Preparation method and application of lithium cobalt oxide with pre-lithiated core-shell structure

A technology of structural lithium cobalt oxide and pre-lithiation, which is applied in the field of nanomaterials to reduce the effective volume, improve the first efficiency, and improve the reversible gram capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

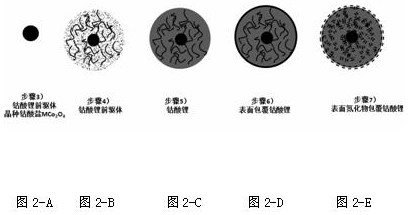

[0059] A preparation method of pre-lithiated core-shell structure lithium cobaltate, comprising the steps of:

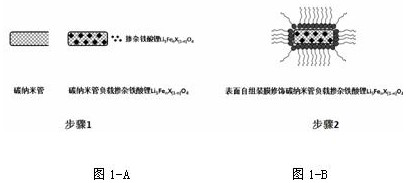

[0060] (1) Preparation of carbon nanotube-supported doped lithium ferrite Li 5 Fe n x (1-n) o 4 :

[0061] Dissolving iron salts and other metal salts in aqueous solution, adding surfactant molecules, lithium compounds and carbon nanotubes, adjusting the pH value and temperature of the solution, stirring, and reacting to obtain a precursor by filtering and washing, the precursor The body is calcined in air, and the calcined product is crushed, sieved, washed, and dried to obtain carbon nanotube-supported doped lithium ferrite Li 5 Fe n x (1-n) o 4 ;

[0062] (2) Preparation of surface self-assembled film modified carbon nanotubes loaded with doped lithium ferrite Li 5 Fe n x (1-n) o 4 :

[0063] The obtained carbon nanotubes were loaded with doped lithium ferrite Li 5 Fe n x (1-n) o 4 placed in an ionic liquid solution containing a surfactant, stirre...

Embodiment 1

[0076] A preparation method of pre-lithiated core-shell structure lithium cobaltate, comprising the steps of:

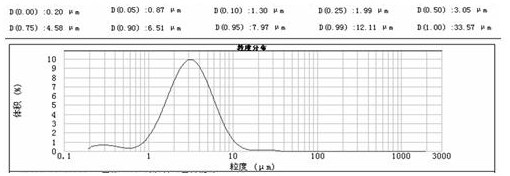

[0077] Step (1): Add 300 grams of polymer surfactant molecule polyvinyl alcohol (PVAL) in 5L of 5mol / L lithium nitrate solution, stir until the solution is clear, adjust the pH of the solution to 9.5 with lithium hydroxide, add 200 grams of 80nm carbon nanotubes with a length of about 3 microns, stirred at a high speed of 1000rpm / min until the solution is uniformly mixed, added 1L of 5mol / L ferric nitrate solution during the stirring process, kept the solution reaction temperature at 90°C, and the reaction time was 10 hours. The material was filtered, washed with hot deionized water until the washing liquid was clear, dried in the air at 100°C, and the prepared product was calcined at 450°C for 5 hours in an air atmosphere, cooled naturally, and crushed through a 150-mesh sieve to prepare the product carbon Nanotube-supported doped lithium ferrite Li 5 FeO 4 ;

[...

Embodiment 2

[0090] The only difference from Example 1 is: step (1): 200 grams of polymer surfactant molecule polyethylene glycol (PEG) is added in 5 L of 5 mol / L lithium nitrate solution.

[0091] Embodiment 1 and embodiment 2 film battery capacity retention curves are as Figure 9 Shown; Embodiment 1 and Embodiment 2 The capacity retention rate is the same after 250 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com