Steering wheel for automobile and method of fabricating the same

A technology of steering wheel, metal frame, applied in the direction of steering control mounted on the car, craft for producing decorative surface effects, decorative art, etc., which can solve the problems of steering wheel embedding, difficulty, heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

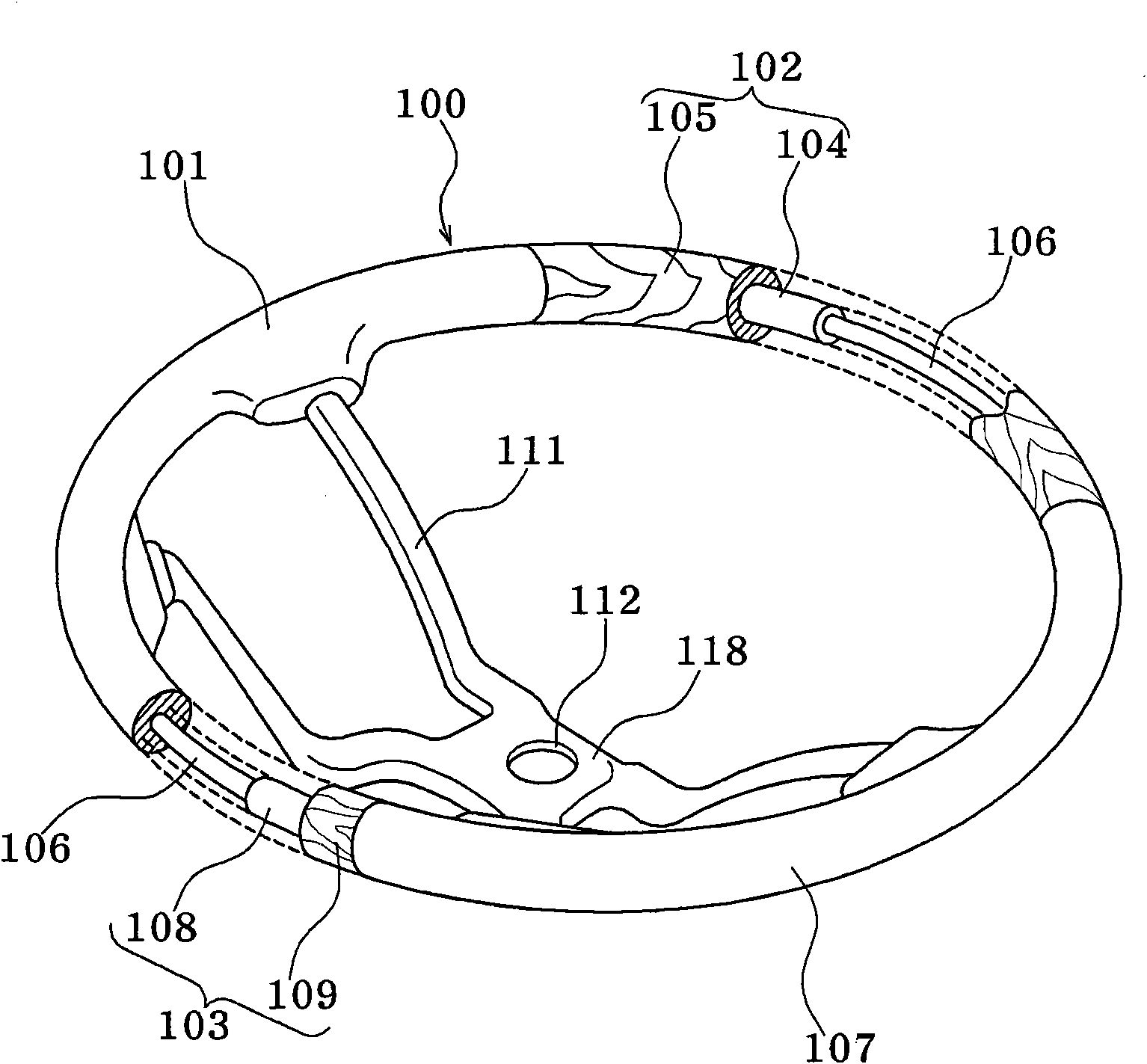

[0104] Example 1 relates to a method of manufacturing a steering wheel by using image 3 The mold is shown embedded with a plurality of pattern parts by applying automatic transfer printing.

[0105] The method of Example 1 generally includes: preheating, building the initial injection molded part, embedding the initial pattern part, building the second injection molded part, embedding the second pattern part, building the third injection molded part, building the polyurethane foam, building the protective coating Layers and stitched leather.

[0106] The preheating is performed in a desiccator to preheat the axle core 13 integrally connected with the gold layer frame 10 .

[0107] For this operation, the axle core 13 is prepared integrally connected with the metal frame 10 .

[0108] The axle core 13 and the metal frame 10 are subjected to various checks to determine whether they are suitable in terms of quality and other conditions for manufacturing the steering wheel.

...

example 2

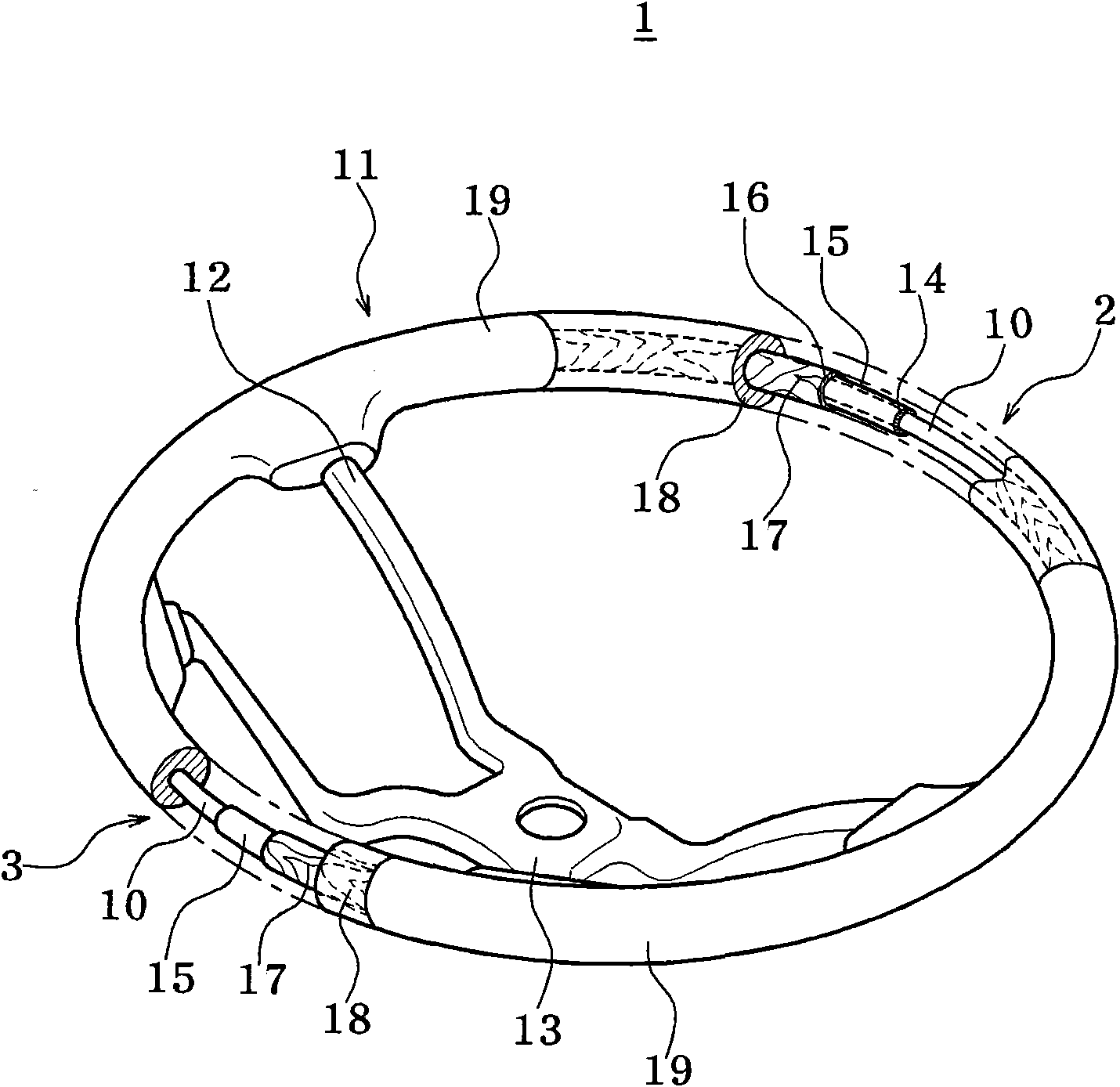

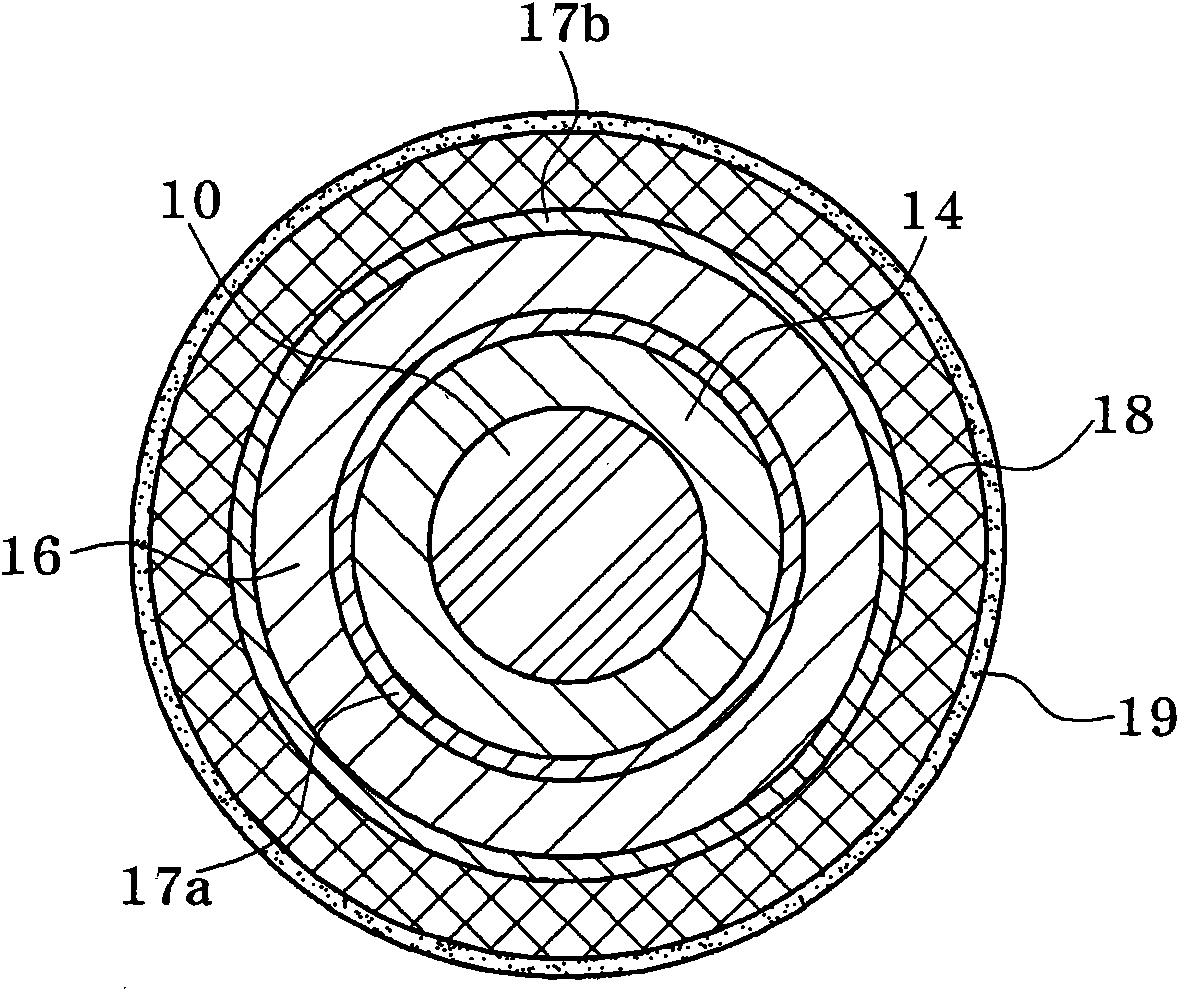

[0148] Example 2 relates to a method of manufacturing a steering wheel by using Figure 4 The mold shown is embedded in the vacuum coating part 15 and the pattern part 17 by a combination of vacuum coating and automatic transfer.

[0149] The method of Example 2 includes: preheating, building the initial injection molded part, embedding the vacuum coating part, building the second injection molded part, embedding the pattern part, building the third injection molded part, building the polyurethane foam, building the protective coating, and sewing leather.

[0150] As in Example 1, the preheating is performed in a dryer to preheat the axle core 13 integrally connected with the metal frame 10 . Therefore, a detailed description thereof is omitted here.

[0151] Here, the opaque resin used for the primary injection molding part 14 may be polycarbonate (PC). However, in Example 2, polyethylene terephthalate (PET) was used as the opaque resin as the primary injection-molded part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com