A material for injection molding flame-retardant plastic seats for stadiums with excellent weather resistance

A flame-retardant plastic and weather-resistant technology, which is applied in the field of materials for stadium flame-retardant plastic seats, can solve the problems of large amount of addition, high price, and difficulty in industrialized production, and achieves the effects of easy injection molding, low price, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

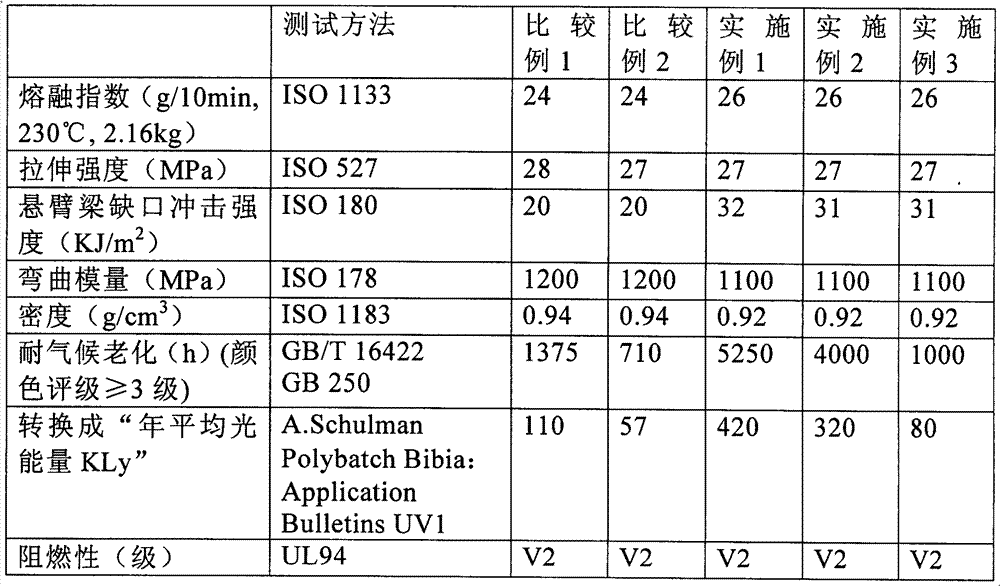

Embodiment 1

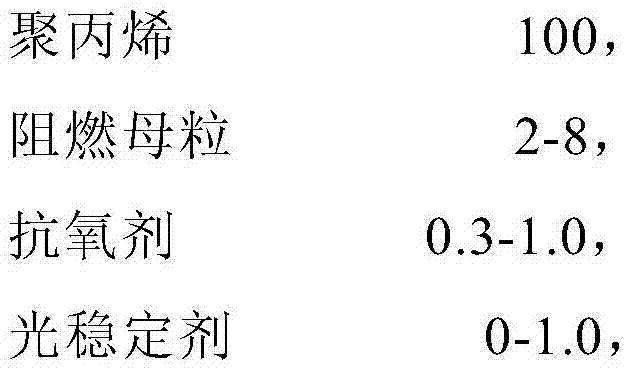

[0043] The following weight (kg) ratio of raw materials is used: polypropylene copolymer (7926, Shanghai Secco): 100, flame retardant masterbatch: 4.5, antioxidant 1010: 0.15, antioxidant 168: 0.4, hindered amine light stabilizer Tinuvin770 (Ciba): 0.5, hindered amine light stabilizer Chimassorb 944 (Ciba): 0.1. After the raw material ratio is mixed, the injection molding process can make the plastic chair. The injection molding process is: material temperature 180°C-200°C-210°C-220°C-220°C-220°C, injection pressure 60MPa, injection speed 50%.

[0044] Wherein the preparation method of flame retardant master batch comprises the following steps:

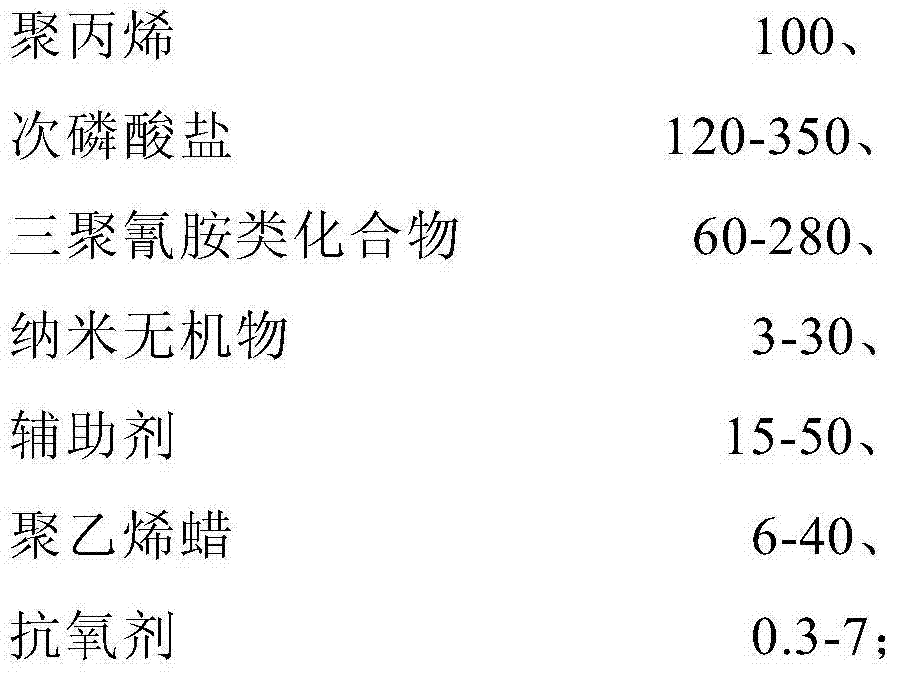

[0045](1) Prepare materials according to the following components and weight (kg): polypropylene 100, calcium hypophosphite 350, melamine hydrobromide 170, nano silicon dioxide (10nm) 30, dimethyldiphenylhexane 40, polyethylene Wax 20, antioxidant 1010 is 0.3;

[0046] (2) After mixing the above-mentioned components, add them to th...

Embodiment 2

[0049] The following weight (kg) ratio of raw materials is used: polypropylene copolymer (7926, Shanghai Secco): 100, flame retardant masterbatch: 3, antioxidant 1010: 0.1, antioxidant 168: 0.3, hindered amine light stabilizer Tinuvin770 (Ciba): 0.3. After the raw material ratio is mixed, the injection molding process can make the plastic chair. The injection molding process is as follows: material temperature 180°C-200°C-220°C-230°C-230°C-220°C, injection pressure 70MPa, injection speed 40%.

[0050] Wherein the preparation method of flame retardant master batch comprises the following steps:

[0051] (1) Prepare materials according to the following components and weight (kg): Copolypropylene 100, aluminum hypophosphite 300, melamine cyanurate 280, nano kaolin (30nm) 10, dimethyl diphenylbutane 15, polyethylene wax 6 , Antioxidant 1010 is 4, Antioxidant 168 is 2;

[0052] (2) After mixing the above-mentioned components, add them to the co-rotating twin-screw extruder to ex...

Embodiment 3

[0055] The following weight (kg) ratio of raw materials is used: polypropylene copolymer (7926, Shanghai Secco): 100, flame retardant masterbatch: 3.8, antioxidant 1010: 0.1, antioxidant 168: 0.3. After the raw material ratio is mixed, the injection molding process can make the plastic chair. The injection molding process is: material temperature 180°C-200°C-210°C-220°C-220°C-220°C, injection pressure 60MPa, injection speed 50%.

[0056] Wherein the preparation method of flame retardant master batch comprises the following steps:

[0057] (1) Prepare materials according to the following components and weight (kg): Copolypropylene 100, calcium hypophosphite 300, melamine 280, nano-montmorillonite (100nm) 10, polydiisopropylbenzene 15, polyethylene wax 6, antioxidant Agent 1010 is 4;

[0058] (2) After mixing the above-mentioned components, add them to the co-rotating twin-screw extruder to extrude and granulate. 180°C-190°C-200°C-200°C-210°C-210°C-220°C-210°C, then control t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com