Siliceous heat-insulation composite material for wall

A technology for thermal insulation materials and walls, applied in the field of building materials, can solve the problems of low construction efficiency, short durability, wall cracking, etc., and achieve the effects of improving thermal insulation effect, uniform interface roughening, and good bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

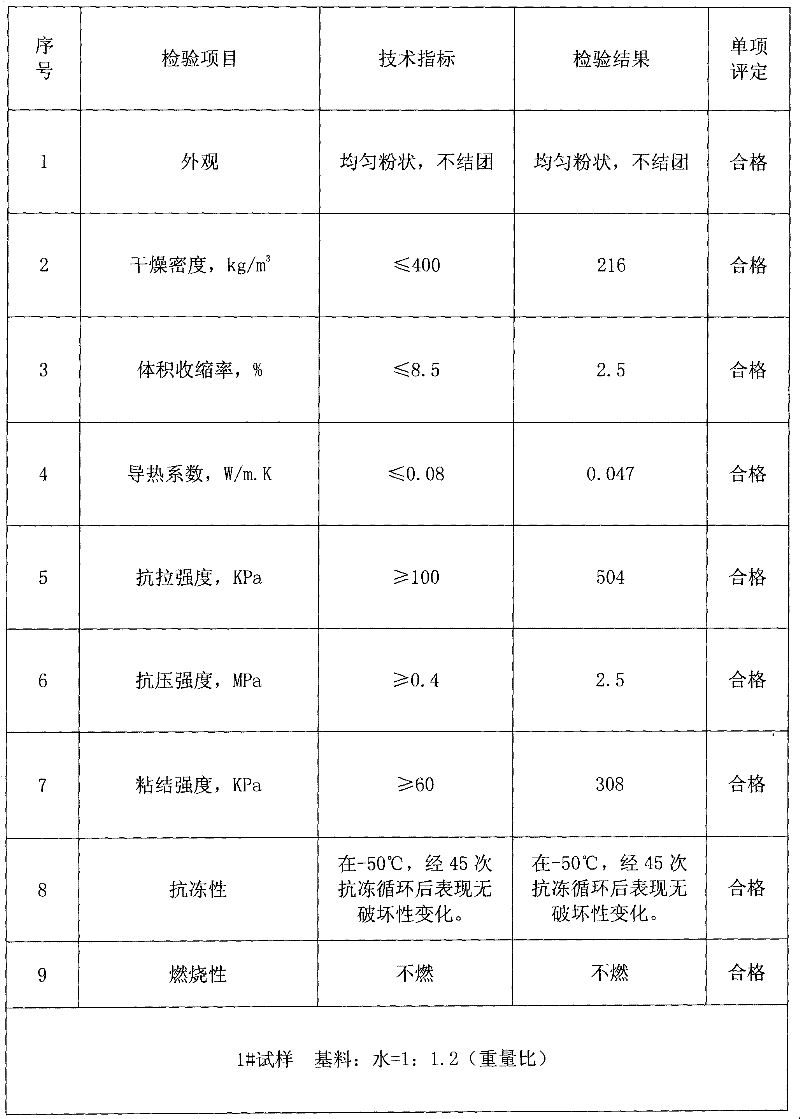

[0020] Embodiment 1 (1# sample):

[0021] 90 kg of closed-cell expanded perlite (Langfang Tenglong Thermal Insulation Building Materials Factory), 130 kg of 525# cement (produced by Chaoyang Qunfeng Cement Co., Ltd.), 20 kg of building gypsum (produced by Shandong Taian Pengcheng Gypsum Powder Co., Ltd.), aluminum silicate fiber 25kg (fiber length 0.5-1.5cm from Zibo New Refractory Insulation Material Company, Shandong Province), 15kg high-viscosity attapulgite (Mingguang Zhongtian Industry and Trade Company), redispersible rubber powder (JMH-07 perlite insulation mortar special Rubber powder (produced by Langfang Zhenxing Thermal Insulation Building Materials Co., Ltd.) 2.5 kg, hydroxypropyl methylcellulose (produced by Beijing Tianhong Ruicheng Thermal Insulation Material Co., Ltd.) 2 kg, SHP50 organic silicon powder water-repellent agent 1.5 kg (Beijing Zhubao New Technology Co., Ltd. produced by the company). During use, the above-mentioned 8 kinds of base materials are m...

Embodiment 2

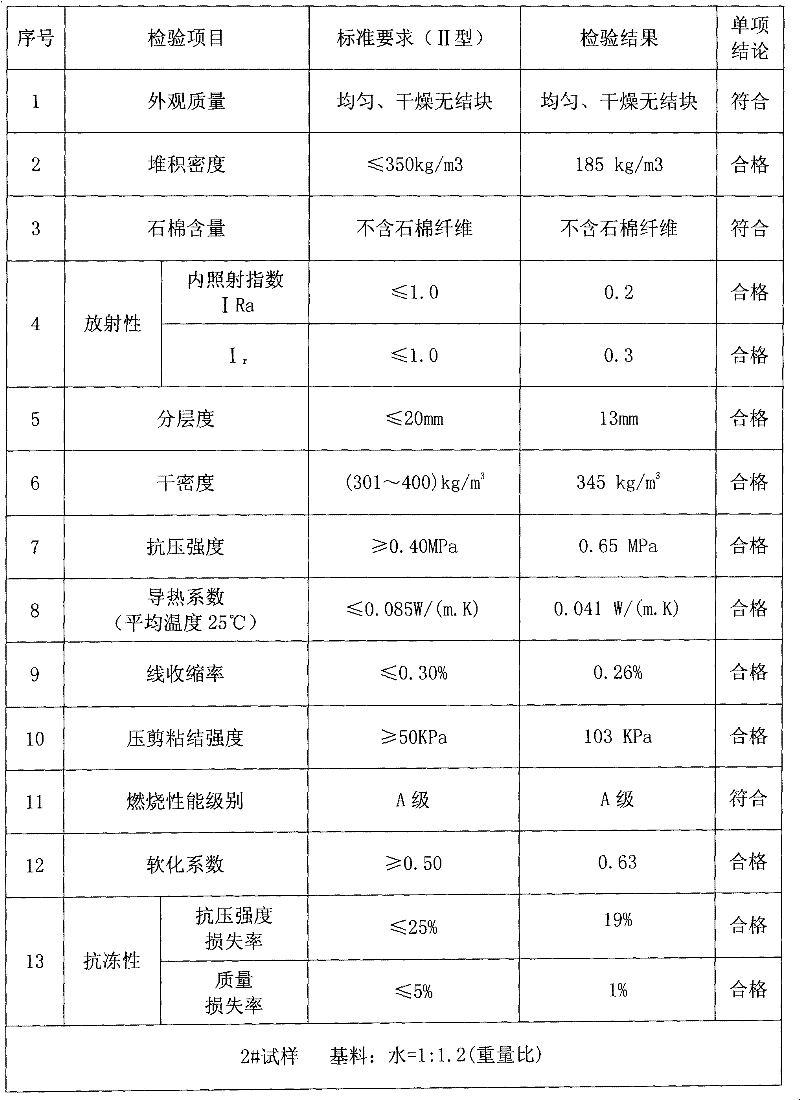

[0022] Embodiment 2 (2# sample):

[0023] 100 kg of closed-cell expanded perlite, 130 kg of 525# cement, 20 kg of building gypsum, 25 kg of brucite fiber (produced by Leifeng Thermal Insulation and Friction Material Company in Yuanyuan County, Hebei Province, fiber length 0.5-1.5cm), high-viscosity attapulgite 15 kg, redispersible rubber powder (polymer resin rubber powder AT-08 self-regulating phase change energy-saving energy storage insulation material special rubber powder - Langfang Aote insulation building materials company production) 2.5 kg, hydroxypropyl methylcellulose 2 kg , SHP50 silicone powder water repellent 1.5 kg. During use, the above-mentioned 8 kinds of base materials are mixed and stirred with water to form a slurry, base material: water=1:1.2 (weight ratio).

Embodiment 3

[0024] Embodiment 3 (3# sample):

[0025] 110 kg of closed-cell expanded perlite, 140 kg of 525# cement, 25 kg of construction gypsum, 30 kg of sepiolite fiber (the length of the fiber produced by Hebei Hongli Sepiolite Wool Co., Ltd. is 0.5-1.5cm), 10 kg of high-viscosity attapulgite , 3.2 kilograms of redispersible rubber powder (dispersible resin rubber powder-Hebei Langfang Hengxin Rubber Industry Co., Ltd. production), 2.5 kilograms of hydroxypropyl methylcellulose, 2 kilograms of SHP50 organic silicon powder water repellent. Base material: water=1:1.2 (weight ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com