Patents

Literature

42results about How to "Achieve weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based coating containing graphene/zinc-aluminum hydrotalcite nano composition and preparation method thereof

InactiveCN106995643AImprove compatibilitySolve reunionFireproof paintsAnti-corrosive paintsWater basedDefoaming Agents

The invention discloses water-based coating containing a graphene / zinc-aluminum hydrotalcite nano composition and a preparation method thereof. The water-based coating is prepared from the following components in parts by weight: 30 to 50 parts of water-based resin, 25 to 40 parts of water, 0.1 to 0.5 part of dispersing agent, 0.1 to 0.5 part of wetting agent, 0.1 to 0.5 part of defoaming agent, 0.1 to 0.5 part of thickening agent, 0.1 to 0.5 part of film forming aids, 0 to 10 parts of curing agent, 0 to 25 parts of titanium dioxide, 0 to 20 parts of calcium carbonate, and 0.1 to 2.5 parts of graphene / zinc-aluminum hydrotalcite nano composition. The graphene / zinc-aluminum hydrotalcite nano composition is added into the water-based coating, so that the high temperature resistance, the corrosion resistance, the flame retardant property, the weather resistance, the impact resistance, the abrasion resistance, the hardness and the obstruction property of the water-based coating are significantly improved, and the multiple functions of the water-based coating are improved.

Owner:东营聚强新材料有限责任公司

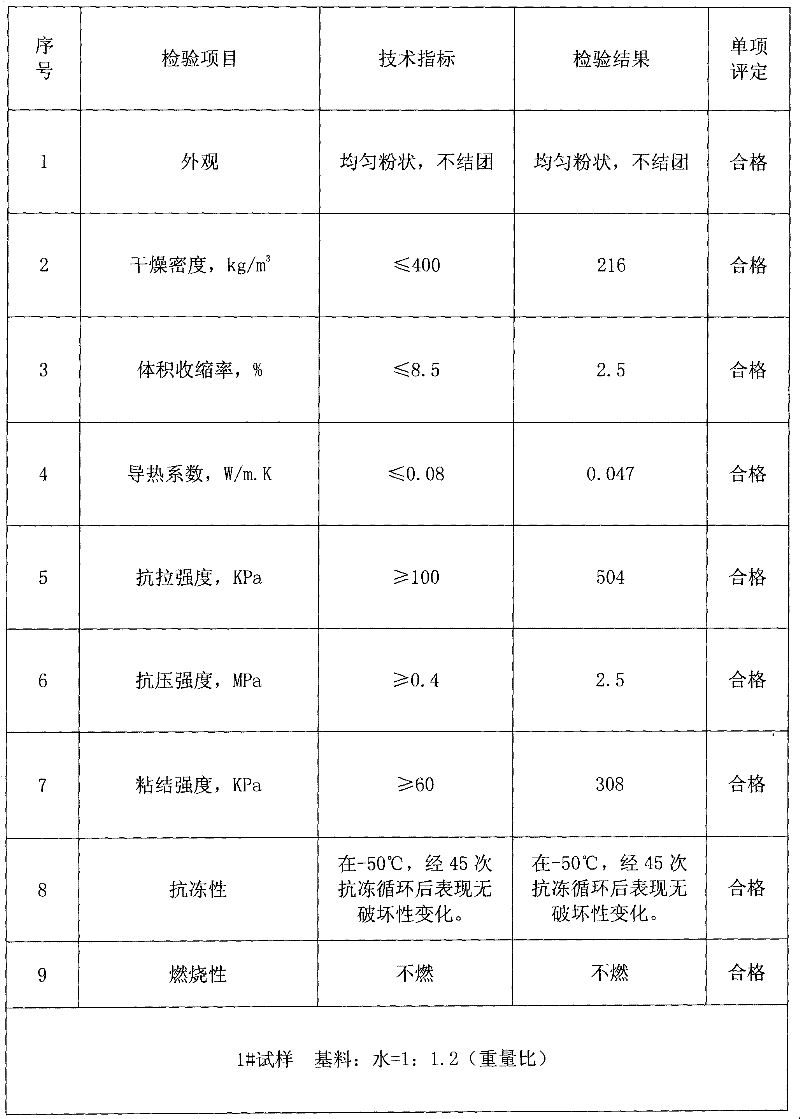

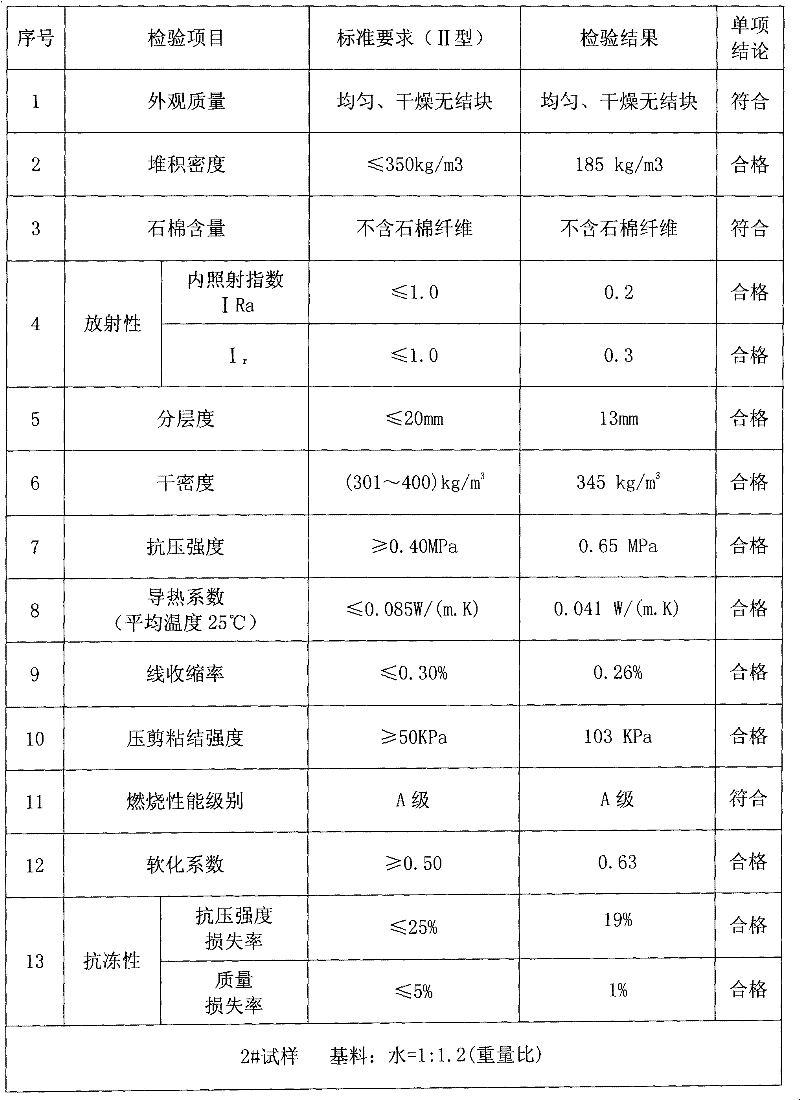

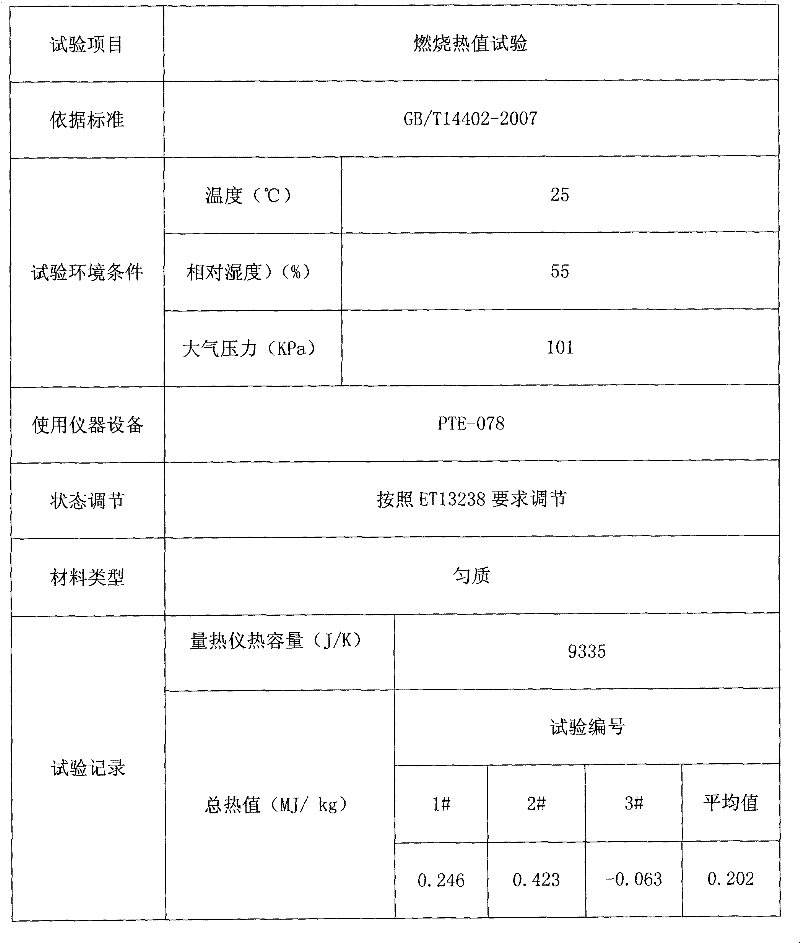

Siliceous heat-insulation composite material for wall

The invention relates to a siliceous heat-insulation composite material for a wall, which comprises base materials and water. The base materials mainly comprise closed-cell expanded perlite, cement, building gypsum, inorganic mineral substance fibers, high-viscosity attapulgite clay, redispersible rubber powder, hydroxypropyl methyl cellulose auxiliaries and a water repellent, wherein the inorganic mineral substance fibers comprise alumina silicate fibers, brucite fibers, mineral cotton fibers and the like, and when the material is used, the weight ratio of the base materials to the water is 1:1.2-1.3. The material as an amorphous powdery heat-insulation material is excellent in energy conservation, heat insulation, sound absorption, flame retardance reaching level A1, fireproofing, seismic resistance, crack control, flexibility and weatherability, does not chemically react with the wall, is high in strength and ageing resistance, avoids deformation, crack, hollowing, shedding and is the same as the wall in service life in use. The material is green, environment-friendly and non-toxic, is applicable to heat insulation of an inner wall and an outer wall made of various wall base materials, a splitting wall and heat-insulation energy-saving projects such as roofs, basements, garages, stairs, corridors, fire-fighting accesses and the like.

Owner:建平县德鑫外墙保温材料有限责任公司

Water-based nano reflection and heat insulation transparent coating and preparation method thereof

ActiveCN105505060AReduce energy consumptionAchieve integrity and water resistanceAntifouling/underwater paintsChemical industryEmulsionNano dispersion

The invention discloses a water-based nano reflection and heat insulation transparent coating and a preparation method thereof. The formula of the coating comprises the followings in percentages by weight: 35%-50% of a water-based acrylic emulsion, 5%-15% of water-based lithium silicate, 5%-15% of a water-based polyurethane emulsion, 5%-10% of a water-based heat insulation nano dispersion sizing agent, 5%-10% of a water-based heat insulation and heat preservation nano dispersion, 2%-12% of a wetting dispersant, 0.2%-0.5% of a flatting agent, 0.2%-1% of a thickener, 0.1%-0.2% of an antifungus and anti-mildew agent, 0.5%-2.5% of a coalescing agent, 0.5%-2% of a silane coupling agent and 5%-25% of deionized water. According to the water-based nano reflection and heat insulation transparent coating disclosed by the invention, under the precondition of without influencing lighting, heat radiation is blocked and infrared heat energy is prevented from being conducted into the interior of a base material through effective reflection and heat energy conduction, and thus the effects of heat insulation and heat preservation are reached. Heat energy, entering the room through the base material, generated by an outdoor heat source can be effectively blocked in summer, and indoor heat can be effectively blocked from being dispersed in winter, so that the application of refrigeration and heat preservation equipment can be effectively reduced, and the energy-saving effect is obvious.

Owner:CHANGSHA MINDE FIRE ENG PAINT CO LTD

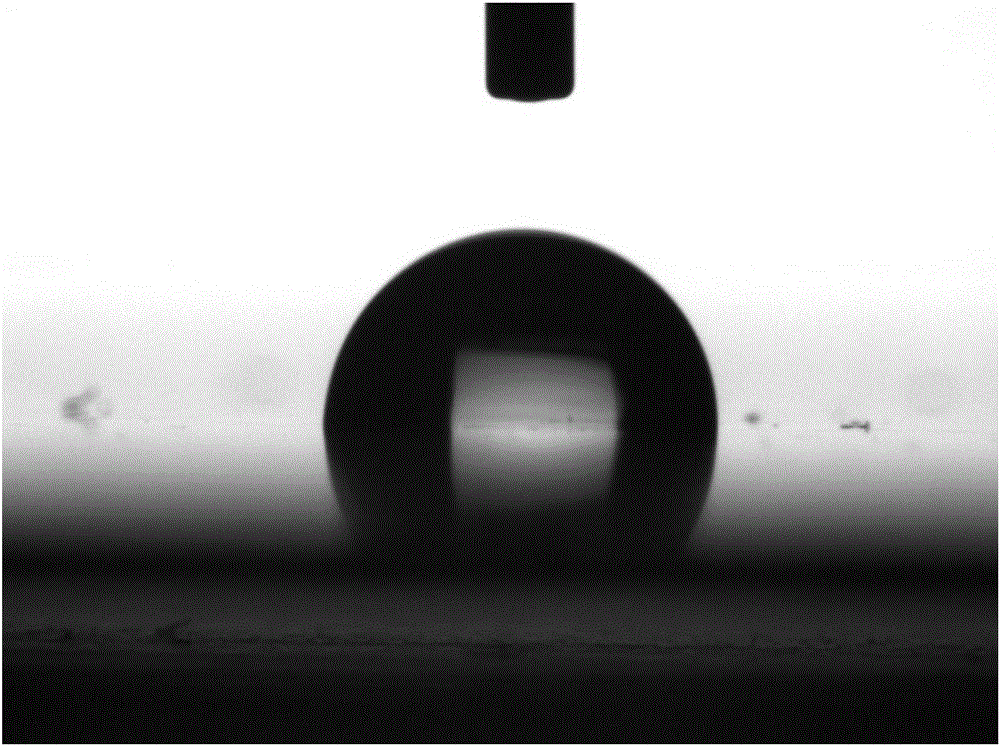

Soap-free fluorocarbon emulsion prepared from perfluoroalkyl ethylenes through copolymerization and preparation method of soap-free fluorocarbon emulsion

ActiveCN105859949AImprove performanceHigh fluorine content on the surfaceCoatingsEmulsionMechanical stability

The invention discloses soap-free fluorocarbon emulsion prepared from perfluoroalkyl ethylenes through copolymerization and a preparation method of the soap-free fluorocarbon emulsion. The soap-free fluorocarbon emulsion is prepared from the following raw materials in percentages by mass through copolymerization: 4-40% of a fluorine-containing component, 50-70% of a component which does not contain fluorine, 3-8% of a pigment dispersing component, 2-8% of a crosslinking component, and 2-8% of a polymerizable emulsifier component. The soap-free fluorocarbon emulsion prepared by the invention is good in mechanical stability, low-temperature stability and ion stability; the problem that an emulsifier of the conventional emulsion is released into the environment is avoided during film formation; and the soap-free fluorocarbon emulsion is environmentally friendly.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Low-temperature artificial turf and preparation method of low-temperature artificial turf

InactiveCN105568422AIncrease reflectionReduce typesGround pavingsMonocomponent polyolefin artificial filamentAdhesiveArtificial turf

The invention discloses a low-temperature artificial turf and a preparation method of the low-temperature artificial turf. The low-temperature artificial turf can be used for lowering the surface temperature. The low-temperature artificial turf disclosed by the invention comprises base cloth, artificial grass turfed on the base cloth and an adhesive, wherein the artificial grass contains high-infrared-reflection paint.

Owner:COCREATION GRASS CO LTD

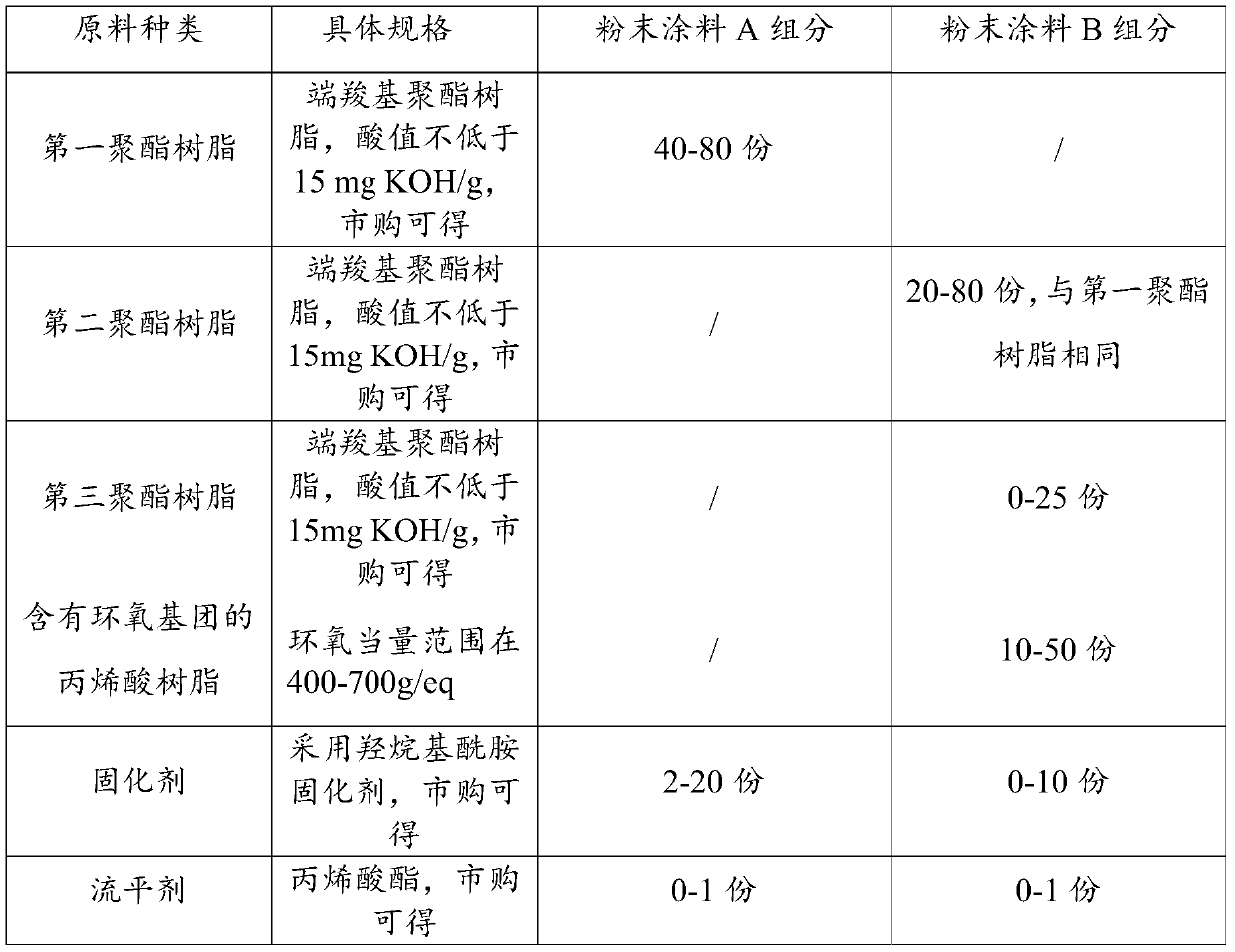

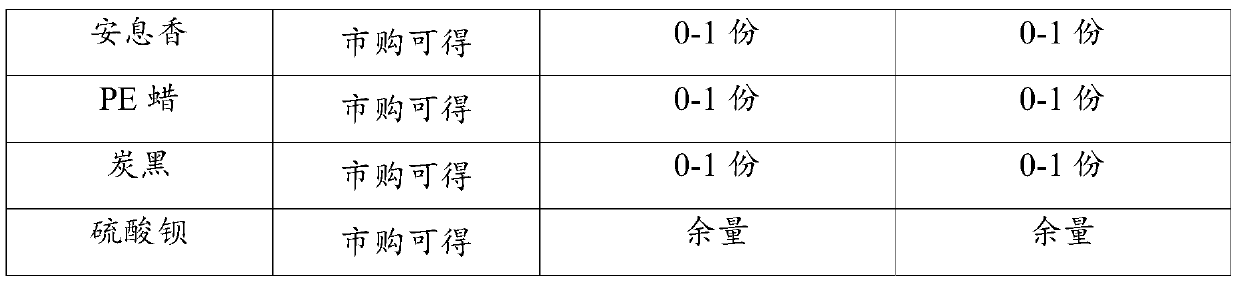

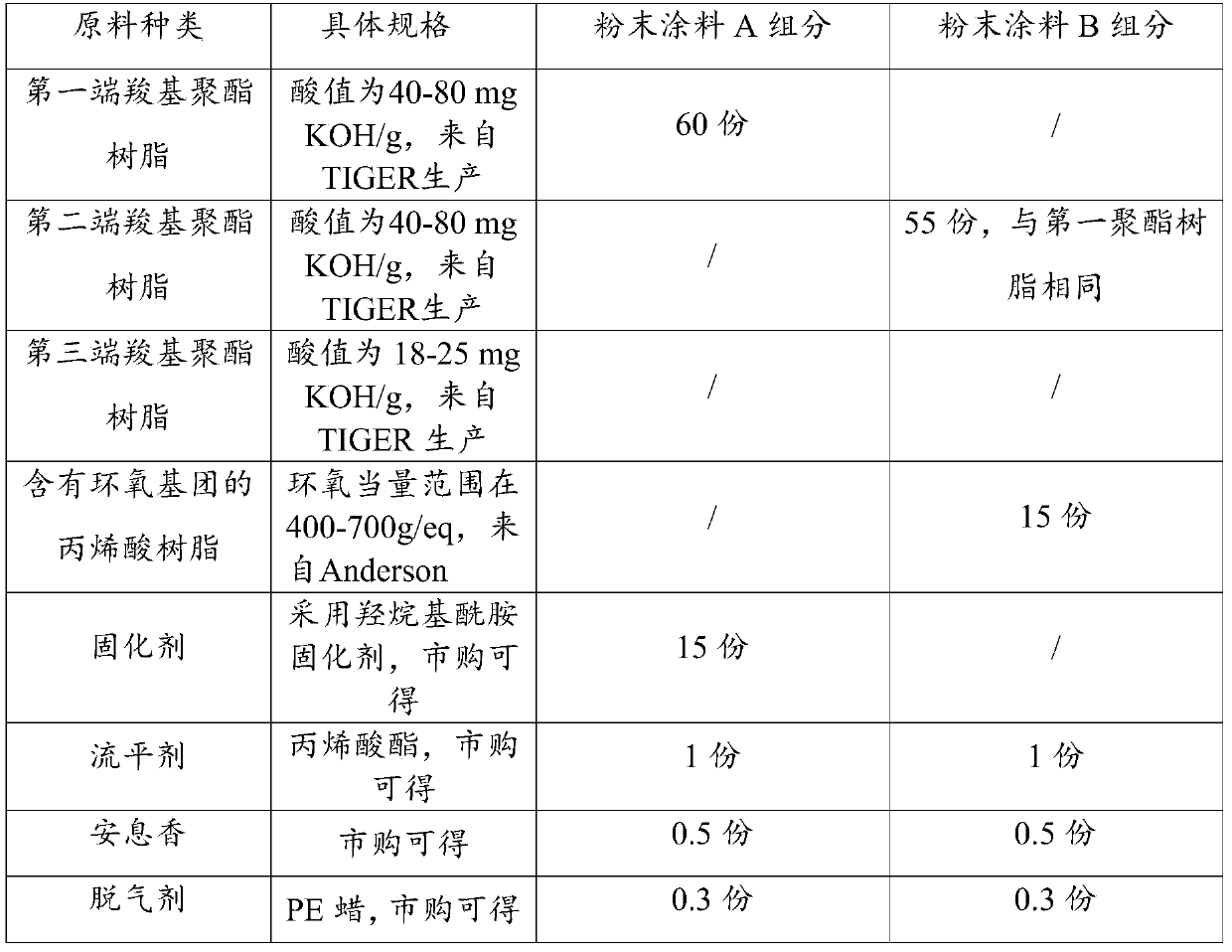

Powder coating with ultrahigh weather-proof extinction effect

ActiveCN110922856AAchieve weather resistanceImprove weather resistancePowdery paintsEpoxy resin coatingsChemistryComposite material

The invention discloses a powder coating with ultrahigh weather-proof extinction effect, wherein the powder coating comprises the raw materials: a powder coating component A and a powder coating component B, wherein the powder coating component A and the powder coating component B are dry-mixed into a whole and have different curing speeds; the powder coating component A is composed of the raw materials: a first polyester resin and a curing agent capable of carrying out curing reaction with the first polyester resin; the powder coating component B is composed of the raw materials: second polyester resin and acrylic resin containing epoxy groups, wherein the acrylic resin and the second polyester resin can be subjected to curing reaction. The powder coating is prepared from the powder coating component A and the powder coating component B through a dry mixing process; the acid value range of the first polyester resin is not less than 15, and the acid value range of the second polyesterresin is not less than 15. By adopting a polyester curing system dry-mixed polyester and acrylic resin curing system, a coating extinction product with the gloss not higher than 10 degrees can be realized at the same time, and meanwhile, a quite excellent super weather-proof effect is achieved.

Owner:TIGER NEW SURFACE MATERIALS QINGYUAN CO LTD

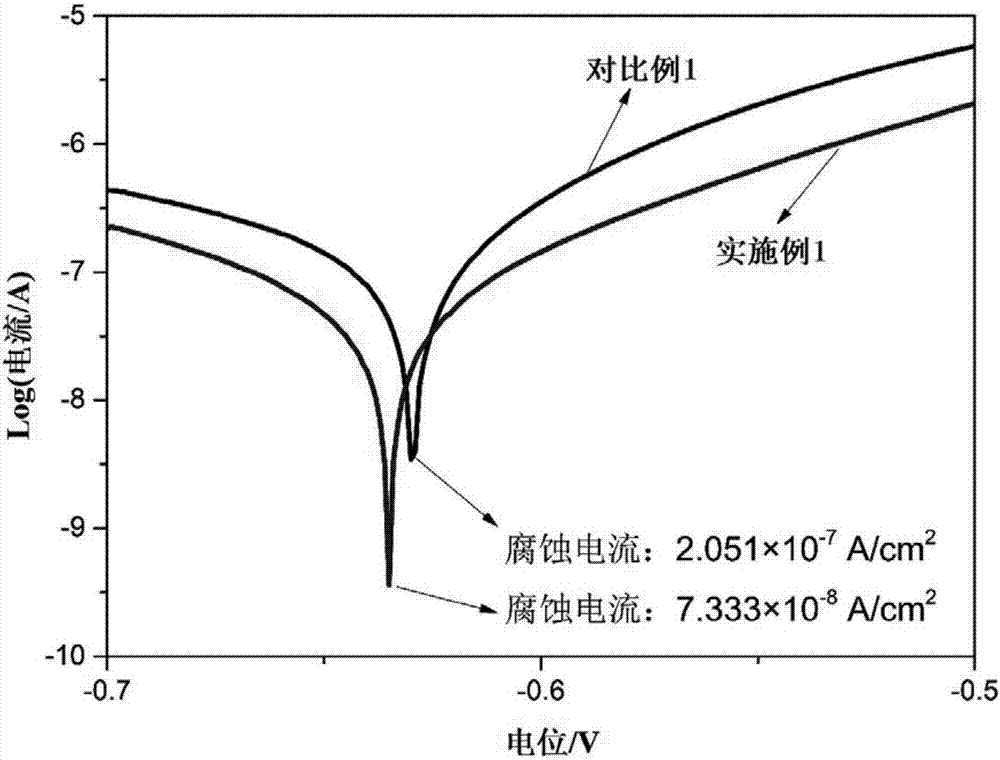

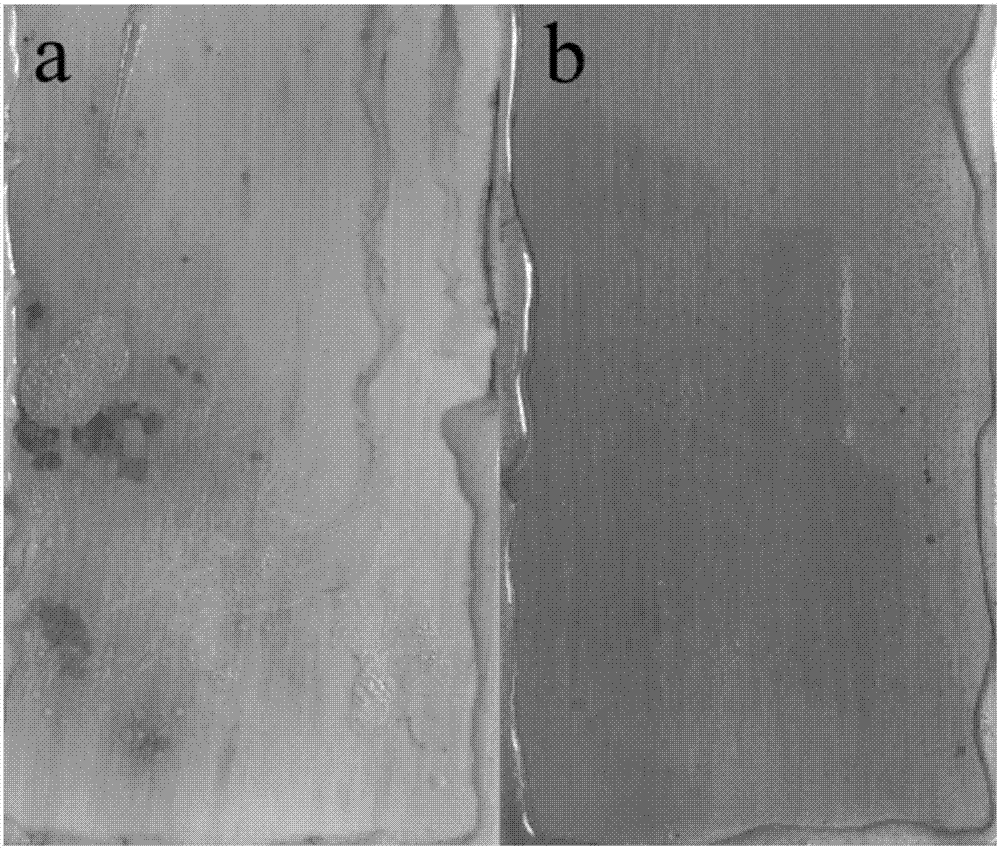

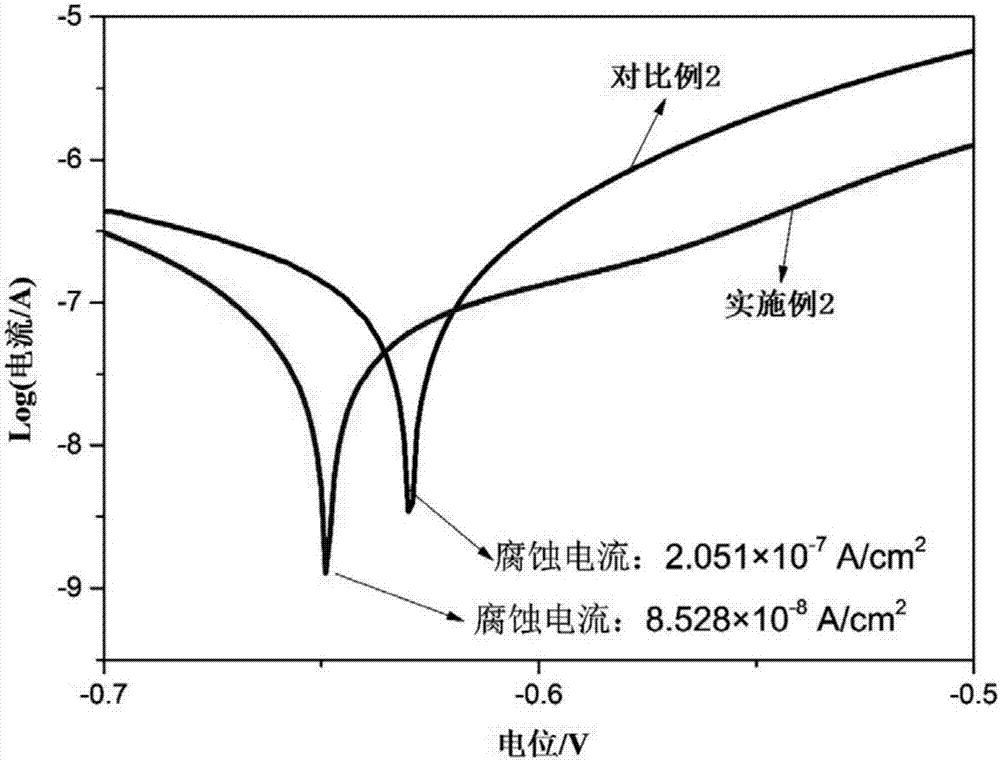

Anticorrosive coating for metal surfaces

PendingCN109233562APlay a synergistic roleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention provides an anticorrosive coating for metal surfaces and a preparation method thereof. The anticorrosive coating comprises epoxy resin, nano magnesium hydroxide, graphene oxide, modifiedinorganic oxide particles, a functional additive and a solvent. The anticorrosive coating achieves a good anticorrosive effect, and all the components are synergistic. The preparation method is simple and easy to implement, and can realize large-scale industrial production. The prepared anticorrosive coating can realize long-term corrosion protection to hulls in deep sea environments.

Owner:SUZHOU ZEMEI NEW MATERIAL TECH

Sunlight reflective thermal-insulation paint, and preparation method thereof

InactiveCN108753058AGood heat insulationBarrier penetrationReflecting/signal paintsThermal insulationHigh reflectivity

The invention discloses a sunlight reflective thermal-insulation paint, and a preparation method thereof. The sunlight reflective thermal-insulation paint comprises, by weight, 35 to 50 parts of fluorocarbon resin emulsion, 5 to 15 parts of a high reflectivity pigment, 5 to 10 parts of polymer hollow micro-sphere, 5 to 10 parts of a reflective material, 5 to 15 parts of nanometer metal powder, 3 to 8 parts of nanometer silica, 0.2 to 0.5 part of a wetting dispersant, 0.4 to 0.8 part of a thickening agent, 0.2 to 0.4 part of a bactericide, 0.5 to 2.5 parts of a film forming auxiliary agent, 0.6to 1.6 parts of an antifoaming agent, and 15 to 25 parts of deionized water. The sunlight reflective thermal-insulation paint is capable of reflecting thermal energy transmission effectively, blocking heat radiation, blocking infrared heat energy, is excellent in thermal insulation performance, is low in energy consumption, is obvious in thermal insulation effect, and is long in service life; thepreparation method is simple, and is suitable for large scale production and applications.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Waterborne nanocomposite thermal insulation coating and preparation method thereof

InactiveCN109054556AGood heat insulationBarrier penetrationAnti-corrosive paintsRadiation-absorbing paintsThermal insulationSlurry

The invention discloses a waterborne nanocomposite thermal insulation coating and a preparation method thereof. The waterborne nanocomposite thermal insulation coating is prepared from the following components in parts by weight: 35-50 parts of waterborne organosilicon modified acrylic emulsion, 5-15 parts of far-infrared ceramic powder, 5-10 parts of infrared reflecting agent, 5-10 parts of nano-ATO slurry, 5-15 parts of rutile titanium dioxide, 3-8 parts of a thermal insulation agent, 0.2-0.5 part of a wetting dispersant, 0.4-0.8 part of a thickener, 0.2-0.4 part of a leveling agent, 0.5-2.5parts of a film forming aid, 0.6-1.6 parts of a silane coupling agent and 15-25 parts of deionized water. The coating provided by the invention is high in reflection efficiency to sunlight, can effectively reflect thermal energy conduction, resist thermal radiation and block infrared heat energy, and is excellent in heat insulation performance, low in energy consumption, remarkable in heat insulation effect and long in service life; furthermore, the preparation method is simple and suitable for large-scale production and application.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

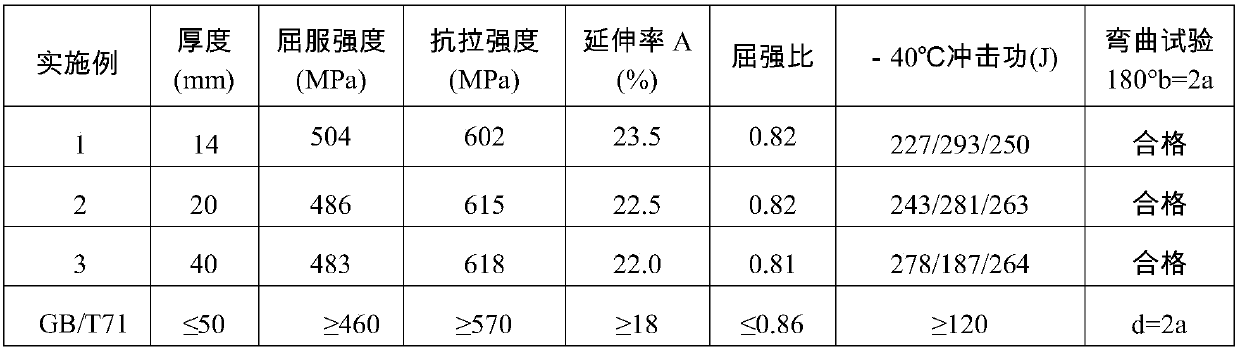

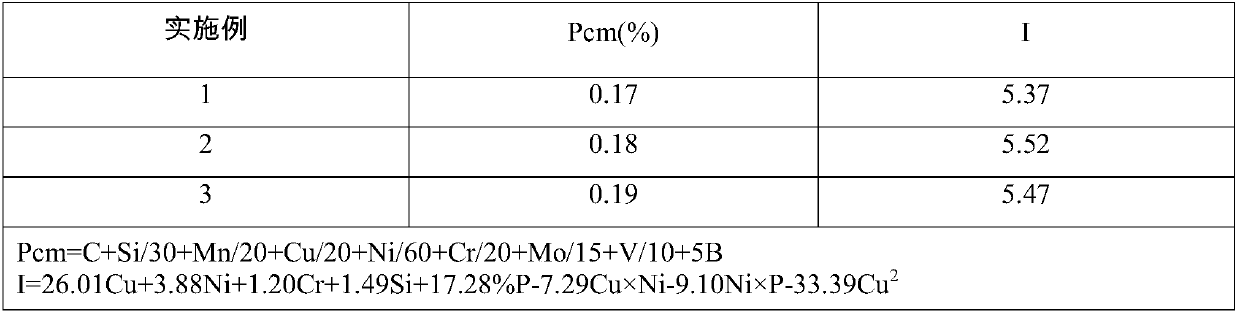

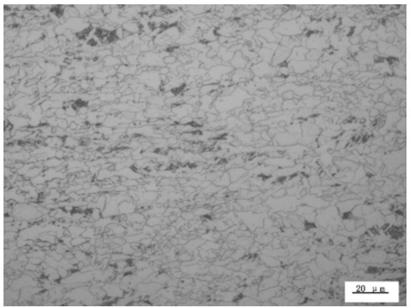

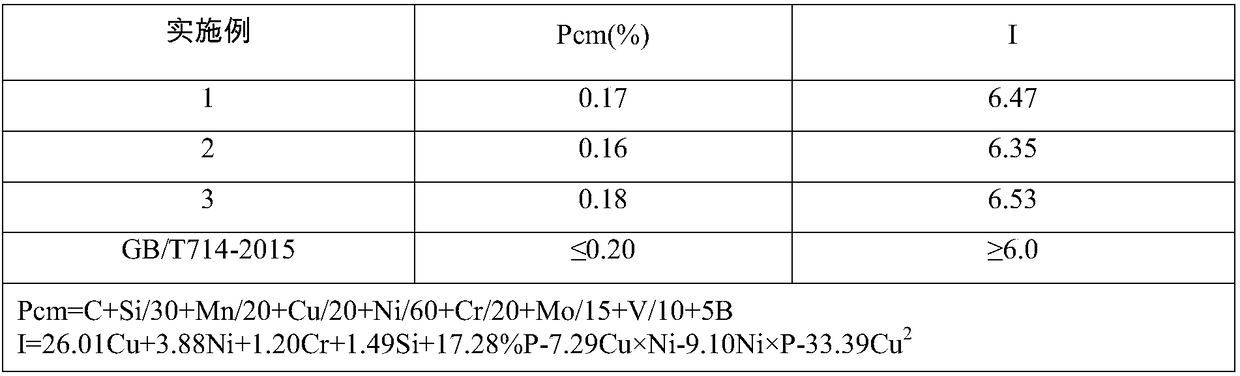

Steel plate with yield strength at 460 MPa grade and preparation method thereof

The invention provides a steel plate with the yield strength at the 460 MPa grade and a preparation method of the steel plate with the yield strength at the 460 MPa grade. The steel plate with the yield strength at the 460 MPa grade comprises 0.06-0.08% of C, 0.20-0.30% of Si, 1.45-1.65% of Mn, not larger than 0. 015% of P, not larger than 0.008% of S, 0.025-0.035% of Nb, 0.010-0.020% of Ti, 0.15-0.25% of Cu, 0.15-0.25% of Ni, Cr: 0.15-0.25% of Cr, 0.024-0.034% of Als, 0.0005-0.0030% of rare earth Ce and the balance Fe and unavoidable impurities. The obtained steel plate has low yield-strengthratio, good low-temperature toughness, good cold forming performance, good welding performance and good corrosion resistance. Meanwhile, the steel plate with the yield strength at the 460 MPa grade has the features of a simple preparation technological process, a short production period, low production cost and the like.

Owner:BAOTOU IRON & STEEL GRP

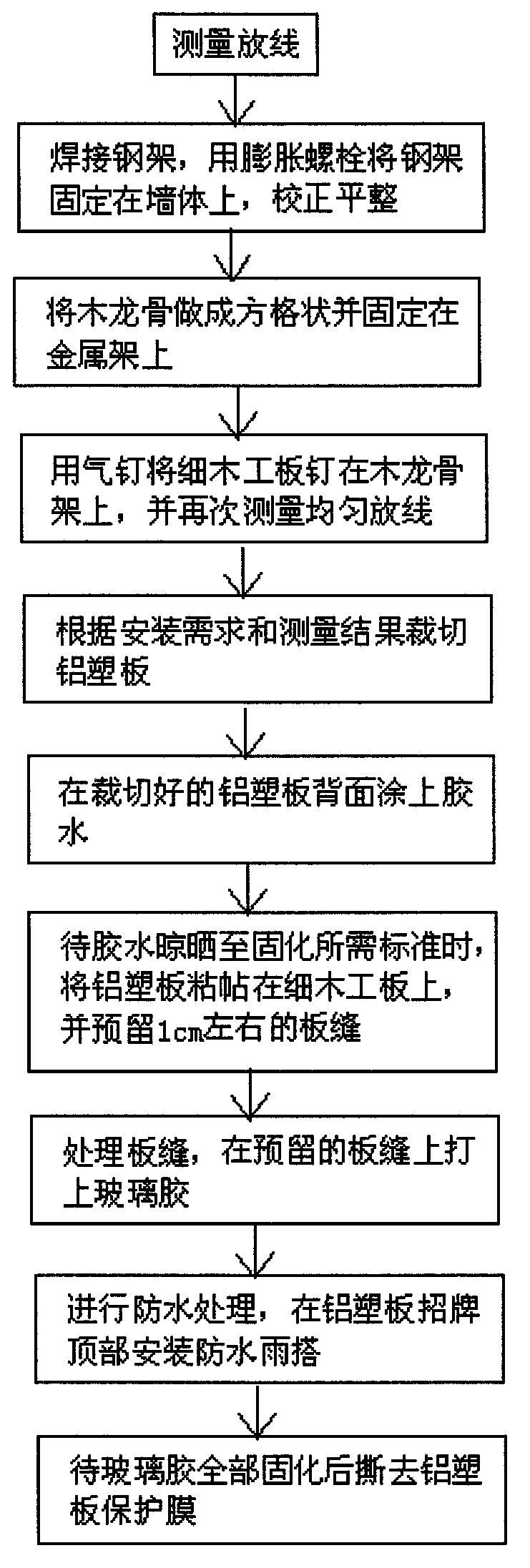

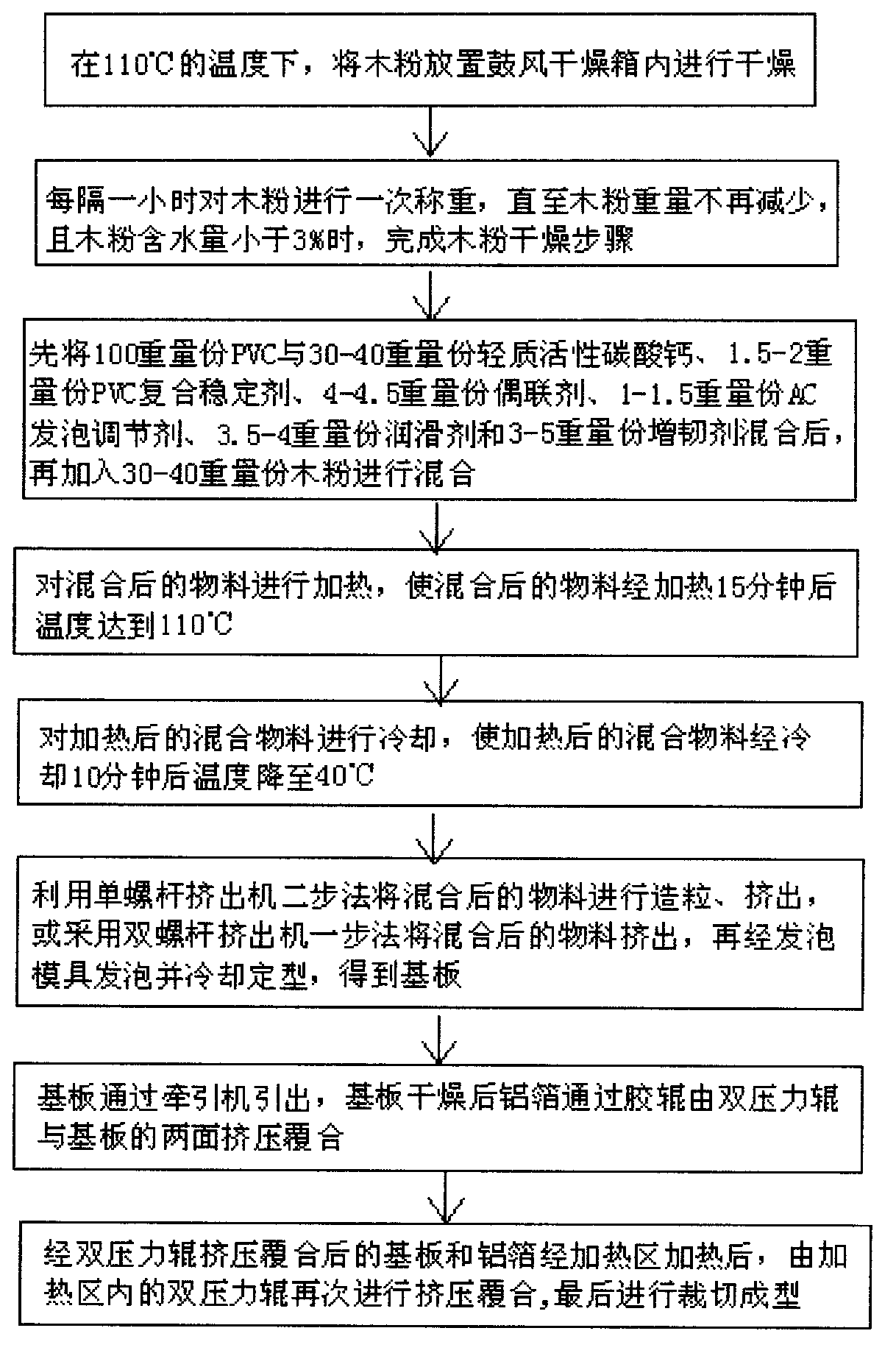

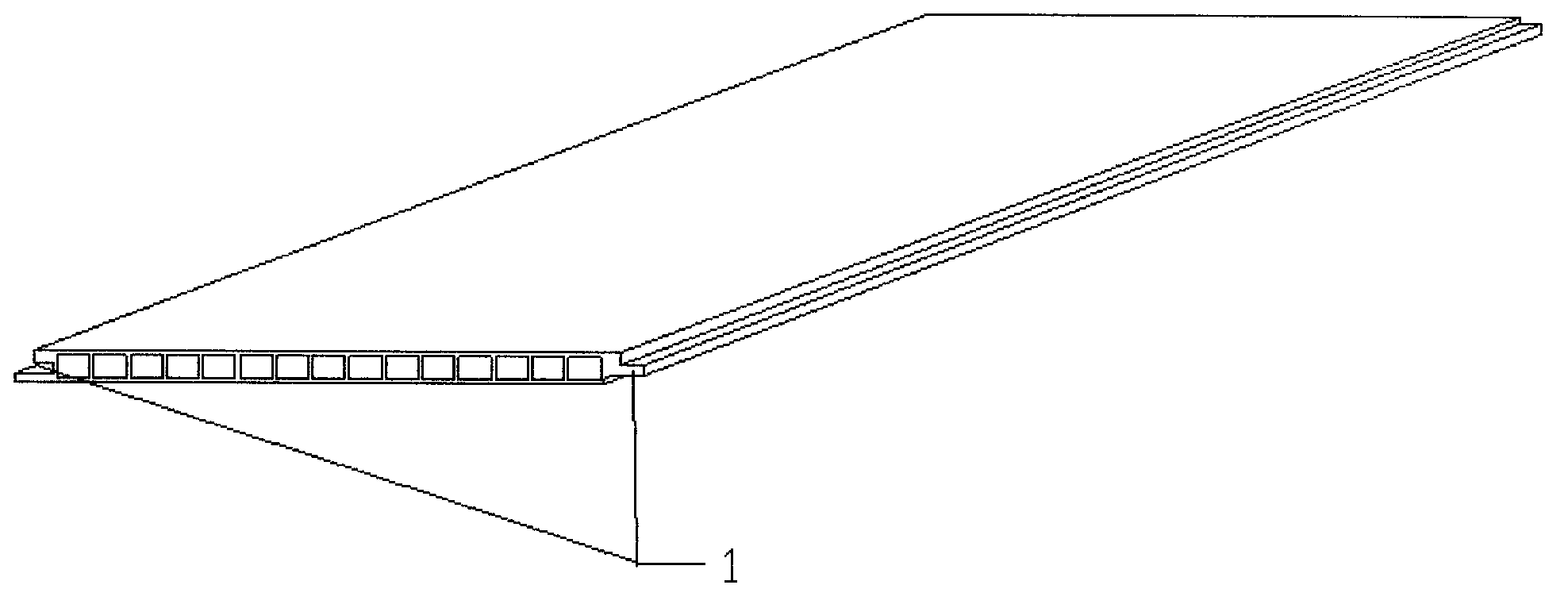

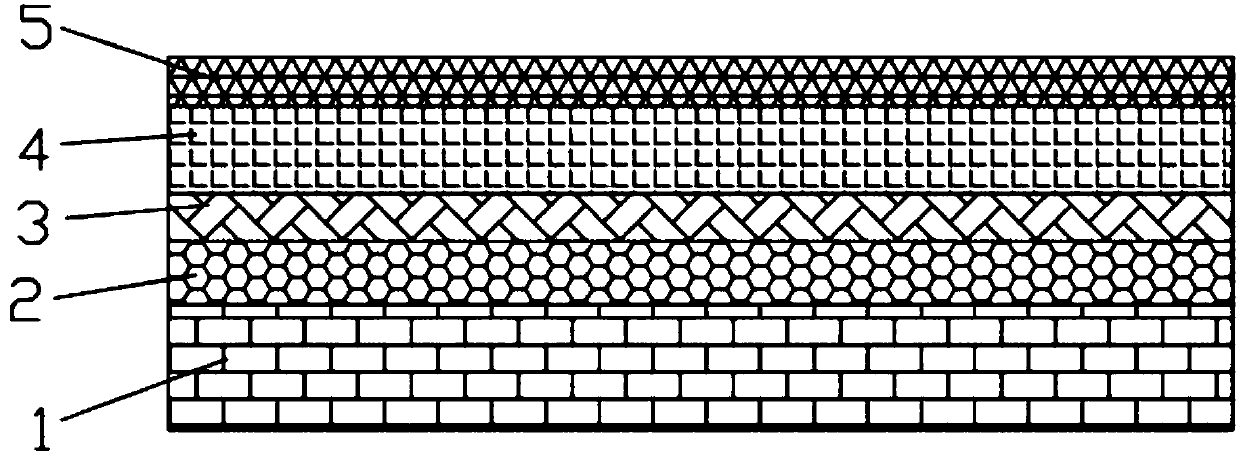

Aluminum-wood-plastic composite integrated decorative plate and preparation method thereof

InactiveCN103660457AAchieve decorative functionAchieve weather resistanceChemical industrySynthetic resin layered productsWeather resistanceSolid wall

The invention discloses an aluminum-wood-plastic composite integrated decorative plate and a preparation method thereof. The upper and lower surfaces of a base plate with a hollow I-shaped structure are thermally coated with aluminum foils, or the upper and lower surfaces of a base plate with a micro-foaming solid wall U-shaped structure are thermally coated with aluminum foils, so that the decorative function and surface weather resistance of an existing aluminum plastic plate can be realized, and the integrated decorative plate has the characteristics of damp-proofing effect, mothproofing effect and deformation resistance, the phenomena of glue failure, hollowing, deformation or drop of the decorative plate in the using process can be prevented, the potential safety hazard is reduced, the construction link can be simplified in the construction process, a great number of raw materials and labor can be saved, the integrated decorative plate has energy-saving and environment-friendly effects and is convenient to install, the construction efficiency can be improved, and the production cost is reduced.

Owner:潘建设

Energy-saving environment-friendly composite color steel plate and production method thereof

InactiveCN107813563ATight adhesionAchieve building insulationRoof covering using slabs/sheetsSynthetic resin layered productsWeather resistanceThermal insulation

The invention discloses an energy-saving environment-friendly composite color steel plate. The energy-saving environment-friendly composite color steel plate comprises a color steel plate, a super-flame retardant crosslinked polyethylene foaming material plate, an iron red phenolic aldehyde anti-rust paint layer and a molybdenum disulfide coating. During production, the super-flame retardant crosslinked polyethylene foaming material plate, the iron red phenolic aldehyde anti-rust paint layer and the molybdenum disulfide coating are sequentially coated on the color steel plate. The energy-saving environment-friendly composite color steel plate disclosed by the invention has the advantages that the energy-saving environment-friendly composite color steel plate utilizes an adhesive-free laminating heat treatment technology and can be tightly adhered with a super-flame retardant crosslinked polyethylene foaming material plate, then the plate is protected by virtue of the iron red phenolicaldehyde anti-rust paint layer and the molybdenum disulfide coating, and the characteristics of thermal insulation, sound insulation, watertightness, prevention of moisture condensation and weather resistance of a building can be achieved only by virtue of a single-layer super-flame retardant crosslinked polyethylene foaming material plate and a single-layer color steel plate.

Owner:宁波聚联塑业有限公司

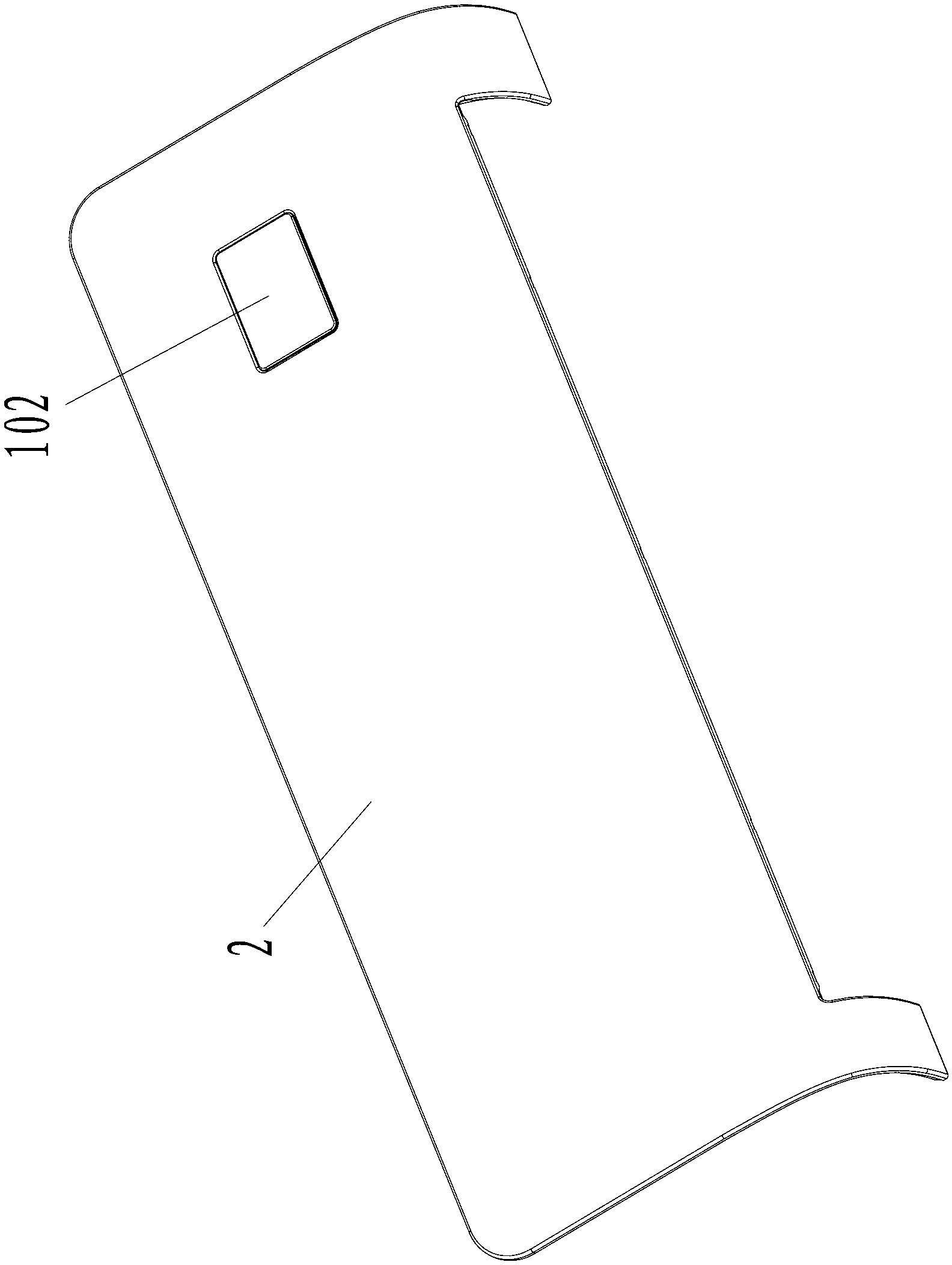

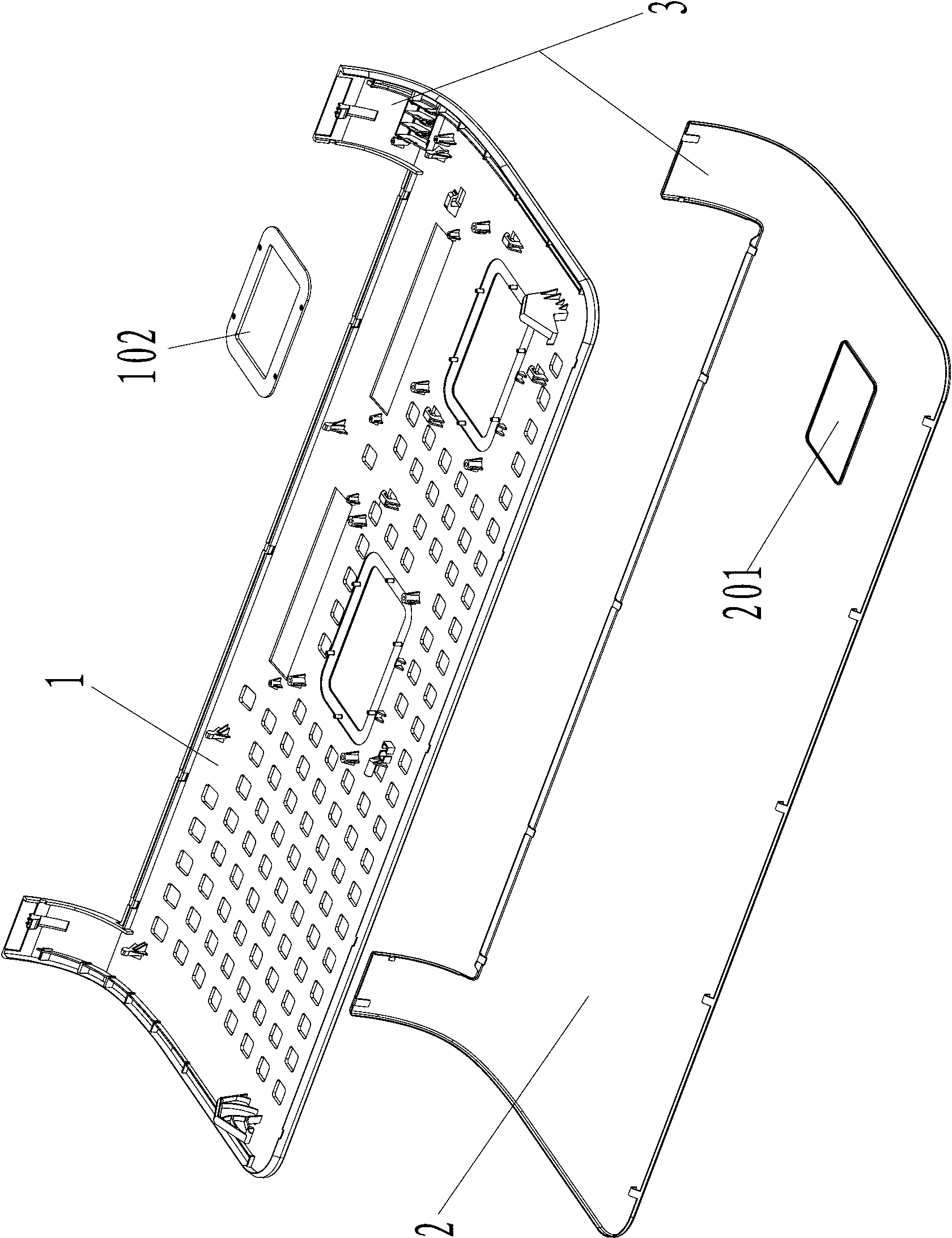

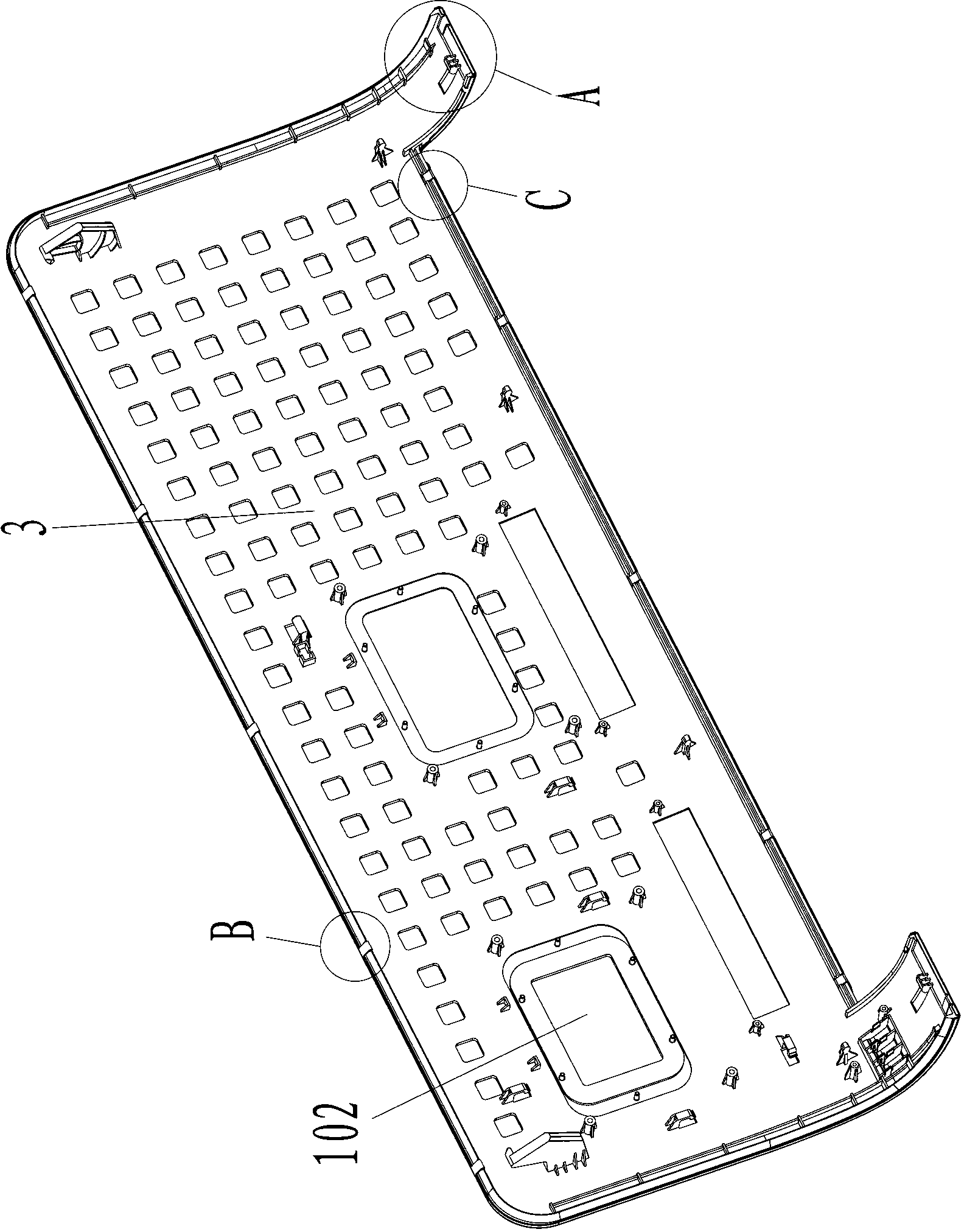

Panel structure of wall-mounted air conditioner

ActiveCN103307728AAccurate and stable installationAchieve weather resistanceHeating and ventilation casings/coversElectromagnetic interferenceEngineering

The invention discloses a panel structure of a wall-mounted air conditioner, which comprises a panel rack and an aluminium alloy panel matched with the former in shape and size, wherein a folded edge is arranged at the periphery of the aluminium alloy panel to form a panel rack accommodating position; a plurality of buckles are arranged on the folded edge of the aluminium alloy panel, and gaps corresponding to the buckles are formed in the periphery of the panel rack; the panel rack is fixed in the panel rack accommodating position through matching between the gaps and the buckles; a display window hole is formed in the aluminium alloy panel; and a transparent display window corresponding to the display window hole is mounted on the panel rack. According to the invention, with the aluminium alloy plate subjected to anodic oxidation and wire drawing processing, the panel structure with folded edge formed through die punch forming, and the especially designed buckles and gaps, the aluminium alloy panel can be accurately and steadily mounted on the panel rack, so as to realize weatherability, fire resistance and electromagnetic interference resistance of the panel.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Water-based nanoscale composite thermal insulation coating and preparation method thereof

InactiveCN108410281AGood heat insulationBarrier penetrationAnti-corrosive paintsRadiation-absorbing paintsWater basedThermal energy

The invention discloses a water-based nanoscale composite thermal insulation coating and a preparation method thereof. The materials comprise the following components in parts by weight: 35 to 50 parts of water-based fluorocarbon emulsion, 5 to 15 parts of light polymer hollow microspheres, 5 to 10 parts of hollow glass microspheres, 5 to 10 parts of nanoscale ATO slurry, 5 to 15 parts of nanoscale metal powder, 3 to 8 parts of nanoscale titanium dioxide, 0.2 to 0.5 parts of dispersant, 0.4 to 0.8 parts of thickening agent, 0.2 to 0.4 parts of anti-mildew and bactericidal agent, 0.5 to 2.5 parts of film coalescing aid, 0.6 to 1.6 parts of silane coupling agent and 15 to 25 parts of deionized water. The coating disclosed by the invention can effectively reflect thermal energy conduction, block thermal radiation and stop infrared thermal energy, the thermal insulation property is excellent, energy consumption is low, the thermal insulation effect is remarkable, the service life is long,the preparation method is simple, and the invention is suitable for mass production and application.

Owner:合肥金云新材料有限公司

Normal-temperature-cured polytetrafluoroethylene-modified high-solid-content automobile varnish and preparation method thereof

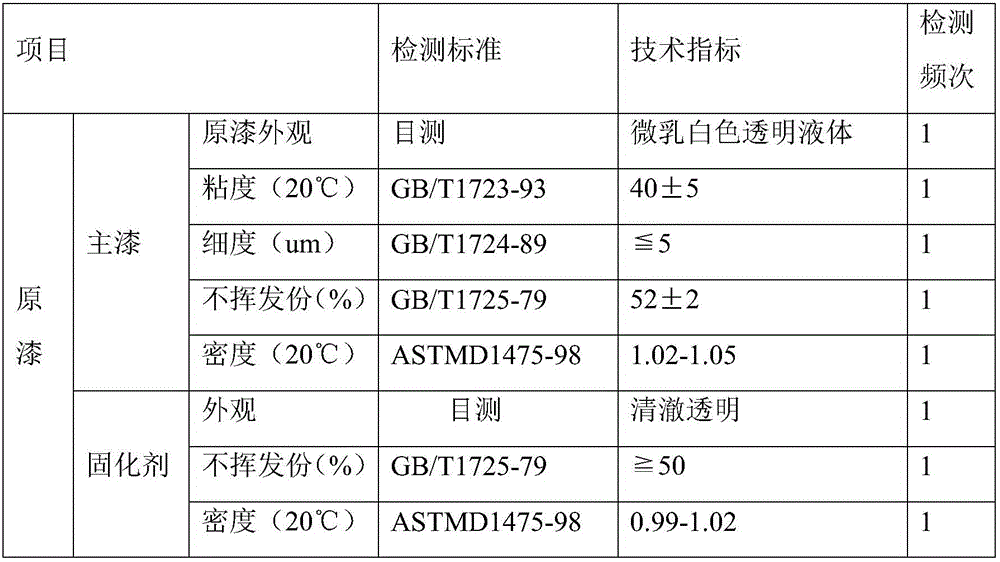

ActiveCN106085171AImprove performanceRealize the requirements of room temperature curingPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a preparation method for a normal-temperature-cured polytetrafluoroethylene-modified high-solid-content automobile varnish. The preparation method is characterized by comprising a step of mixing main paint, a curing agent and a diluent according to a mass ratio of 100: 50: (10-15), wherein the main paint is prepared by mixing 40 to 59 parts of mixing monomer, 1 to 5 parts of an initiator and 40 to 60 parts of a mixed solvent under stirring in the presence of nitrogen and then adding 3 to 5 parts of modified transparent oily polytetrafluoroethylene resin drop by drop; the curing agent is prepared by mixing 50 to 60 parts of polyisocyanate, 30 to 40 parts of butyl acetate and 10 to 20 parts of propylene glycol methyl ether acetate; and the diluent is prepared by mixing 50 to 60 parts of butyl acetate with 40 to 50 parts of propylene glycol methyl ether acetate. According to the invention, the liquid polytetrafluoroethylene resin prepared on the basis of independent research and development is added into hydroxyl-acrylic resin, so the prepared automobile varnish has the excellent properties of super self-cleanness, high hardness, super smoothness, weatherability, etc.

Owner:TIANJIN YIMA PROTECTION MATERIAL CO LTD

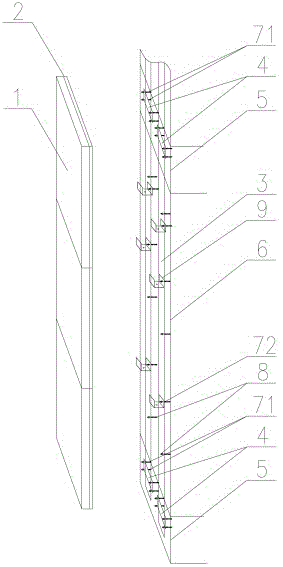

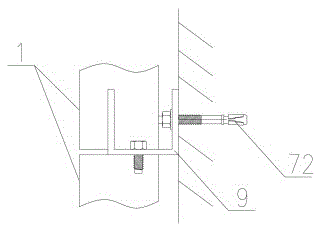

Fixing and installing method for stone pendant through vertical steel belt

ActiveCN105625667AAchieve weather resistanceAchieve firmnessCovering/liningsWeather resistanceSteel belt

The invention relates to a fixing and installing method for a stone pendant through a vertical steel belt. According to the fixing and installing method, the stone pendant is fixed to and installed on an external building wall through the steel belt, and the external building wall is composed of floor concrete cross beams and a bricking wall body located between the floor concrete cross beams; the weathering resistance and the firmness of the heat preservation stone are achieved by making full use of the mechanical bearing capacity of the vertical steel belt and the mechanical bearing capacity of the floor concrete cross beams, the fireproof performance meets the national A-level standard, the service life is as long as that of a building, the construction period is shortened, the construction cost is low, and materials are saved.

Owner:HEBEI JIUJIAN BUILDING DECORATION ENG CO LTD

Method for preparing acrylic acid-based adhesive and adhesive film manufactured thereby

ActiveCN110300785AEffective burialEasy to control heat generationFilm/foil adhesivesEster polymer adhesivesPhoto curingPolymerization

Owner:LG CHEM LTD

Artificial turf capable of reflecting heat energy of sunlight and preparation method thereof

InactiveCN109537399AIncrease reflectionReduce typesGround pavingsMonocomponent polyolefin artificial filamentAdhesiveArtificial turf

The invention discloses an artificial turf capable of reflecting heat energy of sunlight and a preparation method thereof. The temperature of the surface of the artificial turf can be reduced. The low-temperature artificial turf comprises basic cloth, artificial grass arranged on the basic cloth in a tufting mode and an adhesive, and the artificial grass contains highly infrared reflection pigment.

Owner:陆欣瑜

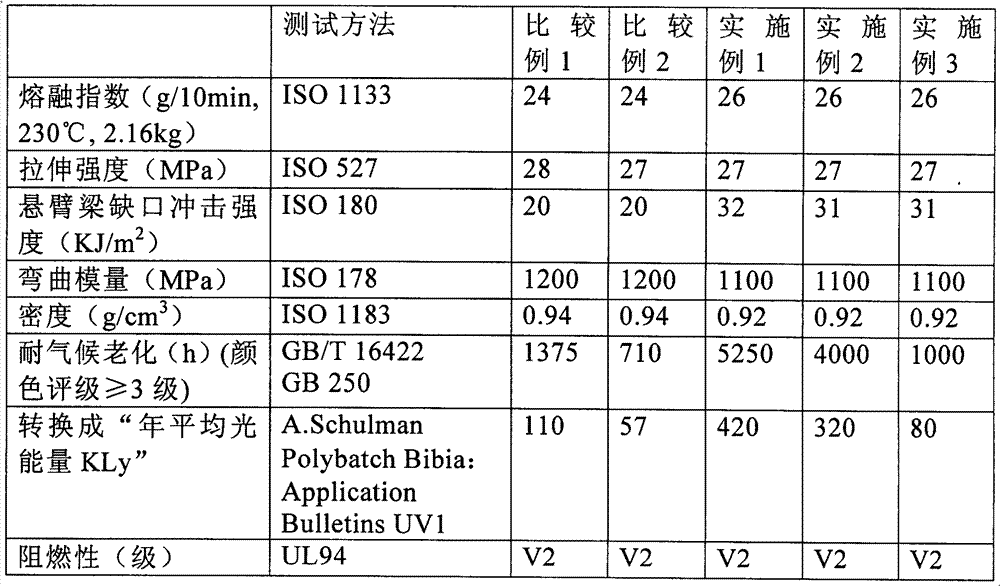

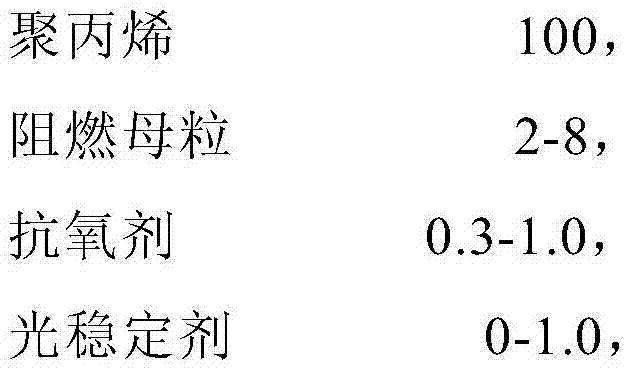

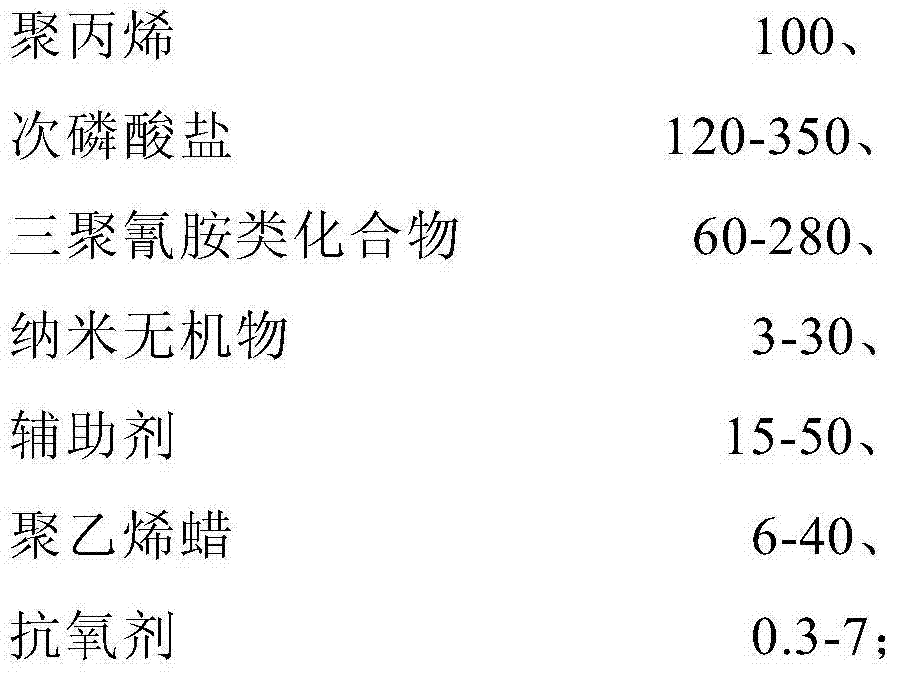

A material for injection molding flame-retardant plastic seats for stadiums with excellent weather resistance

The invention relates to a material used in injection molding of stadium flame-retarding plastic seats with excellent weatherability. According to the invention, a raw material is placed in an injection molding mold, and injection molding is carried out, such that the seats are obtained. During the injection molding process, an injection molding material temperature is controlled at 180-230 DEG C, an injection molding pressure is controlled at 40-70MPa, and an injection molding speed is controlled at 40-60%. The raw material comprises the components of, by weight: 100 parts of polypropylene, 2-8 parts of a flame retardant masterbatch, 0.3-1.0 part of an antioxidant, and 0-1.0 part of a light stabilizer. Compared with prior arts, according to the invention, no antagonistic effect between the flame retardant and the light stabilizer is caused. With a universal light stabilizer, excellent weatherability can be achieved. The material is also advantaged in no precipitation, low cost, and easy injection molding. With the material, industrialized production is easy to realize.

Owner:上海安凸塑料添加剂有限公司

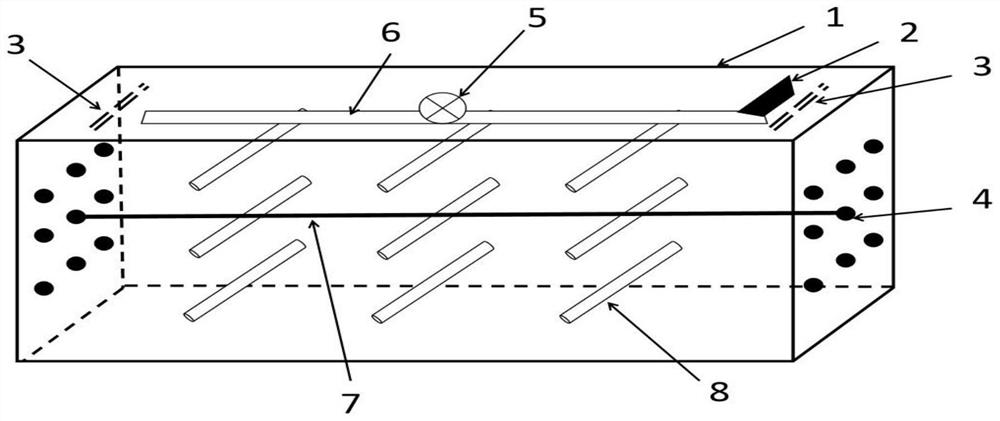

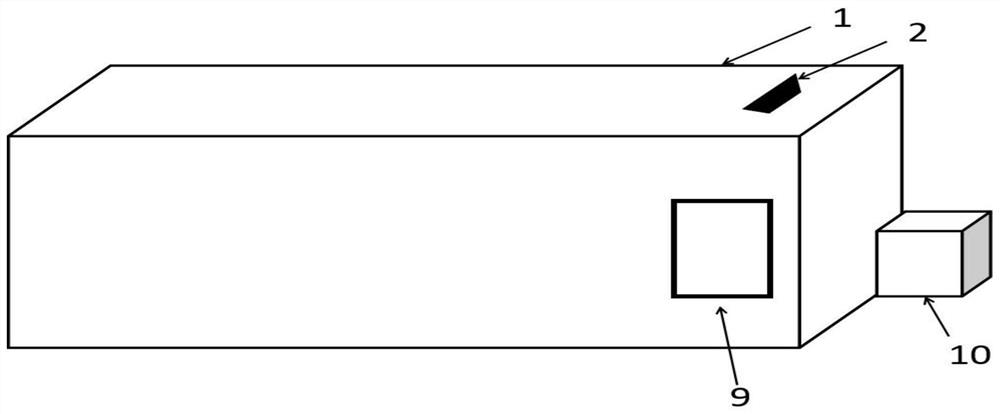

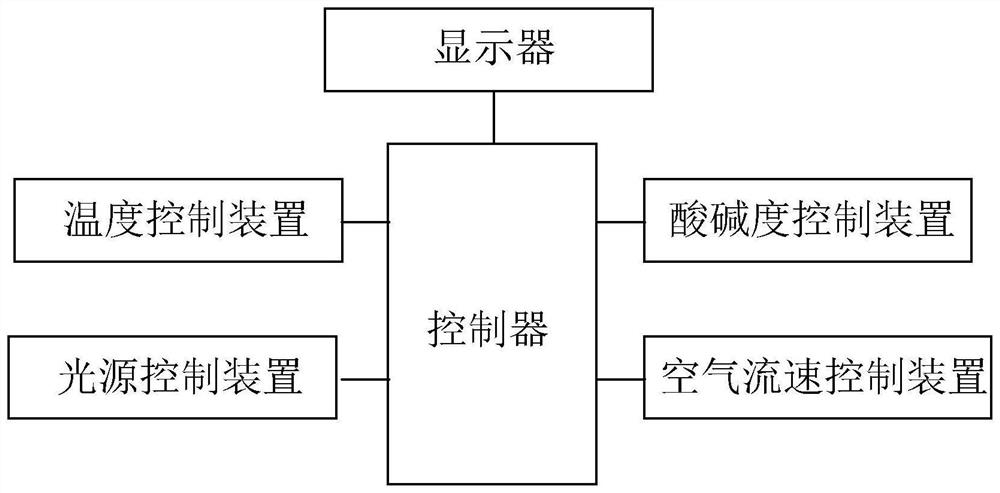

Continuous glass fiber weather resistance testing device and testing method

PendingCN114136870APrevent saggingGuaranteed impregnationMaterial analysis using wave/particle radiationWeather/light/corrosion resistanceGlass fiberYarn

The invention discloses a continuous glass fiber weather resistance testing device and method, and belongs to the technical field of glass fiber testing devices.The continuous glass fiber weather resistance testing device comprises a testing box, a yarn fixing device is arranged in the testing box, and the yarn fixing device is used for fixing glass fiber yarn in the testing box; a temperature control device, a light source control device, an acid-base property control device and an air velocity control device are arranged inside the test box, a controller and a display are arranged outside the test box, and the controller is electrically connected with the display, the temperature control device, the light source control device, the acid-base property control device and the air velocity control device. A plurality of aging corrosion parameters can be changed at the same time according to the use environment of glass fiber downstream products, and the application range is wide. And comprehensively evaluating the weather resistance of the glass fiber yarn by using the tensile breaking strength loss rate and the film forming state of the impregnating compound on the surface of the yarn. The method is accurate and time-saving; the problems in the prior art are solved.

Owner:TAISHAN FIBERGLASS ZOUCHENG

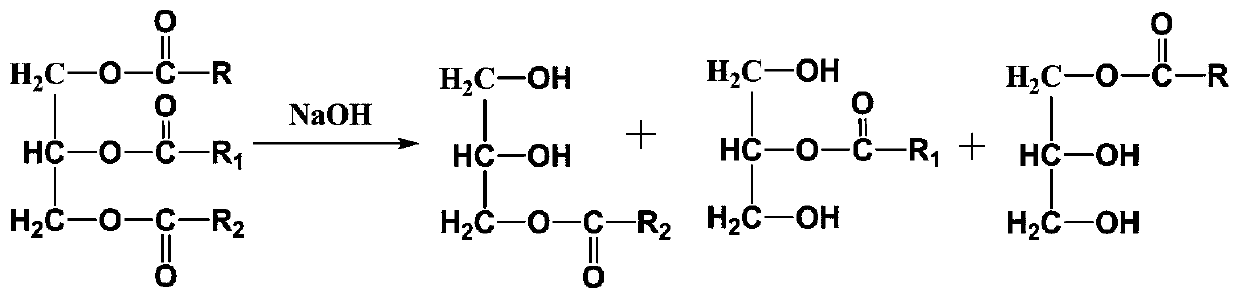

High-performance industrial composite glycerin and preparation method thereof

The invention discloses a high-performance industrial composite glycerin. The high-performance industrial composite glycerin comprises the following raw materials by weight: 55-65 parts of glycerin, 10-20 parts of an alloy assistant liquid, 3-7 parts of Si powder, 5-15 parts of a reinforcing agent and 2-6 parts of rutile type nano-titanium dioxide. According to the invention, the alloy assistant liquid is added into glycerin to improve the adaptability of glycerin at a high temperature and adapt to the temperature change so as to reach a yellowing-resistant effect, the alloy assistant liquid adopts methyl phenyl silicone oil as a matrix liquid, methyl phenyl silicone oil itself has weather resistance, heat resistance, chemical resistance and other excellent properties, and by adding nickelpowder, titanium carbide powder and magnesium borate powder, on the one hand, methyl phenyl silicone oil can serve as bridging liquid to make nickel powder, titanium carbide powder and magnesium borate powder better integrate into glycerin, the nickel powder can play a repairing role, so that glycerin can adapt to the temperature timely at the high temperature, the yellowing resistance effect isimproved, and the titanium carbide powder and magnesium borate powder can improve the temperature resistant effect of glycerin.

Owner:安徽诚宁油脂科技有限公司

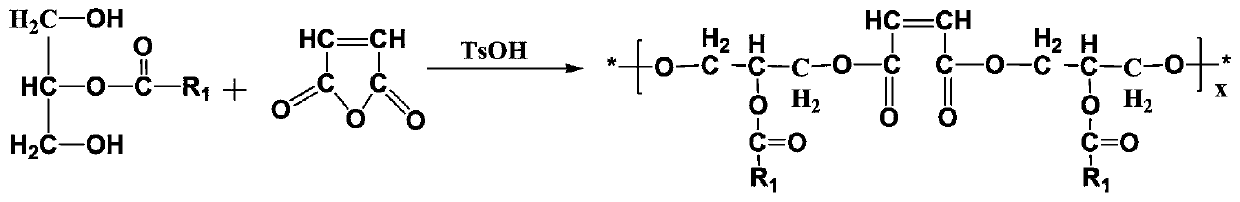

Modified plastic color masterbatch and preparation method thereof

The invention discloses a modified plastic color masterbatch comprising the following components by weight: 63-69 parts of colored polyacrylamide resin, 21-24 parts of soybean oligopeptide, 12-15 parts of glutaraldehyde, 100 parts of water and 3-7 parts of a plasticizer. The carrier resin colored polyacrylamide resin of the color masterbatch is directly polymerized on the surface of a pigment filler to form a coating layer on the surface of the pigment filler, the coating layer is a polymer of maleic anhydride and incompletely saponified fat, the polymer contains an unsaturated olefin bond which is capable of undergoing polymerization and polymerizing with acrylamide and trifluoroethyl methacrylate, so that the surface of the pigment filler is grafted with amino groups and a large amount of fluorine, by glutaraldehyde cross-linking action between the amino groups and the soybean oligopeptide, the center of the prepared colored polyacrylamide resin is the pigment filler, and the pigmentfiller is directly and uniformly dispersed and coated in the carrier resin colored polyacrylamide resin, so that the prepared color masterbatch needs no dispersant to achieve even color distribution.

Owner:WEIHAI WEIYING PLASTIC

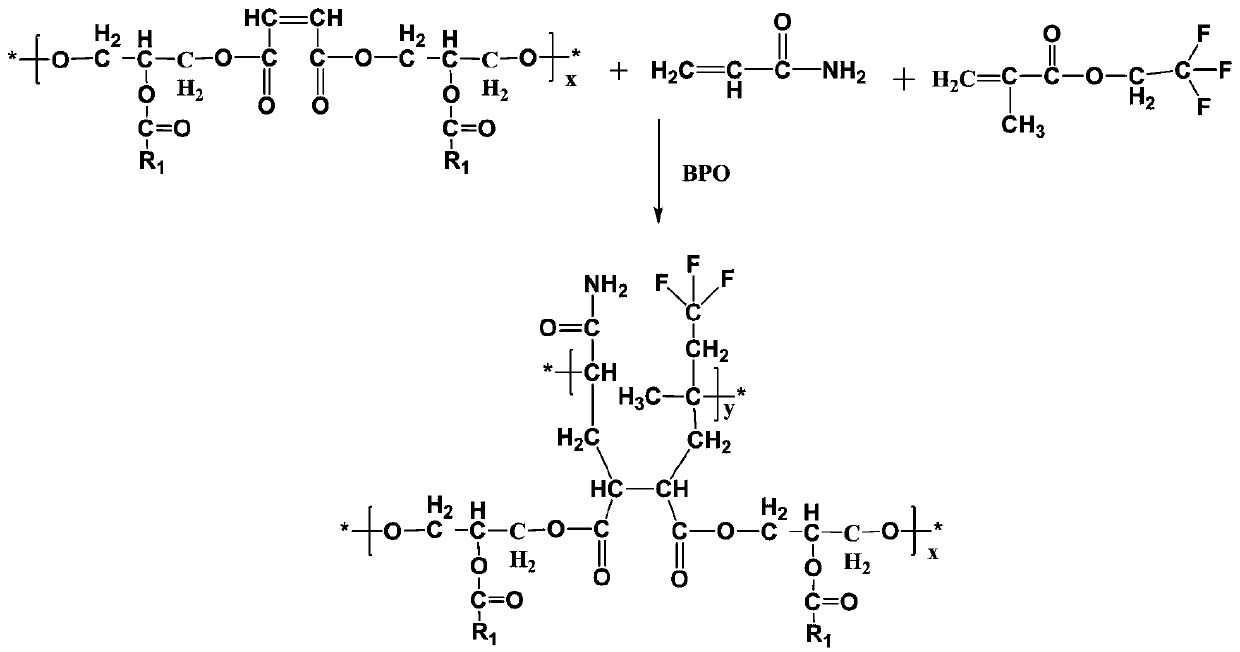

Low-yield-ratio Q370qNH steel plate and preparation method thereof

The invention provides a low-yield-ratio Q370qNH steel plate and a preparation method thereof. The steel plate is prepared from the compositions in percentage by mass: 0.04-0.06% of C, 0.20-0.30% of Si, 1.2-1.4% of Mn, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.01-0.02% of Nb, 0.25-0.35% of Cu, 0.3-0.4% of Ni, 0.4-0.5% of Cr, 0.024-0.034% of Als and the balance of Fe and unavoidable impurities. According to the low-yield-ratio Q370qNH steel plate and the preparation method thereof, the obtained Q370qNH steel plate has a low yield ratio, good corrosion-resistant properties, low-temperature toughness, cold shaping properties and welding properties, and can be used without coating; and meanwhile, the characteristics that the preparation technological process is simple, the production period is short and the production cost is low are achieved.

Owner:BAOTOU IRON & STEEL GRP

Water-based nano-reflective heat-insulating transparent coating and preparation method thereof

ActiveCN105505060BReduce energy consumptionDoes not affect lightingAntifouling/underwater paintsChemical industryWater basedSizing

The invention discloses a water-based nano reflection and heat insulation transparent coating and a preparation method thereof. The formula of the coating comprises the followings in percentages by weight: 35%-50% of a water-based acrylic emulsion, 5%-15% of water-based lithium silicate, 5%-15% of a water-based polyurethane emulsion, 5%-10% of a water-based heat insulation nano dispersion sizing agent, 5%-10% of a water-based heat insulation and heat preservation nano dispersion, 2%-12% of a wetting dispersant, 0.2%-0.5% of a flatting agent, 0.2%-1% of a thickener, 0.1%-0.2% of an antifungus and anti-mildew agent, 0.5%-2.5% of a coalescing agent, 0.5%-2% of a silane coupling agent and 5%-25% of deionized water. According to the water-based nano reflection and heat insulation transparent coating disclosed by the invention, under the precondition of without influencing lighting, heat radiation is blocked and infrared heat energy is prevented from being conducted into the interior of a base material through effective reflection and heat energy conduction, and thus the effects of heat insulation and heat preservation are reached. Heat energy, entering the room through the base material, generated by an outdoor heat source can be effectively blocked in summer, and indoor heat can be effectively blocked from being dispersed in winter, so that the application of refrigeration and heat preservation equipment can be effectively reduced, and the energy-saving effect is obvious.

Owner:CHANGSHA MINDE FIRE ENG PAINT CO LTD

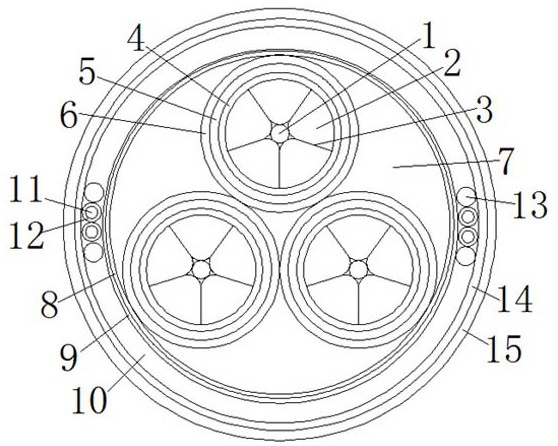

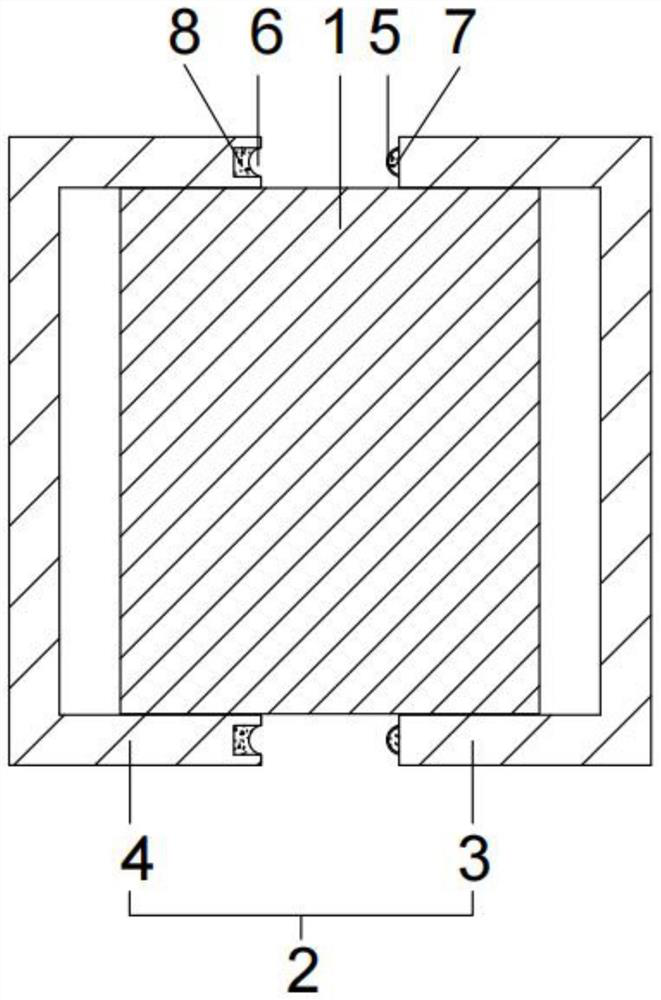

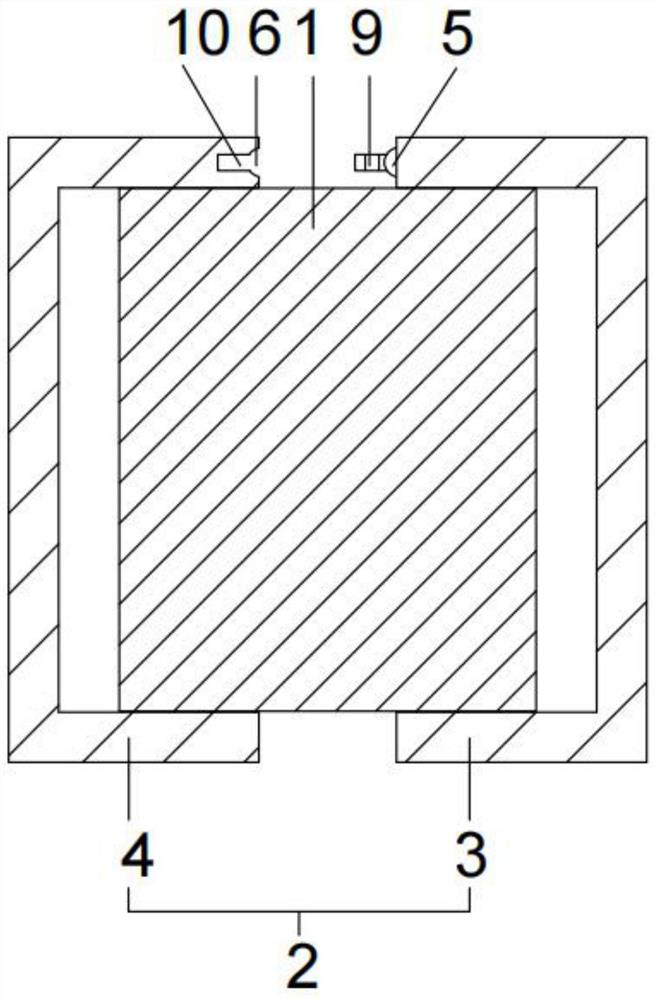

Improved high-performance flame-retardant cable and flame-retardant layer thereof

InactiveCN113270223AReduce skin effectEvenly distributedMaterial nanotechnologyPlastic/resin/waxes insulatorsElectrical conductorFluoroplast

The invention relates to an improved high-performance flame-retardant cable which sequentially comprises a circular structure conductor, a conductor shielding layer, a fluoroplastic insulating layer and an insulating shielding layer. A filler is arranged in a gap of a cable core, and a wrapping layer, a flame-retardant layer I, a braided layer, a flame-retardant layer II and an outer sheath are sequentially arranged outside the cable core and the filler. Four humidity-sensitive insulated wire cores are embedded in the braided layer, the two sides of each humidity-sensitive insulated wire core are respectively provided with the water-blocking ropes, and the flame-retardant layer I and the flame-retardant layer II comprise the following steps of (1) mixing raw materials step by step; (2) putting the mixture into a banburying furnace for banburying; and (3) melting a copolymer, and carrying out injection molding. The cable is excellent in transmission performance, and larger current is introduced by the humidity-sensitive insulating wire cores to dissipate heat, so that moisture is taken away, the overall flame-retardant effect is good, the service life is long, and the flame-retardant layer is excellent in flame-retardant performance and is convenient to process.

Owner:WUXI SUNAN CABLE

Corrosion-resistant and weather-resistant glass bottle and preparation method thereof

PendingCN114590998AAchieve protectionAvoid yellowingBlow machinesGlass tempering apparatusWeather resistanceBottle

The invention discloses a corrosion-resistant and weather-resistant glass bottle and a preparation method thereof, and aims to solve the problem that the service life of the glass bottle is influenced due to yellowing or corrosion of the glass bottle. According to the technical scheme, the corrosion-resistant and weather-resistant glass bottle and the preparation method thereof are characterized in that the corrosion-resistant and weather-resistant glass bottle comprises a glass bottle body, a glass bottle protection piece is arranged on the outer side of the glass bottle body, and the glass bottle protection piece is tightly attached to the outer wall of the glass bottle body; (2) proportioning; 3) mixing; 4) mixing the materials; 5) heating; and 6) cooling. According to the corrosion-resistant and weather-resistant glass bottle and the preparation method thereof, the corrosion-resistant effect and weather resistance of the glass bottle body can be guaranteed, and the service life of the glass bottle body is prolonged.

Owner:兰溪市光大玻璃制品有限公司

A room temperature curing polytetrafluoroethylene modified high-solid automotive varnish and preparation method thereof

ActiveCN106085171BWith fast drying and curing propertiesOvercome the disadvantage of high toxicityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a preparation method for a normal-temperature-cured polytetrafluoroethylene-modified high-solid-content automobile varnish. The preparation method is characterized by comprising a step of mixing main paint, a curing agent and a diluent according to a mass ratio of 100: 50: (10-15), wherein the main paint is prepared by mixing 40 to 59 parts of mixing monomer, 1 to 5 parts of an initiator and 40 to 60 parts of a mixed solvent under stirring in the presence of nitrogen and then adding 3 to 5 parts of modified transparent oily polytetrafluoroethylene resin drop by drop; the curing agent is prepared by mixing 50 to 60 parts of polyisocyanate, 30 to 40 parts of butyl acetate and 10 to 20 parts of propylene glycol methyl ether acetate; and the diluent is prepared by mixing 50 to 60 parts of butyl acetate with 40 to 50 parts of propylene glycol methyl ether acetate. According to the invention, the liquid polytetrafluoroethylene resin prepared on the basis of independent research and development is added into hydroxyl-acrylic resin, so the prepared automobile varnish has the excellent properties of super self-cleanness, high hardness, super smoothness, weatherability, etc.

Owner:TIANJIN YIMA PROTECTION MATERIAL CO LTD

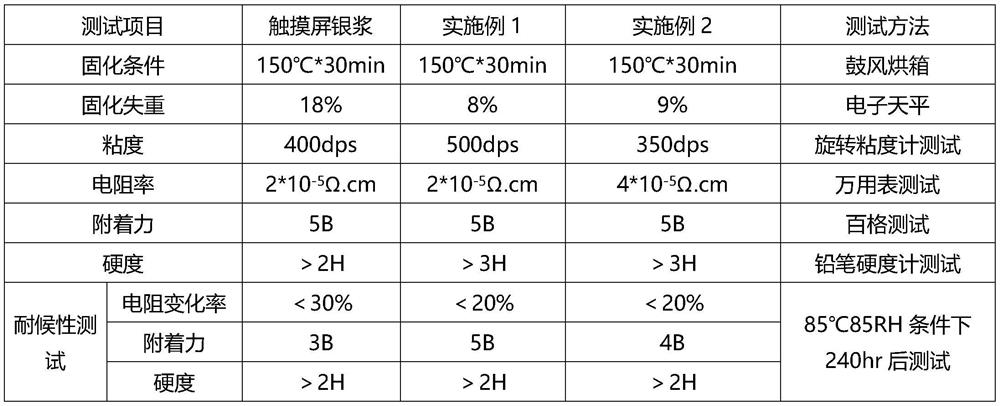

Low-VOCs touch screen silver paste and preparation method thereof

PendingCN114420342AImprove conductivityIncrease crosslink densityMetal/alloy conductorsCable/conductor manufactureSilver pastePolymer science

The low-VOCs touch screen silver paste comprises the following raw material components in parts by weight: 7-15 parts of epoxy resin, 2-5 parts of hyperbranched epoxy resin, 5-15 parts of a reactive diluent, 1-3 parts of a curing agent, 1-3 parts of an auxiliary agent and 60-80 parts of silver powder. The low-VOCs touch screen silver paste provided by the invention is small in curing volatilization, has excellent printability, conductivity and adhesive force on various membrane materials, and is particularly suitable for a glass touch screen.

Owner:衡阳思迈科科技有限公司

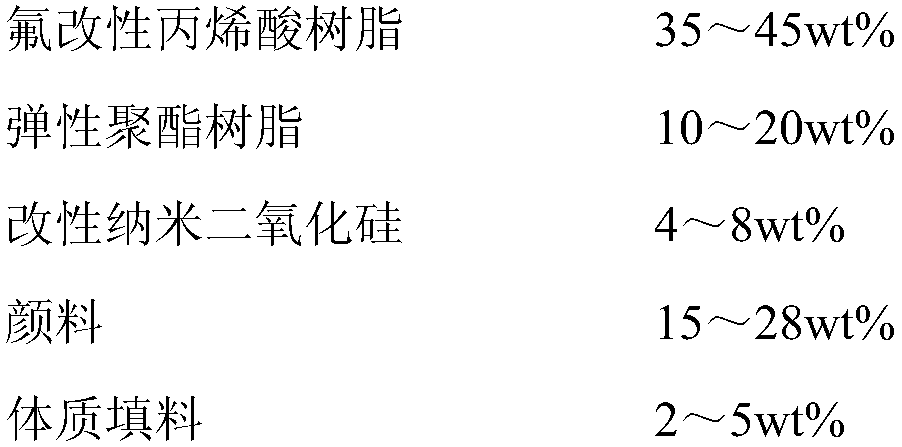

A high-elastic anti-wind, sand, wear-resistant and weather-resistant topcoat for high-speed trains and its preparation method

ActiveCN106047129BGood weather resistanceIncrease elasticityPolyurea/polyurethane coatingsAcrylic resinWear resistant

Owner:CRRC QINGDAO SIFANG CO LTD

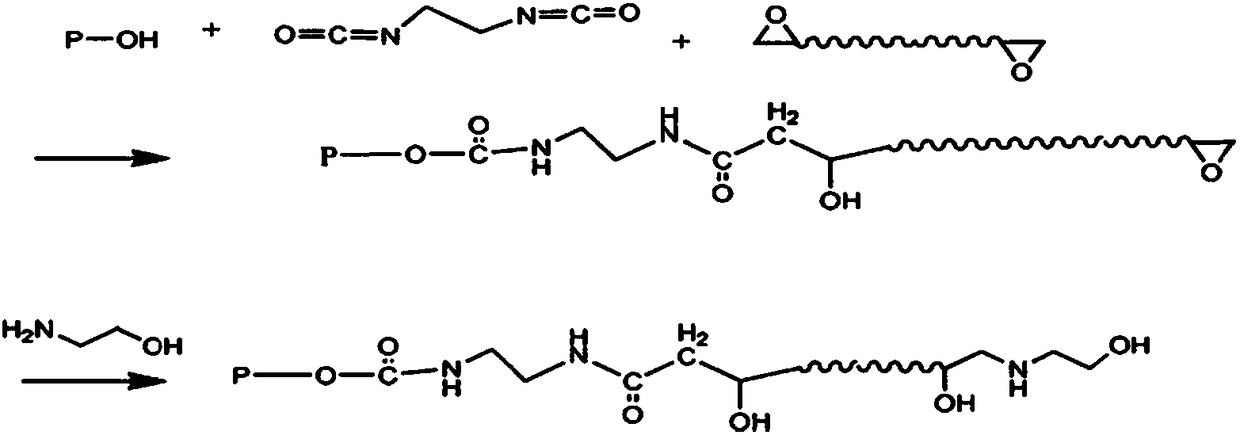

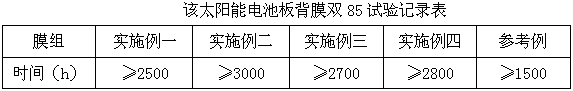

Solar panel covering back film and preparation method thereof

ActiveCN109762482AWeather resistant and convenientEasy to prepareFilm/foil adhesivesSynthetic resin layered productsEngineeringSurface layer

The invention relates to the technical field of solar panel back films, in particular to a solar panel covering back film and a preparation method thereof. The solar panel covering back film comprisesa surface layer, a glue layer, an intermediate layer and a gluing layer from top to bottom sequentially. According to the solar panel covering back film, the purposes of weatherability and convenience in construction of the back film can be achieved by a unique four-layer structure, and the back film prepared in accordance with the formula can maintain the service life of 2500 h or longer when tested by double-80 (temperature of 80 DEG C and humidity of 80%) anti-aging experiments; the preparation method is simple, low in production cost and convenient for mass production, and product qualification rate is high.

Owner:CHANGZHOU HUITIAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com