Production method for artificial stone composite boards

A composite board and production method technology, applied in the field of building decoration materials, can solve the problems of ineffective utilization of waste and inferior products, complicated manufacturing process, high production cost, etc., and achieve the effects of tight combination, reduced product weight, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

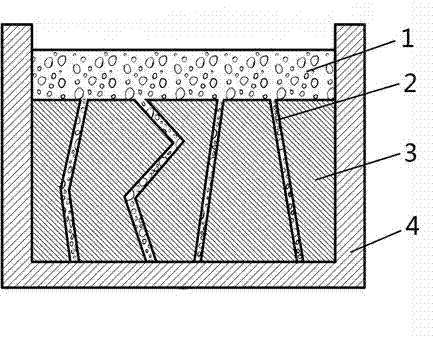

Image

Examples

Embodiment 1

[0032] The amount of the silane coupling agent used as an auxiliary material in this example accounts for 0.05% of the total weight of the mixture, and the silane coupling agent is KH-570, namely γ-methacryloxytrimethoxysilane.

[0033] The amount of curing agent described in this example as an auxiliary material is 2% of the unsaturated polyester resin weight, and the curing agent is methyl ethyl ketone peroxide.

[0034]The amount of dyes used as auxiliary materials in this example is 0.4% of titanium dioxide and 0.17% of fast yellow in the total weight of the mixture.

[0035] The artificial stone filler described in this example is quartz slag.

[0036] The gradation weight ratio of the artificial stone filler described in this example is: 2% for 7-16 mesh, 18% for 16-20 mesh, 20% for 20-40 mesh, 20% for 40-70 mesh, 15% for 70-180 mesh, 180 mesh -325 mesh 25%, the weight ratio is based on the total weight of artificial stone filler.

[0037] The low-shrinkage unsaturated...

Embodiment 2

[0042] In this example, the amount of silane coupling agent used as an auxiliary material accounts for 0.1% of the total weight of the mixture, and the silane coupling agent is KH-570, that is, γ-methacryloxytrimethoxysilane.

[0043] The curing agent consumption of this example as auxiliary material is 2% of unsaturated polyester resin weight, and curing agent is methyl ethyl ketone peroxide; The accelerator consumption as auxiliary material is 3% of unsaturated polyester resin weight, and accelerator is cobalt isooctanoate.

[0044] The amount of dyestuff described in this example as an auxiliary material is 0.3% of the black pigment paste of the total weight of the mixture.

[0045] The artificial stone filler described in this example is a mixture of quartz slag and glass slag.

[0046] The gradation weight ratio of artificial stone filler described in this example is: glass slag 7-16 mesh 13%, 16-20 mesh 13%, 20-40 mesh 19%, 40-70 mesh 18%, quartz sand 70-180 mesh 15%, 1...

Embodiment 3

[0052] The epoxy resin of this example forms a mixture. In the mixture, the amount of epoxy resin accounts for 70% of the total weight of the mixture, and the amount of diluent accounts for 13% of the total weight of the mixture. The diluent is acetone, and the amount of curing agent accounts for 17% of the total weight of the mixture. , the curing agent is ethylenediamine.

[0053] The artificial stone filler described in this example is a mixture of quartz slag and glass slag.

[0054] The gradation weight ratio of the artificial stone filler described in this example is: glass slag 7-16 mesh 15%, 16-20 mesh 15%, quartz sand 20-40 mesh 16%, 40-70 mesh 16%, 70-180 mesh 16%, 180-325 mesh 22%, the weight ratio is based on the total weight of artificial stone filler.

[0055] The low-shrinkage epoxy resin described in this example is bisphenol A type E-44# epoxy resin produced by Jiangsu Sanmu Company.

[0056] Performance indicators of the product obtained in this example: fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com