Automobile thin-wall thermoplastic insulation low-voltage cable

A low-voltage cable, thermoplastic technology, applied in the field of thin-walled thermoplastic insulated low-voltage cables for automobiles, can solve the problems of increased cable weight, difficult to accommodate cable volume, and reduced assembly operability, and achieve good insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

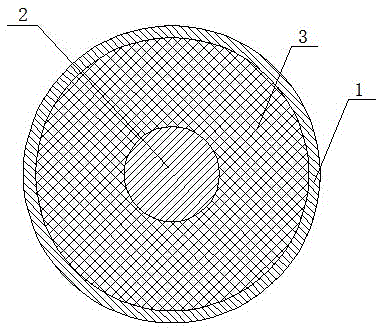

[0011] See figure 1 , a thin-walled thermoplastic insulated low-voltage cable for automobiles, comprising a tinned copper conductive core 1, a polyvinyl chloride thermoplastic elastomer 2 wrapped outside the tinned copper conductive core 1, and a polyvinyl chloride thermoplastic elastomer wrapped in a polyvinyl chloride thermoplastic elastomer 2 outside the halogen-free low-smoke flame-retardant polyolefin sheath layer 3; wherein, the sheath layer 3 is made by a thin-wall extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com