Solar panel covering back film and preparation method thereof

A solar panel and back film technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of poor anti-aging ability and weather resistance, and achieve low production cost, simple preparation method, and convenient mass production The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

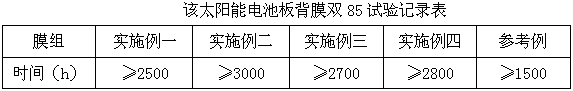

Examples

preparation example Construction

[0047] A preparation method for covering the back film of a solar cell panel:

[0048] Step 1: preparing the surface layer, glue layer, middle layer and adhesive layer;

[0049] Step 2: preparing a solar cell panel covering back film.

[0050] According to another embodiment of the present invention, further comprising:

[0051] Put all the materials in the surface layer into the mixer and stir at a speed of 400-600 rpm for 4-8 minutes, and then put the mixed materials into the extruder to extrude at a speed of 4-6m / min. The outlet temperature is 500-600°C to prepare the surface basement film;

[0052] The surface material is mixed first, and the compatibility of the material after mixing is improved. The extruder itself has heating capacity, and the mixed material is heated and melted, and the surface base film is obtained by extrusion, and the surface base film is flattened. on the countertop.

[0053]Put the glue layer material into the hot-melt machine, heat-melt it at...

Embodiment 1

[0062] A solar cell panel covering back film, which is a surface layer, a glue layer, a middle layer and an adhesive layer from top to bottom;

[0063] The surface layer includes the following components in parts by weight: 160 parts of resin, 8 parts of polystyrene, 5 parts of curing agent, 30 parts of filler, and 15 parts of antioxidant;

[0064] The glue layer includes the following components in parts by weight: 50 parts of epoxy resin, 9 parts of hot-melt adhesive, and 3 parts of additives;

[0065] The middle layer includes the following components in parts by weight: 60 parts of low-density polyethylene, 18 parts of metallocene polyethylene, 5 parts of silicon dioxide, and 20 parts of titanium dioxide;

[0066] The adhesive layer includes the following components in parts by weight: 40 parts of polypropionate, 2 parts of antistatic additive, 0.8 part of curing agent, 8 parts of PVC resin, 3 parts of coupling agent and 6 parts of antiaging agent.

[0067] According to a...

Embodiment 2

[0086] A solar cell panel covering back film, which is a surface layer, a glue layer, a middle layer and an adhesive layer from top to bottom;

[0087] The surface layer includes the following components in parts by weight: 120 parts of resin, 4 parts of polystyrene, 3 parts of curing agent, 20 parts of filler, and 1 part of antioxidant;

[0088] The glue layer includes the following components in parts by weight: 30 parts of epoxy resin, 5 parts of hot-melt adhesive, and 1 part of additive;

[0089] The middle layer includes the following components in parts by weight: 40 parts of low-density polyethylene, 10 parts of metallocene polyethylene, 3 parts of silicon dioxide, and 1 part of titanium dioxide;

[0090] The adhesive layer includes the following components in parts by weight: 20 parts of polypropionate, 1 part of antistatic additive, 0.3 parts of curing agent, 5 parts of PVC resin, 1 part of coupling agent, and 2 parts of antiaging agent.

[0091] According to another...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com