Corrosion-resistant and weather-resistant glass bottle and preparation method thereof

A glass bottle, anti-corrosion technology, applied in glass manufacturing equipment, glass tempering, blowing-blowing glass forming machine, etc., can solve the problems that affect the service life of glass bottles, yellowing of glass bottles, corrosion, etc., to ensure anti-corrosion Effect and weather resistance, increase service life, achieve corrosion resistance effect and weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

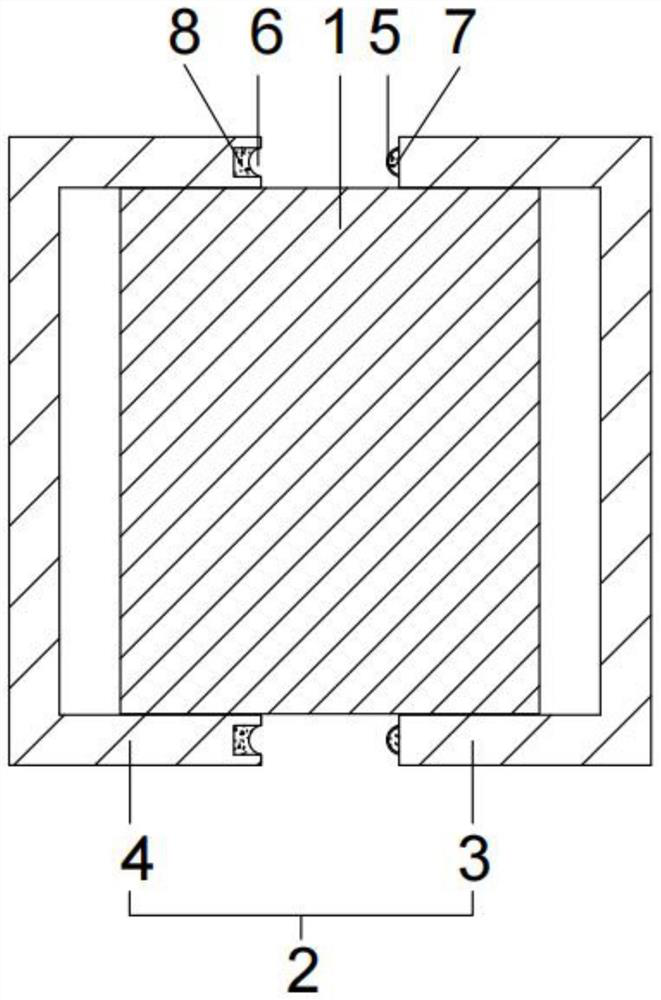

[0032] Example 1: Reference Figure 1 , a corrosion-resistant and weather-resistant glass bottle, comprising a glass bottle body 1, the outside of the glass bottle body 1 is provided with a glass bottle protective member 2, the glass bottle protective part 2 is closely fitted to the outer wall of the glass bottle body 1, the glass bottle protection member 2 includes a detachable connection of the first protective shell 3 and the second protective shell 4, the first protective shell 3 near the end of the second protective shell 4 is provided with a snap-in bump 5, the second protective shell 4 near the first protective shell 3 has a groove for the snap-in bump 5 snap-in 6, the snap-in bump 5 and the groove 6 are equipped with several groups, The first protective case 3 and the second protective case 4 are both glass.

[0033]While the interior of the carded bump 5 is filled with a number of magnets 8, the interior of the second protective shell 4 is filled with a number of adsorbed ...

Embodiment 2

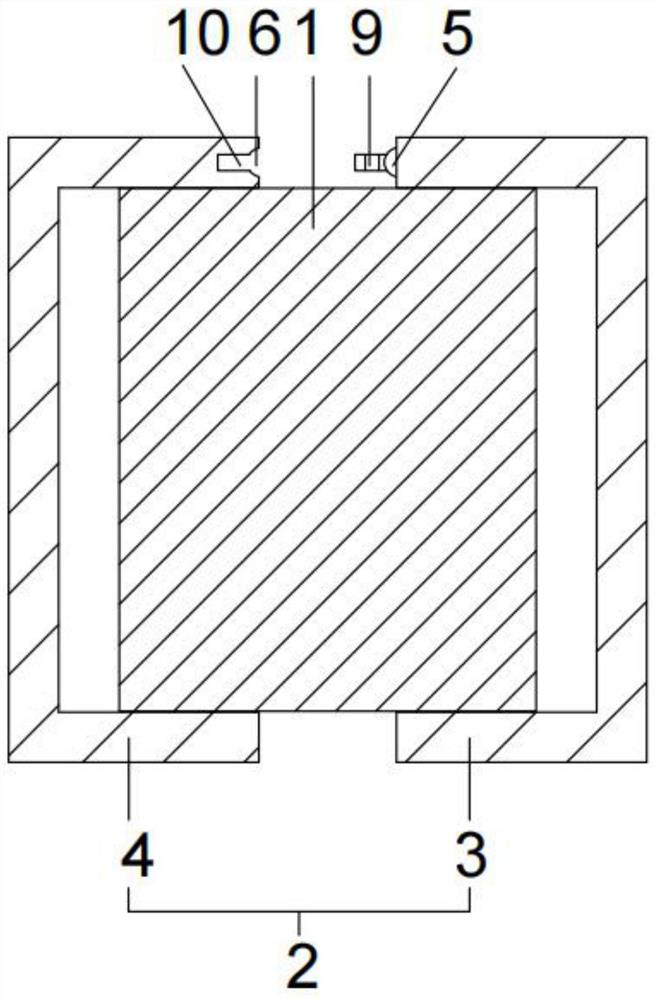

[0037] Example 2: Reference Figure 2Compared with Example I, the difference of Example II is that: the card into the bump 5 is prominently provided with a mortise 9, the mortise 9 is a cross-shaped setting and the surface of the mortise 9 is provided with a slip pattern, the inner wall of groove 6 is provided with a card slot 10 for the mortise 9 card slot 10, the outer wall of the mortise 9 is closely fitted to the inner wall of the card slot 10.

[0038] Working principle: when stuck into the bump 5 card into the groove 6, the mortise 9 stuck into the groove 5 will first be stuck into the groove 6 inner wall opened in the card slot 10, and after the card into the bump 5 is close to the groove 6 and the surface of the groove 6 is fitted, the mortise 9 will be completely stuck into the card slot 10, and then increase the connection force when the card is stuck into the bump 5 and the groove 6, and can achieve the connection force of the first protective shell 3 and the second prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com