Multi-functional diamond disk material conveying machine

A conveyor and multi-functional technology, applied in the field of multi-functional Lingpan conveyor, can solve the problems of low work efficiency, jamming, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

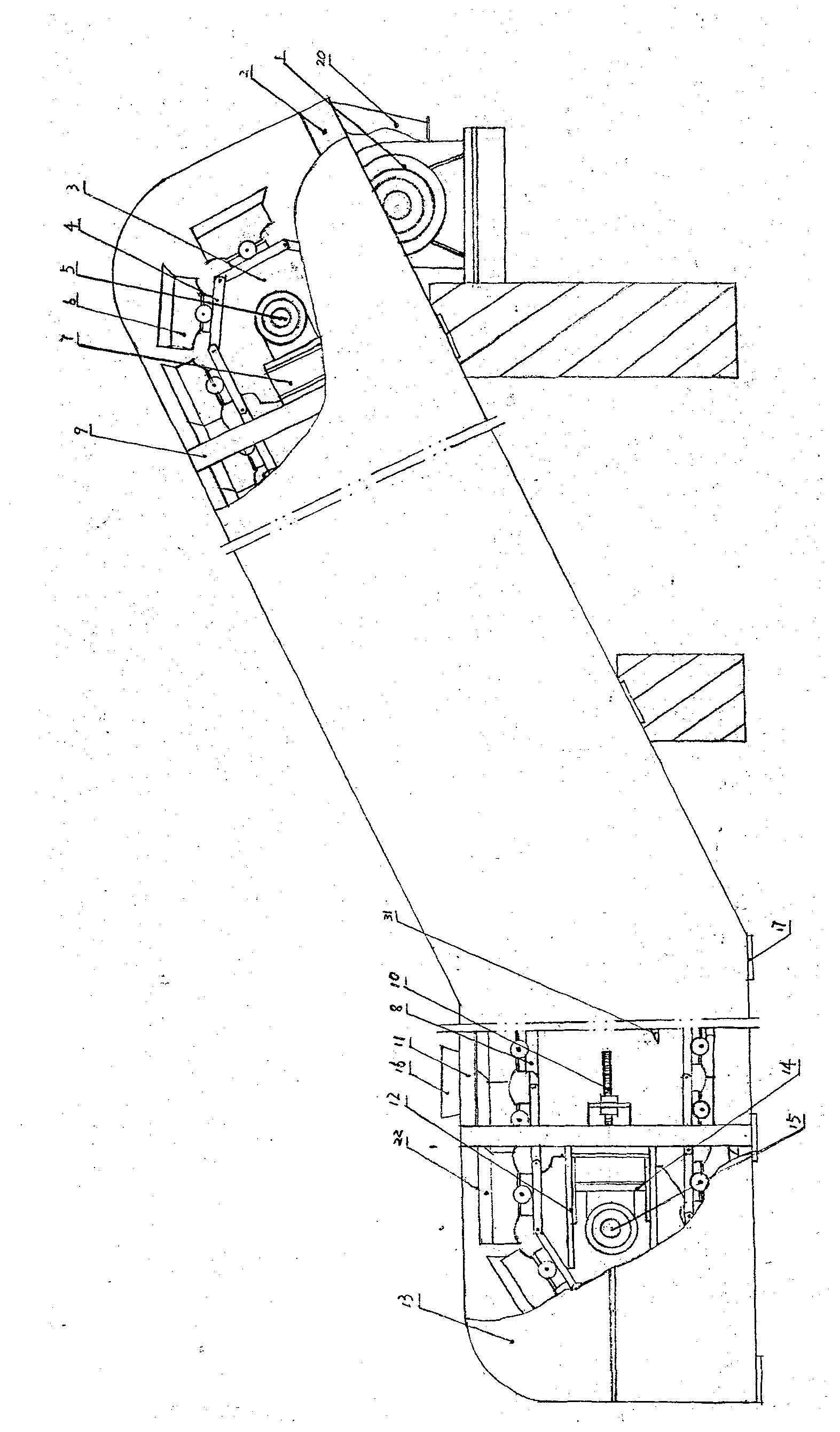

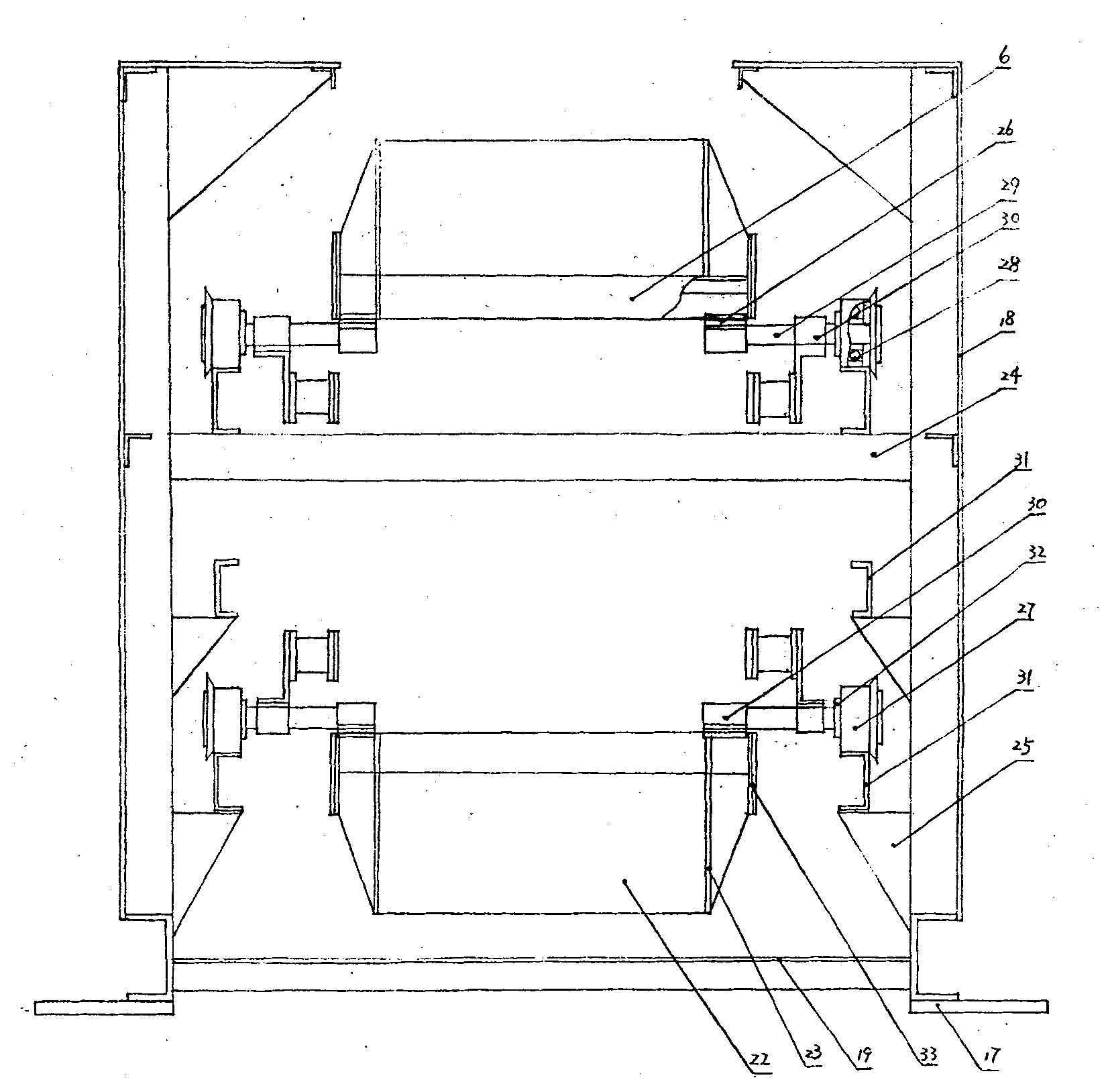

[0013] The following is a further description of the multi-functional Lingpan conveyor in conjunction with the accompanying drawings:

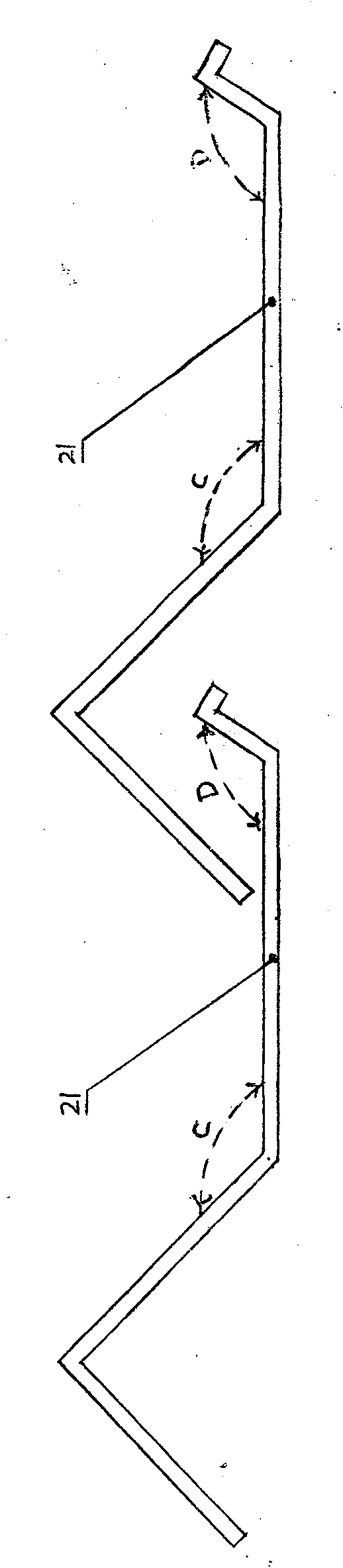

[0014] See attached figure 1 , 2 , the driving assembly (1) is arranged on the tail side of the whole machine, the bottom beam (2), the support frame (9), the crosspiece (24), and the lead beam (11) form a frame body, and the head and tail are provided with a cover ( 13), the bottom and both sides are protected by the lower sealing plate (19) and the side guard plate (18), the feeding hopper (16) is arranged on the leading beam (11) of the head, and there are One set of running tracks (8) and one set of chain adjustment tracks (31) in the middle, respectively located on the crosspiece (24) and the bracket (25), are arranged on the drive shaft (5) at the tail and the slave shaft (5) at the head. One group (two) sprockets (3) are respectively embedded in both sides of the driving shaft (15), and are fixed by a set of driven bearing seats (14) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com