Plastic transport container for transporting and/or storing goods and similar items

A technology for transporting containers and articles, applied in the field of transport containers, can solve the problem of not helping to form the container wall, etc., and achieve the effect of increasing fracture resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

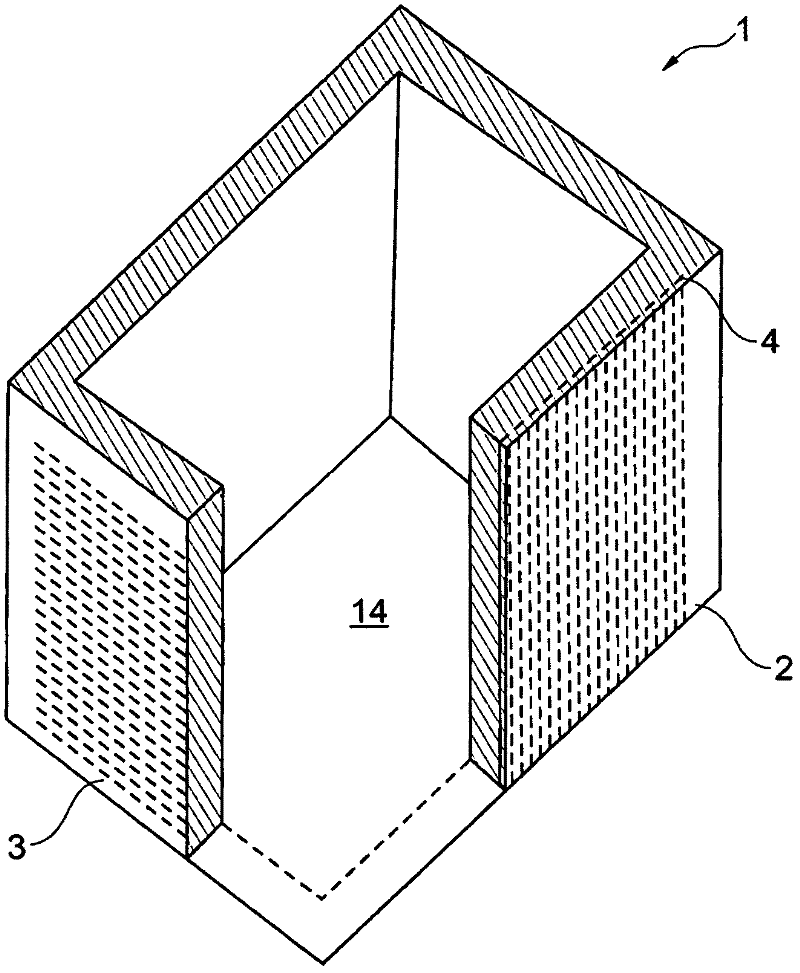

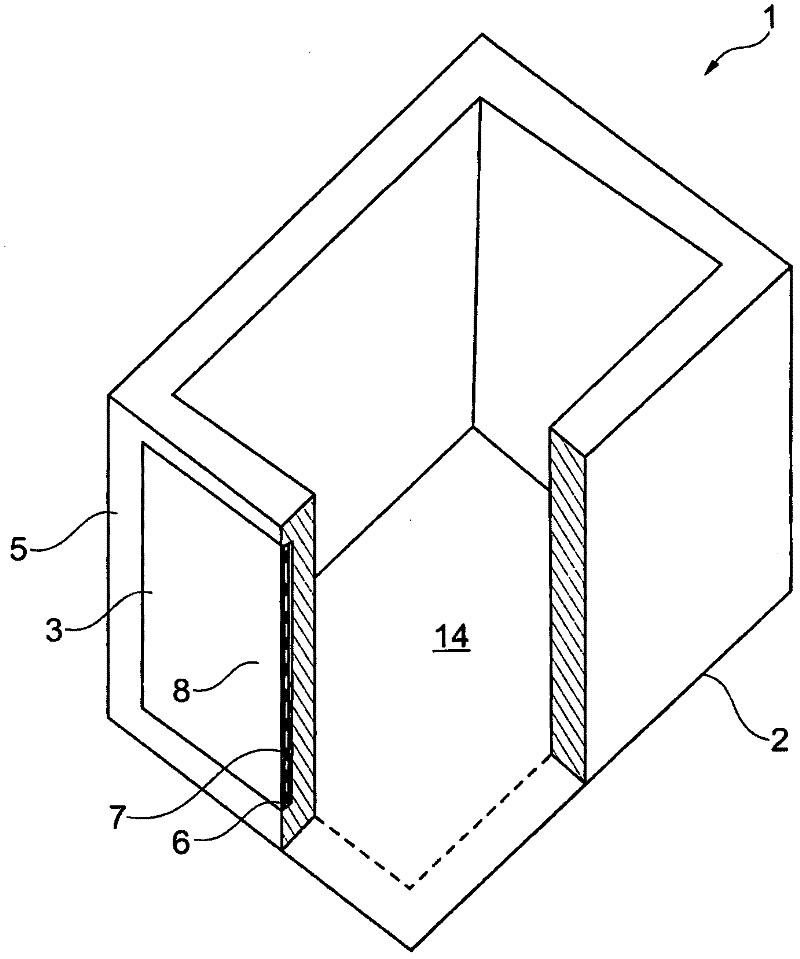

[0020] figure 1 A schematic perspective view of a container designated with reference numeral 1 is shown, here having four peripherally arranged side walls, wherein the two forward side walls facing the viewer are designated with reference numerals 2 and 3 . The bottom is marked 14 and the four side walls are integrally formed at the bottom. figure 1 The container shown is injection molded from a suitable plastics material.

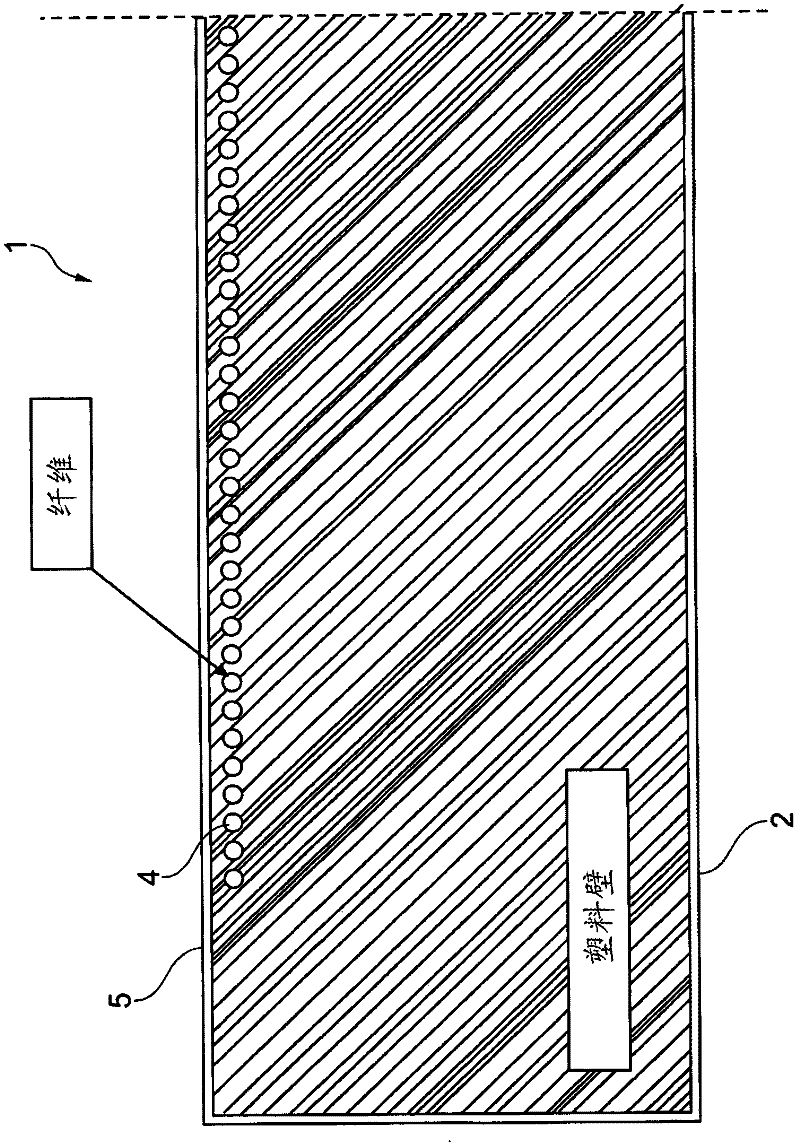

[0021] figure 1 It can be clearly seen in that the fibers 4, such a large number of fibers 4, are embedded (in particular encapsulated) in the side wall of the container, wherein figure 1 The fibers in the illustrated embodiment are arranged substantially parallel to one another. figure 1 The right side wall of , labeled numeral 2, shows such a structure. This means that at least the flat areas of the side walls 2 are provided with fibers embedded in the plastic material of the container 1 . In the illustrated embodiment, the fiber-embedded planar re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com