Copper alloy sheet for heat-dissipating component, and heat-dissipating component

A technology for heat-dissipating components and copper alloy plates, which is applied to electrical components, semiconductor/solid-state device components, and electrical solid-state devices, etc., can solve problems such as inability, low strength, bending processing, etc., and achieve improved corrosion resistance and high heat dissipation. , the effect of preventing performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the copper alloy plate for heat radiation elements of this invention is demonstrated in detail.

[0018]

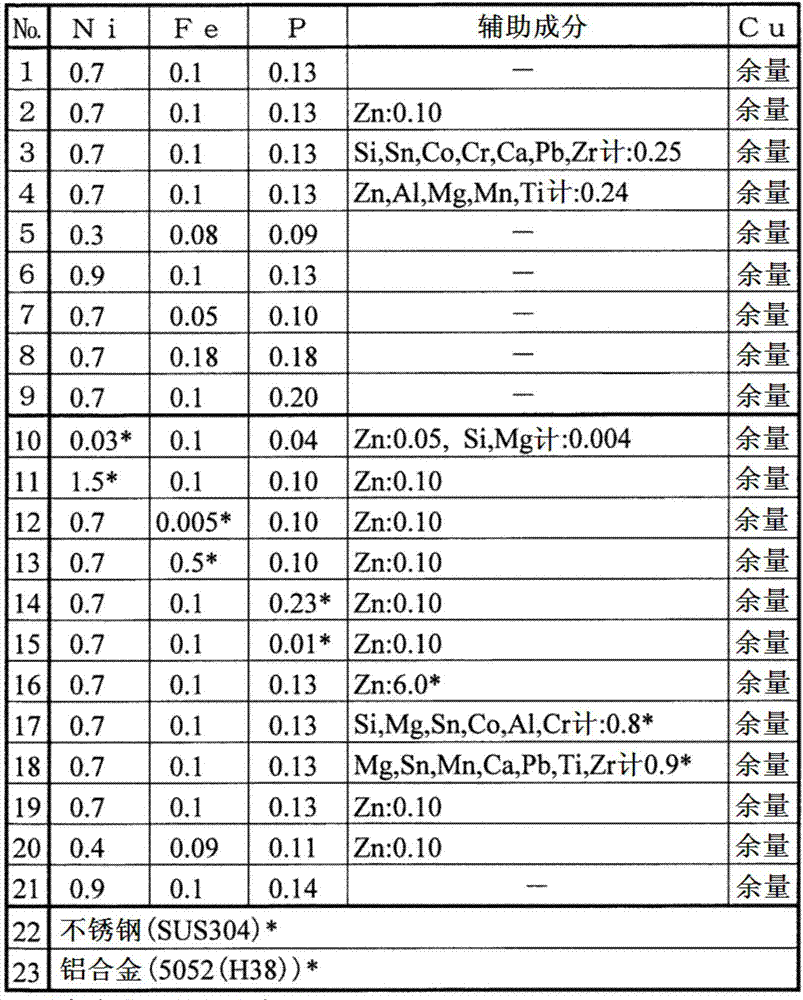

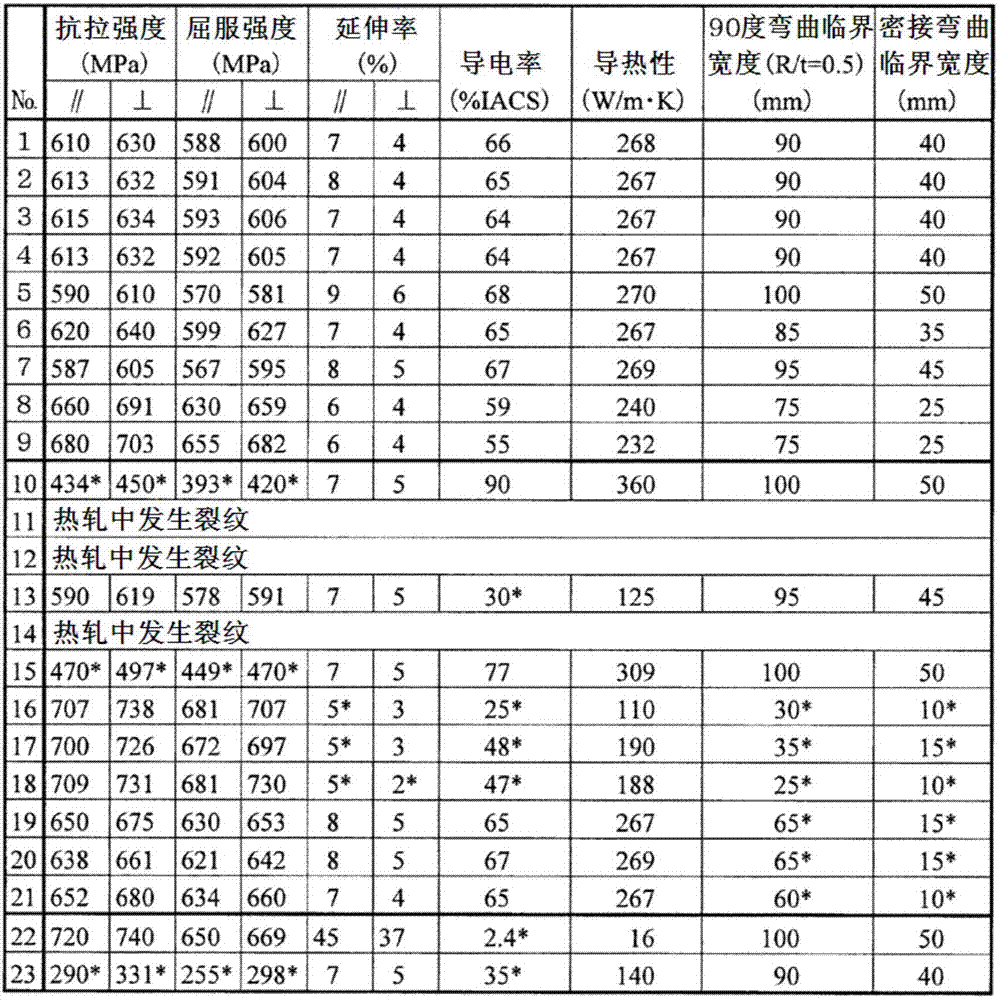

[0019] The composition of the copper alloy contains Ni: 0.1-1.0 mass%, Fe: 0.01-0.3 mass%, P: 0.03-0.2 mass%, and the balance is composed of Cu and unavoidable impurities. In this copper alloy, if necessary, one or two or more of Si, Zn, Sn, Co, Al, Cr, Mg, Mn, Ca, Pb, Ti, and Zr are contained as auxiliary components in a total of 0.3 mass% or less (excluding 0% by mass). This composition is basically identical to the composition of the copper alloy described in Patent Document 1.

[0020] Ni and P, which will be described later, precipitate intermetallic compounds to increase the strength of the copper alloy. When the Ni content is less than 0.1 mass%, the expected strength cannot be obtained because there are few Ni—P compounds. On the other hand, if the Ni content exceeds 1.0 mass%, a large amount of coarse crystallized Ni—P compounds will be f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com