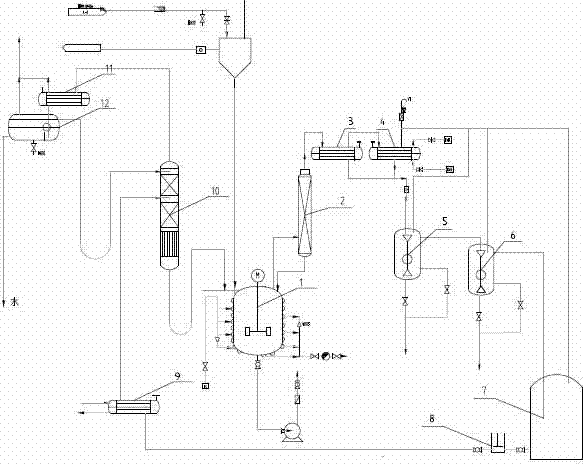

Alcoholysis method and device system for producing dioctyl terephthalate from polyester waste

A technology of dioctyl terephthalate and alcoholysis, which is applied in the field of plasticizer production methods and device systems, can solve the problems of continuous production, catalyst deactivation, increased raw material consumption, etc., and achieves increased economic benefits and improved utilization. efficiency, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] at 8m 3 Take the alcoholysis reaction kettle as an example, respectively add polyester waste, octanol and tetrabutyl titanate catalyst into the alcoholysis reaction kettle according to the weight ratio of 60:60:2. In the process, ethylene glycol is absorbed and separated through a specific absorption tank, and octanol with water is dehydrated by a refining device and then returned to the alcoholysis reactor to continue to participate in the reaction. After 8 hours, the processing capacity of polyester waste is 1.5 tons, and the polyester waste is 1.5 tons. The conversion rate was 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com