Normal-temperature-cured polytetrafluoroethylene-modified high-solid-content automobile varnish and preparation method thereof

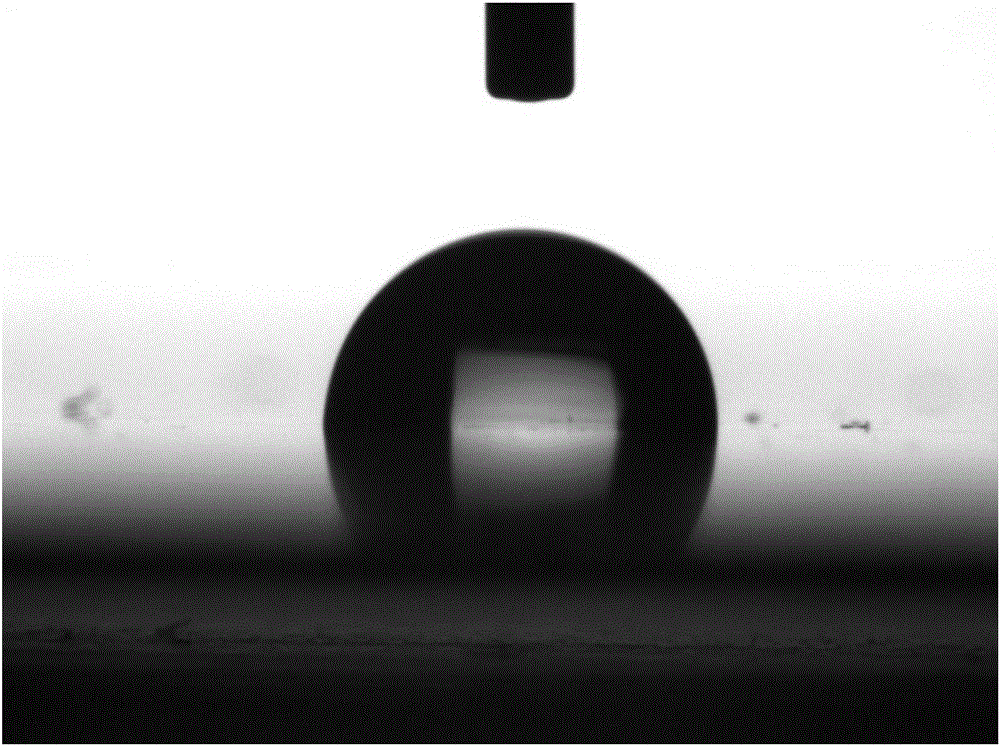

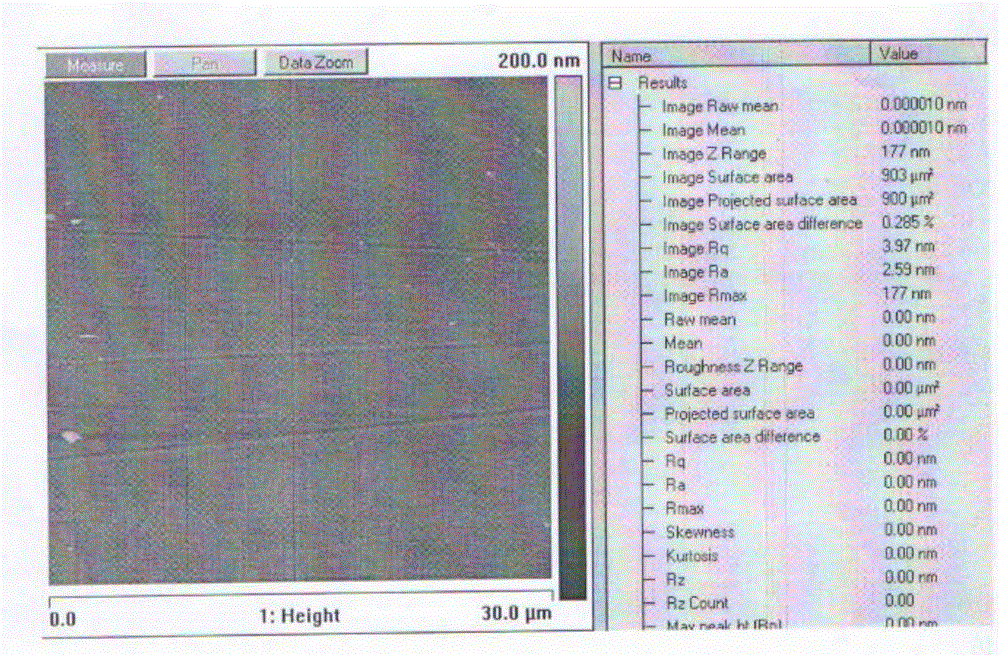

A polytetrafluoroethylene, room temperature curing technology, used in polyurea/polyurethane coatings, coatings, pretreated surfaces, etc., can solve the problems of poor dispersion, low hardness, easy pollution, etc., to reduce surface energy and bond energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of a room temperature curing polytetrafluoroethylene modified high-solid automotive varnish

[0047] (1) Preparation of main paint: mix 20 parts of methyl methacrylate, 8 parts of butyl methacrylate, 6 parts of hydroxyethyl acrylate, 6 parts of hydroxybutyl acrylate, 6 parts of hydroxypropyl acrylate, benzene peroxide Add 1 part of formyl, 30 parts of butyl acetate, 5 parts of methyl isobutyl ketone, 3 parts of propylene glycol methyl ether acetate, 2 parts of N-methylpyrrolidone, and 10 parts of hexamethylene diisocyanate into a magnetic stirrer, Introduce nitrogen, 40°C, 3500 rpm, stir for 1 hour, raise the temperature to 80°C and stir for 2 hours, then start to drop 3 parts of modified transparent oily polytetrafluoroethylene resin at a rate of 60 drops / min, drop Finish, stir 2 hours at 5000 rpm, keep warm for 1 hour, cool to normal temperature, and make the main paint;

[0048] (2) curing agent preparation: put 50 parts of polyisocyanate, 30 parts of bu...

Embodiment 2

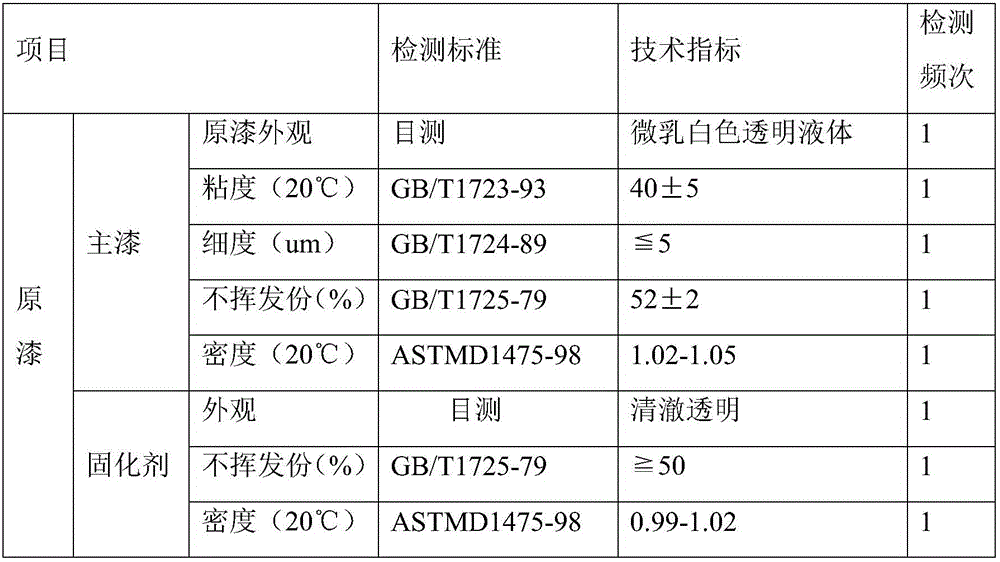

[0054] For the main paint and curing agent prepared in Example 1, the performance test was carried out with reference to the national standard, and the test results were as follows:

[0055]

Embodiment 3

[0057] With the prepared varnish in embodiment one, spray by following parameters

[0058]

[0059] Spraying construction process:

[0060] Pretreatment→spraying intermediate coating→spraying topcoat→spraying varnish→baking

[0061] 1. Pre-treatment: first use a degreasing agent to clean and degrease the metal paint, and then wipe it with a dust cloth.

[0062] 2. Spraying: first spray the epoxy primer, then spray the above diluted varnish once, let it dry for 8-10 minutes, and then spray the second time;

[0063] 3. Baking: After spraying the varnish, let it dry for 8-10 minutes, then bake at 60℃ / 45-60 minutes.

[0064] Note: Check whether the spraying environment is clean and dust-free, wear work clothes and protective masks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com