Special bulb milling cutter for milling titanium alloy thin-wall parts

A technology for thin-walled parts and ball-end milling cutters, which is applied in the field of machining, can solve the problems affecting the workpiece surface quality, the tool life, the inconsistency between the machining accuracy and the machined surface quality, and the difficulty in taking into account the cutting performance, so as to achieve the workpiece surface quality. Better, increased self-lubricating properties, smooth and light cut in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0016] see Figure 1-3 , the present invention provides a technical solution:

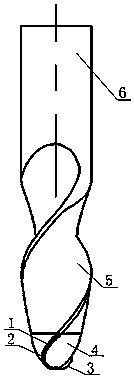

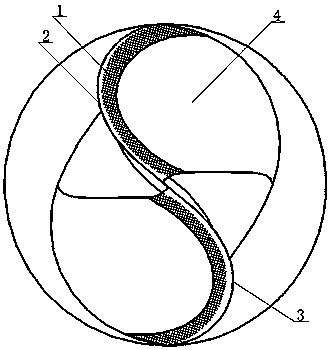

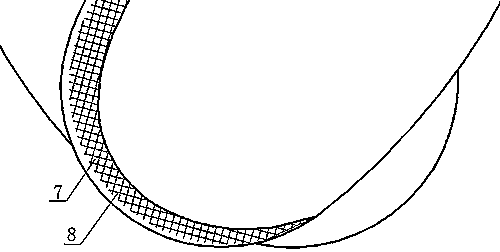

[0017] A special ball-end milling cutter for milling titanium alloy thin-walled parts, which includes a shank (6) and a cutter head (5) composed of cutting edge one (2) and cutting edge two (3), and The flank (4) connected to the cutting edge is characterized in that: the flank (4) is a surface provided with a 60° cross texture structure (1), and the cutting edge one (2) and the cutting edge Blade 2 (3) has a rake angle of 8°, a relief angle of 13°, a helix angle of 42°, and a 45° negative chamfer.

[0018] When the tool cuts the workpiece, the freshly machined surface of the workpiece and the flank surface will contact and rub against each other, and the friction condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com