Polymer-coated lithium battery positive electrode material and preparation method thereof

A battery positive electrode and positive electrode material technology, applied in the direction of battery electrodes, active material electrodes, positive electrodes, etc., can solve the problem of not allowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for preparing PVDF-coated lithium ferrite, the specific steps are as follows:

[0047] (1) Get 1.0g PVDF and dissolve it in 99.0g N-methylpyrrolidone to prepare a 1wt% PVDF solution;

[0048] (2) Take 5.0g lithium ferrite (Li 5 FeO 4 ) was slowly added to the above PVDF solution, and then placed in a high-pressure reactor, the temperature was adjusted to 150° C., the pressure was 5 MPa, and the reaction was carried out for 10 hours, so that PVDF was coated on the surface of lithium ferrite, and filtered to obtain a filter residue;

[0049] (3) Heat the filter residue obtained in step (2) to 200° C. at a heating rate of 10° C. / min under a nitrogen atmosphere, and heat-preserve and sinter for 10 hours to obtain PVDF-coated lithium ferrite.

[0050] According to the mass change before and after the lithium ferrite coating, the content of the PVDF coating layer in the PVDF coated lithium ferrite is 5.49wt%.

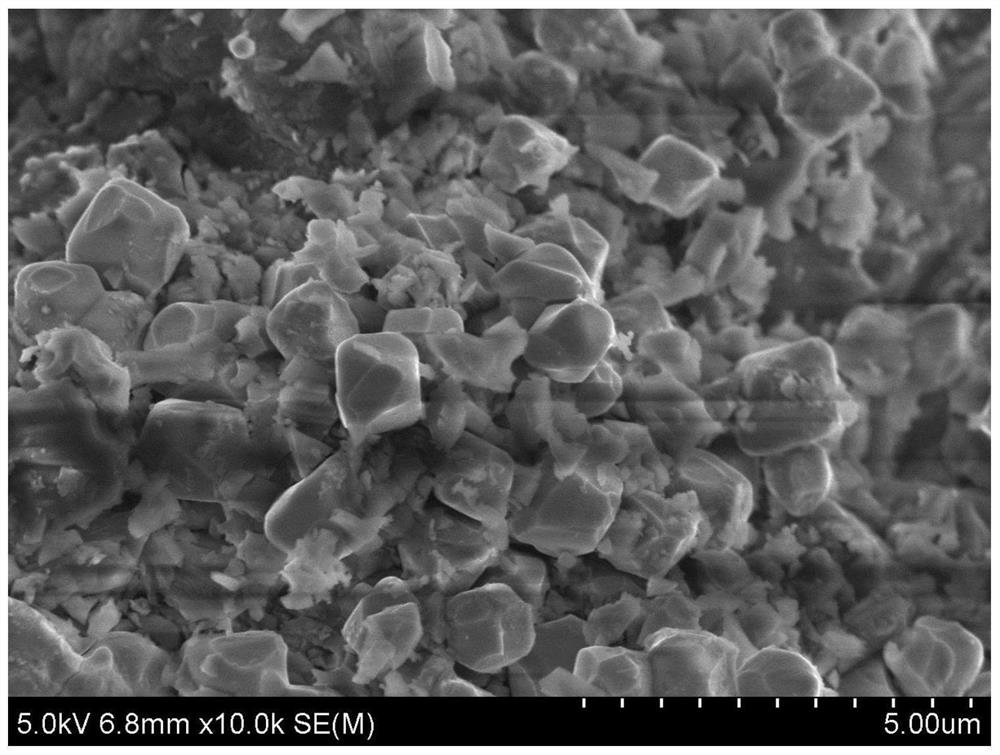

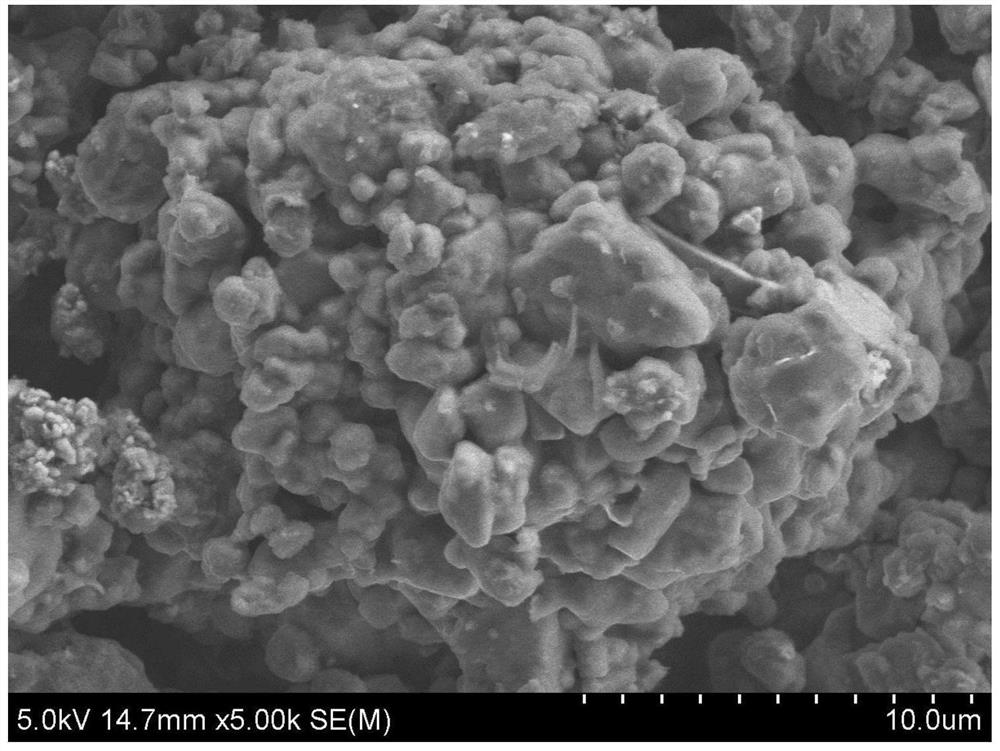

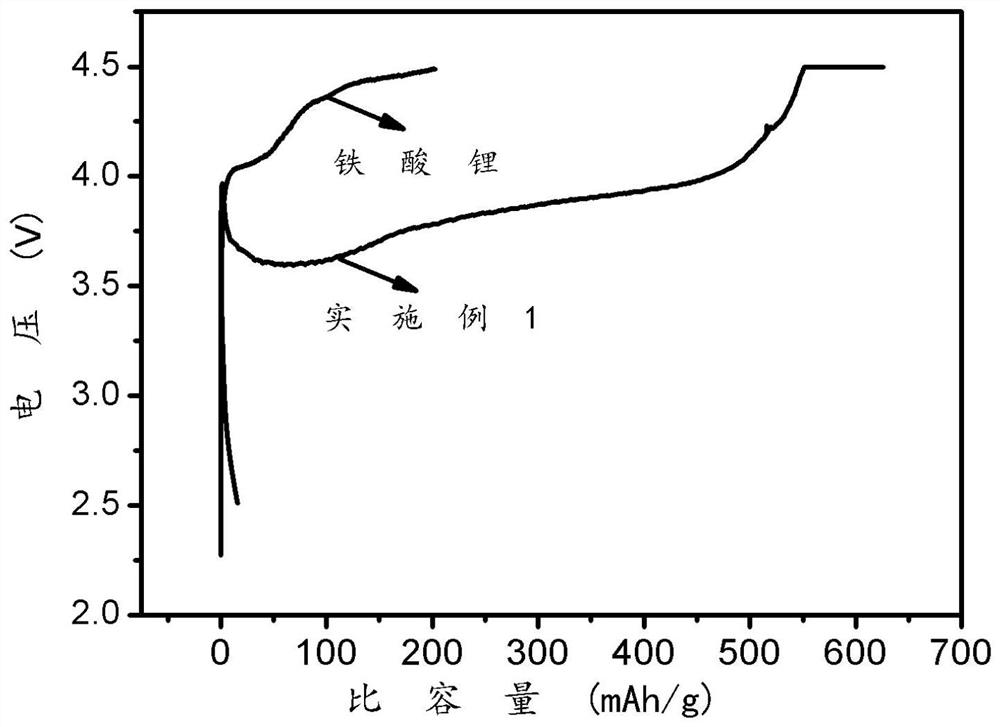

[0051] Scanning electron mic...

Embodiment 2

[0053] This embodiment provides a preparation method of starch-coated lithium ferrite, the specific steps are as follows:

[0054] (1) get 0.1g starch and dissolve in 99.9g ethanol, be mixed with the starch solution of 0.1wt%;

[0055] (2) Take 1.0g lithium ferrite (Li 5 FeO 4 ) was slowly added to the above starch solution, and then placed in a high-pressure reactor, the temperature was adjusted to 60° C., the pressure was 1 MPa, and the reaction was carried out for 20 hours, so that the starch was coated on the surface of lithium ferrite, and filtered to obtain a filter residue;

[0056] (3) Heat the filter residue obtained in step (2) to 300° C. at a heating rate of 20° C. / min under a nitrogen atmosphere, and heat-preserve and sinter for 5 hours to obtain starch-coated lithium ferrite.

[0057] According to the mass change before and after coating the lithium ferrite, the content of the starch coating layer in the starch-coated lithium ferrite is 1.36wt%.

Embodiment 3

[0059] This embodiment provides a preparation method of PVP-coated lithium ferrite, the specific steps are as follows:

[0060] (1) Get 20.0g PVP and be dissolved in 80.0g N-methylpyrrolidone, be mixed with the PVP solution of 20wt%;

[0061] (2) Take 20.0g lithium ferrite (Li 5 FeO 4 ) was slowly added to the above PVP solution, and then placed in a high-pressure reactor, the temperature was adjusted to 200 ° C, the pressure was 14 MPa, and the reaction was carried out for 6 hours, so that the PVP was coated on the surface of lithium ferrite, and filtered to obtain a filter residue;

[0062] (3) Heat the filter residue obtained in step (2) to 80° C. at a heating rate of 1° C. / min under a nitrogen atmosphere, and heat-preserve and sinter for 20 hours to obtain PVP-coated lithium ferrite.

[0063] The content of the PVP coating layer in the PVP-coated lithium ferrite was calculated to be 14.37wt% according to the mass change before and after coating the lithium ferrite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com