Powder coating with ultrahigh weather-proof extinction effect

A technology of powder coating and weather resistance, which is applied in the direction of powder coating, epoxy resin coating, coating, etc., which can solve the problems of products that cannot realize coating film matting, achieve excellent super weather resistance effect, achieve weather resistance, smooth and delicate surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

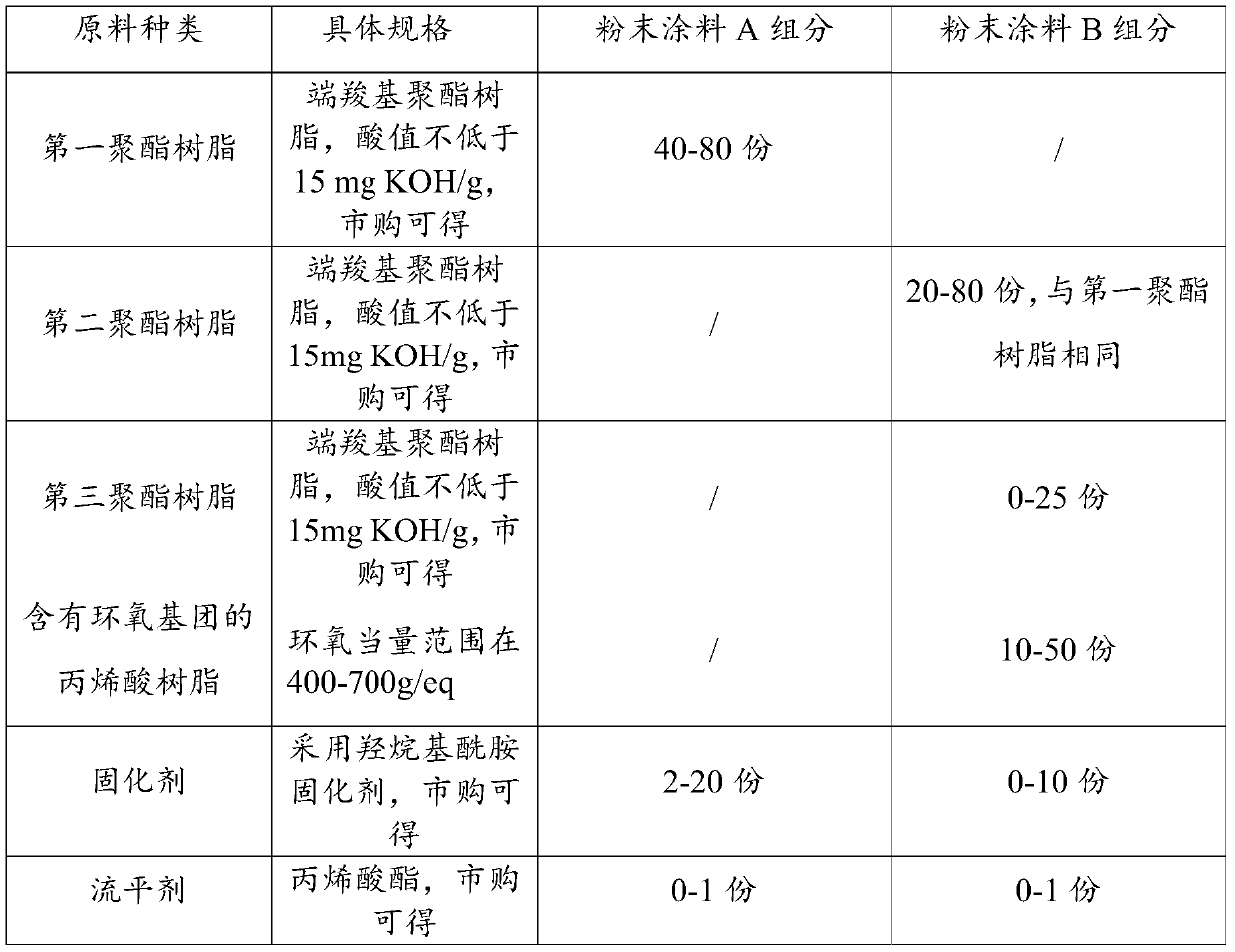

[0047] Embodiment 1: the raw material formula of present embodiment 1 adopts following table 2:

[0048] Table 2: the raw material formula table of the present embodiment 1

[0049]

[0050]

[0051] Prepare the raw materials of powder coating A component and powder coating B component according to the formula in the above table 2, and then prepare them respectively through the known powder coating preparation process, and then mix powder coating A component and powder coating B component according to 1:1 The weight ratio is dry mixed to obtain a powder coating with ultra-high weather resistance and matting effect.

Embodiment 2

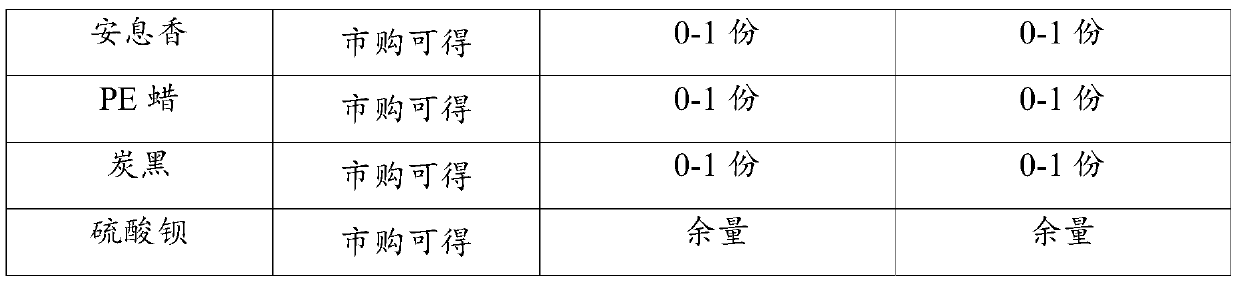

[0052] Embodiment 2: the raw material formula of present embodiment 2 adopts following table 3:

[0053] Table 3: the raw material formula table of the present embodiment 2

[0054]

[0055] Prepare the raw materials of powder coating A component and powder coating B component according to the formula in the above table 3, and then prepare them respectively through the known powder coating preparation process, and then mix powder coating A component and powder coating B component according to 0.5:1 The weight ratio is dry mixed to obtain a powder coating with ultra-high weather resistance and matting effect.

Embodiment 3

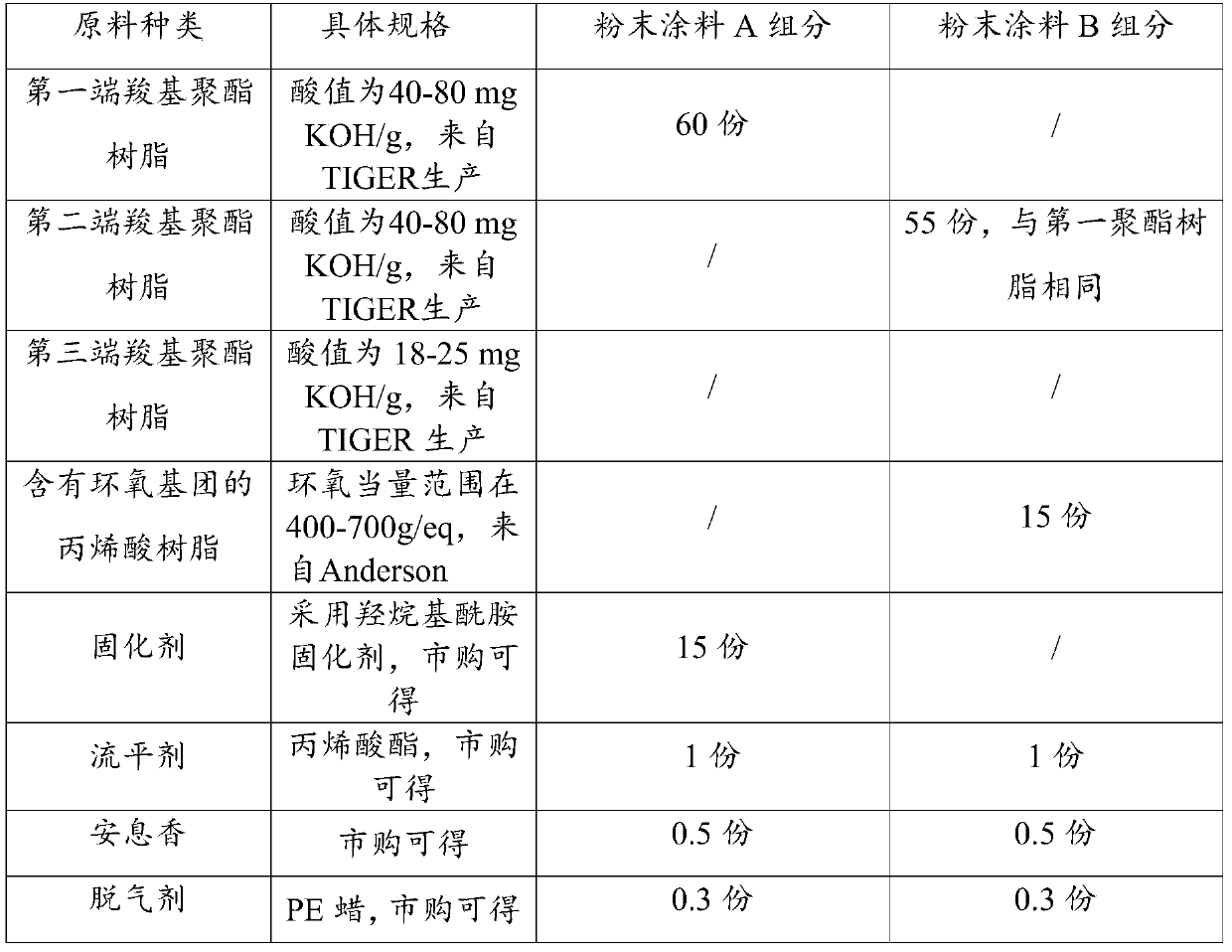

[0056] Embodiment 3: the raw material formula of present embodiment 3 adopts following table 4:

[0057] Table 4: The raw material formula table of present embodiment 3

[0058]

[0059] Prepare the raw materials of powder coating A component and powder coating B component according to the formula in the above table 4, and then prepare them respectively through the known powder coating preparation process, and then mix powder coating A component and powder coating B component according to 2:1 The weight ratio is dry mixed to obtain a powder coating with ultra-high weather resistance and matting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com