A floating grooving machine

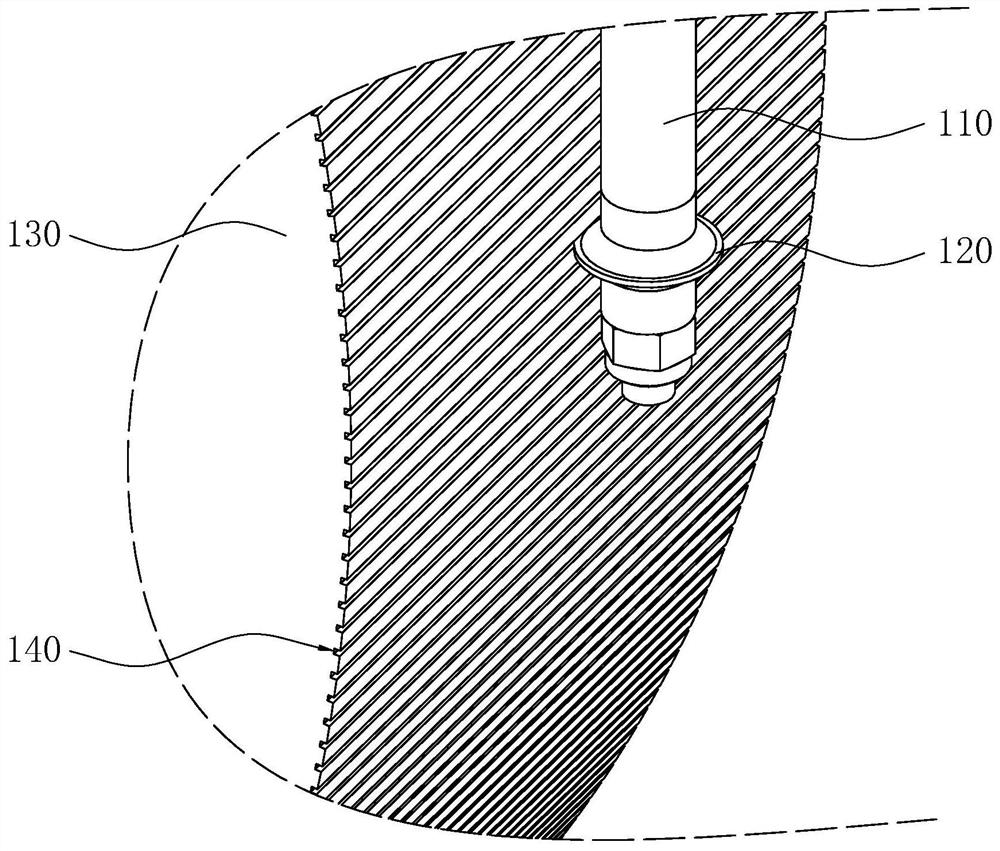

A grooved, floating technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of deepening the depth of the mica groove 140, reducing the commutator 130, deformation of the outer peripheral surface, etc., so as to reduce the runout. The probability of improving the commutation performance and the effect of improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

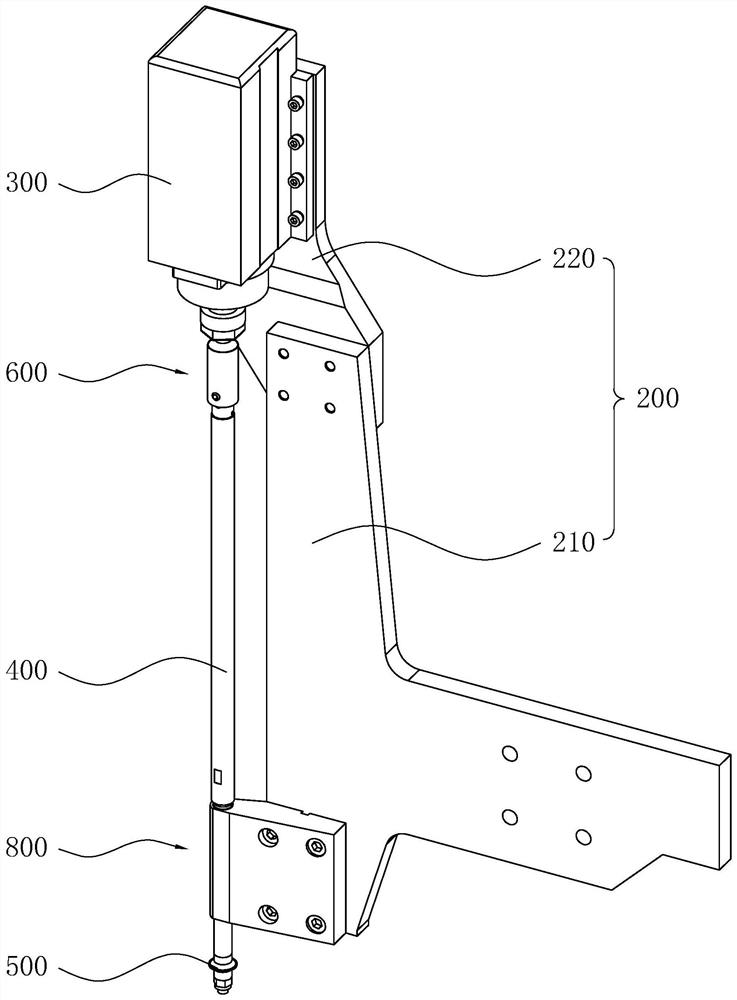

[0042] Attached to the following Figure 2-5 This application will be described in further detail.

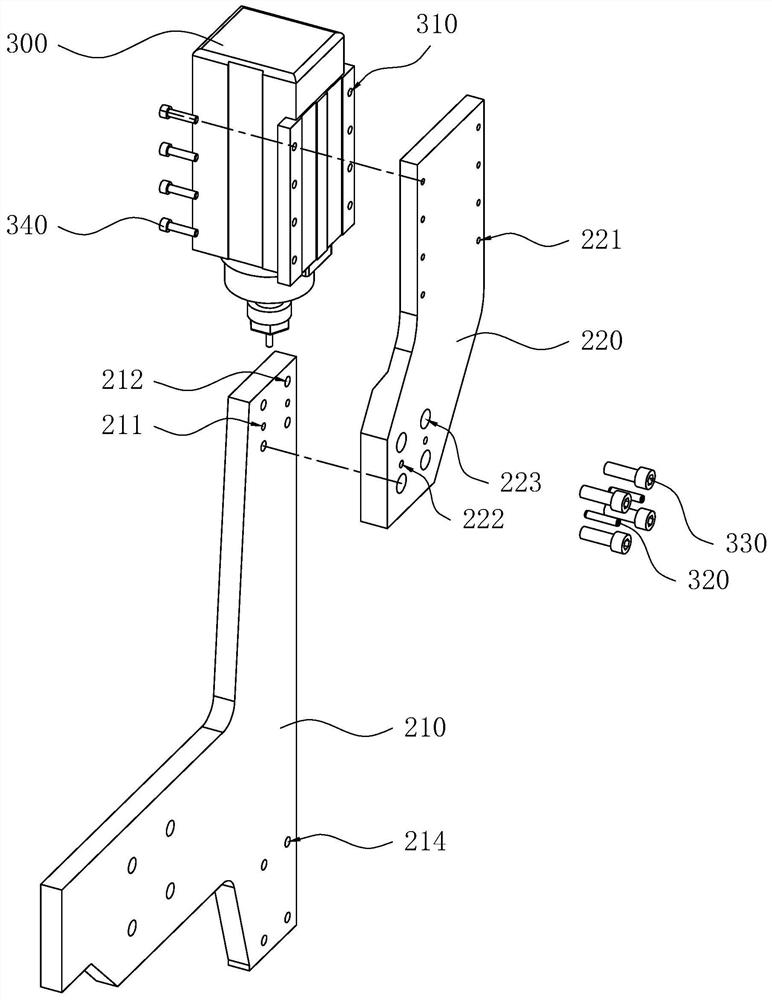

[0043] The embodiment of the present application proposes a floating type notching machine. refer to figure 2 , the floating slotting machine includes a frame 200 , a drive motor 300 , a main shaft 400 , a milling cutter 500 , a floating connection mechanism 600 and a guide mechanism 800 . The drive motor 300 is installed on the frame 200, the main shaft 400 is coaxially connected to the output shaft of the drive motor 300 through the floating connection mechanism 600, the guide mechanism 800 is installed on the frame 200, and the guide mechanism 800 is connected with the main shaft 400 and is the main shaft 400 is guided, and the milling cutter 500 is coaxially mounted on the main shaft 400.

[0044] refer to figure 2 and image 3 The frame 200 includes a main bracket 210 and a motor mounting bracket 220. The main bracket 210 is provided with two first positioning holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com