Combined carbon brush for electric polisher

A polishing machine and electric technology, which is applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of unstable motor commutation, large vibration amplitude of the fuselage, card brushing, etc., to improve commutation performance, improve motor performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

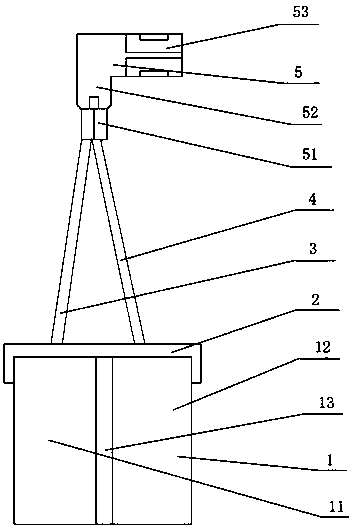

[0018] See figure 1 , Combined carbon brush for this electric polishing machine, including carbon body 1. copper jacket 2, left wire 3, right wire 4 and insertion 5, copper set 2 set on the carbon body 1, copper set 2 extend the left -guide line3 and right wire 4, the length of the left and right wires is 28mm, and the cross -sectional area is 0.5mm 2 , Insert 5 include clip connection 51, connecting tablet 52 and terminal pillar 53, plug 5 to clamp the left and right wires through clamping connection 51, clamp the connector 51 directly connected to the connector 52, the connector 52 and the clamping joint 51 mutual each other.The vertical side is arranged with two terminals 53. The carbon body 1 includes two symmetrical carbon blocks 11 and right carbon blocks 12, and the two carbon pieces are equipped with an insulating gel layer 13, two carbon blocks, two carbon blocksBonded through the insulation gel layer 13 into a whole. There are four chamfers on the four long sides on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com