Lithium iron oxide material and preparation method thereof

A lithium ferrite and lithium source technology, applied in the field of electrochemistry, can solve the problems of the decrease of battery energy density and the first efficiency decrease of battery reversible capacity, and achieve the effect of improving electrical performance and promoting the exertion of capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

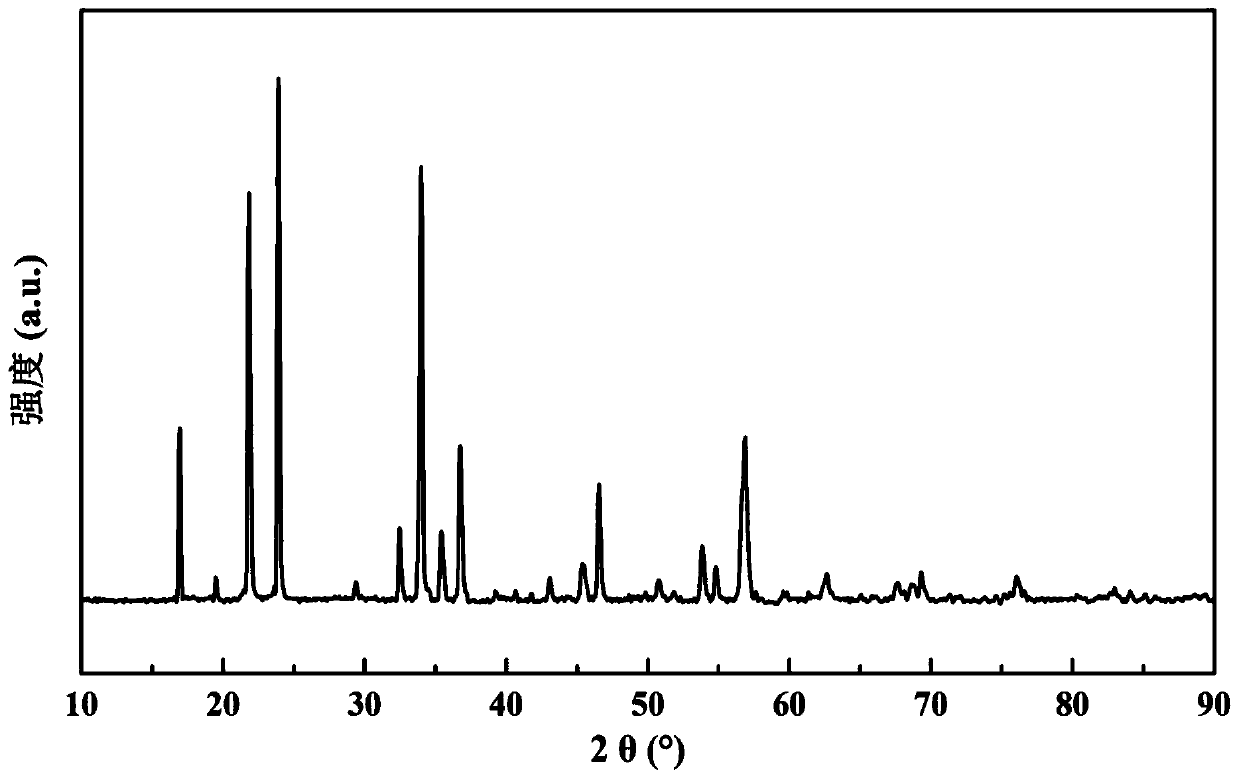

Image

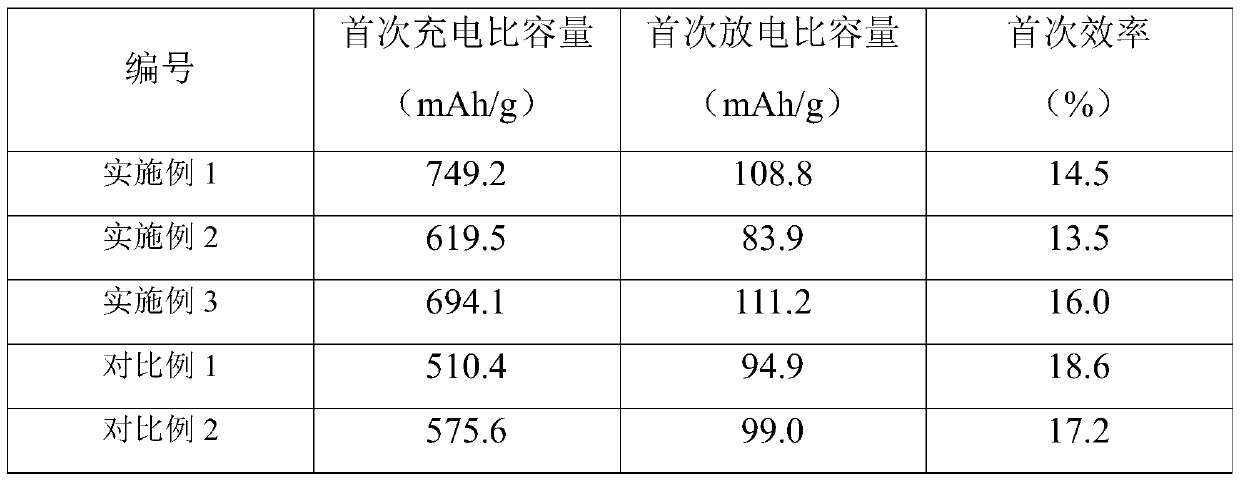

Examples

preparation example Construction

[0027] One aspect of the present invention provides a Li 5 FeO 4 The preparation method of material, described preparation method comprises the following steps:

[0028] (1) Mix iron source, lithium source, carbon source and deionized water to obtain a mixed solution;

[0029] (2) Grinding the mixed solution obtained in step (1), so that the particle size of the solid particles in the mixed solution is below 0.4 μm;

[0030] (3) Spray-dry the mixed solution after grinding to obtain Li 5 FeO 4 Precursor;

[0031] (4) the Li 5 FeO 4 The precursor is sintered and pulverized to obtain Li 5 FeO 4 Material;

[0032] Wherein, the amount of the carbon source makes the prepared Li 5 FeO 4 The content of the surface carbon coating layer in the material is 0.5-15% by weight, specifically, for example, it can be 0.5% by weight, 1% by weight, 3% by weight, 5% by weight, 7% by weight, 9% by weight, 11% by weight, 13% by weight and 15% by weight. In the present invention, by int...

Embodiment 1

[0047] (1) 1548g LiOH·H 2 O, 500g Fe 2 o 3 , 105g of glucose and deionized water are mixed to obtain a mixed solution.

[0048] (2) Put the mixed liquid obtained in step (1) into a grinder for grinding, so that the particle size of the solid particles in the mixed liquid is below 150nm.

[0049] (3) Spray-dry the mixed solution after grinding to obtain Li 5 FeO 4 Precursor, wherein the spray inlet temperature is 135°C, and the outlet temperature is 90°C.

[0050] (4) the Li 5 FeO 4 The precursor was placed in the sagger, and then put into the box furnace, and the N 2 Under a protective atmosphere, the temperature was raised to 850°C at 2°C / min for sintering, the sintering time was 24h, and then pulverized to obtain the target Li 5 FeO 4 Material S1.

Embodiment 2

[0052] (1) 924g Li 2 CO 3 , 196g Fe 2 o 3 , 200g sucrose and deionized water are mixed to obtain a mixed solution.

[0053] (2) Put the mixed liquid obtained in step (1) into a grinder for grinding, so that the particle size of the solid particles in the mixed liquid is below 200nm.

[0054] (3) Spray-dry the mixed solution after grinding to obtain Li 5 FeO 4 Precursor, wherein the spray inlet temperature is 140°C, and the outlet temperature is 95°C.

[0055] (4) the Li 5 FeO 4 The precursor was placed in the sagger, and then put into the box furnace, and the N 2 Under a protective atmosphere, the temperature was raised to 900°C at 5°C / min for sintering, the sintering time was 48h, and then pulverized to obtain the target Li 5 FeO 4 Material S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com