Mould for concrete rails and manufacturing method of mould

A manufacturing method and technology for concrete railings, which are applied in the field of molds for stone-like or wood-like concrete railings and their manufacture, to achieve the effect of luxurious appearance, extraordinary style and simple production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

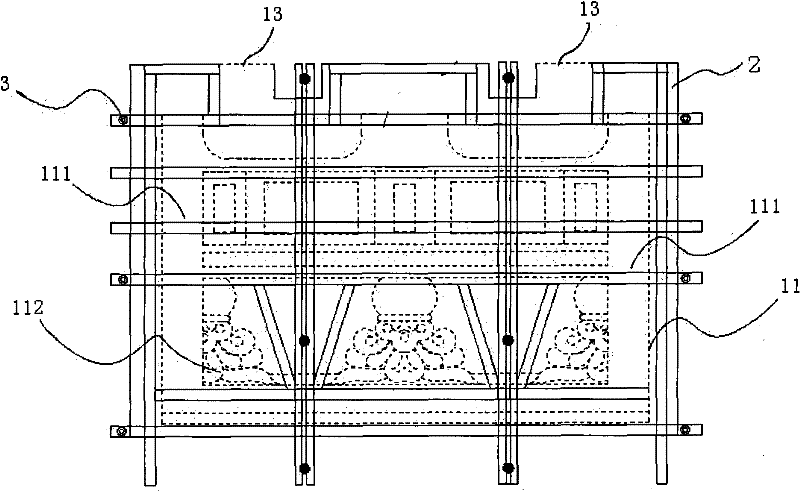

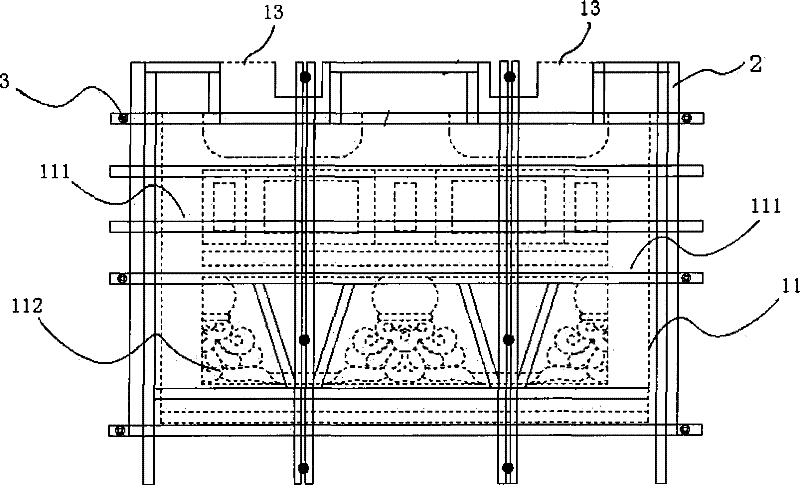

Image

Examples

Embodiment 1

[0041] The method for preparing a stone-like railing with a volume of 0.5 cubic meters and a weight of 80 kilograms is carried out according to the following steps:

[0042] 1. Prepare the mold core:

[0043] 1) Select coniferous tree species as the model of the imitation stone concrete railing mold, and perform mechanical carving on the model according to the shape of the required railing pillars and railings;

[0044] 2) After the carving is completed, sand the surface of the model with woodworking sandpaper until the surface of the model is smooth;

[0045] 3) Evenly coat a layer of release agent on the smooth surface of the model, the release agent is a concentration of 5% LEYCO-SLICK, and then dry at room temperature;

[0046] 4) Use a woodworking drill to drill a ventilation hole on the back of the mold at the position where the mold has obvious unevenness, and then blow the drill hole with compressed air at 4 atmospheres until the air flow is smooth and unblocked, then...

Embodiment 2

[0062] The method for preparing imitation stone balusters whose head is phoenix-shaped, slab is plum-shaped, and has a volume of 1 cubic meter and a weight of 120 kg is carried out according to the following steps:

[0063] 1. Prepare the mold core:

[0064] 1) Select coniferous tree species as the model of the imitation stone concrete railing mold, and perform mechanical carving on the model according to the shape of the required railing pillars and railings;

[0065] 2) After the carving is completed, sand the surface of the model with woodworking sandpaper until the surface of the model is smooth;

[0066] 3) Apply a layer of LEYCO-SLICK with a concentration of 12% evenly on the smooth mold surface, and then dry it at room temperature;

[0067] 4) Use a woodworking drill to drill a ventilation hole on the back of the mold at the position where the mold has obvious unevenness, and then blow the drill hole with compressed air at 5 atmospheres until the air flow is smooth and...

Embodiment 3

[0083] The head of the imitation stone railing is auspicious cloud shape, the slab is magnolia shape, and the method for the imitation stone railing with a volume of 1.5 cubic meters and a weight of 150 kg is carried out according to the following steps:

[0084] 1. Prepare the mold core:

[0085] 1) Select coniferous tree species as the model of the imitation stone concrete railing mold, and perform mechanical carving on the model according to the shape of the required railing pillars and railings;

[0086] 2) After the carving is completed, sand the surface of the model with woodworking sandpaper until the surface of the model is smooth;

[0087] 3) Apply a layer of 5% talcum powder evenly on the surface of the smooth model, and then dry it at room temperature;

[0088] 4) Drill a ventilation hole on the back of the mold with a woodworking drill at the position where the mold has obvious unevenness, and then blow the drill hole with compressed air at 6 atmospheres until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com