A high-elastic anti-wind, sand, wear-resistant and weather-resistant topcoat for high-speed trains and its preparation method

A high-speed train and high-elasticity technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor environmental capabilities, and achieve strong hiding power, high solar reflection coefficient, and good wind and sand erosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

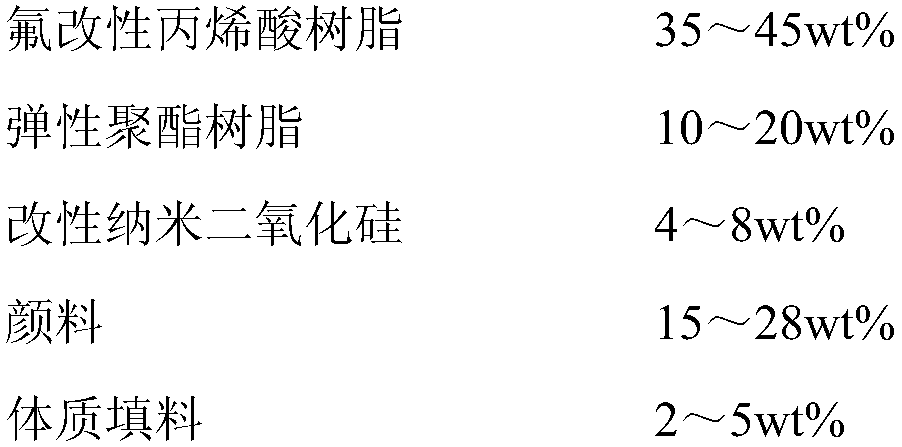

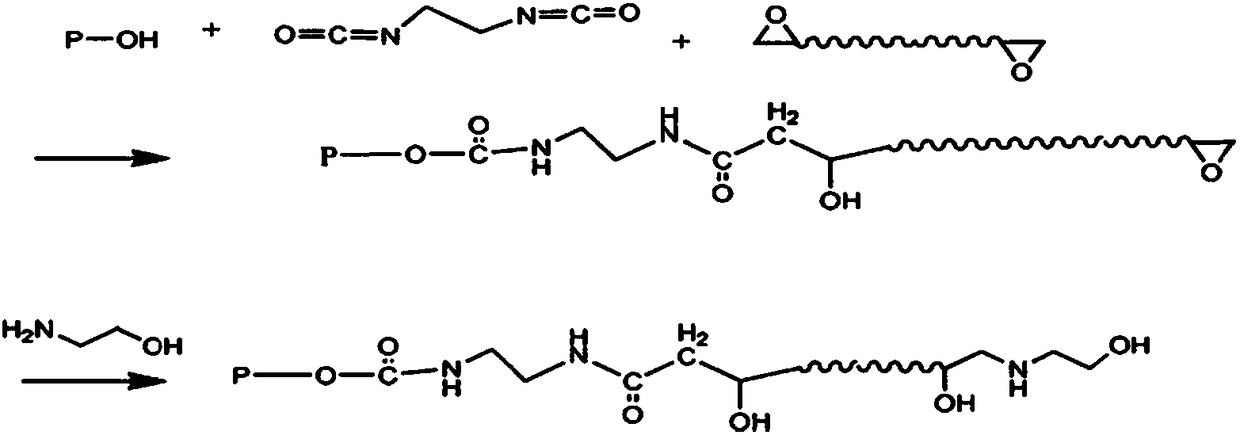

[0046] First, the modified nano-silica is prepared by the organic-inorganic hybrid modification method, and the colloidal solution containing nano-silica, isocyanate N3200 and epoxy resin E51 are mixed and reacted to obtain an intermediate product, and then the epoxy group is opened by the alkali The ring reaction is used to obtain organic-inorganic hybrid nano-silica grafted on the surface with flexible chain segments of hydroxyl groups.

[0047] Carry out the preparation of high-elastic anti-wind, sand, wear-resistant and weather-resistant topcoat for high-speed trains, the method steps are as follows:

[0048] (1) In terms of mass percentage, 35wt% of fluorine-modified acrylic resin GK570, 20wt% of FTH polyester resin, 1wt% of polyamide wax, 1.5wt% of BYK-530A, 1.5wt% of BYK- 320 and 5wt% mixed solvent (the volume ratio of the three components in the mixed solvent is xylene: ethyl acetate: cyclohexanone = 2:1:1) into the dispersion tank in turn, stirring;

[0049] (2) Slow...

Embodiment 2

[0053] Firstly, the modified nano-silica is prepared by the organic-inorganic hybrid modification method, and the colloidal solution containing nano-silica, isocyanate N3800 and epoxy resin F51 are mixed and reacted to obtain an intermediate product, and then the epoxy group is opened by the alkali The ring reaction is used to obtain organic-inorganic hybrid nano-silica grafted on the surface with flexible chain segments of hydroxyl groups.

[0054] Carry out the preparation of high-elastic anti-wind, sand, wear-resistant and weather-resistant topcoat for high-speed trains, the method steps are as follows:

[0055] (1) In terms of mass percentage, 40wt% of fluorine-modified acrylic resin GK570, 15wt% of FTH polyester resin, 1wt% of organic bentonite, 1wt% of Deqian 6800, 1wt% of EFKA-2022 and 7wt% % of the mixed solvent (the volume ratio of the three components in the mixed solvent is xylene: ethyl acetate: cyclohexanone=2:3:1) is poured into the dispersion tank in turn, and s...

Embodiment 3

[0060] Firstly, the modified nano-silica is prepared by the organic-inorganic hybrid modification method, and the colloidal solution containing nano-silica, isocyanate N75 and epoxy resin E54 are mixed and reacted to obtain an intermediate product, and then the epoxy group is opened by the alkali The ring reaction is used to obtain organic-inorganic hybrid nano-silica grafted on the surface with flexible chain segments of hydroxyl groups.

[0061] Carry out the preparation of high-elastic anti-wind, sand, wear-resistant and weather-resistant topcoat for high-speed trains, the method steps are as follows:

[0062] (1) In terms of mass percentage, 45wt% of fluorine-modified acrylic resin GK570, 10wt% of FTH polyester resin, 0.5wt% of fumed silica, 1wt% of Deqian 6800, 0.5wt% of BYK -320 and 10wt% of the mixed solvent (the volume ratio of the three components in the mixed solvent is xylene: ethyl acetate: cyclohexanone = 1:1.3:1) is poured into the dispersion tank in turn, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com