Screwed stator frame for an electric motor and associated manufacturing process

A technology of a motor stator and a manufacturing method, which is applied in the manufacture of motor generators, stator/rotor bodies, and electric components, etc., can solve problems such as the formation of hot spots or magnetic imbalances, which are not conducive to the normal operation of motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

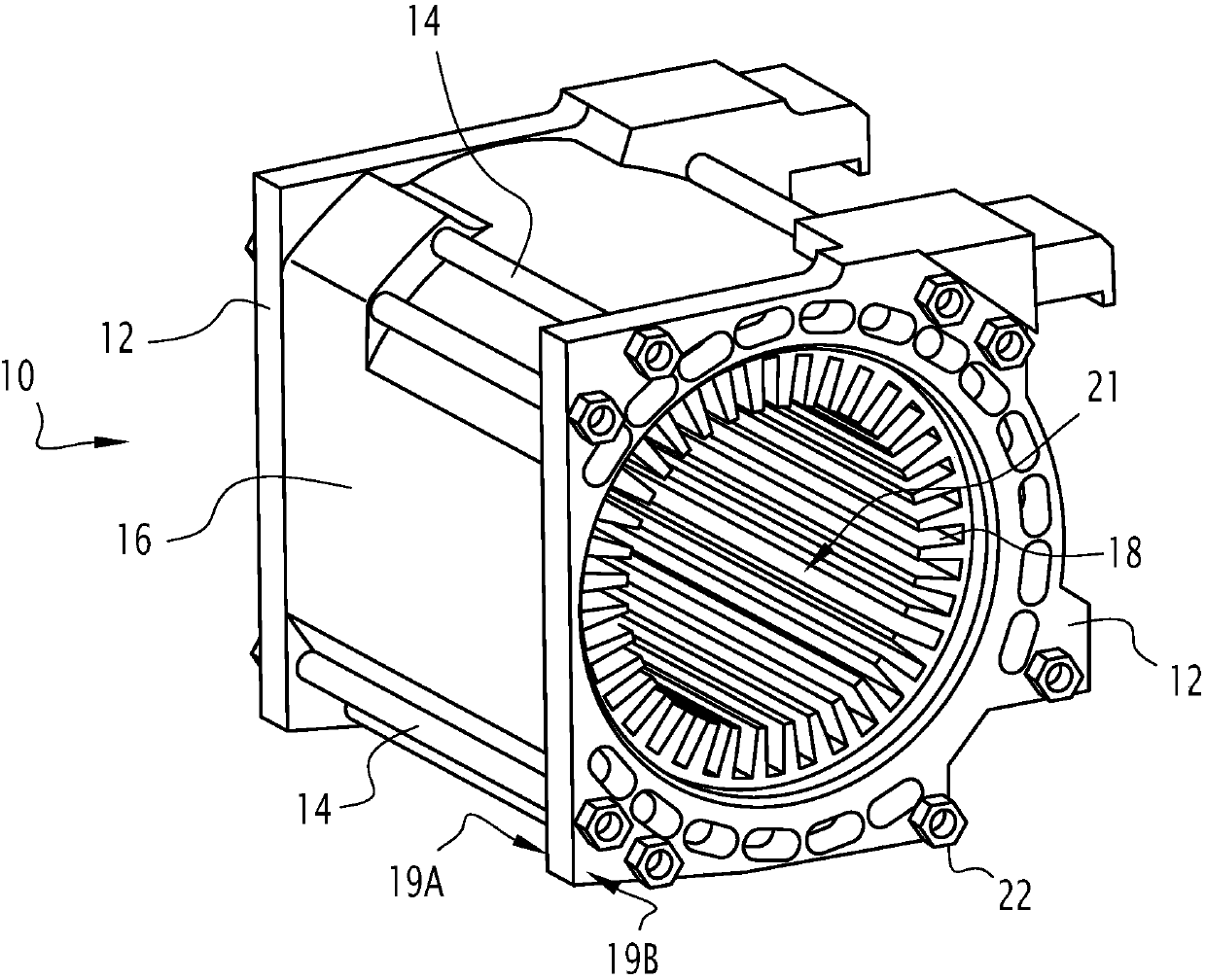

[0032] figure 1 The motor stator frame 10 shown in FIG. 2 includes two substantially parallel plates 12 and at least one bar 14 connecting the two plates 12 . Advantageously, the frame 10 comprises a side wall 16 fitted by clamping between two plates 12 and capable of housing and protecting the stator 18 of the electric motor.

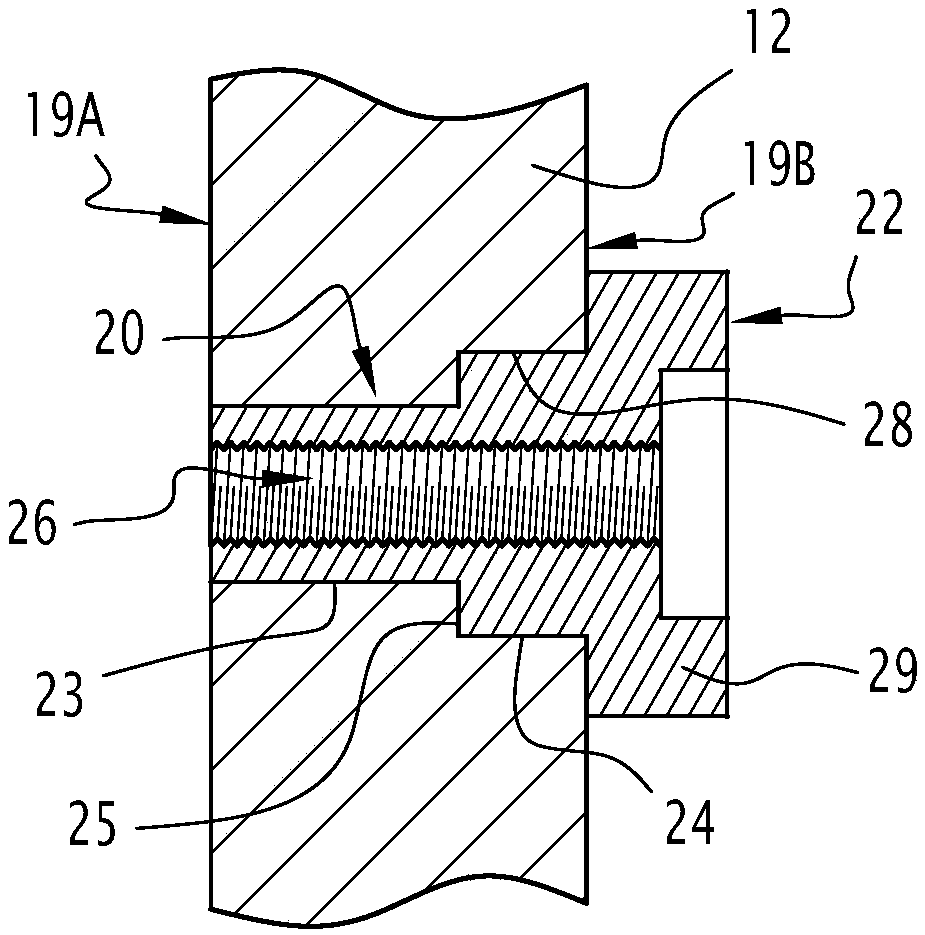

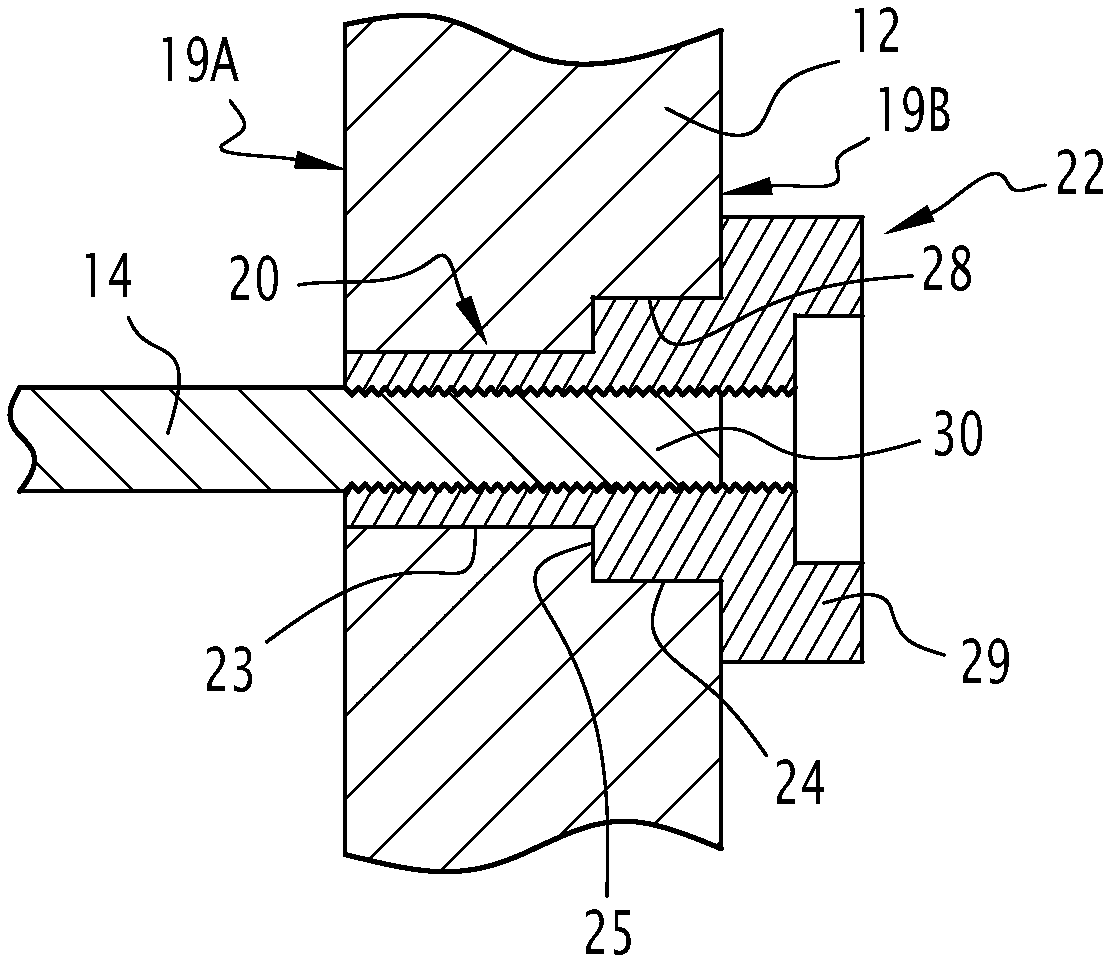

[0033] The plate 12 is molded from cast iron and is generally flat and has an inner face 19A and an outer face 19B. Both plates 12 also include at least one through hole 20 . By through hole is meant that each hole 20 is open at both ends thereof and opens onto the inner face 19A and the outer face 19B of the plate 12 . Each plate 12 also includes a generally circular central aperture 21 that allows passage of the rotor in the frame 10 .

[0034] Each hole 20 is punched in the plate 12 and has a circular cross-section. Additionally, each bore 20 receives a threaded bushing 22 . In addition, each hole 20 is composed of an inner section 23 opening o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com