An internal drive feedback type digital reversing valve

A reversing valve and feedback technology, applied in valve details, valve devices, multi-way valves, etc., can solve problems such as hydraulic shocks, achieve the effects of alleviating hydraulic shocks, reducing hydraulic shocks, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

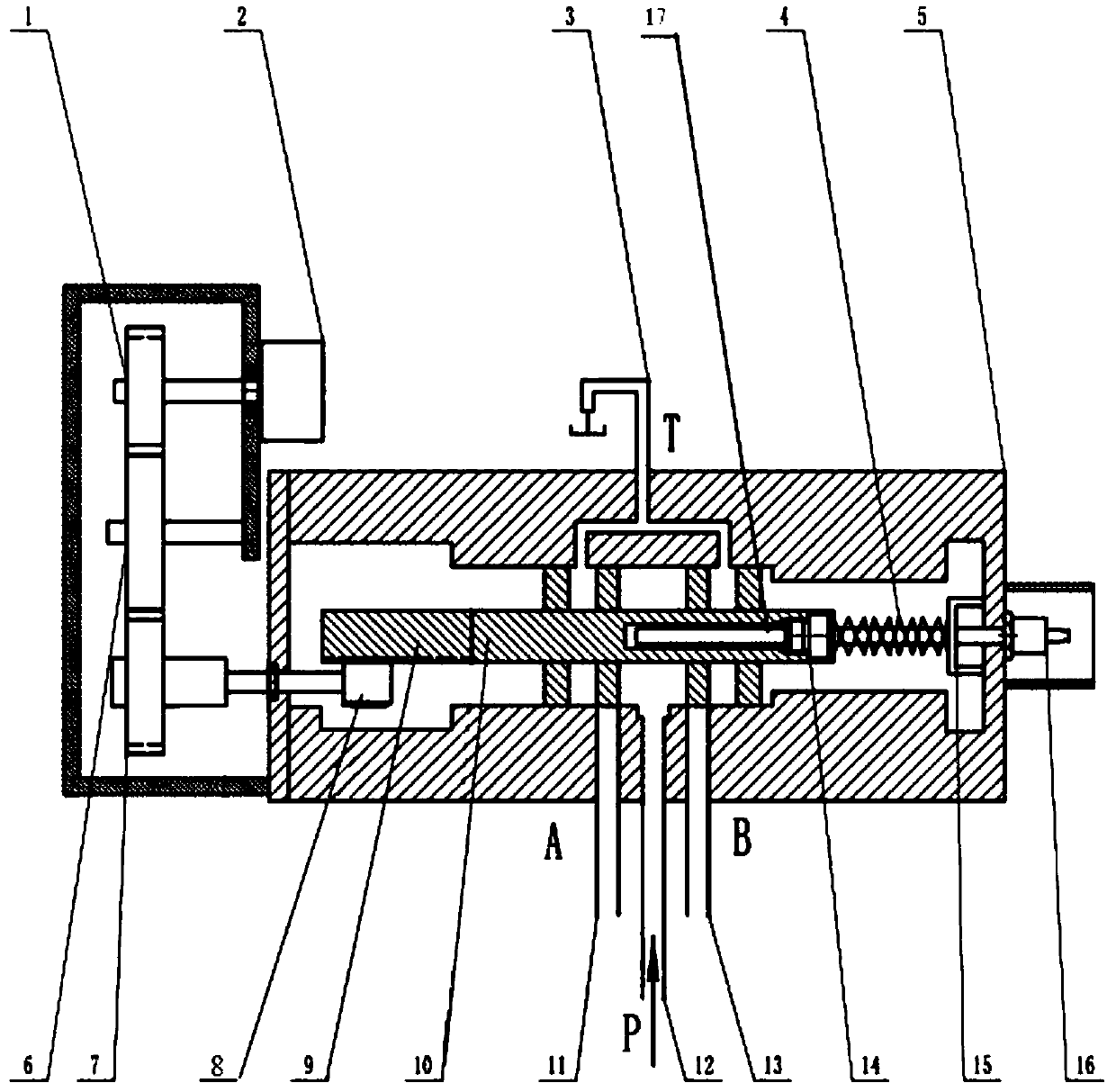

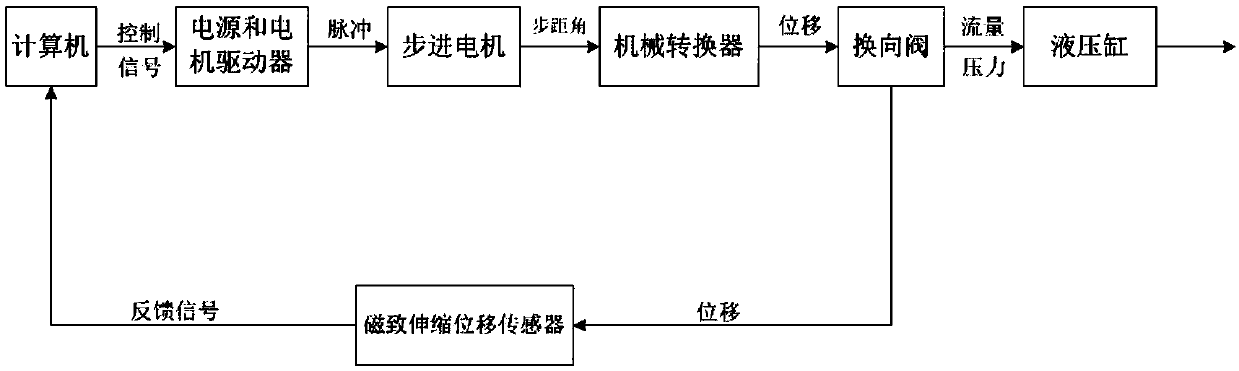

[0025] The embodiments of the present application provide an internal drive feedback digital directional valve, which solves the problem of severe hydraulic shock in the prior art when the electromagnetic directional valve changes direction or speed.

[0026] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0027] An internal drive feedback digital reversing valve, including: a stepping motor, a transmission gear set, a rack and pinion pair, a reversing valve, a return spring, and a magnetostrictive displacement sensor;

[0028] The reversing valve includes a reversing valve body and a reversing valve spool;

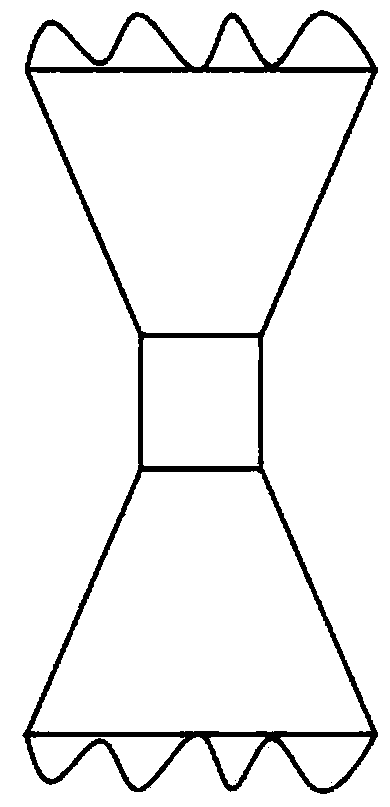

[0029] The transmission gear set is composed of a main shaft gear, a trapezoidal gear, and a driven gear meshing with each other;

[0030] The stepping motor is connected with the main shaft gear, the driven gear is connected with the gear of the rack-and-pinion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com