Preparation of dimer acid lanthanum extreme pressure anti-wear additive and energy-saving anti-wear hydraulic oil including dimer acid lanthanum extreme pressure anti-wear additive

An extreme pressure anti-wear agent and anti-wear hydraulic oil technology, applied in the field of hydraulic oil, can solve the problems of poor versatility, anti-oxidation, anti-detergency, weak repair function, and the hydraulic oil cannot meet the requirements of harsh working conditions, etc. Achieve the effect of improving wear resistance, good wear resistance and increasing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

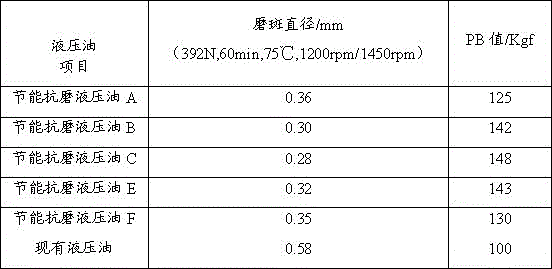

Embodiment 1

[0029] An energy-saving anti-wear hydraulic oil containing lanthanum dimer acid extreme-pressure anti-wear agent, specifically comprising: 80 parts of base oil, 0.1 part of dimer lanthanum acid extreme-pressure anti-wear agent, 0.01 part of antioxidant, 0.01 part of antirust agent, 1 part of viscosity index improver, 0.1 part of pour point depressant, and 0.0001 part of defoamer; according to the above formulation parts, energy-saving and anti-wear hydraulic oil A was prepared.

Embodiment 2

[0031] An energy-saving anti-wear hydraulic oil comprising a dimer lanthanum acid extreme pressure anti-wear agent, specifically comprising: 90 parts of base oil, 0.3 parts of a dimer lanthanum acid extreme pressure anti-wear agent, 0.03 parts of an antioxidant, 0.3 parts of anti-rust agent, 3 parts of viscosity index improver, 0.2 parts of pour point depressant and 0.0002 parts of defoamer; energy-saving and anti-wear hydraulic oil B was prepared according to the above-mentioned parts of the preparation.

Embodiment 3

[0033] An energy-saving and anti-wear hydraulic oil comprising a dimer lanthanum acid extreme pressure anti-wear agent, specifically comprising: 90 parts of base oil, 0.5 parts of a dimer lanthanum acid extreme pressure anti-wear agent, 0.03 parts of an antioxidant, 0.3 parts of anti-rust agent, 3 parts of viscosity index improver, 0.2 parts of pour point depressant and 0.0002 parts of defoamer; energy-saving and anti-wear hydraulic oil C was prepared according to the above-mentioned parts of the preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com