Energy-saving environment-friendly composite color steel plate and production method thereof

An energy saving and environmental protection, color steel plate technology, applied in chemical instruments and methods, roofs using flat/curved panels, roof coverings, etc., can solve the problems of easy generation of chips, no sound insulation, and low basic performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

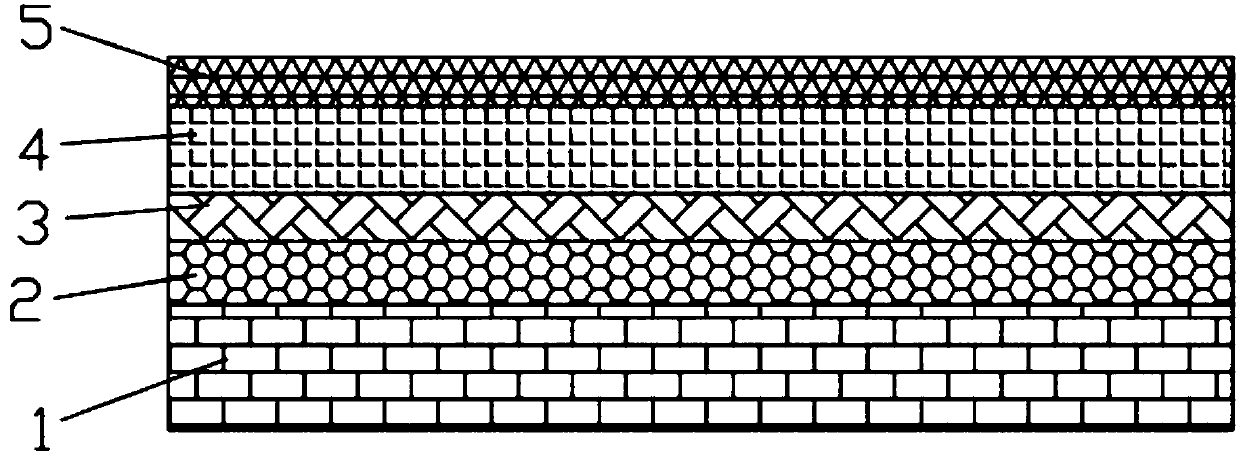

[0013] The energy-saving and environment-friendly composite color steel plate of the present invention and the embodiment of its manufacturing method will be further described below in conjunction with the accompanying drawings.

[0014] An energy-saving and environment-friendly composite color steel plate, including a base layer and a functional layer, the functional layer includes a super-flame-retardant cross-linked polyethylene foam board 2, which is pasted on the surface of the super-flame-retardant cross-linked polyethylene foam board 2 The anti-wear layer and the anti-rust layer arranged between the anti-wear layer and the super flame-retardant cross-linked polyethylene foam board 2, the base layer is a color steel plate 1, the anti-rust layer is an iron red phenolic anti-rust paint layer 3, and the anti-rust layer is The wear layer is molybdenum disulfide coating4. The energy-saving and environment-friendly composite color steel plate can be closely adhered to the supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com