High-performance high-compaction lithium ferrite material for phase shifter, and preparation method thereof

A lithium ferrite and densification technology, which is applied in the field of lithium ferrite materials for high-performance and high-densification phase shifters and its preparation, can solve the problems of high moisture absorption, high coercive force, low density, etc., and achieve low Effects of dielectric loss, low coercive force, and high densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

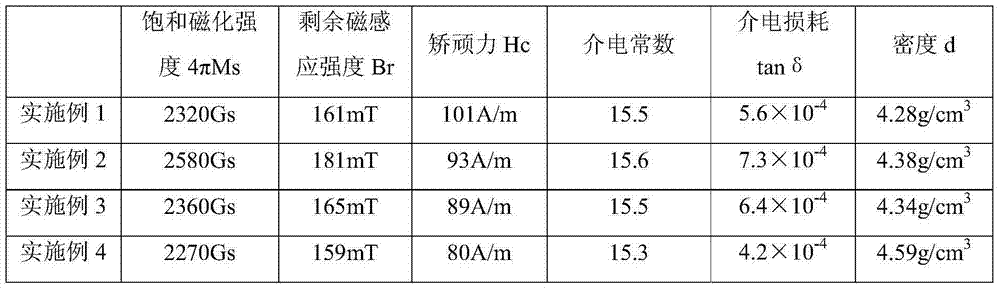

Embodiment 1

[0031] 6987g Fe 2 o 3 , 1010g Li 2 CO 3 , 378g ZnO, 546g MnCO 3 , 1143g TiO 2 , 65g Bi 2 o 3 Mix with 87gNiO and 11140ml of absolute ethanol, then ball mill and pulverize, the time of ball milling is 6h, and the speed of ball mill is 70r / min; the components after ball mill pulverization are mixed evenly and then put into an oven at 90°C for 24h; The final components are put into the furnace for calcination. The calcination method is programmed calcination. The heating rate is 50°C / h at the 0th to 4th hour, and 92°C / h at the 5th to 11th hour. Heat preservation for 3 hours; after heat preservation, cool down to room temperature naturally with the air in the furnace; put the calcined components into a ball mill and add distilled water for ball milling, the ball milling time is 24 hours, and the ball mill speed is 70r / min; the ball milled components Add a polyvinyl alcohol aqueous solution with a mass concentration of 5% and a weight ratio of 8%, and use a spray granulator ...

Embodiment 2

[0033] 7056g Fe 2 o 3 , 1020g Li 2 CO 3 , 381g ZnO, 551g MnCO 3 , 1156g TiO 2 , 65g Bi 2 o 3 and 175g of NiO were put into a ball mill and added with 10400ml of distilled water for ball milling. The time of ball milling was 16h, and the speed of ball mill was 50r / min. The dried components are put into a furnace for calcination. The calcination method is programmed calcination. The heating rate is 40°C / h at the 0th to 4th hour, and 93°C / h at the 5th to 11th hour. , heat preservation for 4h; after heat preservation, naturally cool down to room temperature with the air in the furnace; put the calcined components into a ball mill and add distilled water to ball mill and pulverize, the time of ball mill is 24h, and the speed of ball mill is 60r / min; After sub-drying, add polyvinyl alcohol aqueous solution with a mass concentration of 8% and a weight ratio of 10%, and pass through a 40-mesh sieve; the granules obtained after granulation are pressed at 55 MPa under a fully aut...

Embodiment 3

[0035] 7200g Fe 2 o 3 , 990g Li 2 CO 3 , 378g ZnO, 545g MnCO 3 , 929g TiO 2 、32g Bi 2 o 3 and 21gV 2 o 5Put them into a ball mill and add 10100ml of distilled water for ball milling, the time of ball milling is 16h, and the speed of ball mill is 60r / min; the components after ball milling are mixed evenly and put them in an oven at 110°C for 24h; The components are put into the furnace for calcination. The calcination method is programmed calcination. The heating rate is 40°C / h at the 0th to 4th hour, and 94°C / h at the 5th to 11th hour. 5h; after heat preservation, cool down to room temperature naturally with the air in the furnace; put the calcined components into a ball mill and add distilled water for ball milling, the ball milling time is 24h, and the ball mill speed is 70r / min; the ball milled components are baked After drying, add a polyvinyl alcohol aqueous solution with a mass concentration of 10% and a weight ratio of 10%, and pass through a 40-mesh sieve; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com