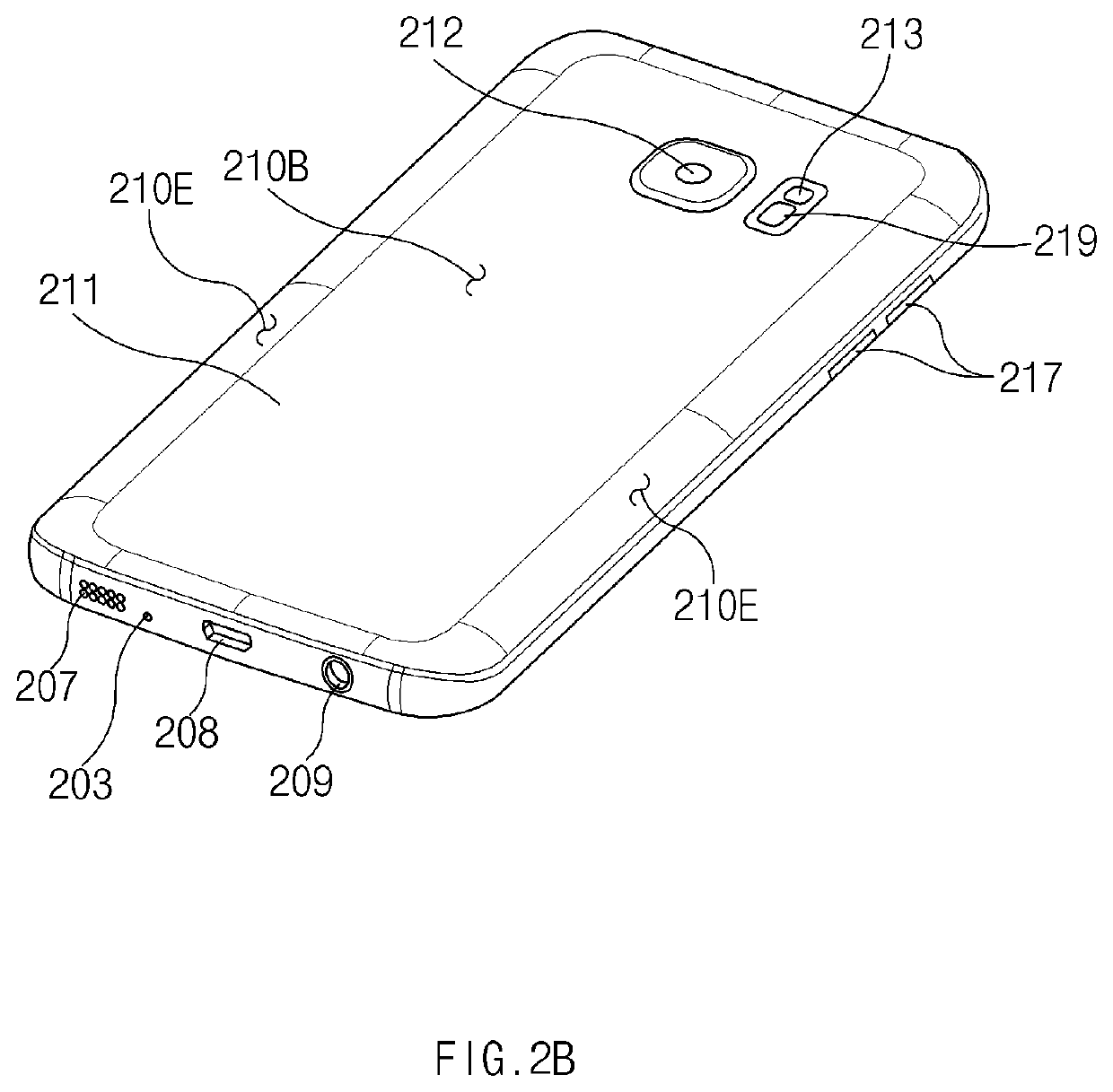

Plate including fine pattern, and electronic device including same

ActiveUS20210347145A1Luxurious appearanceIncrease brightnessSpecial ornamental structuresSubstation equipmentPrismEngineering physics

Disclosed is an electronic device that includes a first plate that forms a first surface of the electronic device through which contents are output, a second plate that forms a second surface facing away from the first surface, and a side member that surrounds a space between the first plate and the second plate. The second plate includes a UV curable resin layer including a fine pattern that implements an interference effect and a prism effect of light and a metal nanoparticle layer printed on the fine pattern so as to have a specific orientation. Besides, it may be permissible to prepare various other embodiments speculated through the specification.

Owner:SAMSUNG ELECTRONICS CO LTD

Vapor deposition film, black metallic product, vehicle interior/exterior member, container, and casing

ActiveUS20200230919A1Luxurious appearanceGood physical propertiesSynthetic resin layered productsVacuum evaporation coatingIndiumPhotopigment

Provided are a vapor deposition film, a black metallic product, a vehicle interior / exterior member, a container, and a casing, which are capable of expressing a jet black metallic design having a luxurious appearance on items of various dimensions by a method simpler than a case of applying black plating and are excellent in physical properties such as light resistance. The vapor deposition film comprises: a protection layer; a decoration layer; and a vapor deposition layer, wherein the vapor deposition layer includes a metal including at least any one of indium and tin, wherein the decoration layer includes a resin and a black pigment, and wherein the black pigment includes carbon black and manganese ferrite having a spinel structure ((Fe,Mn)(Fe,Mn)2O4).

Owner:OIKE IND

Ceiling interface for luminaires

ActiveUS20200088388A1Remove luminaireImprove acousticsLighting support devicesFixed installationEngineeringPhysics

Owner:SIGNIFY HLDG BV

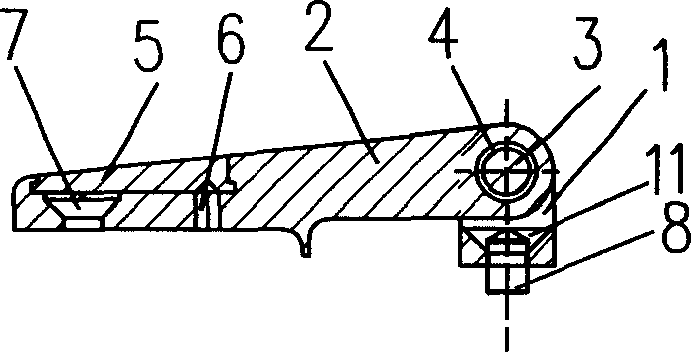

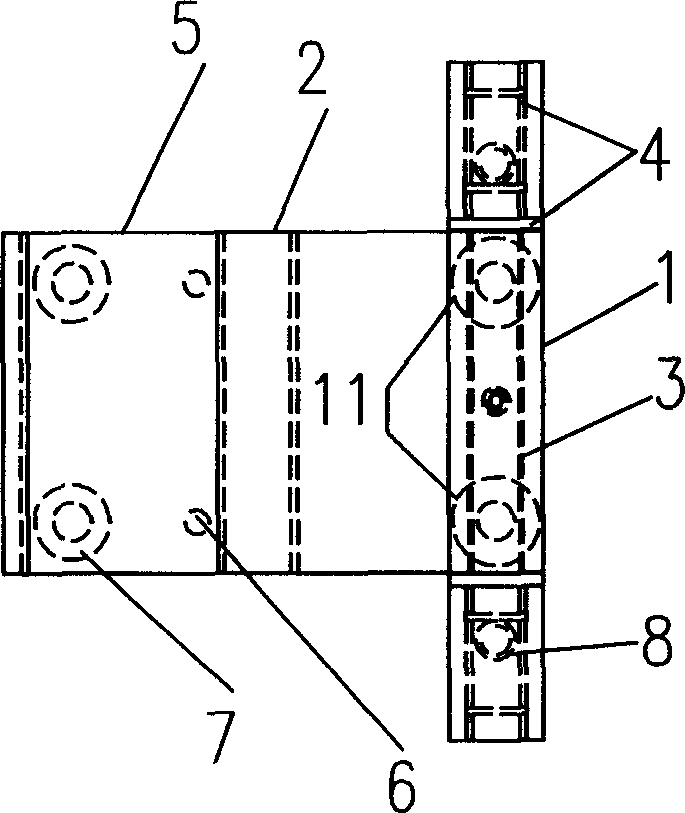

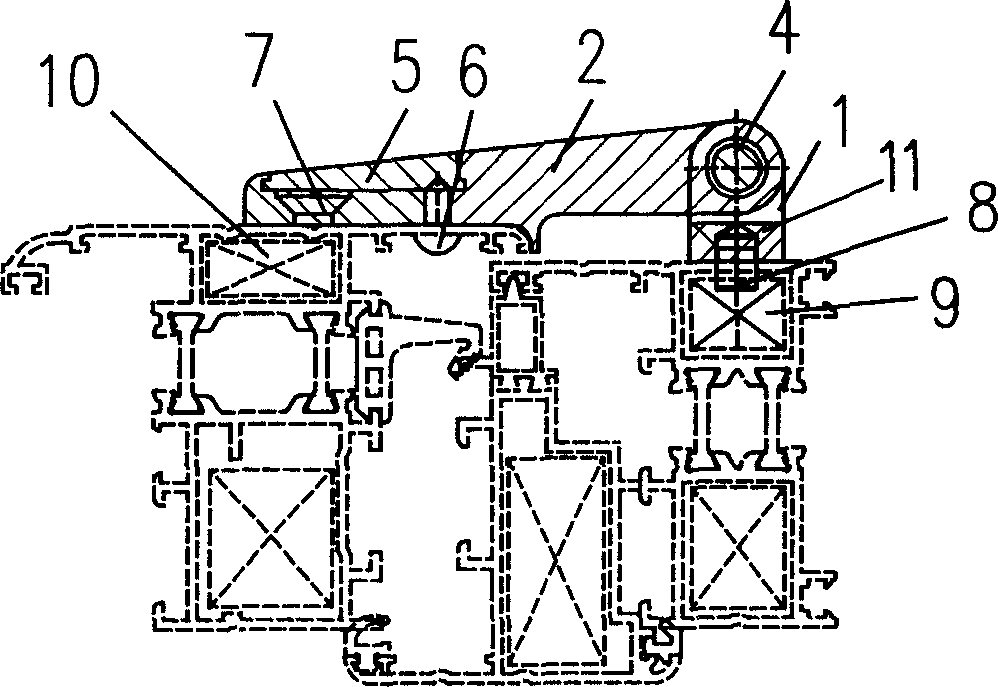

Hinges

Owner:KINGLE ALUMINUM TECH

Light source module of lamp for vehicle

ActiveUS9416934B2Increasing costIncrease awarenessPlanar light sourcesPoint-like light sourceVisibilityPower flow

Disclosed is a light source module for a vehicle. The light source module includes an LED light source, a PCB that controls supply of current to the LED light source, a patterned film disposed on the PCB and provided with an optical pattern which enables a stereoscopic light-emission image of a desired pattern to be formed when light from the LED light source is emitted thereto, and optical resin that is disposed on the patterned film and uniformly transmits the light from the LED light source to the entire range of the patterned film. The light source module improves visibility of the LED light source and makes a lamp using the light source module look luxurious by using a hidden effect of a deposited film even when the LED light source is not turned on.

Owner:HYUNDAI MOTOR CO LTD

Smart wearable device

ActiveUS20210126371A1Effective bandwidthMaximizing metal surfaceAntenna adaptation in movable bodiesAntenna equipments with additional functionsDielectricElectrical conductor

A wearable device comprises wireless communication means and a patch antenna that is coupled to said wireless communication means to receive and / or transmit electromagnetic radiation. Said patch antenna comprises a planar patch conductor and a planar ground conductor that are separated by a dielectric in between said patch conductor and said ground conductor while at least partially overlapping with one another. The device comprises a core inside a shell and comprises at least part of said communication means within said core. Said shell comprises a first shell part and a second shell part opposite said first shell part, wherein said first shell part and said second shell part are at least partially separated by said dielectric. Said first shell part comprises said patch conductor and said second shell part comprises said ground conductor. Said first shell part and said second shell part together form said patch antenna. The wearable device particularly is a piece of jewellery.

Owner:SMARTLINE BV

Smart wearable device

ActiveUS11258175B2Effective bandwidthMaximizing metal surfaceAntenna supports/mountingsAntenna adaptation in movable bodiesDielectricElectrical conductor

A wearable device comprises wireless communication means and a patch antenna that is coupled to said wireless communication means to receive and / or transmit electromagnetic radiation. Said patch antenna comprises a planar patch conductor and a planar ground conductor that are separated by a dielectric in between said patch conductor and said ground conductor while at least partially overlapping with one another. The device comprises a core inside a shell and comprises at least part of said communication means within said core. Said shell comprises a first shell part and a second shell part opposite said first shell part, wherein said first shell part and said second shell part are at least partially separated by said dielectric. Said first shell part comprises said patch conductor and said second shell part comprises said ground conductor. Said first shell part and said second shell part together form said patch antenna. The wearable device particularly is a piece of jewellery.

Owner:SMARTLINE BV

Wood sheet and method for manufacturing the same

ActiveUS9956746B2Good physical propertiesReduce weightVehicle componentsWood layered productsEngineeringWood plank

Disclose are a wood sheet and a method for manufacturing the wood sheet. In particular, the real wood sheet is prepared with natural wood sheets used for interior and exterior materials, a binder and a stiffener, thereby providing patterned veneer appearance. Further, the wood sheet may have improved physical properties and reduced weight and be manufactured with reduced cost.

Owner:HYUNDAI MOTOR CO LTD +1

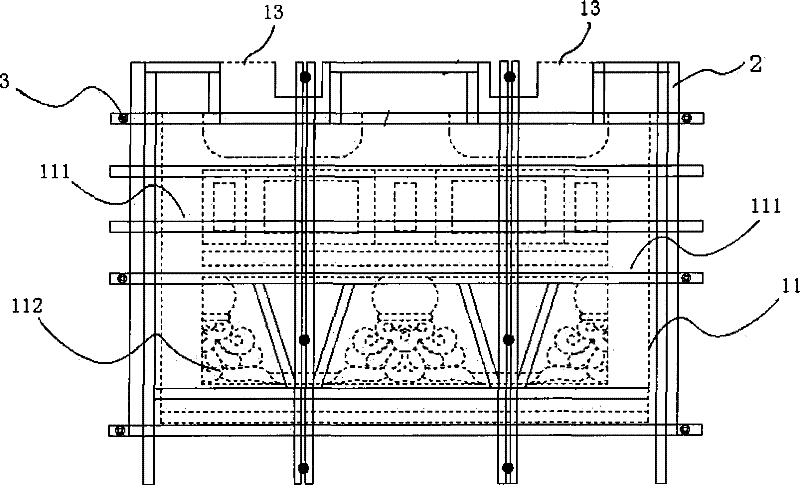

Mould for concrete rails and manufacturing method of mould

ActiveCN102069529BSave resourcesFull display of harmonyMouldsWood working apparatusWeather resistanceStructural engineering

The invention relates to a mould for rails, in particular to a mould for stone-like or wood-like concrete rails suitable for decoration engineering of water conservancy watercourses, municipal bridges, landscape boardwalks, reservoir enclosures, houses, courtyards, flower beds and the like and a manufacturing method of the mould. The mould comprises a mould core and an external mould framework, wherein the mould core comprises a front mould and a rear mould which are provided with pouring holes; the front mould at least comprises two pillar front moulds and a breast board front mould; the breast board front mould is arranged between the two pillar front moulds; in a similar way, the rear mould at least comprises two pillar rear moulds and a breast board rear mould; the breast board rear mould is arranged between the two pillar rear moulds; after the front mould and the rear mould are assembled, the breast board mould cavities are communicated with the pillar mould cavities; the front mould and the rear mould are connected by stationary fixture through sealing; and the external mould framework is fixed on the external surface of the mould core by adhesion materials and / or bolts. The mould and the manufacturing method have the following advantages: simple production steps, energy saving, environmental protection, low cost, simple and reasonable structure, convenience in use, perfect and vivid effect, high strength, water resistance, weather resistance and the like.

Owner:SHANGHAI SHANGTENG INDAL DEV

Production method of artificial stone composite board

InactiveCN103240790BCuring shrinkage is smallHigh densityCeramic shaping apparatusEpoxyArchitectural engineering

Owner:成都汇玉科技产业有限公司

Vapor deposition film, black metallic product, vehicle interior/exterior member, container, and casing

ActiveUS11130311B2Luxurious appearanceGood physical propertiesSynthetic resin layered productsCasings/cabinets/drawers detailsIndiumPhotopigment

Provided are a vapor deposition film, a black metallic product, a vehicle interior / exterior member, a container, and a casing, which are capable of expressing a jet black metallic design having a luxurious appearance on items of various dimensions by a method simpler than a case of applying black plating and are excellent in physical properties such as light resistance. The vapor deposition film comprises: a protection layer; a decoration layer; and a vapor deposition layer, wherein the vapor deposition layer includes a metal including at least any one of indium and tin, wherein the decoration layer includes a resin and a black pigment, and wherein the black pigment includes carbon black and manganese ferrite having a spinel structure ((Fe,Mn)(Fe,Mn)2O4).

Owner:OIKE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com