Low-VOCs touch screen silver paste and preparation method thereof

A touch screen, silver paste technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as environmental pollution, achieve less harm to production personnel and the environment, improve electrical conductivity, and improve electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In addition, the present invention also provides the preparation method of above-mentioned conductive silver paste, comprises the steps:

[0035] S1: Add low-viscosity epoxy resin and polyester hyperbranched epoxy resin to reactive diluent, heat and stir at 80°C for 6 hours, then filter through 400-mesh polyester mesh, cool the collected filtrate to room temperature, and obtain resin dispersion body;

[0036] S2: Add additives such as curing agent and coupling agent to the resin dispersion, disperse at a high speed of 50-300r / min for 10min; then disperse evenly through three-roll grinding to obtain a silver paste precursor;

[0037] S3: Add silver powder to the precursor, disperse at high speed for 5 minutes, and grind the obtained mixture 5 to 7 times with three rollers, so that the fineness of the ground mixture does not exceed 5 microns, and then use a revolution and rotation rotary defoamer for 3 minutes at 1600r / min Rotary defoaming, the vacuum degree of rotary de...

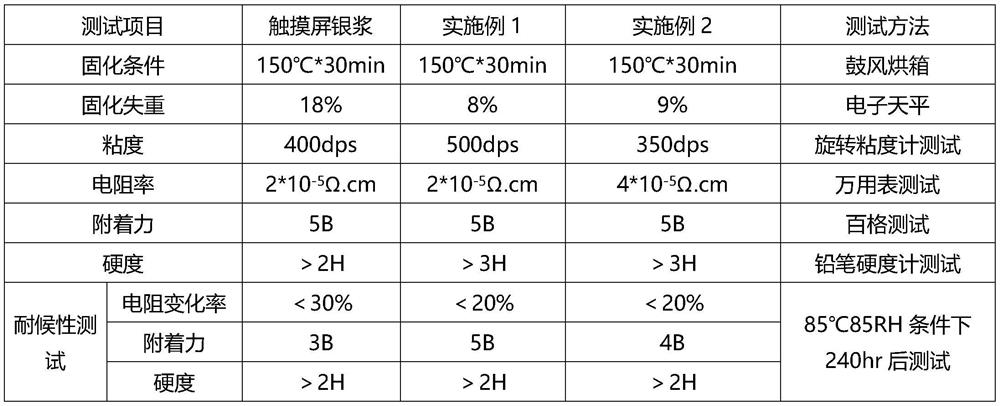

Embodiment 1

[0040]This embodiment provides a silver paste for a touch screen. The raw material components are calculated in parts by weight, including: 10 parts of bisphenol F epoxy ED-509S epoxy resin, 2 parts of polyester hyperbranched epoxy resin, 1,4- 11 parts of butanediol glycidyl ether, 1 part of hexafluoroantimonate, 0.8 parts of fumed silica, 0.2 parts of silane coupling agent, and 75 parts of flaky silver powder with an average particle diameter of 2 microns.

[0041] According to above-mentioned raw material, adopt preparation method provided by the invention, prepare conductive silver paste:

[0042] S1: Add low-viscosity epoxy resin and polyester hyperbranched epoxy resin to reactive diluent, heat and stir at 80°C for 6 hours, then filter with 400-mesh polyester mesh, and cool the collected filtrate to room temperature to obtain resin Dispersion; S2: add curing agent, coupling agent and other additives to the resin dispersion, disperse at a high speed of 50-300r / min for 10min...

Embodiment 2

[0044] This embodiment provides a silver paste for a touch screen. The raw material components are calculated in parts by weight, including: 12 parts of NPEF-170 novolac epoxy resin, 2 parts of polyester hyperbranched epoxy resin, 1,4-butanediol glycidol 11 parts of ether, 1 part of hexafluoroantimonate, 0.8 parts of fumed silica, 0.2 parts of silane coupling agent, and 73 parts of flaky silver powder with an average particle diameter of 2 microns.

[0045] According to above-mentioned raw material, adopt preparation method provided by the invention, prepare conductive silver paste:

[0046] S1: Add low-viscosity epoxy resin and polyester hyperbranched epoxy resin to reactive diluent, heat and stir at 80°C for 6 hours, then filter with 400-mesh polyester mesh, and cool the collected filtrate to room temperature to obtain resin Dispersion; S2: add curing agent, coupling agent and other additives to the resin dispersion, disperse at a high speed of 50-300r / min for 10min; then di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com