Production method of artificial stone composite board

A composite board and production method technology, applied in the field of building decoration materials, can solve the problems of ineffective utilization of waste and inferior products, complicated manufacturing process, high production cost, etc., and achieve the effects of tight combination, reduced product weight, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

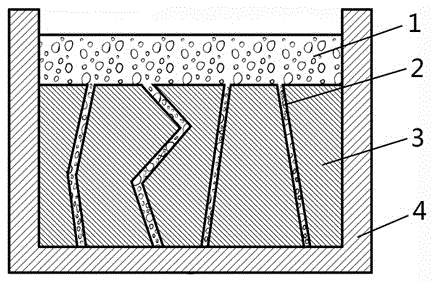

Image

Examples

Embodiment 1

[0032] The production method of the artificial stone composite board in this example is to place the ceramic puzzle board in a mold, and then grade the artificial stone filler, mix it with the low-shrinkage unsaturated polyester resin and auxiliary materials to obtain the mixture, and directly mix the mixture Spread on the jigsaw board, smooth and vibrate to make the material surface level, put it into vacuum equipment to remove air bubbles, and solidify naturally to obtain the artificial stone composite board product.

[0033] The amount of artificial stone filler in this example accounts for 80% of the total weight of the mixture, the amount of low-shrinkage unsaturated polyester resin accounts for 19% of the total weight of the mixture, and the rest are auxiliary materials; the auxiliary materials are curing agent and silane coupling Agents and dyes.

[0034] The amount of the silane coupling agent used as the auxiliary material in this example accounts for 0.05% of the total we...

Embodiment 2

[0042] The production method of the artificial stone composite board in this example is to place the whole ceramic substrate in a mold, and then gradate the artificial stone filler, and fully mix it with the low-shrinkage unsaturated polyester resin auxiliary material to obtain the mixture, and directly mix the mixture It is spread on the substrate, smoothed and vibrated to make the material surface level, put into vacuum equipment to remove air bubbles, heated and solidified, and the surface is polished and polished to obtain an artificial stone composite board product.

[0043] The amount of artificial stone filler in this example accounts for 87% of the total weight of the mixture, the amount of low-shrinkage unsaturated polyester resin accounts for 12% of the total weight of the mixture, and the rest are auxiliary materials; the auxiliary materials are curing agent and silane coupling Agents, accelerators, dyes.

[0044] In this example, the amount of silane coupling agent used...

Embodiment 3

[0052] The production method of the artificial stone composite board in this example is to place a cement concrete substrate in a mold, and then grade the artificial stone filler, mix it with the low-shrinkage epoxy resin mixture and auxiliary materials to obtain the mixture, and directly spread the mixture After smoothing and vibrating on the substrate, the material surface is leveled, and then placed in a vacuum device to remove air bubbles and solidify naturally to obtain an artificial stone composite board product.

[0053] The amount of artificial stone filler described in this example accounts for 81% of the total weight of the mixture, the amount of low-shrinkage epoxy resin mixture accounts for 18% of the total weight of the mixture, and the amount of dye as an auxiliary material accounts for 1% of the total weight of the mixture Brown paint paste.

[0054] The epoxy resin in this example is a mixture. In the mixture, the amount of epoxy resin accounts for 70% of the total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com