Preparation method of nano lithium ferrite

A lithium ferrite, nanotechnology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of affecting the capacity and discharge platform of lithium iron phosphate, failing to enhance the conductivity of lithium iron phosphate, lithium ferrite primary Large particle size and other issues, to achieve the effect of low cost, high conductivity and heat, high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

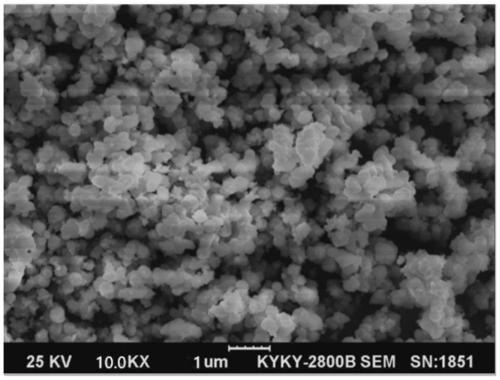

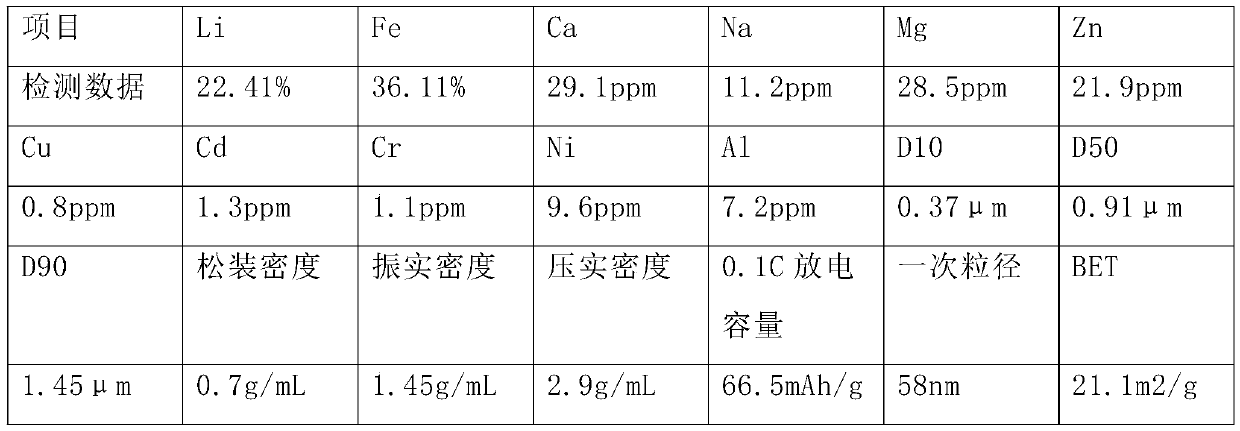

Image

Examples

Embodiment 1

[0042] A preparation method of nano-lithium ferrite, which comprises the following steps:

[0043]Add ferrous ammonium sulfate crystals into hot pure water, stir and dissolve to prepare a solution, add sodium acetate to adjust the pH of the solution to 2-2.5 to obtain a ferrous solution, add battery-grade lithium carbonate to pure water to slurry, and then introduce carbon dioxide under stirring , to obtain a clear lithium bicarbonate solution, the mol ratio of the ferrous ammonium sulfate in the ferrous solution to the lithium bicarbonate in the lithium bicarbonate solution is 1:5.03.

[0044] The detection data of ferrous ammonium sulfate are as follows:

[0045] project Fe Ca Na Mg Zn Cu Test data 14.09% 21.9ppm 29.7ppm 23.9ppm 19.8ppm 0.5ppm Ni Cd Fe 3+

Ti Al Water insoluble matter pH 11.9ppm 0.7ppm 216ppm 2.9ppm 4.7ppm 67ppm 1.59

[0046] The concentration of ferrous iron in the finally obtaine...

Embodiment 2

[0060] A preparation method of nano-lithium ferrite, which comprises the following steps:

[0061] 1) Add ferrous ammonium sulfate crystals into hot pure water, stir and dissolve to prepare a solution, add sodium acetate to adjust the pH of the solution to 2.1 to obtain a ferrous solution, add battery-grade lithium carbonate to pure water to slurry, and then introduce carbon dioxide under stirring , to obtain a clear lithium bicarbonate solution;

[0062] 2) Add the bottom liquid in the reaction kettle, the bottom liquid is a mixed solution of urea and polyethylene glycol, then raise the temperature to 97°C, add the ferrous solution, lithium bicarbonate solution, and acid-base regulator to the reaction kettle Inside, the stirring speed is maintained at 280r / min, the reaction temperature is 98°C, the pH of the reaction process is 7.2, and the feeding time is 1h. After the feeding is completed, stir and react at this temperature for 2h to obtain a slurry;

[0063] 3) Transfer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com