Special mixed cement for on-site preparation of concrete as well as preparation method and application

A technology for mixing cement and concrete, applied in cement production, etc., can solve problems such as increased cracking risk, lack, and shortage, and achieve the effects of improving homogeneity and quality stability, simplifying the preparation process, and preventing early cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

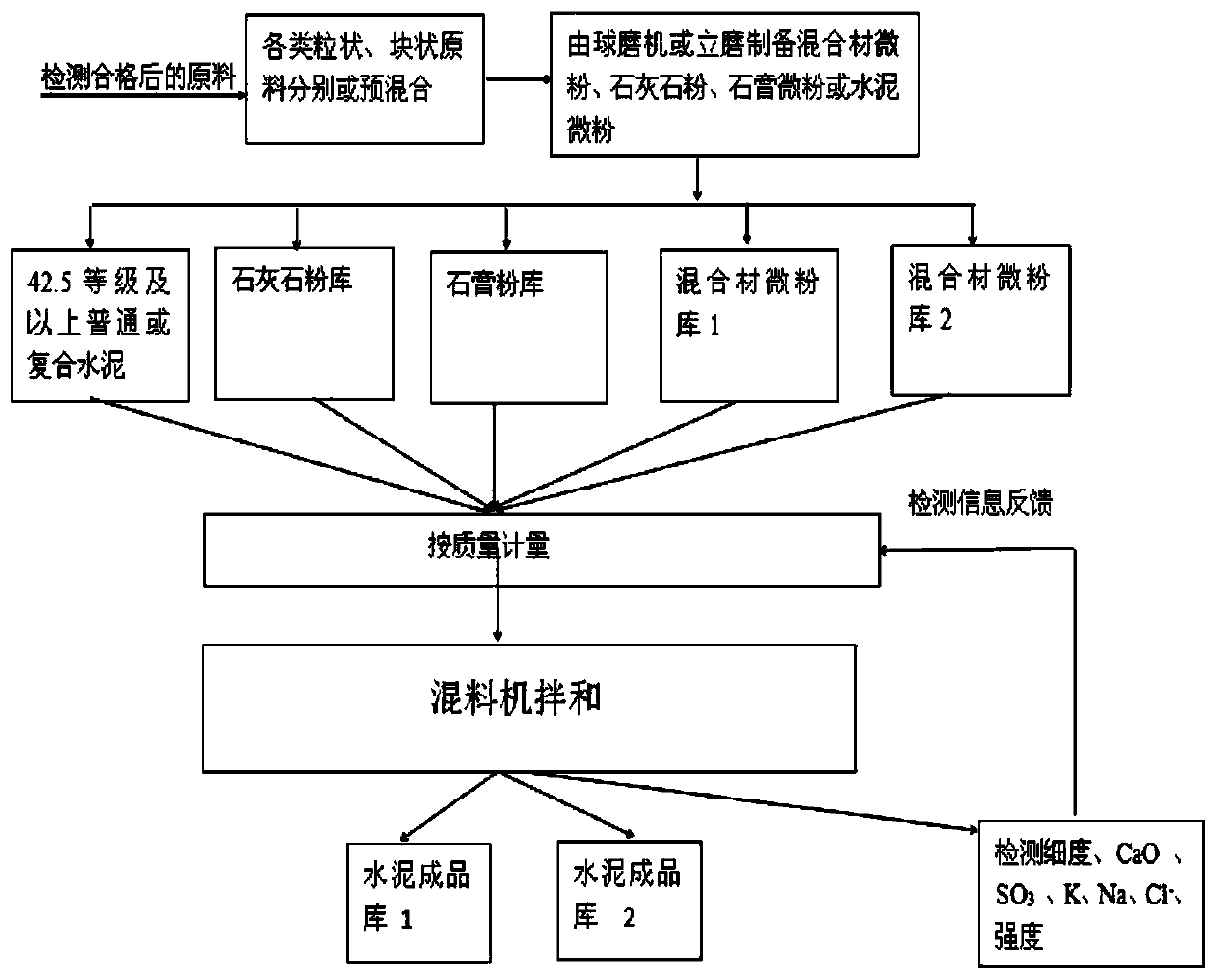

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing special mixed cement for on-site concrete preparation, using general-purpose Portland cement of grade 42.5 and above and other raw material micropowders that have been ground into corresponding fineness through ball mills or vertical mills. Process additives can be added during grinding; the steps are:

[0040] Step 1, raw material selection, general-purpose portland cement, admixture, gypsum, limestone, composite modified water reducer and other functional admixtures of 42.5 grade and above are tested, and the raw materials that meet the regulations are allowed to be put into the next production process.

[0041] Step 2. When preparing, limestone, admixture, gypsum, and process additives are pre-mixed individually or any of them according to the mass ratio, and then ground by a ball mill or a vertical mill to make a specific surface area ≥ 330m 2 / kg and ≤450m 2 / kg, and the corresponding type of micropowder with the mass of ≤3um micropowder acc...

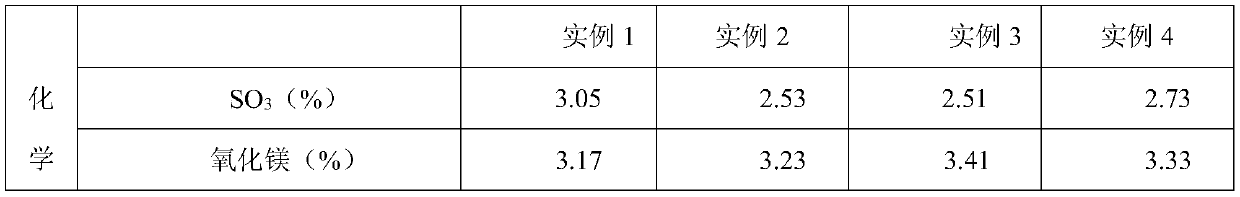

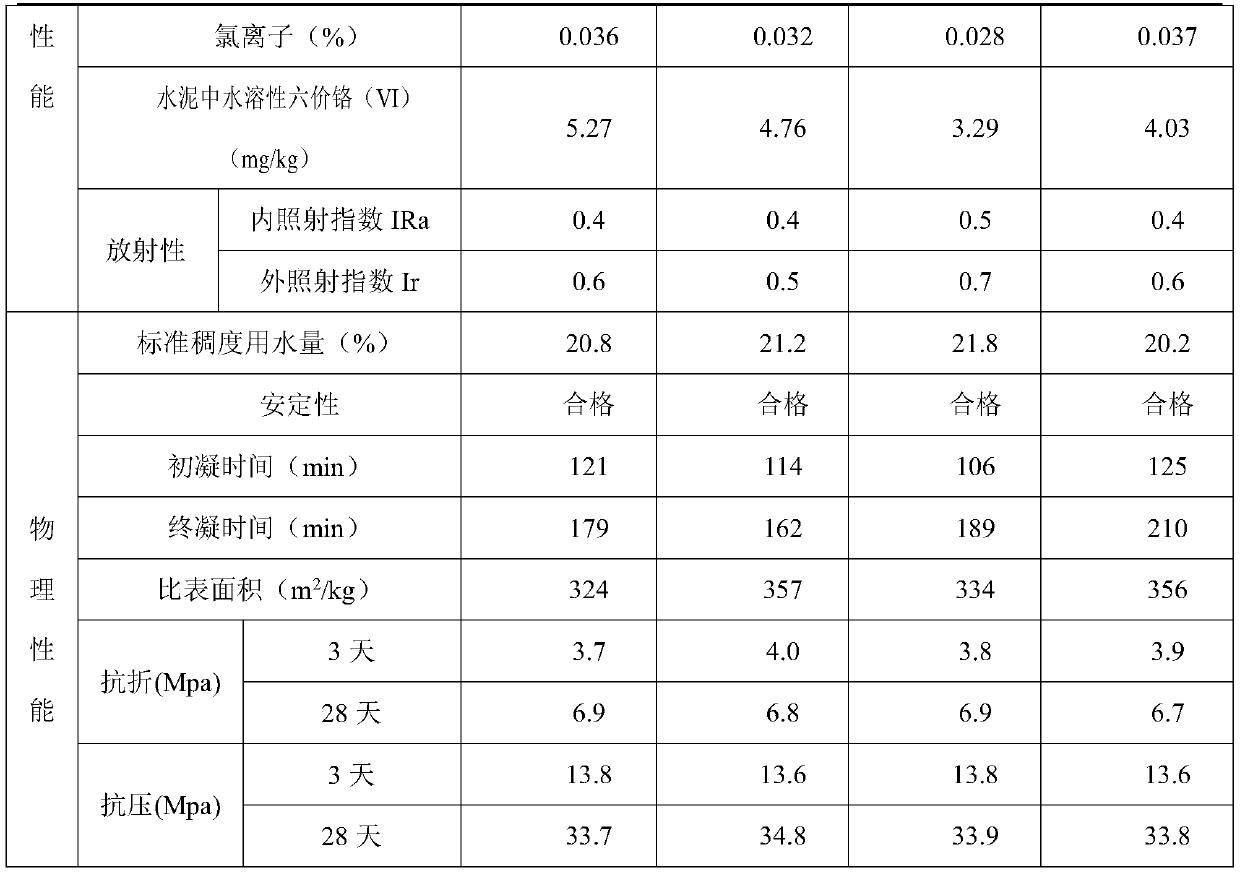

Embodiment 1

[0051] A special mixed cement for concrete prepared on site, its mass ratio is: 42.5 grade ordinary portland cement 60%, gypsum 6%, limestone 5%, admixture materials (fly ash, granulated blast furnace slag) 26.5%, functional Admixture (composite modified superplasticizer) 2.5%. Component materials meet relevant standards and requirements. The preparation method and specific steps are as follows:

[0052] The 42.5 ordinary Portland cement must meet the requirements of GB175, and its control parameters: the proportion of fine powder of ≤3um is ≤10%, the compressive strength of 1 day is ≤12MPa, the compressive strength of 3 days is ≥20MPa, and the compressive strength of 28 days Strength ≥ 45MPa, water consumption for standard consistency of cement paste ≤ 28%, alkali content requirement 2 O and Na 2 The sum of O represents that the chloride ion content is 2 / kg and ≤450m 2 / kg, wherein the mass proportion of fine powder ≤ 3um is ≥ 15%; the alkali content in the mixed material...

Embodiment 2

[0061] A special mixed cement for concrete prepared on site, its mass ratio is: 42.5 grade ordinary Portland cement 65%, gypsum 4%, limestone 10%, admixture (slag, granulated blast furnace slag) 20.5%, functional admixture (Composite modified water reducer) 0.5%. The component materials meet the relevant standards and the aforementioned requirements. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com