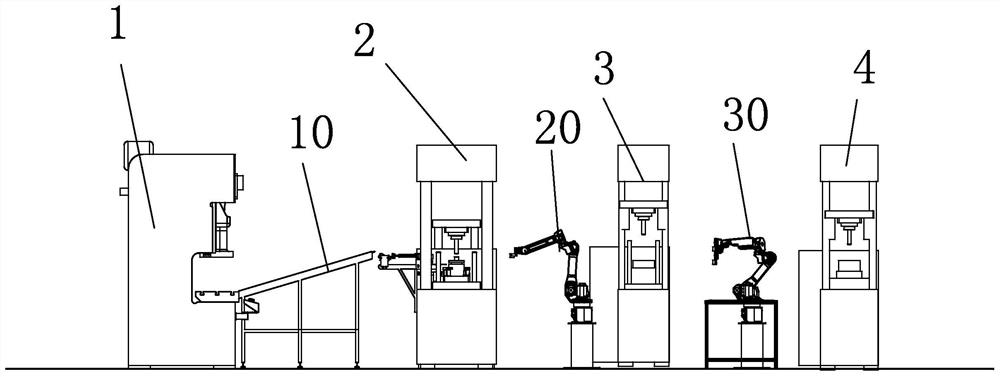

A stamping and stretching automatic production device and its control method

A technology for stamping and drawing, production equipment, applied in the direction of presses, manufacturing tools, etc., can solve problems affecting the working stability and reliability of hydraulic systems, damage to hydraulic system components, pipes, instruments, etc., to achieve simple structure and stability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For ease of description, if spatially relative terms such as "upper", "lower", "left" and "right" are used in the embodiments,

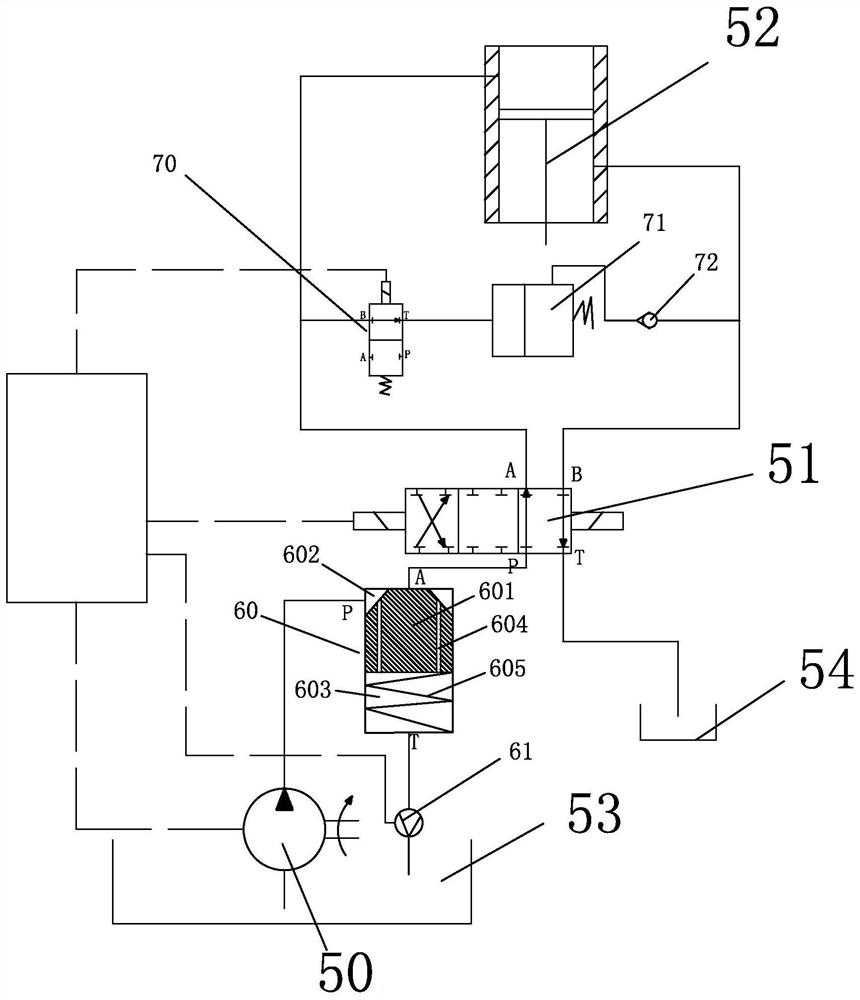

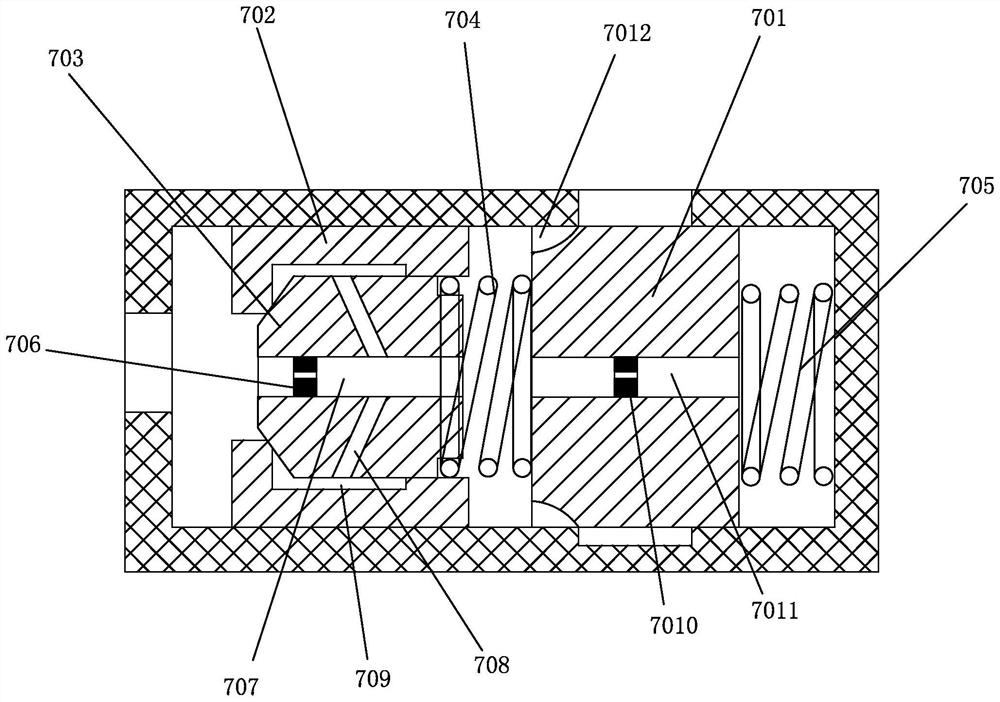

[0038] The present invention is further set to, the second buffer valve 70 includes a valve cavity, a buffer valve core 701 disposed in the valve cavity,

[0042] S3) the second module controls the first on-off valve 61 in the first buffer oil circuit from the open state to the closed state gradually,

[0045] S6) If the valve is suddenly interrupted on the main road, and the emergency stop phenomenon is formed, the hydraulic oil in the rodless cavity cannot be pressed down,

[0047] S8) by opening the second on-off valve 70 through the third module, the second buffer oil circuit is opened, and the entry into the rodless cavity

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com