Method for preparing lubricating oil containing carbon nano tube and graphene

A carbon nanotube and graphene technology, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of not obtaining significant energy saving in fuel consumption, high degree of engine wear, and unsatisfactory anti-wear effect, so as to save fuel consumption. , reduce wear and protect the effect of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

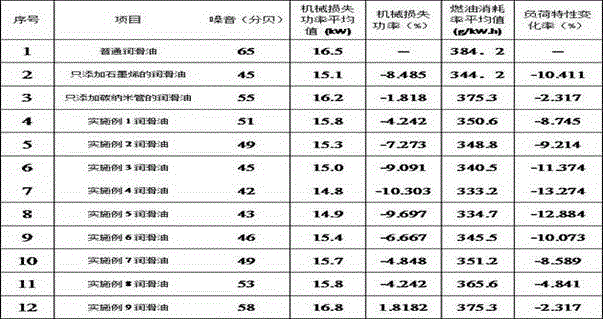

Examples

Embodiment 1

[0032] The preparation method of the lubricating oil containing carbon nanotube and graphene, comprises the following steps:

[0033] (1) Treatment of carbon nanotubes

[0034] Take 100 g of multi-walled carbon nanotubes prepared by catalytic cracking of hydrocarbons, add 500 ml of 98% sulfuric acid by volume: 70% nitric acid = 3: 1 mixed acid, and ultrasonically disperse at 60 ° C for 2 hours at a constant temperature. The frequency is 20KHz, then repeatedly rinsed with deionized water, filtered until the pH value is 7, and finally dried at a constant temperature of 60°C for 6 hours, and the processed carbon nanotubes are obtained;

[0035] (2) Graphene treatment

[0036] The graphene prepared by the vapor phase precipitation method is ultrasonically dispersed in a petroleum ether solvent added with a dispersant for 1 hour, and the ultrasonic frequency is 20KHz. After dispersion, the solvent oil is removed, and the processed graphene is obtained;

[0037] (3) Preparation of...

Embodiment 2

[0041] Except that the addition amount of carbon nanotube, graphene, dispersant, emulsifier is different, all the other methods are the same as embodiment 1.

[0042] Wherein: the mass percentage of carbon nanotube is 0.01%, the mass percentage of graphene is 0.01%, the mass percentage of dispersant is 0.03%, and the mass percentage of emulsifier is 0.03%.

Embodiment 3

[0044] Except that the addition amount of carbon nanotube, graphene, dispersant, emulsifier is different, all the other methods are the same as embodiment 1.

[0045] Wherein: the mass percentage of carbon nanotube is 0.04%, the mass percentage of graphene is 0.06%, the mass percentage of dispersant is 0.05%, and the mass percentage of emulsifier is 0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com