Heat-resistant high-toughness polystyrene resin expanded plastic

A technology of polystyrene resin and foamed plastics, which is applied in the field of heat-resistant and high-toughness polystyrene resin foamed plastics, which can solve the problems of poor temperature resistance, insufficient toughness of foamed plastics, and poor support of objects, etc. problem, to achieve the effect of improving strength and toughness, enhancing compatibility, and small specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

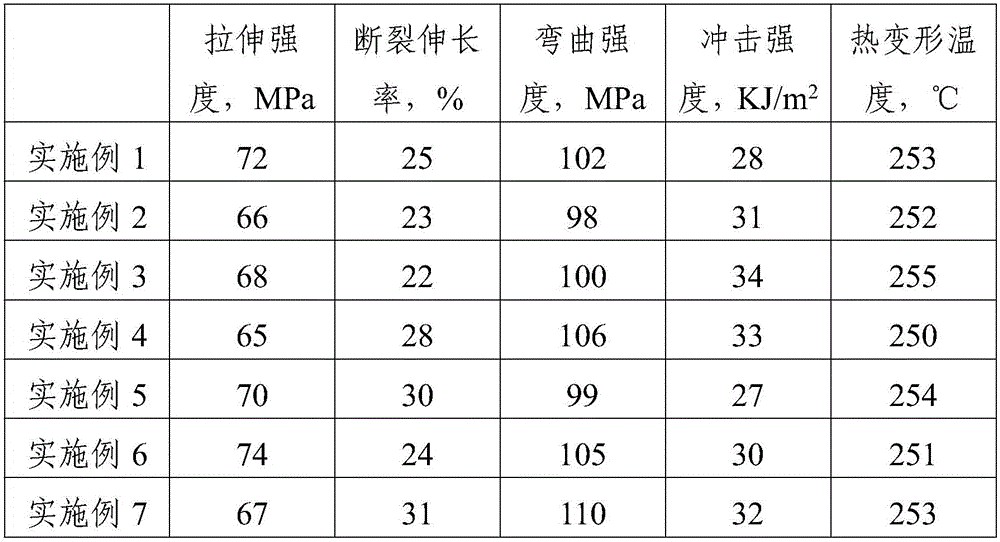

Examples

Embodiment 1

[0020] Heat-resistant and high-toughness polystyrene resin foam plastic is made of the following mass parts: 46 parts of polystyrene resin, 23 parts of polyimide resin, 18 parts of polysulfone, 8 parts of nano hydrotalcite, 5 parts of PBO fiber, 3 parts of glyceryl monostearate, 8 parts of chlorinated paraffin, 10 parts of nano-montmorillonite, 4 parts of rutile powder, 4 parts of aluminum borate whiskers, 4.5 parts of coupling agent.

[0021] The coupling agent is a composition of isopropyl tris (dioctyl pyrophosphate acyloxy) phthalate and oxyacetate bis (dioctyl phosphate) phthalate in a mass ratio of 1:1.

[0022] Heat-resistant high-toughness polystyrene resin foamed plastics, the preparation steps are as follows:

[0023] 1) Weigh the raw materials by weight, and dry the nano-hydrotalcite at 10°C / h from 150°C to 180°C for later use;

[0024] 2) Put polystyrene resin, polyimide resin, and polysulfone into a high-speed mixer, heat and stir at a speed of 28r / min to 80°C, t...

Embodiment 2

[0028] Heat-resistant and high-toughness polystyrene resin foam plastic is made of the following mass parts: 53 parts of polystyrene resin, 25 parts of polyimide resin, 20 parts of polysulfone, 10 parts of nano hydrotalcite, 4 parts of PBO fiber, 2.5 parts of glyceryl monostearate, 9 parts of chlorinated paraffin, 12 parts of nano-montmorillonite, 6 parts of rutile powder, 5.5 parts of aluminum borate whiskers, and 5 parts of coupling agent.

[0029] The coupling agent is a composition of isopropyl tris (dioctyl pyrophosphate acyloxy) phthalate and oxyacetate bis (dioctyl phosphate) phthalate in a mass ratio of 1:2.

[0030] Heat-resistant high-toughness polystyrene resin foamed plastics, the preparation steps are as follows:

[0031] 1) Weigh the raw materials by weight, and dry the nano-hydrotalcite at 10°C / h from 150°C to 180°C for later use;

[0032] 2) Put polystyrene resin, polyimide resin, and polysulfone into a high-speed mixer, heat and stir at a speed of 26r / min to ...

Embodiment 3

[0036] The heat-resistant and high-toughness polystyrene resin foam plastic is made of the following mass parts: 58 parts of polystyrene resin, 20 parts of polyimide resin, 16 parts of polysulfone, 9 parts of nano hydrotalcite, 3 parts of PBO fiber, 1.8 parts of glyceryl monostearate, 10 parts of chlorinated paraffin, 8 parts of nano-montmorillonite, 5 parts of rutile powder, 6 parts of aluminum borate whiskers, and 2 parts of coupling agent.

[0037] The coupling agent is a composition of isopropyl tris (dioctyl pyrophosphate acyloxy) phthalate and oxyacetate bis (dioctyl phosphate) phthalate in a mass ratio of 1:3.

[0038] Heat-resistant high-toughness polystyrene resin foamed plastics, the preparation steps are as follows:

[0039] 1) Weigh the raw materials by weight, and dry the nano-hydrotalcite at 10°C / h from 150°C to 180°C for later use;

[0040] 2) Put polystyrene resin, polyimide resin, and polysulfone into a high-speed mixer, heat and stir at a speed of 29r / min to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com